ASTM E2683-17

(Test Method)Standard Test Method for Measuring Heat Flux Using Flush-Mounted Insert Temperature-Gradient Gages

Standard Test Method for Measuring Heat Flux Using Flush-Mounted Insert Temperature-Gradient Gages

SIGNIFICANCE AND USE

5.1 The purpose of this test method is to measure the net heat flux to or from a surface location. For measurement of the radiant energy component the emissivity or absorptivity of the surface coating of the gage is required. When measuring the convective energy component the potential physical and thermal disruptions of the surface must be minimized and characterized. Requisite is to consider how the presence of the gage alters the surface heat flux. The desired quantity is usually the heat flux at the surface location without the presence of the gage.

5.1.1 Temperature limitations are determined by the gage material properties, the method of mounting the sensing element, and how the lead wires are attached. The range of heat flux that can be measured and the time response are limited by the gage design and construction details. Measurements of a fraction of 1 kW/m 2 to above 10 MW/m2 are easily obtained with current gages. With thin film sensors a time response of less than 10 μs is possible, while thicker sensors may have response times on the order of 1 s. It is important to choose the gage style and characteristics to match the range and time response of the required application.

5.1.2 When differential thermocouple sensors are operated as specified for one-dimensional heat flux and within the corresponding time response limitations, the voltage output is directly proportional to the heat flux. The sensitivity, however, may be a function of the gage temperature.

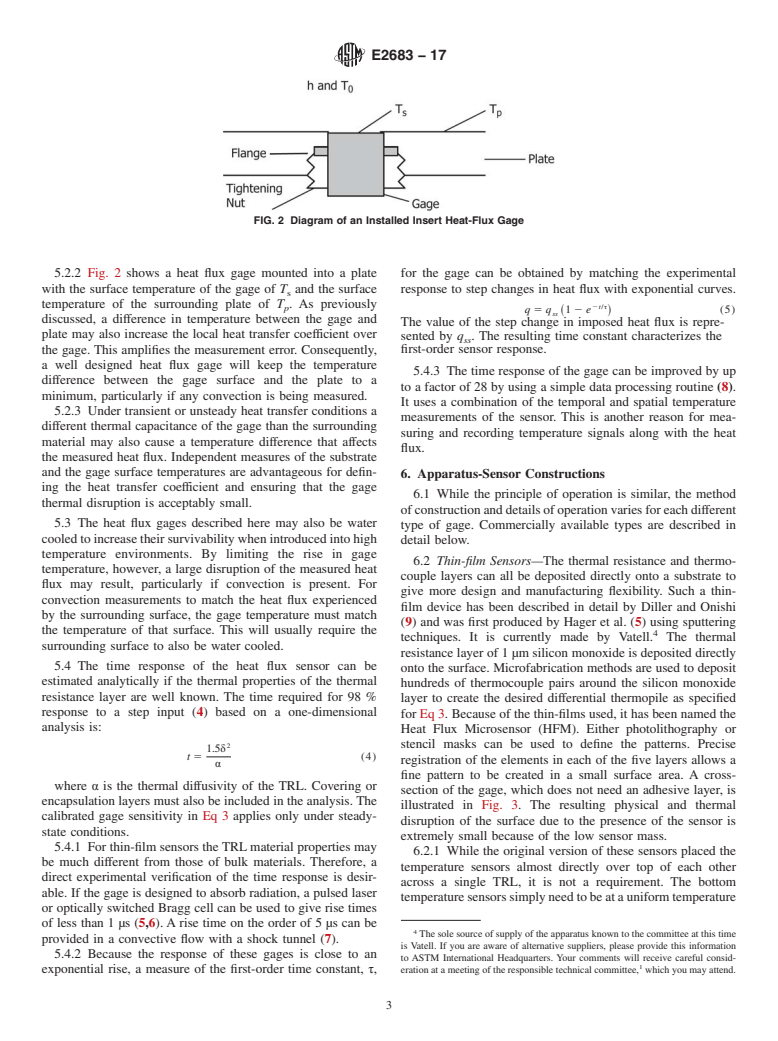

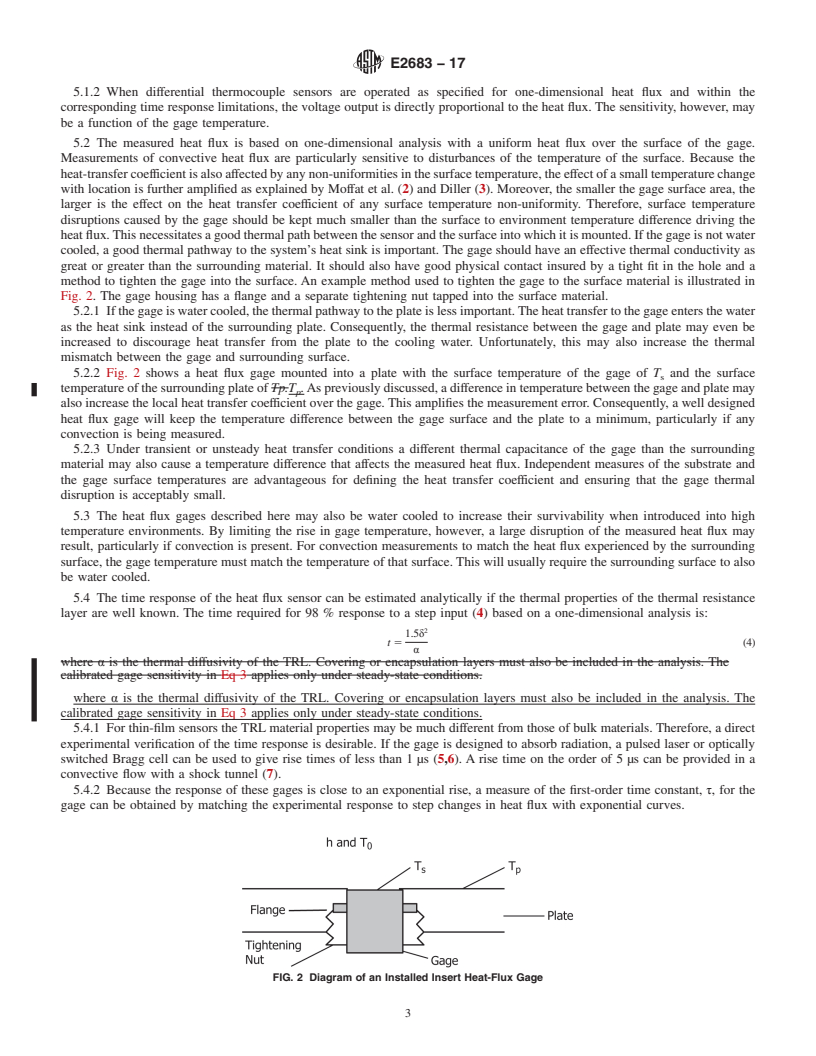

5.2 The measured heat flux is based on one-dimensional analysis with a uniform heat flux over the surface of the gage. Measurements of convective heat flux are particularly sensitive to disturbances of the temperature of the surface. Because the heat-transfer coefficient is also affected by any non-uniformities in the surface temperature, the effect of a small temperature change with location is further amplified as explained by Moffat et al. (2) and Diller (3). Moreover, the smaller the gage s...

SCOPE

1.1 This test method describes the measurement of the net heat flux normal to a surface using gages inserted flush with the surface. The geometry is the same as heat-flux gages covered by Test Method E511, but the measurement principle is different. The gages covered by this standard all use a measurement of the temperature gradient normal to the surface to determine the heat that is exchanged to or from the surface. Although in a majority of cases the net heat flux is to the surface, the gages operate by the same principles for heat transfer in either direction.

1.2 This general test method is quite broad in its field of application, size and construction. Two different gage types that are commercially available are described in detail in later sections as examples. A summary of common heat-flux gages is given by Diller (1).2 Applications include both radiation and convection heat transfer. The gages used for aerospace applications are generally small (0.155 to 1.27 cm diameter), have a fast time response (10 μs to 1 s), and are used to measure heat flux levels in the range 0.1 to 10 000 kW/m2. Industrial applications are sometimes satisfied with physically larger gages.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2683 − 17

Standard Test Method for

Measuring Heat Flux Using Flush-Mounted Insert

1

Temperature-Gradient Gages

This standard is issued under the fixed designation E2683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 This test method describes the measurement of the net

Barriers to Trade (TBT) Committee.

heatfluxnormaltoasurfaceusinggagesinsertedflushwiththe

surface. The geometry is the same as heat-flux gages covered

2. Referenced Documents

by Test Method E511, but the measurement principle is

3

2.1 ASTM Standard:

different. The gages covered by this standard all use a

E511TestMethodforMeasuringHeatFluxUsingaCopper-

measurementofthetemperaturegradientnormaltothesurface

Constantan Circular Foil, Heat-Flux Transducer

to determine the heat that is exchanged to or from the surface.

Although in a majority of cases the net heat flux is to the

3. Terminology

surface, the gages operate by the same principles for heat

3.1 Definitions of Terms Specific to This Standard:

transfer in either direction.

3.1.1 heat flux—the heat transfer per unit area, q, with units

1.2 This general test method is quite broad in its field of

2 2

ofW/m (Btu/ft -s). Heat transfer (or alternatively heat transfer

application, size and construction. Two different gage types

rate) is the rate of thermal energy movement across a system

that are commercially available are described in detail in later

boundary with units of watts (Btu/s). This usage is consistent

sections as examples. A summary of common heat-flux gages

with most heat transfer books.

2

is given by Diller (1). Applications include both radiation and

3.1.2 heat transfer coeffıcient, (h)—an important parameter

convection heat transfer. The gages used for aerospace appli-

2 2

inconvectiveflowswithunitsofW/m -K(Btu/ft -s-F).Thisis

cations are generally small (0.155 to 1.27 cm diameter), have

defined in terms of the heat flux q as:

afasttimeresponse(10µsto1s),andareusedtomeasureheat

2

flux levels in the range 0.1 to 10 000 kW/m . Industrial q

h 5 (1)

applications are sometimes satisfied with physically larger

∆T

where ∆T is a prescribed temperature difference between the

gages.

surface and the fluid. The resulting value of h is intended to

1.3 The values stated in SI units are to be regarded as the

be only a function of the fluid flow and geometry, not the

standard. The values stated in parentheses are provided for

temperature difference. If the surface temperature is non-

information only.

uniform or if there is more than a single fluid free stream

temperature, the proper definition of ∆ T may be difficult to

1.4 This standard does not purport to address all of the

specify (2). It is always important to clearly define ∆T when

safety concerns, if any, associated with its use. It is the

calculating the heat transfer coefficient.

responsibility of the user of this standard to establish appro-

3.1.3 surfaceemissivity,(ε)—theratiooftheemittedthermal

priate safety and health practices and determine the applica-

radiation from a surface to that of a blackbody at the same

bility of regulatory limitations prior to use.

temperature.Surfacesareassumedtobegraybodieswherethe

1.5 This international standard was developed in accor-

emissivity is equal to the absorptivity.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4. Summary of Test Method

4.1 A schematic of the sensing technique is illustrated in

Fig. 1. Temperature difference is measured across a thermal-

1

This test method is under the jurisdiction of ASTM Committee E21 on Space

Simulation andApplications of SpaceTechnology and is the direct responsibility of resistance layer of thickness, δ. This is the heat flux sensing

Subcommittee E21.08 on Thermal Protection.

Current edition approved Sept. 1, 2017. Published October 2017. Originally

3

approved in 2009. Last previous edition approved in 2009 as E2683–09. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/E2683-17. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

this test method. the ASTM website.

Copyright © ASTM International,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2683 − 09 E2683 − 17

Standard Test Method for

Measuring Heat Flux Using Flush-Mounted Insert

1

Temperature-Gradient Gages

This standard is issued under the fixed designation E2683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes the measurement of the net heat flux normal to a surface using gages inserted flush with the

surface. The geometry is the same as heat-flux gages covered by Test Method E511, but the measurement principle is different.

The gages covered by this standard all use a measurement of the temperature gradient normal to the surface to determine the heat

that is exchanged to or from the surface. Although in a majority of cases the net heat flux is to the surface, the gages operate by

the same principles for heat transfer in either direction.

1.2 This general test method is quite broad in its field of application, size and construction. Two different gage types that are

commercially available are described in detail in later sections as examples. A summary of common heat-flux gages is given by

2

Diller (1). Applications include both radiation and convection heat transfer. The gages used for aerospace applications are

generally small (0.155 to 1.27 cm diameter), have a fast time response (10 μs to 1 s), and are used to measure heat flux levels in

2

the range 0.1 to 10 000 kW/m . Industrial applications are sometimes satisfied with physically larger gages.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in parentheses are provided for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standard:

E511 Test Method for Measuring Heat Flux Using a Copper-Constantan Circular Foil, Heat-Flux Transducer

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

2 2

3.1.1 heat flux—the heat transfer per unit area, q, with units of W/m (Btu/ft -s). Heat transfer (or alternatively heat transfer rate)

is the rate of thermal energy movement across a system boundary with units of watts (Btu/s). This usage is consistent with most

heat transfer books.

2 2

3.1.2 heat transfer coeffıcient, (h)—an important parameter in convective flows with units of W/m -K (Btu/ft -s-F). This is

defined in terms of the heat flux q asas:

q

h 5 (1)

ΔT

where ΔT is a prescribed temperature difference between the surface and the fluid. The resulting value of h is intended to be

only a function of the fluid flow and geometry, not the temperature difference. If the surface temperature is non-uniform or if

1

This test method is under the jurisdiction of ASTM Committee E21 on Space Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.08 on Thermal Protection.

Current edition approved June 15, 2009Sept. 1, 2017. Published August 2009October 2017. Originally approved in 2009. Last previous edition approved in 2009 as

E2683–09. DOI: 10.1520/E2683-09.10.1520/E2683-17.

2

The boldface numbers in parentheses refer to the list of references at the end of this test method.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2683 − 17

there is more than a single fluid free stream temperature, the proper definition of Δ T may be difficult to specify (2). It is al-

ways important to clearly define ΔT when calculating the heat transfer coefficient.

3.1.3 surface emissivity, (ε)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.