ASTM C1511-15

(Test Method)Standard Test Method for Determining the Water Retention (Repellency) Characteristics of Fibrous Glass Insulation (Aircraft Type)

Standard Test Method for Determining the Water Retention (Repellency) Characteristics of Fibrous Glass Insulation (Aircraft Type)

SIGNIFICANCE AND USE

5.1 The water retention of the insulation can result in an increase in weight and a resultant potential degradation in the properties of the insulation.

SCOPE

1.1 This test method covers a laboratory procedure for evaluating the water absorption potential of blanket insulation for aircraft, thereby providing a measure of potential weight increase due to water retention in an aircraft.

1.2 The water repellency (or retention) characteristics of materials can be affected by conditions such as contamination or temperature of the water. Values obtained as a result of this test method does not adequately describe the water repellency characteristics of materials subject to these conditions.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1511 − 15

Standard Test Method for

Determining the Water Retention (Repellency)

1

Characteristics of Fibrous Glass Insulation (Aircraft Type)

This standard is issued under the fixed designation C1511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers a laboratory procedure for 4.1 The insulation is weighed then submerged in de-ionized

evaluating the water absorption potential of blanket insulation (or distilled) water for 15 min; it is drained for 60 s and

for aircraft, thereby providing a measure of potential weight reweighed. The amount of water retained is the difference in

increase due to water retention in an aircraft. specimen weights and is expressed in grams.

1.2 The water repellency (or retention) characteristics of

5. Significance and Use

materials can be affected by conditions such as contamination

5.1 The water retention of the insulation can result in an

or temperature of the water. Values obtained as a result of this

increase in weight and a resultant potential degradation in the

test method does not adequately describe the water repellency

properties of the insulation.

characteristics of materials subject to these conditions.

1.3 The values stated in inch-pound units are to be regarded

6. Apparatus

as standard. The values given in parentheses are mathematical

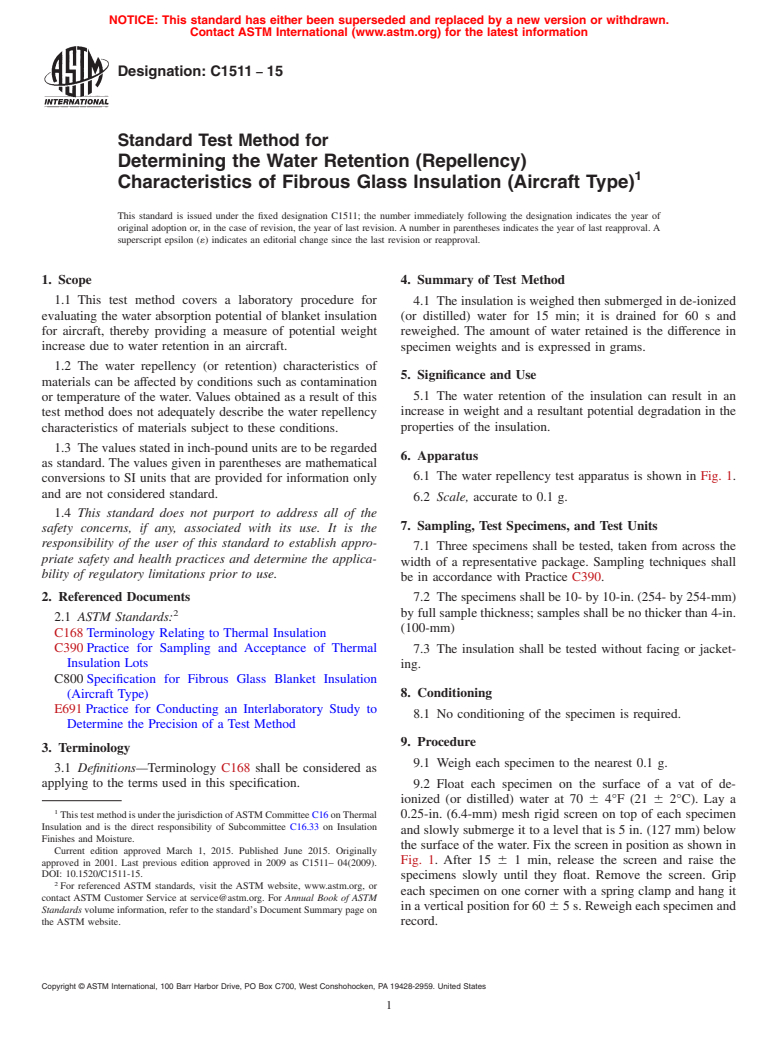

6.1 The water repellency test apparatus is shown in Fig. 1.

conversions to SI units that are provided for information only

and are not considered standard.

6.2 Scale, accurate to 0.1 g.

1.4 This standard does not purport to address all of the

7. Sampling, Test Specimens, and Test Units

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

7.1 Three specimens shall be tested, taken from across the

priate safety and health practices and determine the applica-

width of a representative package. Sampling techniques shall

bility of regulatory limitations prior to use.

be in accordance with Practice C390.

2. Referenced Documents 7.2 The specimens shall be 10- by 10-in. (254- by 254-mm)

2

by full sample thickness; samples shall be no thicker than 4-in.

2.1 ASTM Standards:

(100-mm)

C168 Terminology Relating to Thermal Insulation

C390 Practice for Sampling and Acceptance of Thermal

7.3 The insulation shall be tested without facing or jacket-

Insulation Lots

ing.

C800 Specification for Fibrous Glass Blanket Insulation

(Aircraft Type) 8. Conditioning

E691 Practice for Conducting an Interlaboratory Study to

8.1 No conditioning of the specimen is required.

Determine the Precision of a Test Method

9. Procedure

3. Terminology

9.1 Weigh each specimen to the nearest 0.1 g.

3.1 Definitions—Terminology C168 shall be considered as

applying to the terms used in this specification.

9.2 Float each specimen on the surface of a vat of de-

ionized (or distilled) water at 70 6 4°F (21 6 2°C). Lay a

1

This test method is under the jurisdiction ofASTM Committee C16 on Thermal

0.25-in. (6.4-mm) mesh rigid screen on top of each specimen

Insulation and is the direct responsibility of Subcommittee C16.33 on Insulation

and slowly submerge it to a level that is 5 in. (127 mm) below

Finishes and Moisture.

the surface of the water. Fix the screen in position as shown in

Current edition approved March 1, 2015. Published June 2015. Originally

Fig. 1. After 15 6 1 min, release the screen and raise the

approved in 2001. Last previous edition approved in 2009 as C1511– 04(2009).

DOI: 10.1520/C1511-15.

specimens slowly until they float. Remove the screen. Grip

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

each specimen on one corner with a spring clamp and hang it

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in a vertical position for 60 6 5 s. Reweigh each specimen and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. record.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1511 − 15

FIG. 1 Water Repellency Test Apparatus

10. Calculation or Interpretation of Results of the data.All of the test specimens were provided by a single

laboratory. The details are given in ASTM Research Report:

10.1 Determine water retained by each specimen by sub-

3

C16-1017.

tracting the original specimen weight from the final specimen

12.2 Test Results—The following information on precision,

weight. Calculate water repellency

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1511 − 04 (Reapproved 2009) C1511 − 15

Standard Test Method for

Determining the Water Retention (Repellency)

1

Characteristics of Fibrous Glass Insulation (Aircraft Type)

This standard is issued under the fixed designation C1511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a laboratory procedure for evaluating the water absorption potential of blanket insulation for

aircraft, thereby providing a measure of potential weight increase due to water retention in an aircraft.

1.2 The water repellency (or retention) characteristics of materials maycan be affected by conditions such as contamination or

temperature of the water. Values obtained as a result of this test method maydoes not adequately describe the water repellency

characteristics of materials subject to these conditions.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C800 Specification for Fibrous Glass Blanket Insulation (Aircraft Type)

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—Terminology C168 shall be considered as applying to the terms used in this specification.

4. Summary of Test Method

4.1 The insulation is weighed then submerged in de-ionized (or distilled) water for 15 min; it is drained for 60 s and reweighed.

The amount of water retained is the difference in specimen weights and is expressed in grams.

5. Significance and Use

5.1 The water retention of the insulation can result in an increase in weight and a resultant potential degradation in the properties

of the insulation.

6. Apparatus

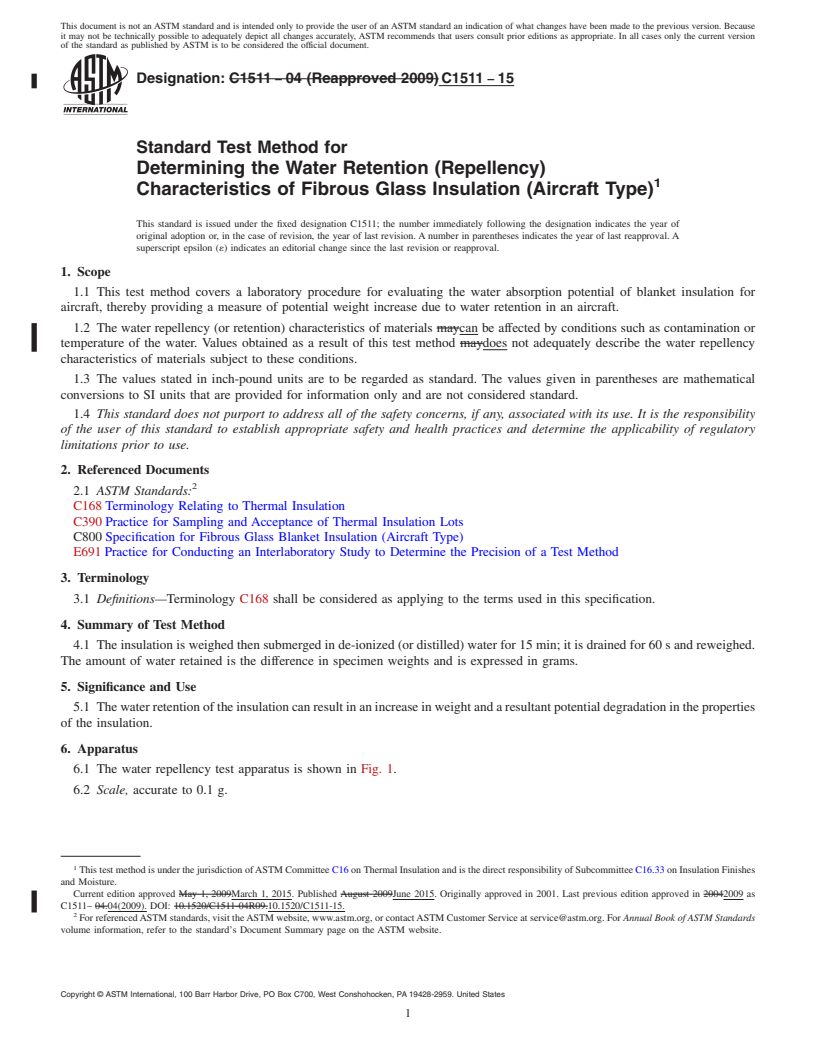

6.1 The water repellency test apparatus is shown in Fig. 1.

6.2 Scale, accurate to 0.1 g.

1

This test method is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.33 on Insulation Finishes

and Moisture.

Current edition approved May 1, 2009March 1, 2015. Published August 2009June 2015. Originally approved in 2001. Last previous edition approved in 20042009 as

C1511– 04.04(2009). DOI: 10.1520/C1511-04R09.10.1520/C1511-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1511 − 15

FIG. 1 Water Repellency Test Apparatus

7. Sampling, Test Specimens, and Test Units

7.1 Three specimens shall be tested, taken from across the width of a representative package. Sampling techniques shall be in

accordance with Practice C390.

7.2 The specimens shall be 10- by 10-in. (254- by 254-mm) by full sample thickness; samples shall be no thicker than 4-in.

(100-mm)

7.3 The insulation shall be tested without facing or jacketing.

8. Conditioning

8.1 No conditioning of the specimen is required.

9. Procedure

9.1 Weigh each specimen to the nearest 0.1 g.

9.2 Float each specimen on the surface of a vat of de-ionized (or distilled) water at 70 6 4°F (21 6 2°C). Lay a 0.25-in.

(6.4-mm) mesh rigid screen on top of each specimen and slowly submerge it to a level that is 5 in. (127 mm) below the surface

of the water. Fix the screen in position as shown in Fig. 1. After 15 6 1 min, release the screen and raise the specimens slowly

until they float. Remove the screen. Grip each specimen on one corner with a spring clamp and hang it in a vertical position for

60 6 5 s. Reweigh each specimen and record.

10. Calculation or Interpretatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.