ASTM A595/A595M-18

(Specification)Standard Specification for Steel Tubes, Low-Carbon or High-Strength Low-Alloy, Tapered for Structural Use

Standard Specification for Steel Tubes, Low-Carbon or High-Strength Low-Alloy, Tapered for Structural Use

ABSTRACT

This specification covers three grades of seam-welded, round, tapered steel tubes for structural use. Grades A and B are of low-carbon steel or high-strength low-alloy steel composition and Grade C is of weather-resistance steel composition. The tube steel shall be hot-rolled aluminum-semikilled or fine-grained killed sheet or plate manufactured by one or more of the following processes: open-hearth, basic-oxygen, or electric-furnace. The tubes shall be made from trapezoidal sheet or plate that is preformed and then seam welded. They shall be brought to final size and properties by roll compressing cold on a hardened mandrel. A tensile test shall be done to determine the yield strength and the ultimate tensile strength of the tubes.

SCOPE

1.1 This specification covers three grades of seam-welded, round, tapered steel tubes for structural use. Grades A and B are of low-carbon steel or high-strength low-alloy steel composition and Grade C is of weather-resistant steel composition.

1.1.1 The product may be modified from its round cross section into other shapes without subsequent retesting.

1.2 This tubing is produced in welded sizes in a range of diameters from 2 3/8 to 30 in. [60 to 762 mm] inclusive. Wall thicknesses range from 0.1046 to 0.375 in. [2.66 to 9.53 mm]. Tapers are subject to agreement with the manufacturer.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A595/A595M −18

Standard Specification for

Steel Tubes, Low-Carbon or High-Strength Low-Alloy,

1

Tapered for Structural Use

This standard is issued under the fixed designationA595/A595M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Point, with Atmospheric Corrosion Resistance

A606/A606MSpecification for Steel, Sheet and Strip, High-

1.1 This specification covers three grades of seam-welded,

Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, with

round,taperedsteeltubesforstructuraluse.GradesAandBare

Improved Atmospheric Corrosion Resistance

of low-carbon steel or high-strength low-alloy steel composi-

A751Test Methods, Practices, and Terminology for Chemi-

tion and Grade C is of weather-resistant steel composition.

cal Analysis of Steel Products

1.1.1 The product may be modified from its round cross

G101Guide for Estimating the Atmospheric Corrosion Re-

section into other shapes without subsequent retesting.

sistance of Low-Alloy Steels

1.2 This tubing is produced in welded sizes in a range of

3

diameters from 2 ⁄8 to 30 in. [60 to 762 mm] inclusive. Wall

3. Ordering Information

thicknesses range from 0.1046 to 0.375 in. [2.66 to 9.53 mm].

3.1 The inquiry and order should indicate the following:

Tapers are subject to agreement with the manufacturer.

3.1.1 Large and small diameters (in.) [mm], length (ft) [m],

1.3 The values stated in either SI units or inch-pound units

wall thickness (in.) [mm], taper (in./ft) [mm/m];

are to be regarded separately as standard. The values stated in

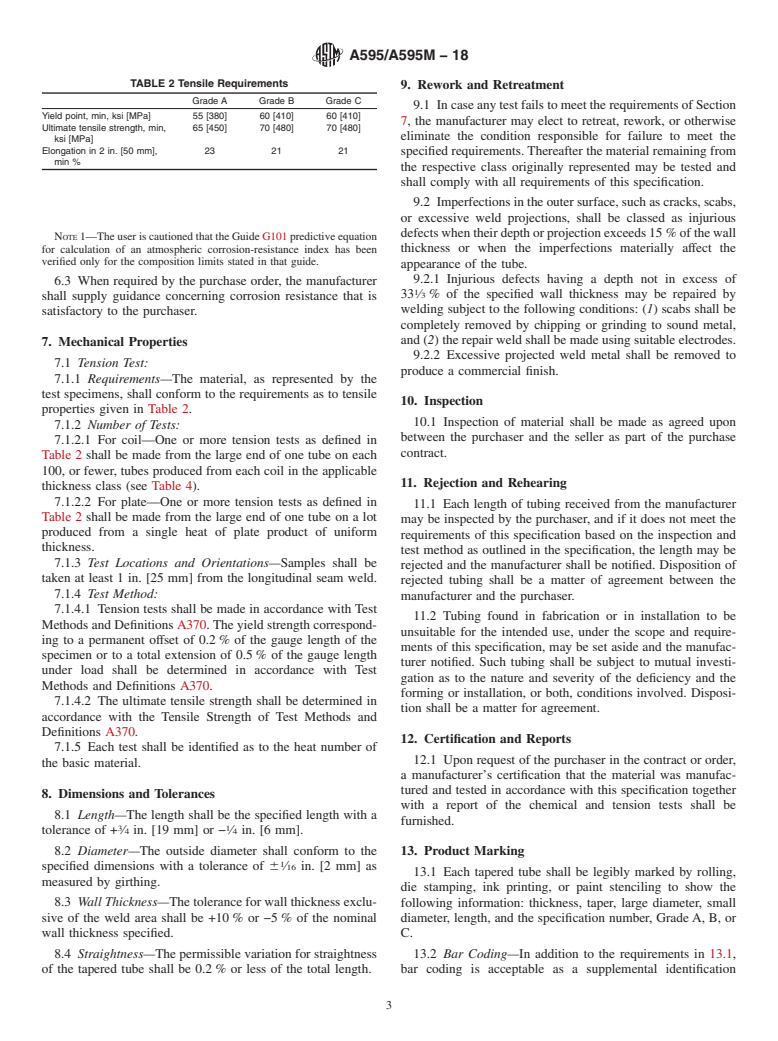

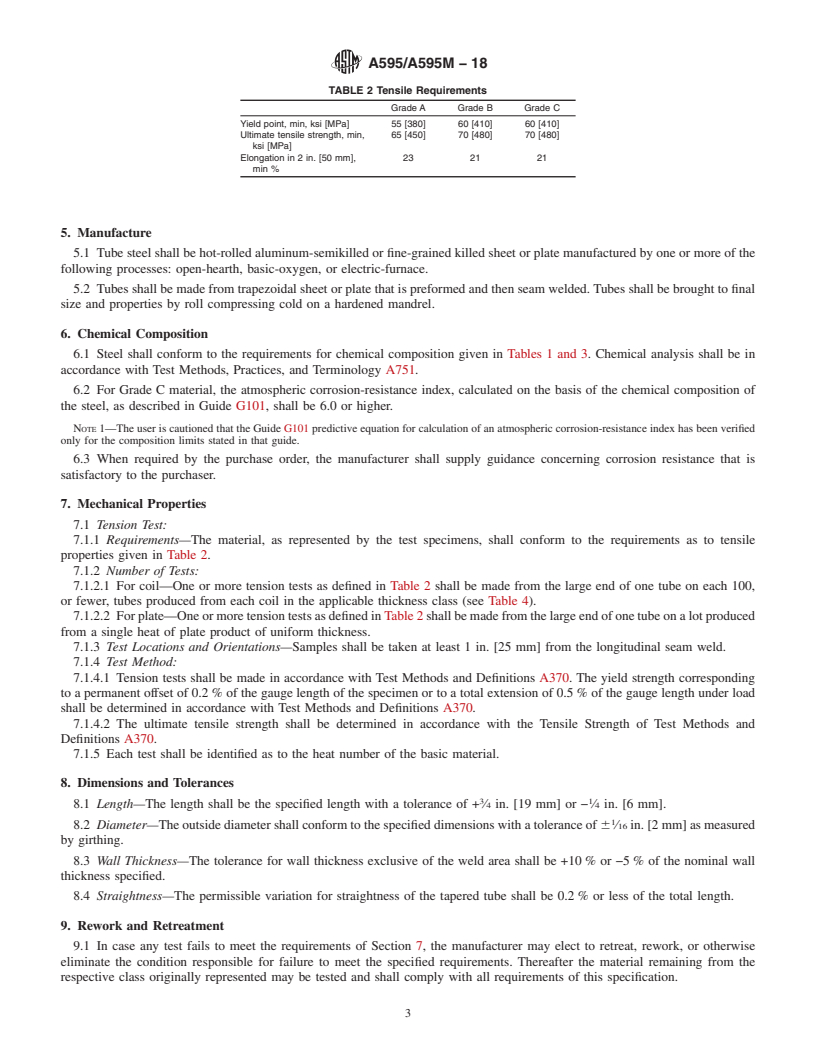

3.1.2 (see Table 1 and Table 2);

each system may not be exact equivalents; therefore, each

3.1.3 Extra test material requirements, if any; and

system shall be used independently of the other. Combining

3.1.4 Supplementary requirements, if any.

values from the two systems may result in non-conformance

4. General Requirements for Delivery

with the standard.

1.4 This international standard was developed in accor- 4.1 Required date of shipment or date of receipt, and

dance with internationally recognized principles on standard-

4.2 Special shipping instructions, if any.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Manufacture

mendations issued by the World Trade Organization Technical

5.1 Tube steel shall be hot-rolled aluminum-semikilled or

Barriers to Trade (TBT) Committee.

fine-grained killed sheet or plate manufactured by one or more

of the following processes: open-hearth, basic-oxygen, or

2. Referenced Documents

electric-furnace.

2

2.1 ASTM Standards:

5.2 Tubes shall be made from trapezoidal sheet or plate that

A370Test Methods and Definitions for Mechanical Testing

is preformed and then seam welded. Tubes shall be brought to

of Steel Products

final size and properties by roll compressing cold on a

A588/A588MSpecification for High-Strength Low-Alloy

hardened mandrel.

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

6. Chemical Composition

6.1 Steel shall conform to the requirements for chemical

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

composition given in Tables 1 and 3. Chemical analysis shall

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

be in accordance with Test Methods, Practices, and Terminol-

Current edition approved Nov. 1, 2018. Published November 2018. Originally

ogy A751.

approved in 1969. Last previous edition approved in 2014 as A595/A595M–14.

DOI: 10.1520/A0595_A0595M-18.

6.2 For Grade C material, the atmospheric corrosion-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

resistance index, calculated on the basis of the chemical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

composition of the steel, as described in Guide G101, shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.0 or higher.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A595/A595M − 18

2

TABLE 1 Chemical Requirements

Composition by Heat Analysis, %

Grade A Grade B Grade C

Elements Carbon HSLA SS HSLAS Cl1 HSLAS Cl2 Carbon Steel HSLA SS HSLAS Cl1 HSLAS Cl2 A 606 A 588/A A 588/B A 588/C A 588/K

Steel

Carbon 0.15–0.25 0.25 max 0.23 max 0.15 max 0.15–0.25

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A595/A595M − 14 A595/A595M − 18

Standard Specification for

Steel Tubes, Low-Carbon or High-Strength Low-Alloy,

1

Tapered for Structural Use

This standard is issued under the fixed designation A595/A595M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers three grades of seam-welded, round, tapered steel tubes for structural use. Grades A and B are of

low-carbon steel or high-strength low-alloy steel composition and Grade C is of weather-resistant steel composition.

1.1.1 The product may be modified from its round cross section into other shapes without subsequent retesting.

3

1.2 This tubing is produced in welded sizes in a range of diameters from 2 ⁄8 to 30 in. [60 to 762 mm] inclusive. Wall

thicknesses range from 0.1046 to 0.375 in. [2.66 to 9.53 mm]. Tapers are subject to agreement with the manufacturer.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used indepedentlyindependently of the other. Combining

values from the two systems may result in non-conformance with the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A588/A588M Specification for High-Strength Low-Alloy Structural Steel, up to 50 ksi [345 MPa] Minimum Yield Point, with

Atmospheric Corrosion Resistance

A606A606/A606M Specification for Steel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, with

Improved Atmospheric Corrosion Resistance

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

G101 Guide for Estimating the Atmospheric Corrosion Resistance of Low-Alloy Steels

3. Ordering Information

3.1 The inquiry and order should indicate the following:

3.1.1 Large and small diameters (in.) [mm], length (ft) [m], wall thickness (in.) [mm], taper (in./ft) [mm/m];

3.1.2 (see Table 1 and Table 2);

3.1.3 Extra test material requirements, if any; and

3.1.4 Supplementary requirements, if any.

4. General Requirements for Delivery

4.1 Required date of shipment or date of receipt, and

4.2 Special shipping instructions, if any.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved May 1, 2014Nov. 1, 2018. Published May 2014November 2018. Originally approved in 1969. Last previous edition approved in 20112014 as

A595/A595M – 11.A595/A595M – 14. DOI: 10.1520/A0595_A0595M-14.10.1520/A0595_A0595M-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A595/A595M − 18

2

TABLE 1 Chemical Requirements

Composition by Heat Analysis, %

Grade A Grade B Grade C

Elements Carbon HSLA SS HSLAS Cl1 HSLAS Cl2 Carbon Steel HSLA SS HSLAS Cl1 HSLAS Cl2 A 606 A 588/A A 588/B A 588/C A 588/K

Steel

Carbon 0.15–0.25 0.25 max 0.23 max 0.15 max 0.15–0.25 0.25 max 0.26 max 0.15 max 0.22 max 0.19 max 0.20 max 0.15 max 0.17 max

Manganese 0.30–0.90 1.35 max 1.35 max 1.35 max 0.40–1.35 1.35 max 1.50 max 1.50 max 1.25 max 0.80–1.25 0.75–1.35 0.80–1.35 0.50–1.20

A

Phosphorous 0.035 max 0.035 max 0.04 max 0.04 max 0.035 max 0.035 max 0.04 max 0.04 max 0.04 max 0.04 max 0.04 max 0.04 max

Sulfur 0.035 max 0.04 max 0.04 max 0.04 max 0.035 max 0.04 max 0.04 max 0.04 max 0.04 max 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.