ASTM D4125-94(2000)

(Test Method)Standard Test Methods for Asphalt Content of Bituminous Mixtures by the Nuclear Method

Standard Test Methods for Asphalt Content of Bituminous Mixtures by the Nuclear Method

SCOPE

1.1 These test methods cover the procedures for determining the asphalt content of samples of uncompacted bituminous mixtures (Test Method A), and of laboratory compacted specimens of bituminous mixtures (Test Method B) by examining a test sample with an apparatus that utilizes neutron thermalization techniques.

1.2 The values expressed in SI units are regarded as the standard. The inch-pounds equivalents may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 6 and Note 1, Note 4, and Note 6, for specific hazards.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4125–94 (Reapproved 2000)

Standard Test Methods for

Asphalt Content of Bituminous Mixtures by the Nuclear

Method

This standard is issued under the fixed designation D 4125; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 These test methods cover the procedures for determin- 3.1 These test methods are useful as a rapid, nondestructive

ing the asphalt content of samples of uncompacted bituminous technique for determination of asphalt content of bituminous

mixtures (Test Method A), and of laboratory compacted mixtures.

specimens of bituminous mixtures (Test Method B) by exam- 3.2 These test methods are suitable for quality control and

ining a test sample with an apparatus that utilizes neutron acceptance testing for construction and for research and

thermalization techniques. development applications. The test method is used for deter-

1.2 The values expressed in SI units are regarded as the mination of asphalt content only as it does not provide

standard. The inch-pounds equivalents may be approximate. extracted aggregate for gradation analysis.

1.3 This standard does not purport to address all of the 3.3 The non-destructive nature of the test allows repetitive

safety concerns, if any, associated with its use. It is the measurements to be made on a single test sample for statistical

responsibility of the user of this standard to establish appro- analysis of test data.

priate safety and health practices and determine the applica- 3.4 These test methods determine the asphalt content of a

bility of regulatory limitations prior to use. See Section 6 and test sample by comparing the measured asphalt content with

Note 1, Note 4, and Note 6, for specific hazards. previously established calibration data.

3.4.1 The asphalt content of a material expressed as a

2. Referenced Documents

percentage, is the ratio of the mass of asphalt in a given mass

2.1 ASTM Standards: of material to the total mass of the sample or to the mass of the

C 670 Practice for Preparing Precision and Bias Statements

solid material particles.

for Test Methods of Construction Materials

4. Interferences

D 75 Practice for Sampling Aggregates

D 140 Practice for Sampling Bituminous Materials 4.1 The fundamental assumptions inherent in this test

D 979 Practice for Sampling Bituminous Paving Mixtures method are that the material under test is homogeneous and

D 1461 Test Method for Moisture or Volatile Distillates in that hydrogen present is in the form of asphalt or has been

Bituminous Paving Mixtures otherwise accounted for in the calibration process.

D 1559 Test Method for Resistance to Plastic Flow of 4.2 Accurate results will be dependent upon proper calibra-

Bituminous Mixtures Using Marshall Apparatus tion of the apparatus to the material being tested.

D 1561 PracticeforPreparationofBituminousMixtureTest 4.3 Thisapparatusmeasuresthetotalamountofhydrogenin

Specimens by Means of California Kneading Compactor the sample including hydrogen present in the form of water.

D 3387 Test Method for Compaction and Shear Properties Unlessthetestsampleisfreeofwater,suchpercentagemustbe

of Bituminous Mixtures by Means of the U.S. Corps of determined in accordance with the provisions of Test Method

Engineers Gyratory Testing Machine (GTM) D 1461 and the percentage determined subtracted from the

D 4013 Practice for Preparation of Test Specimens of Bitu- asphalt percentage as measured by the apparatus.

minous Mixtures by Means of Gyratory Shear Compactor 4.3.1 Alternatively, the sample may be dried to a constant

mass in an oven at 110 6 5°C (230 6 9°F), thereby nullifying

the need for the correction.

These test methods are under the jurisdiction of ASTM Committee D04 on

4.4 This apparatus may be sensitive to outside influences,

Road and Paving Materials and is the direct responsibility of Subcommittee D04.25

therefore, any other source of neutron radiation shall be kept at

on Analysis of Bituminous Mixtures.

Current edition approved May 15, 1994. Published July 1994. Originally least 10 m (30 ft) from the apparatus during use. The area

published as D 4125 – 83. Last previous edition D 4125 – 92.

Annual Book of ASTM Standards, Vol 04.02.

Annual Book of ASTM Standards, Vol 04.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4125

around the apparatus shall be kept free of large amounts of

hydrogenous material, such as water, plastics or asphalt during

use.

4.5 Movingtheapparatustoadifferentlocation,evenwithin

the same laboratory, can cause a change in background

radiation measurements. Also, if objects containing hydrog-

enous materials are moved in the area near the apparatus, the

measurement counts may be affected. New background mea-

surements shall be taken prior to use whenever background

conditions have changed (see Section 10).

5. Apparatus

5.1 While exact details of construction for the apparatus

may vary, the system shall consist of the following items:

5.1.1 Neutron Source— An encapsulated and sealed radio-

active source such as americium/beryllium.

5.1.2 Detectors—Any type of thermal neutron detectors,

such as helium-3 or boron trifluoride.

5.1.3 Read-Out Instrument, such as a scaler or a direct

reading digital device calibrated in percent asphalt.

5.2 Other Apparatus:

5.2.1 Stainless Steel Sample Pans, of uniform size and

mass.

5.2.2 Balance, capable of weighing to 20 kg (44 lb),

readable to 1 g (0.0002 lbm).

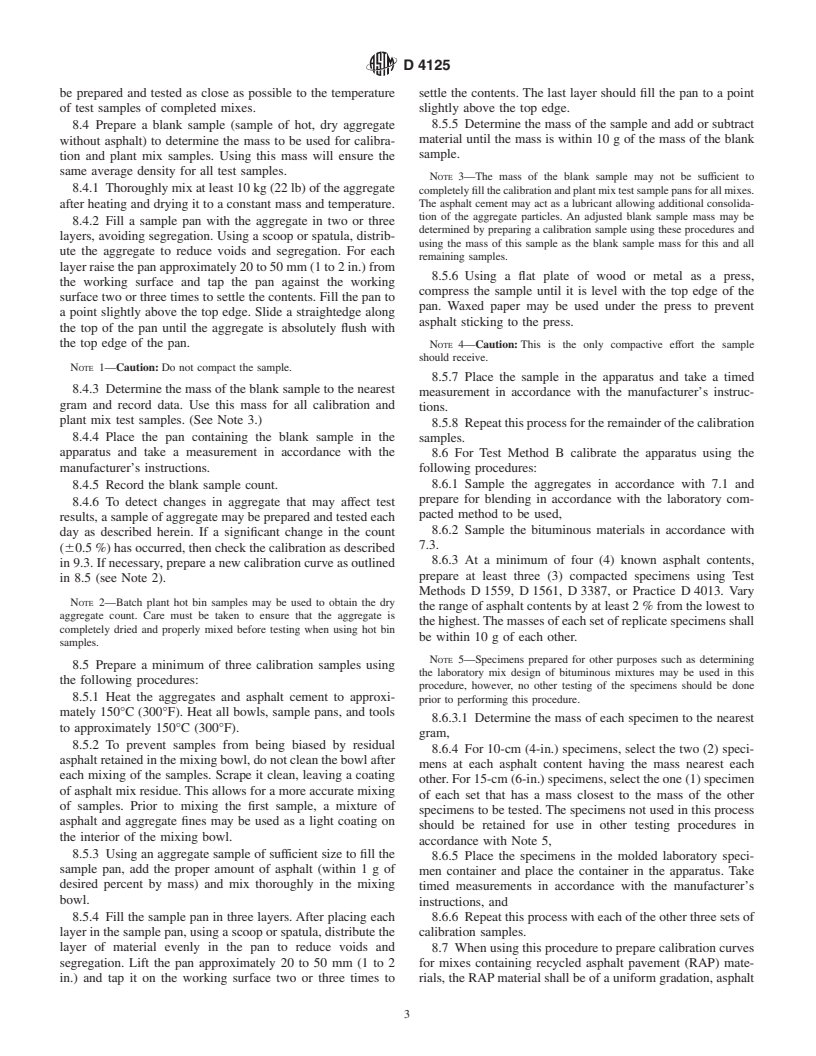

FIG. 1 Molded Laboratory Specimen-Containers Measurement

5.2.3 Oven, capable of heating to 177 6 3°C (350 6 5°F).

Values in SI Units (CM)—Other Values for Reference Only

5.2.4 Straightedge, steel, approximately 450 mm (18 in.) in

length.

7.3 Obtain random samples of bituminous materials in

5.2.5 Flat Plate, metal or wood, having an area slightly

accordance with Practice D 140.

larger than the sample pan. The metal plate shall have a

minimum thickness of 10 mm ( ⁄8 in.). The wooden plate shall

8. Calibration

have a minimum thickness of 20 mm ( ⁄4 in.).

8.1 The test results obtained using this test method will be

5.2.6 Assorted Spoons and Mixing Bowls.

influenced by the types of aggregate, source and grade of

5.2.7 Thermometer with a temperature range of 10 to

asphalt, and by the mix gradation. Accordingly, a calibration

250°C (50 to 482°F).

curve must be developed for each mix type and aggregate

5.3 Additional Apparatus for Test Method B:

blend to be tested under this test method.

5.3.1 MoldedLaboratorySpecimenContainer,(providedby

8.1.1 A new calibration curve shall be developed whenever

instrument manufacturer) to allow for proper testing of labo-

there is a change in the source of asphalt or aggregate or a

ratory compacted samples (see Fig. 1).

significant change in aggregate gradation.

5.3.2 Apparatus, necessary to prepare compacted specimens

8.1.2 Anewcalibrationcurveshallbeestablishedfornewor

as specified in Test Methods D 1559, D 1561, D 3387, or

repaired apparatus.

Practice D 4013.

8.2 For Test Method A calibrate the apparatus using the

following procedures:

6. Hazards

8.2.1 Sample the aggregates in accordance with 7.1 and

6.1 Warning—This equipment utilizes radioactive materi-

blend the aggregates in the proper proportions. Obtain enough

als which may be hazardous to the health of the users unless

aggregate for a minimum of three samples. Approximately 30

proper precautions are taken. Users of this equipment must

kg (65 lb) will be required, and

become completely familiar with possible safety hazards and

8.2.2 Sample the bituminous materials in accordance with

with all applicable regulations concerning the handling and use

7.3. Approximately 2.5 kg (5.5 lb) will be required.

of radioactive materials. Effective user instructions together

8.3 Use a minimum of three prepared samples to establish

with routine safety procedures are a recommended part of the

the calibration curve. The range of asphalt contents shall vary

operation of this apparatus.

by at least two percent asphalt content from the lowest to the

highest contents in the samples.The range shall encompass the

7. Sampling

asphalt content of the proposed mix design. The mass of the

7.1 Obtain random samples of aggregates in accordance samples shall be within 10 g of each other.

with Practice D 75. 8.3.1 Unless the apparatus makes provision for temperature

7.2 Obtain random samples of freshly produced bituminous corrections, all calibration samples shall be tested at a uniform

paving mixture in accordance with Practice D 979. temperature, within 65°C (9°F). Calibration samples should

D4125

be prepared and tested as close as possible to the temperature settle the contents. The last layer should fill the pan to a point

of test samples of completed mixes. slightly above the top edge.

8.5.5 Determine the mass of the sample and add or subtract

8.4 Prepare a blank sample (sample of hot, dry aggregate

material until the mass is within 10 g of the mass of the blank

without asphalt) to determine the mass to be used for calibra-

sample.

tion and plant mix samples. Using this mass will ensure the

same average density for all test samples.

NOTE 3—The mass of the blank sample may not be sufficient to

8.4.1 Thoroughly mix at least 10 kg (22 lb) of the aggregate

completelyfillthecalibrationandplantmixtestsamplepansforallmixes.

after heating and drying it to a constant mass and temperature. The asphalt cement may act as a lubricant allowing additional consolida-

tion of the aggregate particles. An adjusted blank sample mass may be

8.4.2 Fill a sample pan with the aggregate in two or three

determined by preparing a calibration sample using these procedures and

layers, avoiding segregation. Using a scoop or spatula, distrib-

using the mass of this sample as the blank sample mass for this and all

ute the aggregate to reduce voids and segregation. For each

remaining samples.

layer raise the pan approximately 20 to 50 mm (1 to 2 in.) from

8.5.6 Using a flat plate of wood or metal as a press,

the working surface and tap the pan against the working

compress the sample until it is level with the top edge of the

surface two or three times to settle the contents. Fill the pan to

pan. Waxed paper may be used under the press to prevent

a point slightly above the top edge. Slide a straightedge along

asphalt sticking to the press.

the top of the pan until the aggregate is absolutely flush with

the top edge of the pan. NOTE 4—Caution: This is the only compactive effort the sample

should receive.

NOTE 1—Caution: Do not compact the sample.

8.5.7 Place the sample in the apparatus and take a timed

8.4.3 Determine the mass of the blank sample to the nearest

measurement in accordance with the manufacturer’s instruc-

gram and record data. Use this mass for all calibration and

tions.

plant mix test samples. (See Note 3.)

8.5.8 Repeatthisprocessfortheremainderofthecalibration

8.4.4 Place the pan containing the blank sample in the

samples.

apparatus and take a measurement in accordance with the 8.6 For Test Method B calibrate the apparatus using the

manufacturer’s instructions.

following procedures:

8.6.1 Sample the aggregates in accordance with 7.1 and

8.4.5 Record the blank sample count.

prepare for blending in accordance with the laboratory com-

8.4.6 To detect changes in aggregate that may affect test

pacted method to be used,

results, a sample of aggregate may be prepared and tested each

8.6.2 Sample the bituminous materials in accordance with

day as described herein. If a significant change in the count

7.3.

(60.5 %) has occurred, then check the calibration as described

8.6.3 At a minimum of four (4) known asphalt contents,

in 9.3. If necessary, prepare a new calibration curve as outlined

prepare at least three (3) compacted specimens using Test

in 8.5 (see Note 2).

Methods D 1559, D 1561, D 3387, or Practice D 4013. Vary

NOTE 2—Batch plant hot bin samples may be used to obtain the dry

the range of asphalt contents by at least 2 % from the lowest to

aggregate count. Care must be taken to ensure that the aggregate is

the highest.The masses of each set of replicate specimens shall

completely dried and properly mixed before testing when using hot bin

be within 10 g of each other.

samples.

NOTE 5—Specimens prepared for other purposes such as determining

8.5 Prepare a minimum of three calibration samples using

the laboratory mix design of bituminous mixtures may be used in this

the following procedures:

procedure, however, no other testing of the specimens should be done

8.5.1 Heat the aggregates and asphalt cement to approxi-

prior to performing this procedure.

mately 150°C (300°F). Heat all bowls, sample pans, and tools

8.6.3.1 Determine the mass of each specimen to the nearest

to approximately 150°C (300°F).

gram,

8.5.2 To prevent samples from being biased by residual

8.6.4 For 10-cm (4-in.) specimens, select the two (2) speci-

asphalt retained in the mixing bowl, do not clean the bowl after

mens at each asphalt content having the mass nearest each

each mixing of the samples. Scrape it clean, leaving a coating

other. For 15-cm (6-in.) specimens, select the one (1) specimen

of asphalt mix residue. This allows for a more accurate mixing

of each set that has a mass closest to the mass of the other

of samples. Prior to mixing the first sample, a mixture of

specimens to be tested. The specimens not used in this process

asphalt and aggregate fines may be used as a light coating on

should be retained for use in other testing procedures in

the interior of the mixing bowl.

accordance with Note 5,

8.5.3 Using an aggregate sample of sufficient size to fill the

8.6.5 Place the specimens in the molded laboratory speci-

sample pan, add the proper amount of asphalt (within1gof

men container and place the container in the apparatus. Take

desired percent by mass) and mix thoroughly in the mixing

timed measurements in accordance with the manufacturer’s

bowl.

instructions, and

8.5.4 Fill the sample pan in three layers. After placing each 8.6.6 Repeat this process with each of the other three sets of

layer in the sample pan, using a scoop or spatula, distribute the calibration samples.

layer of material evenly in the pan to reduce voids and 8.7 When using this procedure to prepare calibration curves

segregation. Lift the pan approximately 20 to 50 mm (1 to 2 for mixes containing recycled asphalt pavement (RAP) mate-

in.) and tap it on the working surface two or three times to rials, the R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.