ASTM A1081/A1081M-21

(Test Method)Standard Test Method for Evaluating Bond of Seven-Wire Steel Prestressing Strand

Standard Test Method for Evaluating Bond of Seven-Wire Steel Prestressing Strand

SIGNIFICANCE AND USE

5.1 Prestressing steel strand is used in pre-tensioned and post-tensioned concrete construction.

5.2 In pre-tensioned concrete applications, the prestressing steel strand is expected to transfer prestressing forces to the structural member by means of the adhesion (that is, bond) of the exposed wire strand surfaces to the surrounding cementitous material.

5.3 Manufacturing processes, subsequent handling, and storage conditions can influence the strand bond.

5.4 Prestressing steel strand is used in construction applications with a variety of concrete mixtures. Developing tests and threshold values for the performance of the strand in each of these unique mixtures is impractical.

SCOPE

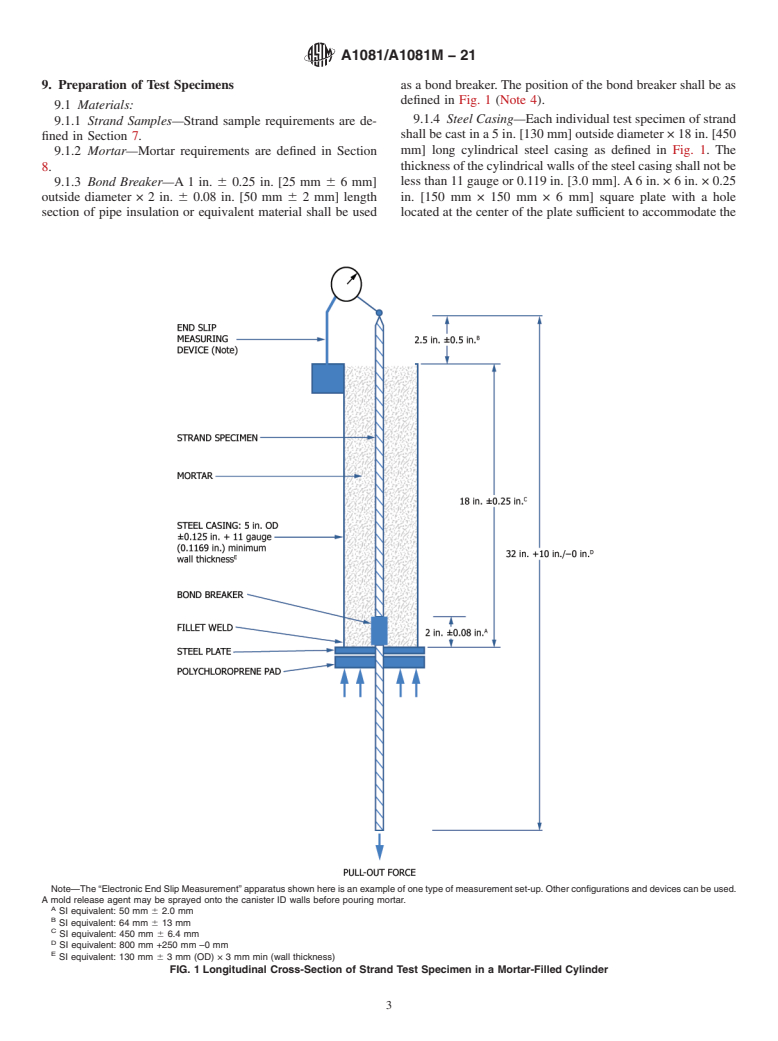

1.1 This test method describes procedures for determining the bond of seven-wire steel prestressing strand. The bond determined by this test method is stated as the tensile force required to pull the strand through the cured mortar in a cylindrical steel casing. The result of the test is the tensile force measured on the loaded-end of the strand corresponding to a movement of 0.1 in. [2.5 mm] at the free-end of the strand.

1.2 This test method is applicable either in inch-pound units (as Test Method A1081) or SI units (as Test Method A1081M).

1.3 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A1081/A1081M − 21

Standard Test Method for

1

Evaluating Bond of Seven-Wire Steel Prestressing Strand

This standard is issued under the fixed designation A1081/A1081M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C33/C33MSpecification for Concrete Aggregates

C109/C109MTest Method for Compressive Strength of

1.1 This test method describes procedures for determining

Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube

the bond of seven-wire steel prestressing strand. The bond

Specimens)

determined by this test method is stated as the tensile force

C150/C150MSpecification for Portland Cement

required to pull the strand through the cured mortar in a

C192/C192MPractice for Making and Curing ConcreteTest

cylindricalsteelcasing.Theresultofthetestisthetensileforce

Specimens in the Laboratory

measured on the loaded-end of the strand corresponding to a

C670Practice for Preparing Precision and Bias Statements

movement of 0.1 in. [2.5 mm] at the free-end of the strand.

for Test Methods for Construction Materials

1.2 Thistestmethodisapplicableeitherininch-poundunits

C1437Test Method for Flow of Hydraulic Cement Mortar

(asTest MethodA1081) or SI units (asTest MethodA1081M).

3. Terminology

1.3 The values stated in either inch-pound units or in SI

units are to be regarded separately as standard.Within the text, 3.1 Definitions of Terms Specific to This Test Method:

3.1.1 bond, n—the adhesion of strand to concrete or mortar.

SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system

3.1.2 bond breaker, n—a product wrapped around strand to

shall be used independently of the other. Combining values

prevent strand-to-concrete bond over the installed length.

from the two systems may result in non-conformance with the

Extruded polystyrene foam pipe insulation is commonly used

test method.

for this purpose.

1.4 This standard does not purport to address all of the

3.1.3 manufactured length, n—a length of strand that is

safety concerns, if any, associated with its use. It is the

manufactured in one continuous length.

responsibility of the user of this standard to establish appro-

3.1.4 mortar,n—amixtureofcement,fineaggregate(thatis,

priate safety, health, and environmental practices and deter-

sand) and water.

mine the applicability of regulatory limitations prior to use.

3.1.5 strand, n—all references to strand in this test method

1.5 This international standard was developed in accor-

shall be interpreted to be Specification A416/A416M seven-

dance with internationally recognized principles on standard-

wire prestressing steel strand with nominal diameters of 0.500

ization established in the Decision on Principles for the

in. [12.70 mm] or 0.600 in. [15.24 mm].

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.1.6 test specimen, n—an assembly consisting of one steel

Barriers to Trade (TBT) Committee. casing, one sample of strand and mortar.

4. Summary of Test Method

2. Referenced Documents

2

4.1 Six samples of seven-wire steel prestressing strand with

2.1 ASTM Standards:

nominal diameters of 0.500 in. [12.7 mm] or 0.600 in. [15.24

A416/A416M Specification for Low-Relaxation, Seven-

mm] are selected from a single continuous length. Each of the

Wire Steel Strand for Prestressed Concrete

six strand samples are individually cast in a steel cylinder

casingwithaspecifiedcementmortar.Thestrandisexposedon

1

This test method is under the jurisdiction of ASTM Committee A01 on Steel,

both ends of the cylinder with a designated loaded-end and

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

free-end. Once the mortar reaches a specified compressive

A01.05 on Steel Reinforcement.

strength, the cylinder with the embedded steel strand is loaded

Current edition approved March 1, 2021. Published March 2021. Originally

into a tensile testing machine. The designated loaded-end of

approved in 2013. Last previous edition approved in 2015 as A1081/A1081M – 15.

DOI: 10.1520/A1081_A1081M-21.

the steel strand is gripped by the tensile testing machine and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pulled away from the cylinder at a specified displacement rate.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The tensile force on the loaded-end of the strand is m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A1081/A1081M − 15 A1081/A1081M − 21

Standard Test Method for

1

Evaluating Bond of Seven-Wire Steel Prestressing Strand

This standard is issued under the fixed designation A1081/A1081M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method describes procedures for determining the bond of seven-wire steel prestressing strand. The bond determined

by this test method is stated as the tensile force required to pull the strand through the cured mortar in a cylindrical steel casing.

The result of the test is the tensile force measured on the loaded-end of the strand corresponding to a movement of 0.1 in. [2.5

mm] at the free-end of the strand.

1.2 This test method is applicable either in inch-pound units (as SpecificationTest A1081) Method A1081) or SI units (as

SpecificationTest A1081M).Method A1081M).

1.3 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the specification.test

method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A416/A416M Specification for Low-Relaxation, Seven-Wire Steel Strand for Prestressed Concrete

C33/C33M Specification for Concrete Aggregates

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens)

C150/C150M Specification for Portland Cement

C192/C192M Practice for Making and Curing Concrete Test Specimens in the Laboratory

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

C1437 Test Method for Flow of Hydraulic Cement Mortar

3. Terminology

3.1 Definitions:Definitions of Terms Specific to This Test Method:

1

This test method is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.05

on Steel Reinforcement.

Current edition approved Nov. 1, 2015March 1, 2021. Published January 2016March 2021. Originally approved in 2013. Last previous edition approved in 2015 as

A1081/A1081M – 13.15. DOI: 10.1520/A1081_A1081M-15.10.1520/A1081_A1081M-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1081/A1081M − 21

3.1.1 bond—bond, n—the adhesion of strand to concrete or mortar.

3.1.2 bond breaker—breaker, n—a product wrapped around strand to prevent strand-to-concrete bond over the installed length.

Extruded polystyrene foam pipe insulation is commonly used for this purpose.

3.1.3 manufactured length—length, n—a length of strand that is manufactured in one continuous length.

3.1.4 mortar—mortar, n—a mixture of cement, fine aggregate (that is, sand) and water.

3.1.5 strand—strand, n—all references to strand in this test method shall be interpreted to be Specification A416/A416M

seven-wire prestressing steel strand with nominal diameters of 0.500 in. [12.70 mm] or 0.600 in. [15.24 mm].

3.1.6 test specimen—specimen, n—an assembly consisting of one steel casing, one sample of strand and mortar.

4. Summary of Test Method

4.1 Six sample

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.