ASTM E2820-13(2019)

(Test Method)Standard Test Method for Evaluating Thermal EMF Properties of Base-Metal Thermocouple Connectors

Standard Test Method for Evaluating Thermal EMF Properties of Base-Metal Thermocouple Connectors

SIGNIFICANCE AND USE

5.1 A thermocouple connector, exposed to a temperature difference, contributes to the output of a thermocouple circuit. The output uncertainty allocated to the connector depends on the connector design and temperature gradient.

5.2 Connector performance can be classified based on the results of this method and used as part of a component specification.

5.3 The method can be used as an engineering tool for evaluating different connector designs tested under similar thermal conditions.

SCOPE

1.1 This standard describes a thermal emf test method for base-metal thermocouple connectors including Types E, J, K, N, and T. Standard connectors such as found in Specifications E1129/E1129M and E1684/E1684M as well as non-standard connector configurations and connector components can be evaluated using this method.

1.2 The measured emf is reported as an equivalent temperature deviation or error relative to a reference thermocouple of the same type. This method can be used to verify deviations introduced by the connector greater than or equal to 1°C.

1.3 The connector is tested with thermocouple contacts axially aligned with a temperature gradient using a specified thermal boundary condition. The actual temperature difference developed across the connector and corresponding error will depend on the connector design.

1.4 Connector contacts are often fabricated from raw materials having temperature-emf relationships in accordance with Specification E230/E230M. However, verifying Specification E230/E230M tolerances is not within the scope of this method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2820 − 13 (Reapproved 2019) An American National Standard

Standard Test Method for

Evaluating Thermal EMF Properties of Base-Metal

Thermocouple Connectors

This standard is issued under the fixed designation E2820; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This standard describes a thermal emf test method for

2.1 ASTM Standards:

base-metal thermocouple connectors including Types E, J, K, E220 Test Method for Calibration of Thermocouples By

N, and T. Standard connectors such as found in Specifications

Comparison Techniques

E1129/E1129M and E1684/E1684M as well as non-standard E230/E230M Specification for Temperature-Electromotive

connector configurations and connector components can be

Force (emf) Tables for Standardized Thermocouples

evaluated using this method. E344 Terminology Relating to Thermometry and Hydrom-

etry

1.2 The measured emf is reported as an equivalent tempera-

E563 Practice for Preparation and Use of an Ice-Point Bath

ture deviation or error relative to a reference thermocouple of

as a Reference Temperature

the same type. This method can be used to verify deviations

E1129/E1129M Specification for Thermocouple Connectors

introduced by the connector greater than or equal to 1°C.

E1684/E1684M Specification for Miniature Thermocouple

1.3 The connector is tested with thermocouple contacts

Connectors

axially aligned with a temperature gradient using a specified

E2488 Guide for the Preparation and Evaluation of Liquid

thermal boundary condition. The actual temperature difference

Baths Used for Temperature Calibration by Comparison

developed across the connector and corresponding error will

depend on the connector design.

3. Terminology

1.4 Connector contacts are often fabricated from raw mate-

3.1 Definitions—The definitions given inTerminology E344

rials having temperature-emf relationships in accordance with

apply to the terms used in this standard.

Specification E230/E230M. However, verifying Specification

E230/E230M tolerances is not within the scope of this method.

4. Summary of Test Method

1.5 The values stated in SI units are to be regarded as

4.1 The connector is tested as part of a thermocouple circuit

standard. No other units of measurement are included in this

and compared to a reference thermocouple of the same type

standard.

and material lot.

1.6 This standard does not purport to address all of the

4.2 Measurements are made while the connector is sub-

safety concerns, if any, associated with its use. It is the

jected to a temperature gradient established by a specified

responsibility of the user of this standard to establish appro-

boundary condition.

priate safety, health, and environmental practices and deter-

4.3 Performance is evaluated at a fixed position within a

mine the applicability of regulatory limitations prior to use.

dry-well furnace or stirred liquid bath (Method 1 or 2A

1.7 This international standard was developed in accor-

respectively) or variable position within a stirred liquid bath

dance with internationally recognized principles on standard-

(Method 2B). The latter method can be used to survey the

ization established in the Decision on Principles for the

connectortoidentifyapositionwithinthethermalgradientthat

Development of International Standards, Guides and Recom-

produces a maximum output deviation.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4.4 Results are interpreted relative to the properties of the

reference thermocouple.

This test method is under the jurisdiction of ASTM Committee E20 on

Temperature Measurement and is the direct responsibility of Subcommittee E20.13

on Thermocouples - Materials and Accessories Specifications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2019. Published May 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2011. Last previous edition approved in 2013 as E2820 – 13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2820-13R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2820 − 13 (2019)

5. Significance and Use 6.3.2 Method 2—atemperaturecontrolledstirredliquidbath

of non-conductive fluid with an immersion depth of at least

5.1 A thermocouple connector, exposed to a temperature

150 mm and the capability of maintaining the specified tem-

difference, contributes to the output of a thermocouple circuit.

peraturewithin1°C.Comparisoncalibrationbathsasdescribed

The output uncertainty allocated to the connector depends on

in Guide E2488 are suitable for this test.

the connector design and temperature gradient.

5.2 Connector performance can be classified based on the 7. Hazards

results of this method and used as part of a component

7.1 Review the Material Safety Data Sheet (MSDS) before

specification.

using a fluid in a temperature-controlled bath. Temperature

5.3 The method can be used as an engineering tool for limits, flammability, vapor pressure, toxicity and chemical

evaluating different connector designs tested under similar stability are important factors in determining a suitable fluid.

thermal conditions.

8. Preparation of Apparatus

6. Apparatus

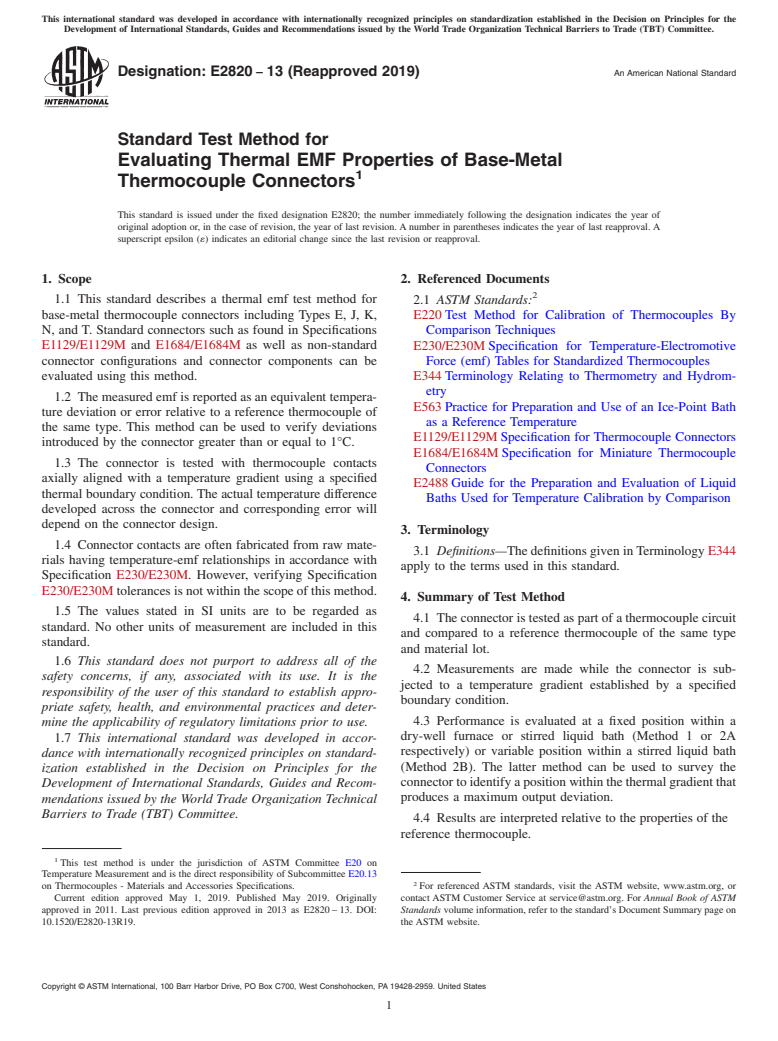

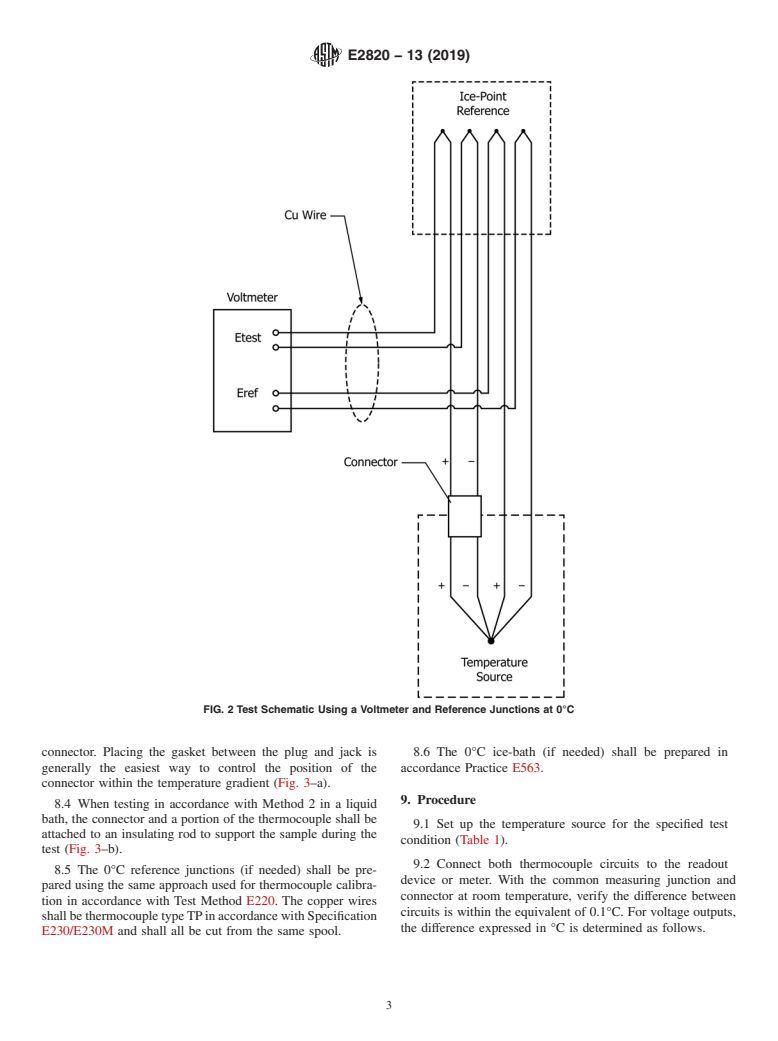

8.1 The apparatus requires a dual thermocouple circuit with

6.1 The apparatus includes a temperature source, thermo- a common measuring junction. The circuit shall be fabricated

couple readout device or voltmeter and ice-bath as shown in from the same spool of wire. Except for the connector under

Fig.1andFig.2.Anice-bathisneededonlyifthereadoutdoes test, the length of wire shall be continuous without splices or

not provide cold junction compensation. other connections between the measuring junction and the

readout device.

6.2 The thermocouple readout device or voltmeter shall

have two or more channels and have equivalent temperature 8.2 The thermocouple wire shall carry the same letter

resolution of at least 0.1°C. The difference between channels designation (for example, Type K) as the connector under test.

shall not exceed the equivalent of 0.1°C when supplied with The wire shall conform to the special tolerance in Specification

the same voltage input. E230/E230M over the range of 0°C to the maximum specified

connector test temperature. The wire size shall be 24 gage

6.3 The temperature source heats the measuring junctions

(0.5 mm) unless specified otherwise.

and produces a temperature gradient across the connector. The

source is either a dry-well furnace or stirred liquid bath 8.3 The test connector shall be installed approximately

depending on the specified method. 70 mm from the measuring junction. When testing in a

6.3.1 Method 1—a temperature controlled dry-well furnace dry-well furnace in accordance with Method 1, a thermally and

with an immersion depth of at least 100 mm and the capability electrically insulating gasket shall be used to seal the furnace

of maintaining the specified test temperature within 1°C. entrance, accentuating the temperature gradient across the

FIG. 1 Test Schematic Using a Readout Device with Cold Junction Compensation, Providing Temperature Indications of the Test Ther-

mocouple T and Reference Thermocouple T

test ref

E2820 − 13 (2019)

FIG. 2 Test Schematic Using a Voltmeter and Reference Junctions at 0°C

connector. Placing the gasket between the plug and jack is 8.6 The 0°C ice-bath (if needed) shall be prepared in

generally the easiest way to control the position of the accordance Practice E563.

connector within the temperature gradient (Fig. 3–a).

9. Procedure

8.4 When testing in accordance with Method 2 in a liquid

bath, the connector and a portion of the thermocouple shall be

9.1 Set up the temperature source for the specified test

attached to an insulating rod to support the sample during the

condition (Table 1).

test (Fig. 3–b).

9.2 Connect both thermocouple circuits to the readout

8.5 The 0°C reference junctions (if needed) shall be pre-

device or meter. With the common measuring junction and

pared using the same approach used for thermocouple calibra-

connector at room temperature, verify the difference between

tion in accordance with Test Method E220. The copper wires

circuits is within the equivalent of 0.1°C. For voltage outputs,

shallbethermocoupletypeTPinaccordancewithSpecification

the difference expressed in °C is determined as follows.

E230/E230M and shall all be cut from the same spool.

-------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.