ASTM D2949-01a(2008)

(Specification)Standard Specification for 3.25-in. Outside Diameter Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent Pipe and Fittings

Standard Specification for 3.25-in. Outside Diameter Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent Pipe and Fittings

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions and tolerances, deflection load, crush resistance, hydrostatic-burst resistance, flattening resistance, impact resistance, and solvent cement. A form of marking is also included. Plastic which does not meet the material requirements specified in Section 5 is excluded.

Note 1—This specification was formerly issued under the title, 3-in. Thin Wall Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent Pipe and Fittings.

Note 2—Techniques for making solvent-cement joints are given in Practice D 2855.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D2949 – 01a (Reapproved 2008)

Standard Specification for

3.25-in. Outside Diameter Poly(Vinyl Chloride) (PVC) Plastic

Drain, Waste, and Vent Pipe and Fittings

This standard is issued under the fixed designation D2949; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D1599 TestMethodforResistancetoShort-TimeHydraulic

Pressure of Plastic Pipe, Tubing, and Fittings

1.1 This specification covers requirements and test methods

D1600 Terminology for Abbreviated Terms Relating to

formaterials,dimensionsandtolerances,deflectionload,crush

Plastics

resistance, hydrostatic-burst resistance, flattening resistance,

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

impact resistance, and solvent cement. A form of marking is

Compounds and Chlorinated Poly(Vinyl Chloride)

also included. Plastic which does not meet the material

(CPVC) Compounds

requirements specified in Section 5 is excluded.

D2122 Test Method for Determining Dimensions of Ther-

NOTE 1—This specification was formerly issued under the title, 3-in.

moplastic Pipe and Fittings

ThinWallPoly(VinylChloride)(PVC)PlasticDrain,Waste,andVentPipe

D2152 Test Method for Adequacy of Fusion of Extruded

and Fittings.

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

NOTE 2—Techniques for making solvent-cement joints are given in

Acetone Immersion

Practice D2855.

D2412 Test Method for Determination of External Loading

1.2 Thetextofthisspecificationreferencesnotes,footnotes,

Characteristics of Plastic Pipe by Parallel-Plate Loading

and appendixes which provide explanatory material. These

D2444 Test Method for Determination of the Impact Resis-

notesandfootnotes(excludingthoseintablesandfigures)shall

tance of Thermoplastic Pipe and Fittings by Means of a

not be considered as requirements of the specification.

Tup (Falling Weight)

1.3 The values stated in inch-pound units are to be regarded

D2564 Specification for Solvent Cements for Poly(Vinyl

as standard. The values given in parentheses are mathematical

Chloride) (PVC) Plastic Piping Systems

conversions to SI units that are provided for information only

D2855 Practice for Making Solvent-Cemented Joints with

and are not considered standard.

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

1.4 The following precautionary caveat pertains only to the

D3311 Specification for Drain, Waste, and Vent (DWV)

test methods portion, Section 7, of this specification: This

Plastic Fittings Patterns

standard does not purport to address all of the safety concerns,

F402 Practice for Safe Handling of Solvent Cements, Prim-

if any, associated with its use. It is the responsibility of the user

ers, and Cleaners Used for JoiningThermoplastic Pipe and

of this standard to establish appropriate safety and health

Fittings

practices and determine the applicability of regulatory limita-

F412 Terminology Relating to Plastic Piping Systems

tions prior to use.

F1498 Specification for Taper Pipe Threads 60° for Ther-

moplastic Pipe and Fittings

2. Referenced Documents

2.1 ASTM Standards:

3. Terminology

D618 Practice for Conditioning Plastics for Testing

3.1 Definitions—Definitions are in accordance with Termi-

nology F412, and abbreviations are in accordance with Termi-

This specification is under the jurisdiction ofASTM Committee F17 on Plastic nology D1600, unless otherwise specified.

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV.

Current edition approved Nov. 1, 2008. Published February 2009. Originally

4. Significance and Use

´1

approved in 1971. Last previous edition approved in 2001 as D2949–01a . DOI:

4.1 The requirements of this specification are intended to

10.1520/D2949-01AR08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

provide pipe and fittings suitable for drainage of sewage and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

certain other liquid wastes where toughness, resistance to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2949 – 01a (2008)

deterioration from water and chemicals, flattening and aging 6.2.2.4 Fittings Dimensions—The dimensions of fittings

resistance, and strong tight joints are required. coveredbythisspecificationshallmeettherequirementsgiven

4.2 When joining 3.25-in. outside diameter PVC DWV in Table 3 through Table 11.

piping to 3-in. Schedule 40 PVC DWV piping, it is necessary

NOTE 4—Additional fittings in IPS dimensions are included in Speci-

to use either reducer bushings or increasers, as shown in the

fication D3311.

tables at the end of the text, due to the differences in pipe

6.3 Deflection Load and Crush Resistance:

outside diameters.

6.3.1 Pipe—The pipe shall support a minimum load of 600

NOTE 3—Industrial waste disposal lines should be installed only with

lbf/linear ft (810 N/m) at 15% deflection of the original

the specific approval of the cognizant building code authority since

diameter (deflection load), and shall deflect 60% of the

chemicals not commonly found in drains and sewers, and temperatures in

original diameter (crush resistance) without cracking, rupture,

excess of 160°F (70°C), may be encountered.

or other visible evidence of failure when tested in accordance

5. Materials

with7.4.Theminimumpipestiffnessat5%deflectionshallbe

115 lbf/in.·in. (800 kPa).

5.1 Basic Materials—Pipe and fittings shall be made from

6.3.2 Fittings—Individual fittings unassembled shall with-

virgin poly (vinyl chloride) compounds meeting the require-

stand a minimum load of 1000 lbf/ft (1350 N/m) of centerline

mentsofClass12454,asdefinedanddescribedinSpecification

length without cracking or other visible evidence of failure

D1784.

when tested in accordance with 7.4.This requirement does not

5.2 Rework Material—The manufacturer shall use only his

apply to inline fittings.

owncleanpipeorfittingreworkmaterialandthepipeorfitting

6.4 Minimum Hydrostatic Burst Pressure—When tested at

produced shall meet all the requirements of this specification.

73°F (23°C) in accordance with 7.5, the minimum burst

5.3 Solvent Cement—The solvent cement shall meet the

pressure of pipe shall be 500 psi (3.45 MPa) and the minimum

requirements of Specification D2564.

burst pressure of fittings shall be 200 psi (1.38 MPa).

6. Requirements

NOTE 5—The minimum burst pressure for fittings are lower than that

6.1 General—The pipe and fittings shall be homogeneous for pipe because the geometry is such, particularly area and radii, that the

stresses produced in the wall of the fitting are higher than those produced

throughoutandfreeofvisiblecracks,holes,foreigninclusions,

in pipe tested at the same internal pressures. This requirement is intended

or other injurious defects. The pipe shall be as uniform as

only for the purpose of quality control to ensure that the pipe and fittings

commercially practicable in color, opacity, density, and other

have no weak areas, particularly at flow and weld lines.

physical properties.

6.5 Flattening Resistance—The average decrease in inside

6.1.1 The requirements in this section are intended only for

use as quality control tests, not as simulated service tests. diameters of pipe and fittings shall not exceed 10% when

tested in accordance with 7.6 (Note 3).

6.2 Dimensions and Tolerances—All dimensions shall be

measured in accordance with Test Method D2122. All toler- 6.6 Impact Resistance—The minimum impact resistance,

ances shall meet the requirements of Tables 1-11 unless when tested at the time of manufacture, shall be 50 ft·lbf (6.91

otherwise specified. J) at 73°F (23°C) for pipe and 20 ft·lbf (2.77 J) at 73°F for

6.2.1 Pipe: fittings.TestinaccordancewithTestMethodD2444usingTup

C and Holder A for pipe and Tup A and Holder B for fittings.

6.2.1.1 Pipe Dimensions—The outside diameters and wall

thicknesses of the pipe shall meet the requirements of Table 1. Use a 12-lb (5-kg) tup for testing pipe and fittings. Test

couplings cemented to short pieces of pipe and allowed to dry

6.2.1.2 Pipe Length—The pipe shall be in either 10 or 20-ft

or 3 or 6-m lengths, unless otherwise specified with allowable for 24 h.

tolerance of + ⁄2 in., 0 in. or +13 mm, −0 mm. 6.6.1 Test 10 specimens. When 9 or 10 specimens pass,

6.2.2 Fittings: accept the lot. When 2 or more specimens fail, test 10

6.2.2.1 Fittings-Socket Dimensions—The socket dimen- additional specimens. When 17 of 20 specimens tested pass,

sions of fittings shall meet the requirements given in Table 2. accept the lot. When 4 or more of 20 specimens fail, test 20

additional specimens. When 32 of 40 specimens pass, accept

6.2.2.2 Fittings Laying Length Dimensions—The laying

lengthdimensionsoffittings,shallconformtotherequirements the lot. When 9 or more of 40 specimens fail, the lot does not

meet the requirements of this specification.

given in Table 3 through Tables 11.

6.2.2.3 Transition Adapters—The dimensions of adapters 6.6.2 Failure of the test specimen shall be shattering or any

for connecting plastic pipe to cast iron hubs shall conform to crack or break extending entirely through the pipe wall and

the dimensions given in Table 4. visible to the unaided eye.

TABLE 1 Dimensions and Tolerances for Outside Diameters and Thicknesses of PVC 3.25-in. Outside Diameter Plastic Drain, Waste,

and Vent Pipe, in. (mm)

A

Nominal Outside Diameter Wall Thickness

Pipe Size, Tolerance on Out-of-Roundness

Average Min Tolerance

in. Average (maximum minus minimum)

3.25 3.250 (82.56) 60.008 (60.20) 0.030 (0.76) 0.125 (3.18) +0.020 (+0.50)

A

Theminimumisthelowestwallthicknessofthepipeatanycrosssection.Themaximumpermittedwallthickness,atanycrosssection,istheminimumwallthickness

plus the stated tolerance.

D2949 – 01a (2008)

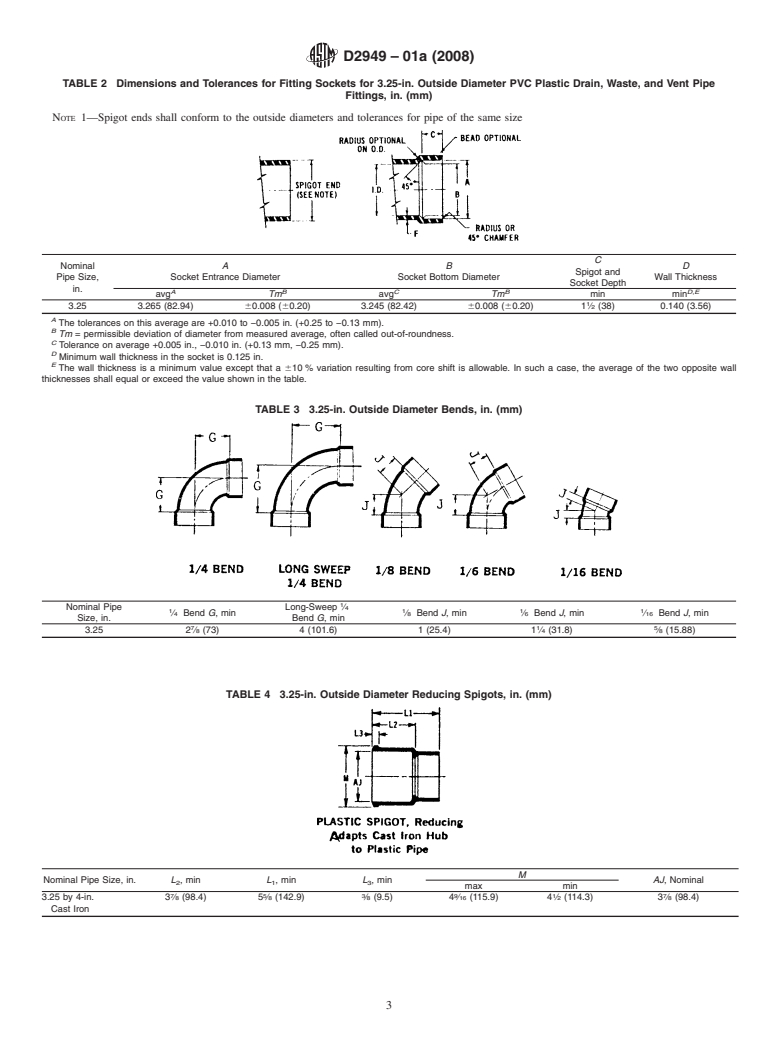

TABLE 2 Dimensions and Tolerances for Fitting Sockets for 3.25-in. Outside Diameter PVC Plastic Drain, Waste, and Vent Pipe

Fittings, in. (mm)

NOTE 1—Spigot ends shall conform to the outside diameters and tolerances for pipe of the same size

C

Nominal A B D

Spigot and

Pipe Size, Socket Entrance Diameter Socket Bottom Diameter Wall Thickness

Socket Depth

in.

A B C B D,E

avg Tm avg Tm min min

3.25 3.265 (82.94) 60.008 (60.20) 3.245 (82.42) 60.008 (60.20) 1 ⁄2 (38) 0.140 (3.56)

A

The tolerances on this average are +0.010 to −0.005 in. (+0.25 to −0.13 mm).

B

Tm = permissible deviation of diameter from measured average, often called out-of-roundness.

C

Tolerance on average +0.005 in., −0.010 in. (+0.13 mm, −0.25 mm).

D

Minimum wall thickness in the socket is 0.125 in.

E

The wall thickness is a minimum value except that a 610 % variation resulting from core shift is allowable. In such a case, the average of the two opposite wall

thicknesses shall equal or exceed the value shown in the table.

TABLE 3 3.25-in. Outside Diameter Bends, in. (mm)

Nominal Pipe Long-Sweep ⁄4

1 1 1 1

⁄4 Bend G,min ⁄8 Bend J,min ⁄6 Bend J,min ⁄16 Bend J,min

Size, in. Bend G,min

7 1 5

3.25 2 ⁄8 (73) 4 (101.6) 1 (25.4) 1 ⁄4 (31.8) ⁄8 (15.88)

TABLE 4 3.25-in. Outside Diameter Reducing Spigots, in. (mm)

M

Nominal Pipe Size, in. L,min L,min L,min AJ, Nominal

2 1 3

max min

7 5 3 9 1 7

3.25 by 4-in. 3 ⁄8 (98.4) 5 ⁄8 (142.9) ⁄8 (9.5) 4 ⁄16 (115.9) 4 ⁄2 (114.3) 3 ⁄8 (98.4)

Cast Iron

D2949 – 01a (2008)

TABLE 5 3.25-in. Outside Diameter Reducing Sanitary Tee and 45° Wyes, in. (mm)

Sanitary Tee Reducing 45° Wye Reducing Single and Double

Nominal Pipe Size, in.

G,min G,min G,min G,min G,min G,min

1 2 3 1 2 3

15 3 3 3 1 17

3.25 by 3.25 by ⁄16 (23.8) 1 ⁄4 (44.5) 2 ⁄16 (55.6) ⁄8 (9.5) 3 ⁄4 (82.5) 3 ⁄32 (89.7)

1 ⁄2-in. IPS

3 1 3 1 11

3.25 by 3.25 by 2-in. IPS 1 ⁄8 (34.9) 2 (50.8) 2 ⁄4 (57.2) ⁄8 (9.5) 3 ⁄4 (82.5) 3 ⁄16 (93.6)

TABLE 6 3.25-in. Outside Diameter Bushings in. (mm)

7.3.1 For referee purposes, conduct tests in the standard

laboratory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 6

5% relative humidity.

7.3.2 For routine quality control testing, conduct tests at the

temperature and humidity of the manufacturers testing area.

7.4 Deflection Load and Crush Resistance—Measure the

deflection load and crush resistance of pipe and fittings in

accordance with Test Method D2412. In the test for pipe note

the load when the initial inside diameter is reduced by 5%

(pipestiffness),by15%(deflectionload),andcontinuethetest

until the diameter is reduced by 60% of its original value

(crush resistance). The rate of head approach shall be 0.20 to

Nominal Pipe Style 1

Size, in. L,min CM,min R,min

0.25 in./min (5.1 to 6.4 mm/min). Each specimen shall meet

1 7 1 3

3.25 by 1 ⁄2-in. IPS 1 ⁄8 (47.6) 1 ⁄8 (28.6) ⁄8 (9.5)

the requirements of 6.3.1.

7 3

3.25 by 2-in. IPS 1 ⁄8 (47.6) 1 (25.4) ⁄8 (9.5)

3 1

3.25 by 3-in. IPS 1 ⁄4 (44.5) ⁄4 (6.4) 0 (0)

7.4.1 Fitting Test Specimens—Test three complete fittings.

Shim fittings to give full centerline contact with platens.

Fittingshavingnonuniformdiameterssuchasreducersshallbe

considered acceptable when the wall thickness at all points is

6.7 Threads—For all fittings having taper pipe threads,

equal to or greater than the wall thickness of pipe of the same

threads shall conform to Specification F1498 and be gaged in

material and diameter that meets the crush resistance require-

accordance with 7.7.

ments. Each specimen shall meet the requirements of 6.3.2.

6.8 Extrusion Quality—The pipe shall not flake or disinte-

7.4.2 Procedure—Terminate the test when the inside diam-

grate when tested in accordance with Test Method D2152.

eter of pipe test specimens is reduced to 40% of its original

7. Test Methods value or the pipe cracks or shows other visible evidence of

failure. Terminate the test on fittings when the load reaches

7.1 Sampling—Take a random sample from each lot or

1000 lbf/ft (1350 N/m) of centerline length. Observe the load

shipment of the pipe and fittings sufficient to determine

and deflection at the first evidence of cracking, if any. Record

conformancewiththisspecification.About40ft(12m)ofpipe

location and type of failure.

are required to make the tests prescribed. The number of

fittings required varies depending on the size and type of 7.4.3 Calculation—For pipe, divide the load in pounds-

force or newtons at 15% deflection (deflection load) and also

fitting.

7.2 Conditioning— at failure (crush resistance), if such occurred, by the length of

7.2.1 For referee testing at 73°F,

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D 2949–01 Designation: D 2949 – 01a (Reapproved 2008)

Standard Specification for

3.25-in. Outside Diameter Poly(Vinyl Chloride) (PVC) Plastic

Drain, Waste, and Vent Pipe and Fittings

This standard is issued under the fixed designation D 2949; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers requirements and test methods for materials, dimensions and tolerances, deflection load, crush

resistance, hydrostatic-burst resistance, flattening resistance, impact resistance, and solvent cement. A form of marking is also

included. Plastic which does not meet the material requirements specified in Section 5 is excluded.

NOTE 1—This specification was formerly issued under the title, 3-in. Thin Wall Poly(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent Pipe and

Fittings.

NOTE 2—Techniques for making solvent-cement joints are given in Practice D2855.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes

and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test methods portion, Section 7, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

Compounds

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2152 Test Method for Adequacy of Fusion of Extruded Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by Acetone

Immersion

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 TestMethodforDeterminationoftheImpactResistanceofThermoplasticPipeandFittingsbyMeansofaTup(Falling

Weight)

D2564 Specification for Solvent Cements for Poly(Vinyl Chloride) (PVC) Plastic Piping Systems

D2855 Practice for Making Solvent-Cemented Joints with Poly(Vinyl Chloride) (PVC) Pipe and Fittings

D3311 Specification for Drain, Waste, and Vent (DWV) Plastic Fittings Patterns

F402 Practice for Safe Handling of Solvent Cements, Primers, and Cleaners Used for JoiningThermoplastic Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

F1498 Specification for Taper Pipe Threads 60°60 for Thermoplastic Pipe and Fittings

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV.

Current edition approved August 10, 2001. Published October 2001. Originally published as D2949–71. Last previous edition D2949–00.

´1

Current edition approved Nov. 1, 2008. Published February 2009. Originally approved in 1971. Last previous edition approved in 2001 as D2949–01a .

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2949 – 01a (2008)

3. Terminology

3.1 Definitions—Definitions are in accordance withTerminology F412, and abbreviations are in accordance withTerminology

D1600, unless otherwise specified.

4. Significance and Use

4.1 The requirements of this specification are intended to provide pipe and fittings suitable for drainage of sewage and certain

other liquid wastes where toughness, resistance to deterioration from water and chemicals, flattening and aging resistance, and

strong tight joints are required.

4.2 When joining 3.25-in. outside diameter PVC DWV piping to 3-in. Schedule 40 PVC DWV piping, it is necessary to use

either reducer bushings or increasers, as shown in the tables at the end of the text, due to the differences in pipe outside diameters.

NOTE 3—Industrial waste disposal lines should be installed only with the specific approval of the cognizant building code authority since chemicals

not commonly found in drains and sewers, and temperatures in excess of 160°F (70°C), may be encountered.

5. Materials

5.1 Basic Materials—Pipe and fittings shall be made from virgin poly (vinyl chloride) compounds meeting the requirements of

Class 12454-B,12454, as defined and described in Specification D1784.

5.2 Rework Material—The manufacturer shall use only his own clean pipe or fitting rework material and the pipe or fitting

produced shall meet all the requirements of this specification.

5.3 Solvent Cement—The solvent cement shall meet the requirements of Specification D2564.

6.Requirements Requirements

6. Requirements

6.1 General—The pipe and fittings shall be homogeneous throughout and free of visible cracks, holes, foreign inclusions, or

other injurious defects. The pipe shall be as uniform as commercially practicable in color, opacity, density, and other physical

properties.

6.1.1 The requirements in this section are intended only for use as quality control tests, not as simulated service tests.

6.2 Dimensions and Tolerances—All dimensions shall be measured in accordance with Test Method D2122. All tolerances

shall meet the requirements of Tables 1-11 unless otherwise specified.

6.2.1 Pipe:

6.2.1.1 Pipe Dimensions—The outside diameters and wall thicknesses of the pipe shall meet the requirements of Table 1.

6.2.1.2 Pipe Length—The pipe shall be in either 10 or 20-ft or 3 or 6-m lengths, unless otherwise specified with allowable

tolerance of + ⁄2 in., 0 in. or +13 mm, −0 mm.

6.2.2 Fittings:

6.2.2.1 Fittings-Socket Dimensions—The socket dimensions of fittings shall meet the requirements given in Table 2.

6.2.2.2 Fittings Laying Length Dimensions—The laying length dimensions of fittings, shall conform to the requirements given

in Table 3 through Tables 11.

6.2.2.3 Transition Adapters—The dimensions of adapters for connecting plastic pipe to cast iron hubs shall conform to the

dimensions given in Table 4.

6.2.2.4 FittingsDimensions—ThedimensionsoffittingscoveredbythisspecificationshallmeettherequirementsgiveninTable

3 through Table 11.

NOTE 4—Additional fittings in IPS dimensions are included in Specification D3311.

6.3 Deflection Load and Crush Resistance :

6.3.1 Pipe—The pipe shall support a minimum load of 600 lbf/linear ft (810 N/m) at 15% deflection of the original diameter

(deflection load), and shall deflect 60% of the original diameter (crush resistance) without cracking, rupture, or other visible

evidence of failure when tested in accordance with 7.4. The minimum pipe stiffness at 5% deflection shall be 115 lbf/in.·in. (800

kPa).

6.3.2 Fittings—Individual fittings unassembled shall withstand a minimum load of 1000 lbf/ft (1350 N/m) of centerline length

withoutcrackingorothervisibleevidenceoffailurewhentestedinaccordancewith7.4.Thisrequirementdoesnotapplytoinline

fittings.

TABLE 1 Dimensions and Tolerances for Outside Diameters and Thicknesses of PVC 3.25-in. Outside Diameter Plastic Drain, Waste,

and Vent Pipe, in. (mm)

A

Nominal Outside Diameter Wall Thickness

Pipe Size, Tolerance on Out-of-Roundness

Average Min Tolerance

in. Average (maximum minus minimum)

3.25 3.250 (82.56) 60.008 (60.20) 0.030 (0.76) 0.125 (3.18) 60.020 (60.50)

3.25 3.250 (82.56) 60.008 (60.20) 0.030 (0.76) 0.125 (3.18) +0.020 (+0.50)

A

Theminimumisthelowestwallthicknessofthepipeatanycrosssection.Themaximumpermittedwallthickness,atanycrosssection,istheminimumwallthickness

plus the stated tolerance.

D 2949 – 01a (2008)

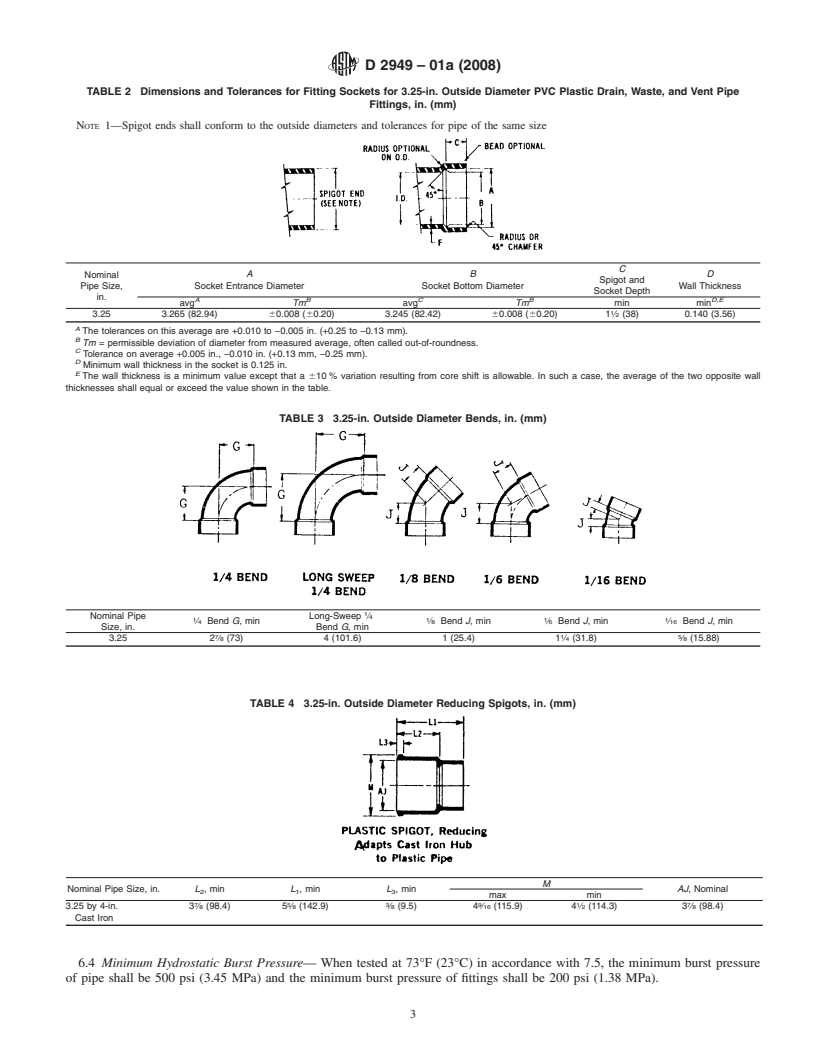

TABLE 2 Dimensions and Tolerances for Fitting Sockets for 3.25-in. Outside Diameter PVC Plastic Drain, Waste, and Vent Pipe

Fittings, in. (mm)

NOTE 1—Spigot ends shall conform to the outside diameters and tolerances for pipe of the same size

C

Nominal A B D

Spigot and

Pipe Size, Socket Entrance Diameter Socket Bottom Diameter Wall Thickness

Socket Depth

in.

A B C B D,E

avg Tm avg Tm min min

3.25 3.265 (82.94) 60.008 (60.20) 3.245 (82.42) 60.008 (60.20) 1 ⁄2 (38) 0.140 (3.56)

A

The tolerances on this average are +0.010 to −0.005 in. (+0.25 to −0.13 mm).

B

Tm = permissible deviation of diameter from measured average, often called out-of-roundness.

C

Tolerance on average +0.005 in., −0.010 in. (+0.13 mm, −0.25 mm).

D

Minimum wall thickness in the socket is 0.125 in.

E

The wall thickness is a minimum value except that a 610 % variation resulting from core shift is allowable. In such a case, the average of the two opposite wall

thicknesses shall equal or exceed the value shown in the table.

TABLE 3 3.25-in. Outside Diameter Bends, in. (mm)

Nominal Pipe Long-Sweep ⁄4

1 1 1 1

⁄4 Bend G,min ⁄8 Bend J,min ⁄6 Bend J,min ⁄16 Bend J,min

Size, in. Bend G,min

7 1 5

3.25 2 ⁄8 (73) 4 (101.6) 1 (25.4) 1 ⁄4 (31.8) ⁄8 (15.88)

TABLE 4 3.25-in. Outside Diameter Reducing Spigots, in. (mm)

M

Nominal Pipe Size, in. L,min L,min L,min AJ, Nominal

2 1 3

max min

7 5 3 9 1 7

3.25 by 4-in. 3 ⁄8 (98.4) 5 ⁄8 (142.9) ⁄8 (9.5) 4 ⁄16 (115.9) 4 ⁄2 (114.3) 3 ⁄8 (98.4)

Cast Iron

6.4 Minimum Hydrostatic Burst Pressure— When tested at 73°F (23°C) in accordance with 7.5, the minimum burst pressure

of pipe shall be 500 psi (3.45 MPa) and the minimum burst pressure of fittings shall be 200 psi (1.38 MPa).

D 2949 – 01a (2008)

TABLE 5 3.25-in. Outside Diameter Reducing Sanitary Tee and 45° Wyes, in. (mm)

Sanitary Tee Reducing 45° Wye Reducing Single and Double

Nominal Pipe Size, in.

G,min G,min G,min G,min G,min G,min

1 2 3 1 2 3

15 3 3 3 1 17

3.25 by 3.25 by ⁄16 (23.8) 1 ⁄4 (44.5) 2 ⁄16 (55.6) ⁄8 (9.5) 3 ⁄4 (82.5) 3 ⁄32 (89.7)

1 ⁄2-in. IPS

3 1 3 1 11

3.25 by 3.25 by 2-in. IPS 1 ⁄8 (34.9) 2 (50.8) 2 ⁄4 (57.2) ⁄8 (9.5) 3 ⁄4 (82.5) 3 ⁄16 (93.6)

TABLE 6 3.25-in. Outside Diameter Bushings in. (mm)

Nominal Pipe Style 1

Size, in. L,min CM,min R,min

1 7 1 3

3.25 by 1 ⁄2-in. IPS 1 ⁄8 (47.6) 1 ⁄8 (28.6) ⁄8 (9.5)

7 3

3.25 by 2-in. IPS 1 ⁄8 (47.6) 1 (25.4) ⁄8 (9.5)

3 1

3.25 by 3-in. IPS 1 ⁄4 (44.5) ⁄4 (6.4) 0 (0)

NOTE 5—Theminimumburstpressureforfittingsarelowerthanthatforpipebecausethegeometryissuch,particularlyareaandradii,thatthestresses

produced in the wall of the fitting are higher than those produced in pipe tested at the same internal pressures. This requirement is intended only for the

purpose of quality control to ensure that the pipe and fittings have no weak areas, particularly at flow and weld lines.

6.5 Flattening Resistance—The average decrease in inside diameters of pipe and fittings shall not exceed 10% when tested in

accordance with 7.6 (Note 3).

6.6 Impact Resistance—The minimum impact resistance, when tested at the time of manufacture, shall be 50 ft·lbf (6.91 J) at

73°F (23°C) and 25 ft·lbf (3.46 J) at 32°F (0°C) for pipe and 20 ft·lbf (2.77 J) at 73°F and 10 ft·lbf (1.38 J) at 32°F for fittings.

Test in accordance withTest Method D2444 usingTup C and HolderAfor pipe andTupAand Holder B for fittings. Use a 12-lb

(5-kg) tup for testing pipe and fittings. Test couplings cemented to short pieces of pipe and allowed to dry for 24 h.

6.6.1 Test 10 specimens. When 9 or 10 specimens pass, accept the lot. When 2 or more specimens fail, test 10 additional

specimens.When17of20specimenstestedpass,acceptthelot.When4ormoreof20specimensfail,test20additionalspecimens.

When 32 of 40 specimens pass, accept the lot. When 9 or more of 40 specimens fail, the lot does not meet the requirements of

this specification.

6.6.2 Failure of the test specimen shall be shattering or any crack or break extending entirely through the pipe wall and visible

to the unaided eye.

6.7 Threads—For all fittings having taper pipe threads, threads shall conform to Specification F 1498 and be gaged in

accordance with 7.7.

6.8 Extrusion Quality—The pipe shall not flake or disintegrate when tested in accordance with Test Method D2152.

7. Test Methods

7.1 Sampling—Take a random sample from each lot or shipment of the pipe and fittings sufficient to determine conformance

with this specification.About 40 ft (12 m) of pipe are required to make the tests prescribed.The number of fittings required varies

depending on the size and type of fitting.

7.2 Conditioning—

D 2949 – 01a (2008)

TABLE 7 4-in. by 3.25-in. Outside Diameter Reducing Closet Ring

NOTE 1—Slot is optional if fully reinforced with a corrosion-resistant material.

4( 3 3( REDUCING CLOSET RING

A

Closet Flange, in. (mm)

in. mm

7 (180)

4 (101.5)

2 ⁄4 ( 70)

1 ⁄4 ( 32)

⁄2 ( 13)

⁄16 (11)

⁄4 ( 6.5)

A

Tolerance 6 ⁄16 in. or 61.6 mm.

TABLE 8 3.25-in. Outside Diameter Sanitary Tees—45° Wyes, in. (mm)

Sanitary Tee Single and Double, min 45° Wye Single and Double, min

Nominal Pipe Size, in.

GN GJ GN GJ

7 15 3 1

3.25 1 ⁄16 (36.5) 2 ⁄16 (74.6) ⁄4 (19.0) 4 ⁄8 (104.8)

TABLE 9 3.25-in. Outside Diameter Couplings and Adapter, in. (mm)

Coupling Female Adapter Male Adapter Female Fitting Adapter

Nominal Pipe Size, in.

N,min N,min N,min N,min

3 7 5 1

3.25 ⁄16 (4.8) ⁄16 (11.1) ⁄16 (7.9) ⁄8 (3.2)

7.2.1 For referee testing at 73°F, condition the specimens prior to test at 73.4 6 3.6°F (23 6 2°C) and 50 6 5% relative

humidity in accordance with Practice D618, Procedure A.

7.2.2 For routine quality control testing at 73°F, c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.