ASTM D7877-22

(Guide)Standard Guide for Electronic Methods for Detecting and Locating Leaks in Waterproof Membranes

Standard Guide for Electronic Methods for Detecting and Locating Leaks in Waterproof Membranes

SIGNIFICANCE AND USE

4.1 The failure to correct membrane defects during and as soon as possible after its installation can cause premature failure of the membrane. Problems include design deficiencies, faulty application of the membrane system, and damage by subsequent trades.4 Roof designs incorporating a waterproof membrane under overburden such as a vegetative roof, insulation layer, wear-course, or topping slab greatly exacerbate the problem of leak locating.

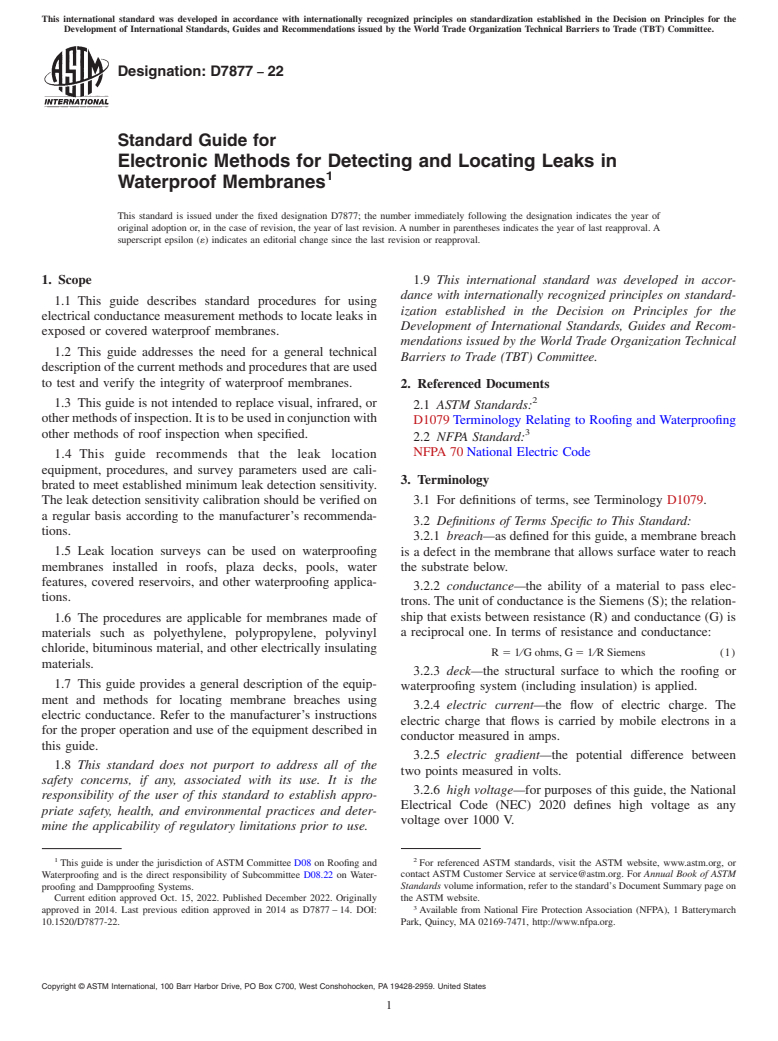

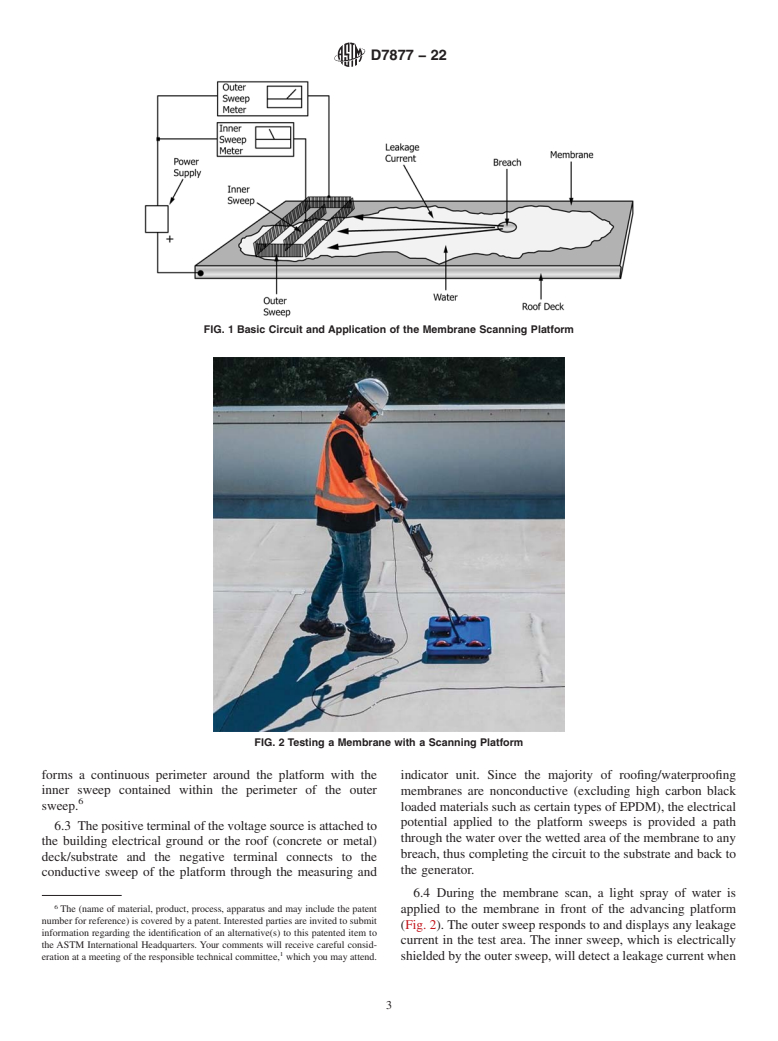

4.2 This guide describes methods for using electric conductance testing to locate breaches in waterproof membranes.5 The methods described include testing procedures designed to provide a part of the construction quality control of membrane installations.

4.3 The methods described in this guide may also be used for integrity or forensic testing of existing waterproof membranes; specific limitations apply.

4.4 The electric conductance methods described in this guide require a conductive substrate under the membrane to serve as a ground return path for the test currents. In roof assemblies where the membrane is installed over electric insulating material such as insulating foam or a protection board, or both, the electric path to any conductive deck is interrupted. The situation can be remedied by placing a conductive material directly under the membrane. The conductive material provides the return path for the test currents.

SCOPE

1.1 This guide describes standard procedures for using electrical conductance measurement methods to locate leaks in exposed or covered waterproof membranes.

1.2 This guide addresses the need for a general technical description of the current methods and procedures that are used to test and verify the integrity of waterproof membranes.

1.3 This guide is not intended to replace visual, infrared, or other methods of inspection. It is to be used in conjunction with other methods of roof inspection when specified.

1.4 This guide recommends that the leak location equipment, procedures, and survey parameters used are calibrated to meet established minimum leak detection sensitivity. The leak detection sensitivity calibration should be verified on a regular basis according to the manufacturer’s recommendations.

1.5 Leak location surveys can be used on waterproofing membranes installed in roofs, plaza decks, pools, water features, covered reservoirs, and other waterproofing applications.

1.6 The procedures are applicable for membranes made of materials such as polyethylene, polypropylene, polyvinyl chloride, bituminous material, and other electrically insulating materials.

1.7 This guide provides a general description of the equipment and methods for locating membrane breaches using electric conductance. Refer to the manufacturer’s instructions for the proper operation and use of the equipment described in this guide.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7877 − 22

Standard Guide for

Electronic Methods for Detecting and Locating Leaks in

1

Waterproof Membranes

This standard is issued under the fixed designation D7877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This guide describes standard procedures for using

ization established in the Decision on Principles for the

electrical conductance measurement methods to locate leaks in

Development of International Standards, Guides and Recom-

exposed or covered waterproof membranes.

mendations issued by the World Trade Organization Technical

1.2 This guide addresses the need for a general technical

Barriers to Trade (TBT) Committee.

descriptionofthecurrentmethodsandproceduresthatareused

to test and verify the integrity of waterproof membranes.

2. Referenced Documents

2

1.3 This guide is not intended to replace visual, infrared, or

2.1 ASTM Standards:

othermethodsofinspection.Itistobeusedinconjunctionwith

D1079 Terminology Relating to Roofing and Waterproofing

3

other methods of roof inspection when specified.

2.2 NFPA Standard:

NFPA 70 National Electric Code

1.4 This guide recommends that the leak location

equipment, procedures, and survey parameters used are cali-

3. Terminology

brated to meet established minimum leak detection sensitivity.

The leak detection sensitivity calibration should be verified on 3.1 For definitions of terms, see Terminology D1079.

a regular basis according to the manufacturer’s recommenda-

3.2 Definitions of Terms Specific to This Standard:

tions.

3.2.1 breach—as defined for this guide, a membrane breach

1.5 Leak location surveys can be used on waterproofing is a defect in the membrane that allows surface water to reach

membranes installed in roofs, plaza decks, pools, water the substrate below.

features, covered reservoirs, and other waterproofing applica-

3.2.2 conductance—the ability of a material to pass elec-

tions.

trons. The unit of conductance is the Siemens (S); the relation-

1.6 The procedures are applicable for membranes made of ship that exists between resistance (R) and conductance (G) is

a reciprocal one. In terms of resistance and conductance:

materials such as polyethylene, polypropylene, polyvinyl

chloride, bituminous material, and other electrically insulating

R 5 1⁄G ohms, G 5 1⁄R Siemens (1)

materials.

3.2.3 deck—the structural surface to which the roofing or

1.7 This guide provides a general description of the equip-

waterproofing system (including insulation) is applied.

ment and methods for locating membrane breaches using

3.2.4 electric current—the flow of electric charge. The

electric conductance. Refer to the manufacturer’s instructions

electric charge that flows is carried by mobile electrons in a

for the proper operation and use of the equipment described in

conductor measured in amps.

this guide.

3.2.5 electric gradient—the potential difference between

1.8 This standard does not purport to address all of the

two points measured in volts.

safety concerns, if any, associated with its use. It is the

3.2.6 high voltage—for purposes of this guide, the National

responsibility of the user of this standard to establish appro-

Electrical Code (NEC) 2020 defines high voltage as any

priate safety, health, and environmental practices and deter-

voltage over 1000 V.

mine the applicability of regulatory limitations prior to use.

1 2

This guide is under the jurisdiction of ASTM Committee D08 on Roofing and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Waterproofing and is the direct responsibility of Subcommittee D08.22 on Water- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

proofing and Dampproofing Systems. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 15, 2022. Published December 2022. Originally the ASTM website.

3

approved in 2014. Last previous edition approved in 2014 as D7877 – 14. DOI: Available from National Fire Protection Association (NFPA), 1 Batterymarch

10.1520/D7877-22. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7877 − 22

3.2.7 leak—any unintended opening, perforation, sli

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7877 − 14 D7877 − 22

Standard Guide for

Electronic Methods for Detecting and Locating Leaks in

1

Waterproof Membranes

This standard is issued under the fixed designation D7877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide describes standard procedures for using electrical conductance measurement methods to locate leaks in exposed

or covered waterproof membranes.

1.2 This guide addresses the need for a general technical description of the current methods and procedures that are used to test

and verify the integrity of waterproof membranes.

1.3 This guide is not intended to replace visual, infrared, or other methods of inspection. It is to be used in conjunction with other

methods of roof inspection when specified.

1.4 This guide recommends that the leak location equipment, procedures, and survey parameters used are calibrated to meet

established minimum leak detection sensitivity. The leak detection sensitivity calibration should be verified on a regular basis

according to the manufacturer’s recommendations.

1.5 Leak location surveys can be used on waterproofing membranes installed in roofs, plaza decks, pools, water features, covered

reservoirs, and other waterproofing applications.

1.6 The procedures are applicable for membranes made of materials such as polyethylene, polypropylene, polyvinyl chloride,

bituminous material, and other electrically insulating materials.

1.7 This guide provides a general description of the equipment and methods for locating membrane breaches using electric

conductance. Refer to the manufacturer’s instructions for the proper operation and use of the equipment described in this guide.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This guide is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.22 on Waterproofing

and Dampproofing Systems.

Current edition approved Aug. 1, 2014Oct. 15, 2022. Published August 2014December 2022. Originally approved in 2014. Last previous edition approved in 2014 as

D7877 – 14. DOI: 10.1520/D7877-14.10.1520/D7877-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7877 − 22

2. Referenced Documents

2

2.1 ASTM Standards:

D1079 Terminology Relating to Roofing and Waterproofing

D5957 Guide for Flood Testing Horizontal Waterproofing Installations

D6747 Guide for Selection of Techniques for Electrical Leak Location of Leaks in Geomembranes

3

2.2 NFPA Standard:

NFPA 70 National Electric Code

3. Terminology

3.1 For definitions of terms, see Terminology D1079.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 breach—as defined for this guide, a membrane breach is a defect in the membrane that allows surface water to reach the

substrate below.

3.2.2 conductance—the ability of a material to pass electrons. The unit of conductance is the Siemens (S),(S); the relationship that

exists between resistance (R) and conductance (G) is a reciprocal one. In terms of resistance and conductance:

R5 1⁄G ohms, G 5 1⁄R Siemens (1)

3.2.3 deck—the structural surface to which the roofing or waterproofing system (including insulation) is applied.

3.2.4 electric current—the flow of electric charge. The electric charge that flows is carried by mobile electrons in a conductor

measured in amps.

3.2.5 electric gradient—the potential difference between two points measured in volts.

3.2.6 high voltage—for purposes of this guide, the United States 2005 National Electrical Code (NEC) 2020 defines high voltage

as any voltage over 600 V (article 490.2).1000 V.

3.2.7 leak—any unintended opening, p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.