ASTM F2861-10

(Test Method)Standard Test Method for Enhanced Performance of Combination Oven in Various Modes

Standard Test Method for Enhanced Performance of Combination Oven in Various Modes

SIGNIFICANCE AND USE

The energy input rate test and thermostat calibration are used to confirm that the combination oven is operating properly prior to further testing and to ensure that all test results are determined at the same temperature.

Preheat energy and time can be useful to food service operators to manage power demands and to know how quickly the combination oven can be ready for operation.

Idle energy rate and pilot energy rate can be used to estimate energy consumption during non-cooking periods.

Cooking-energy efficiency is a precise indicator of combination oven energy performance under various operating conditions. This information enables the food service operator to consider energy performance when selecting a combination oven.

Production capacity can be used by food service operators to choose a combination oven that matches their food output requirements.

Water consumption characterization is useful for estimating water and sewage costs associated with combination oven operation.

Condensate temperature measurement is useful to verify that the condensate temperature does not violate applicable building codes.

Cooking uniformity provides information regarding the combi’s ability to cook food at the same rate throughout the combi’s compartment.

SCOPE

1.1 This test method covers the evaluation of the energy and water consumption and the cooking performance of combination ovens that can be operated in convection, steam and combination modes. The test method is also applicable to convection ovens with limited moisture injection. The results of this test method can be used to evaluate a combination oven and understand its energy consumption.

1.2 This test method is applicable to gas and electric combination ovens that can be operated in convection, steam and combination modes.

1.3 The combination oven can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate and thermostat calibration (10.2).

1.3.2 Preheat energy consumption and time (10.3).

1.3.3 Idle energy rate in convection, steam and combination modes (10.4).

1.3.4 Pilot energy rate (if applicable) (10.5).

1.3.5 Cooking-energy efficiency, cooking energy rate, production capacity, water consumption and condensate temperature in steam mode (10.6).

1.3.6 Cooking-energy efficiency, cooking energy rate, and production capacity in convection mode (10.7).

1.3.7 Cooking uniformity in combination mode (10.8).

1.4 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2861 − 10 AnAmerican National Standard

Standard Test Method for

Enhanced Performance of Combination Oven in Various

Modes

This standard is issued under the fixed designation F2861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thistestmethodcoverstheevaluationoftheenergyand

D3588Practice for Calculating Heat Value, Compressibility

water consumption and the cooking performance of combina-

Factor, and Relative Density of Gaseous Fuels

tion ovens that can be operated in convection, steam and

F1484Test Methods for Performance of Steam Cookers

combination modes. The test method is also applicable to

F1495Specification for Combination Oven Electric or Gas

convection ovens with limited moisture injection. The results

Fired

of this test method can be used to evaluate a combination oven

F1496Test Method for Performance of Convection Ovens

and understand its energy consumption.

F1639Test Method for Performance of Combination Ovens

1.2 This test method is applicable to gas and electric

(Withdrawn 2012)

combination ovens that can be operated in convection, steam

2.2 ASHRAE Documents:

and combination modes.

ASHRAE Guideline 2-1986 (RA90)Engineering Analysis

of Experimental Data

1.3 The combination oven can be evaluated with respect to

ASHRAE Guideline 2-1986 (RA90)Thermal and Related

the following (where applicable):

Properties of Food and Food Materials

1.3.1 Energy input rate and thermostat calibration (10.2).

3. Terminology

1.3.2 Preheat energy consumption and time (10.3).

1.3.3 Idleenergyrateinconvection,steamandcombination

3.1 Definitions:

modes (10.4).

3.1.1 combination mode, n—for the purposes of this test

method, combination mode is defined as moist heat at 350°F

1.3.4 Pilot energy rate (if applicable) (10.5).

(177°C) with the humidity and fan set to operate at their

1.3.5 Cooking-energy efficiency, cooking energy rate, pro-

maximum settings.

duction capacity, water consumption and condensate tempera-

3.1.2 combination oven, n—device that combines the func-

ture in steam mode (10.6).

tion of hot air convection (oven mode), saturated and super-

1.3.6 Cooking-energy efficiency, cooking energy rate, and

heated steam heating (steam mode), and combination

production capacity in convection mode (10.7).

convection/steammodeformoistheating,toperformsteaming,

1.3.7 Cooking uniformity in combination mode (10.8).

baking, roasting, rethermalizing, and proofing of various food

products. In general, the term combination oven is used to

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

describe this type of equipment, which is self contained. The

as standard. The SI units given in parentheses are for informa-

combination oven is also referred to as a combination oven/

tion only.

steamer, combi or combo.

1.5 This standard does not purport to address all of the

3.1.3 condensate, n—mixture of condensed steam and cool-

safety concerns, if any, associated with its use. It is the

ingwater,exitingthecombinationovenanddirectedtoadrain.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This test method is under the jurisdiction of ASTM Committee F26 on Food The last approved version of this historical standard is referenced on

Service Equipment and is the direct responsibility of Subcommittee F26.06 on www.astm.org.

Productivity and Energy Protocol. See the ASHRAE Handbook of Fundamentals, available from the American

Current edition approved Sept. 1, 2010. Published December 2010. DOI: SocietyofHeating,Refrigeration,andAirConditioningEngineers,Inc.,1791Tullie

10.1520/F2861-10. Circle, NE, Atlanta, GA 30329.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2861 − 10

3.1.4 convection mode, n—for the purposes of this test energy input rate. For gas combination ovens, the pilot energy

method, convection mode is defined as dry heat only at 350°F rate and the fan and control energy rates are also determined.

(177°C) with the fan set to operate at the maximum setting.

4.3 The time and energy required to preheat the oven from

3.1.5 cooking-energy effıciency, n—quantity of energy im- room temperature (75 6 5°F (24 6 3°C)) to a ready-to-cook

parted to the specified food product, expressed as a percentage

state (350°F (177°C)), maximum humidity, if adjustable) is

of energy consumed by the combination oven during the

determined.

cooking event.

4.4 Idle energy rate is determined with the combination

3.1.6 cooking energy rate, n—average rate of energy con-

oven set to maintain a ready-to-cook state without cooking in

sumption (Btu/h (kJ/h) or kW) during the cooking-energy

three operating modes—combi mode (350 6 5°F

efficiency tests.

(177 62.8°C)), maximum humidity, if adjustable), convection

mode(350 65°F(177 62.8°C))andsteammode(212 62°F,

3.1.7 energyinputrate,n—peakrateatwhichacombination

maximum humidity, if adjustable).

oven consumes energy (Btu/h (kJ/h) or kW).

4.5 Cooking-energy efficiency, cooking energy rate and

3.1.8 idle energy rate, n—combinationoven’srateofenergy

production rate are determined in steam mode and convection

consumption (Btu/h (kJ/h) or kW), when empty, required to

mode while cooking potatoes.

maintain its cavity temperature at the specified thermostat set

point.

4.6 Water consumption (gal/h (L/h)) is monitored during

3.1.9 oven cavity, n—that portion of the combination oven idle conditions in steam mode, combi mode and convection

in which food products are heated or cooked. mode and while cooking potatoes in steam mode to character-

ize the rate of water usage.

3.1.10 pilot energy rate, n—rate of energy consumption

(Btu/h (kJ/h)) by a combination oven’s continuous pilot (if

4.7 Condensatetemperatureismonitoredtocharacterizethe

applicable). combination oven’s average and maximum drain temperature.

3.1.11 preheat energy, n—amount of energy consumed (Btu

4.8 The uniformity of heating within the combi’s compart-

(kJ) or kWh), by the combination oven while preheating its

ment is determined and reported based on the average tem-

cavityfromambienttemperaturetothespecifiedthermostatset

perature on each pan during ice load cooking tests (pans of ice

point.

simulating pans of frozen food).

3.1.12 preheat time, n—time (in min) required for the

5. Significance and Use

combination oven cavity to preheat from ambient temperature

to the specified thermostat set point.

5.1 The energy input rate test and thermostat calibration are

usedtoconfirmthatthecombinationovenisoperatingproperly

3.1.13 production capacity, n—maximum rate (lb/h (kg/h))

at which a combination oven can bring the specified food prior to further testing and to ensure that all test results are

determined at the same temperature.

producttoaspecified“cooked”condition.Mayalsobereferred

to as throughput.

5.2 Preheat energy and time can be useful to food service

3.1.14 production rate, n—rate (lb/h (kg/h)) at which a

operators to manage power demands and to know how quickly

combination oven brings the specified food product to a the combination oven can be ready for operation.

specified “cooked” condition. Does not necessarily refer to

5.3 Idle energy rate and pilot energy rate can be used to

maximum rate. Production rate varies with the amount of food

estimate energy consumption during non-cooking periods.

being cooked.

5.4 Cooking-energy efficiency is a precise indicator of

3.1.15 steam mode, n—for the purposes of this test method,

combinationovenenergyperformanceundervariousoperating

steam mode is defined as the maximum humidity setting at

conditions. This information enables the food service operator

212°F.

to consider energy performance when selecting a combination

3.1.16 uncertainty, n—measure of systematic and precision

oven.

errors in specified instrumentation or measure of repeatability

5.5 Production capacity can be used by food service opera-

of a reported test result.

tors to choose a combination oven that matches their food

output requirements.

4. Summary of Test Method

5.6 Water consumption characterization is useful for esti-

4.1 Accuracy of the combination oven thermostat is

mating water and sewage costs associated with combination

checkedatasettingof350°F(177°C).Thisisaccomplishedby

oven operation.

comparing the oven’s temperature control setting with the

temperature at the center of the oven’s cavity. If necessary, the 5.7 Condensatetemperaturemeasurementisusefultoverify

control is adjusted so that the maximum difference between its that the condensate temperature does not violate applicable

reading and the temperature at the center of the cavity is no building codes.

more than 65°F (62.8°C).

5.8 Cooking uniformity provides information regarding the

4.2 Energy input rate is determined to confirm that the combi’s ability to cook food at the same rate throughout the

combination oven is operating within 5% of the nameplate combi’s compartment.

F2861 − 10

6. Apparatus 6.8 Temperature Sensor, for measuring natural gas tempera-

ture in the range from 50 to 100°F (10 to 40°C), with an

6.1 Analytical Balance Scale, for measuring weights up to

uncertainty of 61°F (0.3°C).

20 lb (9.0 kg), with a resolution of 0.01 lb (0.005 kg) and an

uncertainty of 0.01 lb (0.005 kg). 6.9 Thermocouple Probes, with a range from 0 to 450°F

(–18 to 232°C), with a resolution of 0.2°F (0.1°C), and an

6.2 Barometer, for measuring absolute atmospheric

uncertainty of 0.5°F (0.3°C), for measuring temperature of the

pressure, to be used for adjustment of measured natural gas

combination oven cavity, food product, water entering the

volume to standard conditions, having a resolution of 0.2 in.

combi oven and condensate water.

Hg (670 Pa) and an uncertainty of 0.2 in. Hg (670 Pa).

6.10 Watt-hour Meter, for measuring the electrical energy

6.3 Canopy Exhaust Hood, 4-ft (1.2-m) in depth, wall-

consumption of a combination oven, having a resolution of at

mounted with the lower edge of the hood 72 in. (2.0 m) from

least 10Wh and a maximum uncertainty no greater than 1.5%

the floor and with the capacity to operate at a nominal exhaust

of the measured value for any demand greater than 100W. For

ventilation rate of 300 cfm per linear foot (360 L/s per linear

any demand less than 100W, the meter shall have a resolution

meter) of active hood length. This hood shall extend a

of at least 10 Wh and a maximum uncertainty no greater than

minimumof6in.(150mm)pastbothsidesandthefrontofthe

10%.

cooking appliance and shall not incorporate side curtains or

partitions. 6.11 Hotel Pans, for ice loads, solid 12 by 20 by 2 ⁄2-in.

(300 by 500 by 65-mm) stainless steel, weighing 2.8 6 0.2 lb

6.4 Flowmeter, for measuring total water consumption of

(1.3 6 0.1 kg), with a temperature sensor located in the center

the appliance, having a resolution of 0.01 gal (40 mL) and an

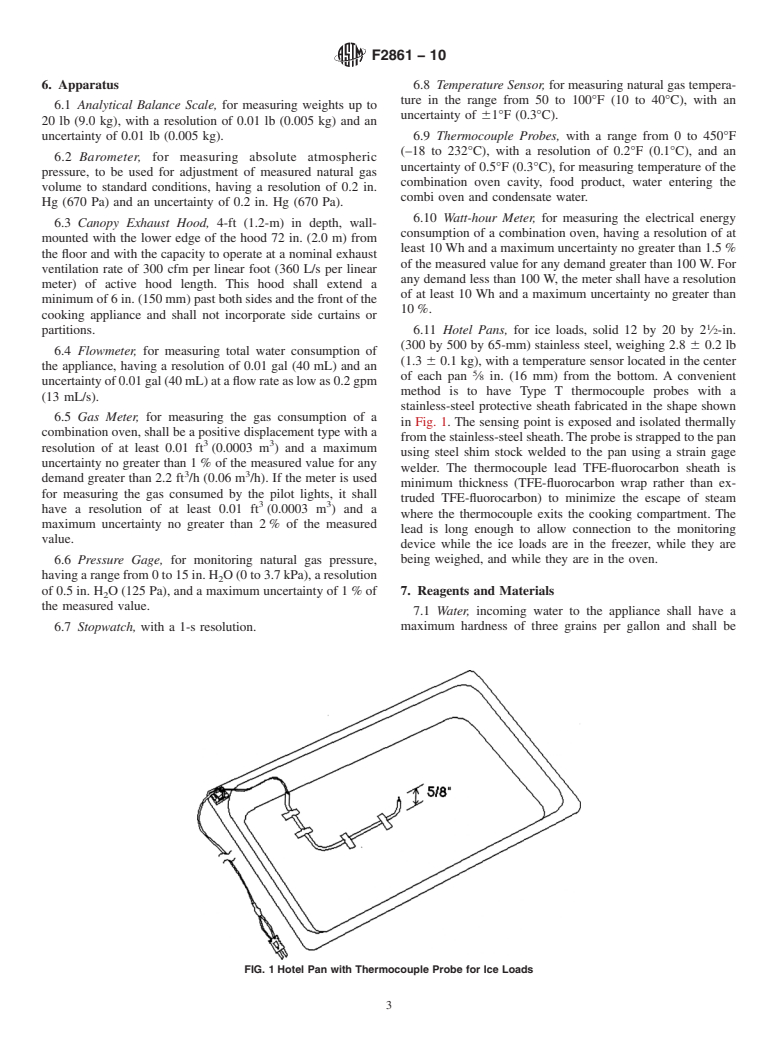

of each pan ⁄8 in. (16 mm) from the bottom. A convenient

uncertaintyof0.01gal(40mL)ataflowrateaslowas0.2gpm

method is to have Type T thermocouple probes with a

(13 mL/s).

stainless-steel protective sheath fabricated in the shape shown

6.5 Gas Meter, for measuring the gas consumption of a

in Fig. 1. The sensing point is exposed and isolated thermally

combinationoven,shallbeapositivedisplacementtypewitha

fromthestainless-steelsheath.Theprobeisstrappedtothepan

3 3

resolution of at least 0.01 ft (0.0003 m ) and a maximum

using steel shim stock welded to the pan using a strain gage

uncertainty no greater than 1% of the measured value for any

welder. The thermocouple lead TFE-fluorocarbon sheath is

3 3

demand greater than 2.2 ft /h (0.06 m /h). If the meter is used

minimum thickness (TFE-fluorocarbon wrap rather than ex-

for measuring the gas consumed by the pilot lights, it shall

truded TFE-fluorocarbon) to minimize the escape of steam

3 3

have a resolution of at least 0.01 ft (0.0003 m ) and a

where the thermocouple exits the cooking compartment. The

maximum uncertainty no greater than 2% of the measured

lead is long enough to allow connection to the monitoring

value.

device while the ice loads are in the freezer, while they are

6.6 Pressure Gage, for monitoring natural gas pressure, being weighed, and while they are in the oven.

havingarangefrom0to15in.H O(0to3.7kPa),aresolution

of 0.5 in. H O (125 Pa), and a maximum uncertainty of 1% of 7. Reagents and Materials

the measured value.

7.1 Water, incoming water to the appliance shall have a

6.7 Stopwatch, with a 1-s resolution. maximum hardness of three grains per gallon and shall be

FIG. 1 Hotel Pan with Thermocouple Probe for Ice Loads

F2861 − 10

within 70 6 5°F (21 6 3°C). If the tester’s water supply does appliance’s pressure regulator to within 62.5% of the operat-

not meet the specification, a water softener or tempering kit or ing manifold pressure specified by the manufacturer. Make

both may be required. adjustments to the appliance following the manufacturer’s

recommendations for optimizing combustion.

7.2 Red Potatoes, for the steam mode efficiency tests shall

be fresh, whole, US No. 1, Size B, red potatoes. The average 9.5 Install a flowmeter to the combination oven water inlet

weight of the potatoes shall be 0.16 6 0.02 lb (73 6 9 g). such that total water flow to the appliance is measured.

NOTE1—Redpotatoesaresoldinthreesizes:A,B,andC.Thistestuses

9.6 Install temperature sensors at the point where the drain

Size B.

waterexitsthecombinationovenandinthedrainlinesuchthat

7.3 Russet Potatoes, for the convection mode efficiency

the sensor is immersed in the condensate water path just as it

testsshallbefresh,whole,prewashed,U.S.No.1Russets.Size

enters the drain.

shallbe100count.Theaverageweightofthepotatoesshallbe

9.7 Tape a temperature sensor firmly to the surface of a

0.48 6 0.02 lb (218 6 91 g).

section of the metal tubing through which city water enters the

7.4 Steam Pans, for the steam performance tests shall be

combi oven.

perforated12by20by2 ⁄2in.(325by530by65mm)stainless

9.8 Installawaterregulatoronincomingwaterlines.Adjust

steel weighing 2.5 6 0.5 lb (1.1 6 0.2 kg).

the dynamic water pressure to 45 psi (3.1 bar).

7.5 Sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.