ASTM D3840-01

(Specification)Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe Fittings for Nonpressure Applications

Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe Fittings for Nonpressure Applications

SCOPE

1.1 This specification covers fiberglass pipe fittings intended for use in gravity flow systems for conveying sanitary sewage, storm water, and those industrial wastes for which the fittings are determined to be suitable. Elbows, tees, laterals, crosses, reducers, and adapters are included. Both glass-fiber-reinforced and thermosetting-resin pipe (RTRP) and glass-fiber-reinforced plastic mortar pipe (RPMP) are fiberglass pipes.

Note 1—For the purpose of this standard, polymer does not include natural polymers.

1.2 This specification is intended to cover only dimensions, material properties, and workmanship rather than the structural design of the fittings. The structural design of the fittings shall be as agreed upon between purchaser and supplier and should take into consideration the anticipated conditions of installation and service.

1.3 This specification covers only fittings fabricated from cut sections of pipe, or from a combination of pipe sections and contact molded (hand layup), or machine fabricated components.

1.4 The values given in parentheses are provided for information purposes only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 11, of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2 —There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 3840 – 01

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

1

Pipe Fittings for Nonpressure Applications

This standard is issued under the fixed designation D 3840; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

2

1. Scope* D 883 Terminology Relating to Plastics

D 1600 Terminology for Abbreviated Terms Relating to

1.1 This specification covers fiberglass pipe fittings in-

2

Plastics

tended for use in gravity flow systems for conveying sanitary

3

D 1763 Specification for Epoxy Resins

sewage, storm water, and those industrial wastes for which the

D 2290 Test Method forApparent Hoop Tensile Strength of

fittings are determined to be suitable. Elbows, tees, laterals,

3

Plastic or Reinforced Plastic Pipe by Split Disk Method

crosses, reducers, and adapters are included. Both glass-fiber-

D 3262 Specification for “Fiberglass’’ (Glass-Fiber-

reinforced and thermosetting-resin pipe (RTRP) and glass-

4

Reinforced Thermosetting-Resin) Sewer Pipe

fiber-reinforced ploymer mortar pipe (RPMP) are fiberglass

D 3567 Practice for Determining Dimensions of Fiberglass

pipes.

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

NOTE 1—For the purposes of this standard, ploymer does not include 4

Fittings

natural polymers.

5

D 3892 Practice for Packaging/Packing of Plastics

4

1.2 This specification is intended to cover only dimensions,

F 412 Terminology Relating to Plastic Piping Systems

material properties, and workmanship rather than the structural

F 477 Specification for Elastomeric Seals (Gaskets) for

4

design of the fittings. The structural design of the fittings shall

Joining Plastic Pipe

be as agreed upon between purchaser and supplier and should

3. Terminology

takeintoconsiderationtheanticipatedconditionsofinstallation

and service.

3.1 Definitions:

1.3 This specification covers only fittings fabricated from

3.1.1 General—Definitions are in accordance with Termi-

cutsectionsofpipe,orfromacombinationofpipesectionsand

nologies D 883 and F 412. Abbreviations are in accordance

contact molded (hand layup), or machine fabricated compo-

with Terminology D 1600, unless otherwise indicated.

nents.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values given in parentheses are provided for infor-

3.2.1 fiberglass pipe—a tubular product containing glass

mation purposes only.

fiber reinforcements embedded in or surrounded by cured

1.5 The following safety hazards caveat pertains only to the

thermosetting resin. The composite structure may contain

test method portion, Section 11, of this specification. This

aggregate, granular or platelet fillers, thixotropic agents, pig-

standard does not purport to address all of the safety concerns,

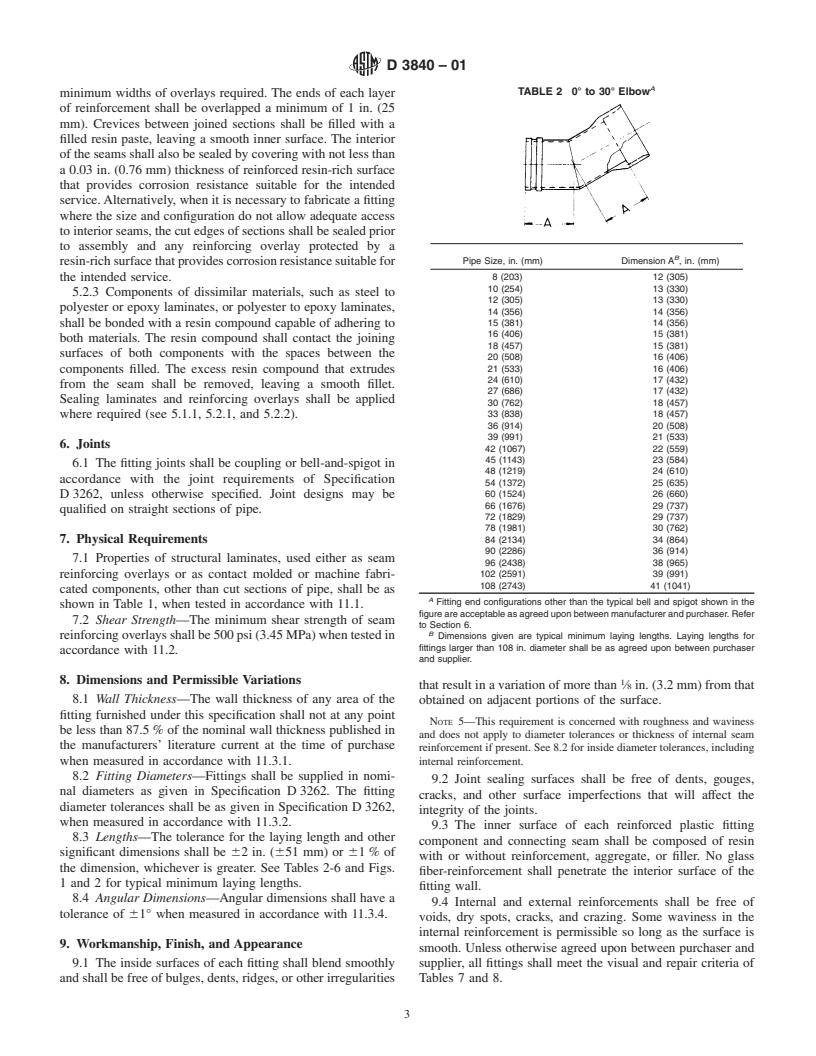

ments or dyes. Thermoplastic or thermosetting liners or coat-

if any, associated with its use. It is the responsibility of the user

ings may be included.

of this standard to establish appropriate safety and health

3.2.2 reinforced polymer mortar pipe—a fiberglass pipe

practices and determine the applicability of regulatory limita- with aggregate.

tions prior to use.

3.2.3 reinforced thermosetting resin pipe—a fiberglass pipe

without aggregate.

NOTE 2—There is no similar or equivalent ISO standard.

3.2.4 qualification—One or more tests used to prove the

2. Referenced Documents design of a product. Not a routine quality control test.

2.1 ASTM Standards:

NOTE 3—Qualification requirements appear in 6.1, 7.2, and 12.3.

2

D 638 Test Method for Tensile Properties of Plastics

4. Materials

4.1 Laminating Resin:

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D 20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

Current edition approved June 10, 2001. Published August 2001. Originally

3

published as D 3840 – 79. Last previous edition D 3840 – 99. This specification Annual Book of ASTM Standards, Vol 08.02.

4

replaces Specification D 4160. Annual Book of ASTM Standards, Vol 08.04.

2 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.03.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3840 – 01

4.1.1 Type 1—Polyester thermosetting resin, with or with- rated as agreed upon between purchaser and supplier, provided

out fillers or thixotropic agents or both. the materials of such components are resistant to the corrosive

effects of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.