ASTM E1129/E1129M-15

(Specification)Standard Specification for Thermocouple Connectors

Standard Specification for Thermocouple Connectors

ABSTRACT

This specification covers separable single-circuit thermocouple connectors with two round pins. The widespread use of thermocouple connectors requires standardization of mating dimensions and performance characteristics. Connectors shall be constructed as either plugs or jacks, and these two forms shall be designed to connect with each other. Contact resistance test, thermal gradient test, and insulation resistance test shall be performed to meet the requirements prescribed.

SIGNIFICANCE AND USE

4.1 The widespread use of thermocouple connectors requires standardization of mating dimensions and performance characteristics.

4.2 This specification describes standardized thermocouple connector dimensions and capabilities and includes test procedures suitable for evaluating the performance of a particular specimen or design. The tests described are not intended for routine inspection or rapid testing of large groups of connectors or for quality control purposes.

SCOPE

1.1 This specification covers separable single-circuit thermocouple connectors with two round pins. Connectors covered by this specification must be rated for continuous use to at least 300°F (150°C), but they may optionally be rated to a higher temperature.

1.2 This specification does not cover multiple-circuit connectors, multi-pin connectors, miniature connectors, or connectors intended primarily for panel mounting. High temperature connectors (for example, those designed for continuous use at temperatures above approximately 500°F (260°C)) are not intended to be covered by this specification.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard.

1.4 The following precautionary statement pertains only to the test methods portion, Section 9, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1129/E1129M −15

Standard Specification for

1

Thermocouple Connectors

ThisstandardisissuedunderthefixeddesignationE1129/E1129M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope 2.2 ASTM Standards:

E230/E230M Specification and Temperature-Electromotive

1.1 This specification covers separable single-circuit ther-

Force (EMF) Tables for Standardized Thermocouples

mocouple connectors with two round pins. Connectors covered

E344 Terminology Relating to Thermometry and Hydrom-

by this specification must be rated for continuous use to at least

etry

300°F (150°C), but they may optionally be rated to a higher

E608/E608M Specification for Mineral-Insulated, Metal-

temperature.

Sheathed Base Metal Thermocouples

E2820 Test Method for Evaluating Thermal EMF Properties

1.2 This specification does not cover multiple-circuit

of Base-Metal Thermocouple Connectors

connectors, multi-pin connectors, miniature connectors, or

connectors intended primarily for panel mounting. High tem-

3. Terminology

perature connectors (for example, those designed for continu-

3.1 Definitions—The definitions given inTerminology E344

ous use at temperatures above approximately 500°F (260°C))

shall apply.

are not intended to be covered by this specification.

3.2 Definitions of Terms Specific to This Standard:

1.3 The values stated in either inch-pound units or SI units

3.2.1 connector pair, n—an assembly consisting of a plug

are to be regarded separately as standard.

and a jack, each having both positive and negative contact

inserts, that will connect two parts of an electrical circuit and

1.4 The following precautionary statement pertains only to

provide a means of physically disconnecting the two parts

the test methods portion, Section 9, of this specification. This

without the use of a tool.

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user 3.2.2 contact insert, n—metallic conductor assembly that,

when installed in a connector body, provides a connection

of this standard to establish appropriate safety and health

between two parts of an electrical circuit. Plug connectors will

practices and determine the applicability of regulatory limita-

contain projecting prong contacts, while jack connectors will

tions prior to use.

contain recessed sockets or receptacle contacts.

1.5 This international standard was developed in accor-

3.2.3 service life, n—period of time that a connector assem-

dance with internationally recognized principles on standard-

bly can be put to use and retain all physical and thermoelectric

ization established in the Decision on Principles for the

properties.

Development of International Standards, Guides and Recom-

3.2.4 test difference, n—thermoelectric emf value attribut-

mendations issued by the World Trade Organization Technical

able to mated connectors observed by the test procedure of this

Barriers to Trade (TBT) Committee.

specification.

2. Referenced Documents

4. Significance and Use

2.1 The following documents of the latest issue form a part

4.1 The widespread use of thermocouple connectors re-

of this specification to the extent referenced herein. In case of

quires standardization of mating dimensions and performance

conflict between this specification and another referenced

characteristics.

document, this specification shall take precedence.

4.2 This specification describes standardized thermocouple

connector dimensions and capabilities and includes test proce-

dures suitable for evaluating the performance of a particular

1

This specification is under the jurisdiction of ASTM Committee E20 on

Temperature Measurement and is the direct responsibility of Subcommittee E20.13

2

on Thermocouples - Materials and Accessories Specifications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2015. Published January 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1986. Last previous edition approved in 2014 as E1129 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E1129_E1129M-15. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

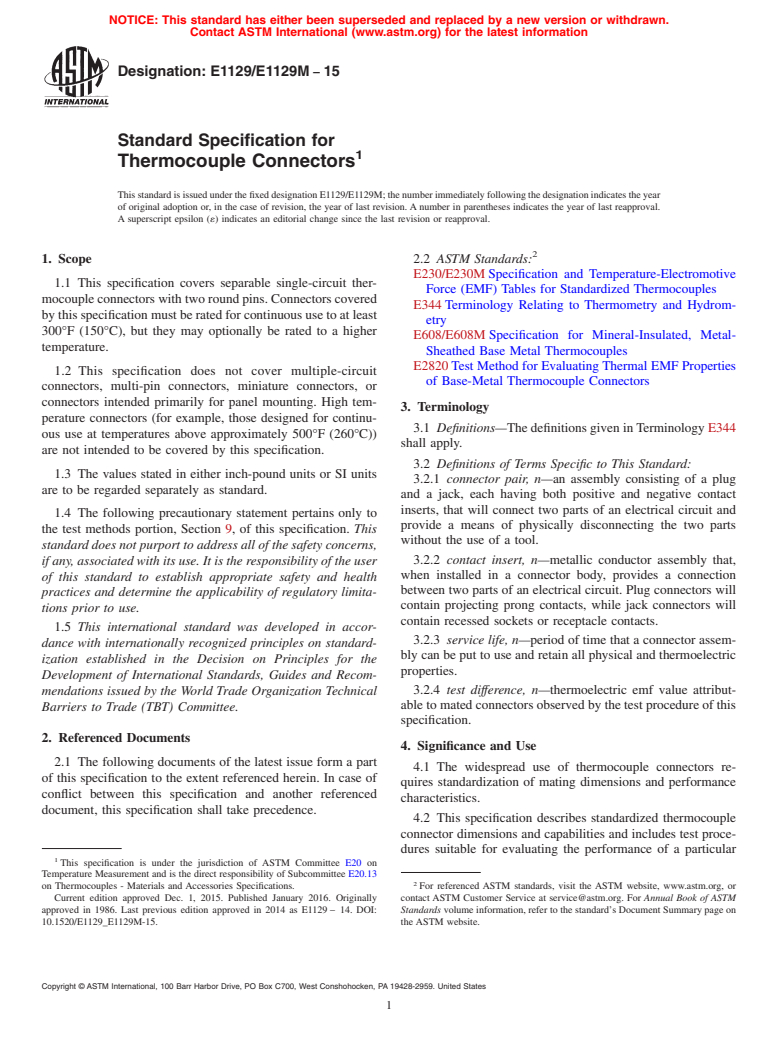

E1129/E1129M − 15

specimen or design. The tests described are not intended for

routineinspectionorrapidtestingoflargegroupsofconnectors

or for quality control purposes.

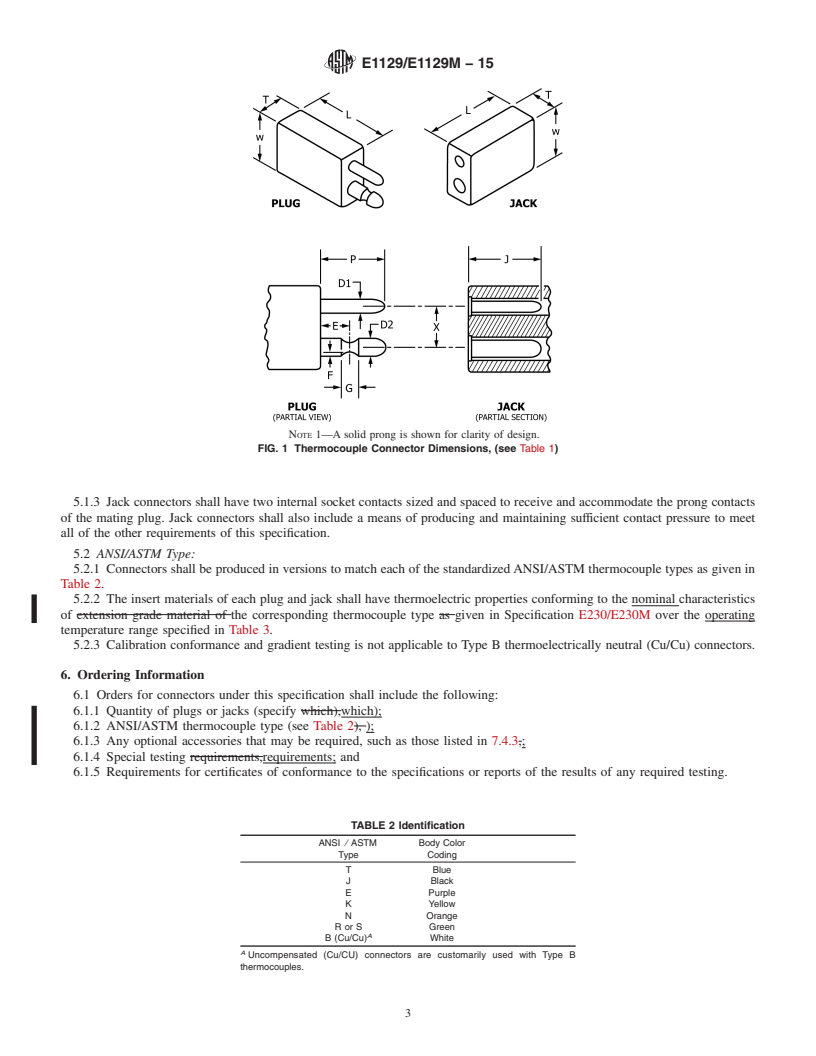

5. Classification

5.1 Plugs or Jacks:

5.1.1 Conne

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1129/E1129M − 14 E1129/E1129M − 15

Standard Specification for

1

Thermocouple Connectors

This standard is issued under the fixed designation E1129/E1129M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers separable single-circuit thermocouple connectors with two round pins. Connectors covered by this

specification must be rated for continuous use to at least 300 °F (150 °C), 300°F (150°C), but they may optionally be rated higher.

to a higher temperature.

1.2 This specification does not cover multiple-circuit connectors, multi-pin connectors, miniature connectors, or connectors

intended primarily for panel mounting. High temperature connectors (for example, those designed for continuous use at

temperatures above approximately 500 °F (260 °C)) 500°F (260°C)) are not intended to be covered by this specification.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard.

1.4 The following precautionary statement pertains only to the test methodmethods portion, Section 9, of this specification.This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 The following documents of the latest issue form a part of this specification to the extent referenced herein. In case of

conflict between this specification and another referenced document, this specification shall take precedence.

2

2.2 ASTM Standards:

E230/E230M Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples

E344 Terminology Relating to Thermometry and Hydrometry

E608/E608M Specification for Mineral-Insulated, Metal-Sheathed Base Metal Thermocouples

E2820 Test Method for Evaluating Thermal EMF Properties of Base-Metal Thermocouple Connectors

3. Terminology

3.1 Definitions—The definitions given in Terminology E344 shall apply.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 connector pair, n—an assembly consisting of a plug and a jack, each having both positive and negative contact inserts,

that will connect two parts of an electrical circuit and provide a means of physically disconnecting the two parts without the use

of tools.a tool.

3.2.2 contact insert, n—metallic conductor assembliesassembly that, when installed in connector bodies, provide connections

a connector body, provides a connection between two parts of an electrical circuit. Plug connectors will contain projecting prong

contacts, while jack connectors will contain recessed socketsockets or receptacle contacts.

3.2.3 service life, n—intervalperiod of time that a connector assembly willcan be put to use and retain all physical and

thermoelectric properties.

3.2.4 test difference, n—apparent thermoelectric difference emf value attributable to mated connectors observed by the test

procedure of this specification.

1

This specification is under the jurisdiction of ASTM Committee E20 on Temperature Measurement and is the direct responsibility of Subcommittee E20.04 on

Thermocouples.

Current edition approved Sept. 1, 2014Dec. 1, 2015. Published January 2015January 2016. Originally approved in 1986. Last previous edition approved in 20082014 as

ε1

E1129 – 08E1129 . – 14. DOI: 10.1520/E1129_E1129M-08E01.10.1520/E1129_E1129M-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1129/E1129M − 15

4. Significance and Use

4.1 The widespread use of thermocouple connectors requires standardization of mating dimensions and performance

characteristics.

4.2 This specification describes standardized thermocouple connector dimensions and capabilities and includes test procedures

suitable for evaluating the performance of a particular specimen or design. The tests described are not intended for ro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.