ASTM F667/F667M-16

(Specification)Standard Specification for 3 through 24 in. Corrugated Polyethylene Pipe and Fittings

Standard Specification for 3 through 24 in. Corrugated Polyethylene Pipe and Fittings

ABSTRACT

This specification covers requirements and test methods for materials, workmanship, dimensions, perforations, pipe stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, bond, and marking of corrugated polyethylene (PE) pipe and fittings. This specification covers tubularly extruded, spirally laminated, and rotationally molded corrugated polyethylene pipe. Corrugated PE pipe and fittings are intended for underground applications where soil provides support to their flexible walls. Their major use is to collect or convey drainage water, or both. The following tests shall be performed: dimensions and tolerances; pipe stiffness; elongation; pipe stiffness while elongated; joint-separation test; and brittleness.

SCOPE

1.1 This specification covers requirements and test methods for materials, workmanship, dimensions, perforations, pipe stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, bond, and marking of corrugated polyethylene (PE) pipe and fittings. It covers nominal sizes 3 in. [76 mm], 4 in. [102 mm], 5 in. [127 mm] 6 in. [152 mm], 8 in. [203 mm], 10 in. [254 mm], 12 in. [305 mm], 15 in. [381 mm], 18 in. [457 mm], and 24 in. [610 mm].

1.2 This specification covers tubularly extruded, spirally laminated, and rotationally molded corrugated polyethylene pipe.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F667/F667M −16

Standard Specification for

1

3 through 24 in. Corrugated Polyethylene Pipe and Fittings

This standard is issued under the fixed designation F667/F667M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* F412Terminology Relating to Plastic Piping Systems

F449Practice for Subsurface Installation of Corrugated

1.1 This specification covers requirements and test methods

Polyethylene Pipe for Agricultural Drainage or Water

for materials, workmanship, dimensions, perforations, pipe

Table Control

stiffness, elongation, joint separation resistance, quality of

3

2.2 Federal Standard:

extruded polyethylene, brittleness, bond, and marking of cor-

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

rugated polyethylene (PE) pipe and fittings. It covers nominal

3

2.3 Military Standard:

sizes 3 in. [76 mm], 4 in. [102 mm], 5 in. [127 mm] 6 in. [152

MIL-STD-129Marking for Shipment and Storage

mm],8in.[203mm],10in.[254mm],12in.[305mm],15in.

[381 mm], 18 in. [457 mm], and 24 in. [610 mm].

3. Terminology

1.2 This specification covers tubularly extruded, spirally

3.1 Definitions—Definitions used in this specification are in

laminated, and rotationally molded corrugated polyethylene

accordance with Terminology F412, unless otherwise noted.

pipe.

3.2 Definitions:

1.3 The values stated in inch-pound units are to be regarded

3.2.1 split—any break or crack that extends through the

as standard. The values given in parentheses are mathematical

wall.

conversions to SI units that are provided for information only

3.2.2 crease—a deformation that cannot be removed like a

and are not considered standard.

dent: generally associated with wall buckling.

1.4 The following precautionary caveat pertains only to the

test method portion, Section 9, of this specification: This

4. Significance and Use

standard does not purport to address all of the safety concerns,

4.1 Corrugated PE pipe and fittings are intended for under-

if any, associated with its use. It is the responsibility of the user

ground applications where soil provides support to their

of this standard to establish appropriate safety and health

flexible walls.Their major use is to collect or convey drainage

practices and determine the applicability of regulatory limita-

water, or both.

tions prior to use.

4.2 Exclusions from Recommended Use:

2. Referenced Documents

4.2.1 Exposure to flame at any time,

2

2.1 ASTM Standards:

4.2.2 Permanent exposure to sunlight or weathering, or

D618Practice for Conditioning Plastics for Testing

both, and

D2412Test Method for Determination of External Loading

4.2.3 Exposure to chemicals, other than those normally

Characteristics of Plastic Pipe by Parallel-Plate Loading

found in ground water, whose compatibility with the tubing

D2444Test Method for Determination of the Impact Resis-

and fittings is not known.

tance of Thermoplastic Pipe and Fittings by Means of a

5. Materials

Tup (Falling Weight)

D3350Specification for Polyethylene Plastics Pipe and Fit-

5.1 Basic Materials—Compounds used in the manufacture

tings Materials

of corrugated PE drainage pipe and fittings shall have a

minimumcellclassificationof323410Cor333410Casdefined

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

and described in Specification D3350. Compounds that have a

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land

higher cell classification in one or more properties are

Drainage.

acceptable, provided the product requirements are met.

Current edition approved Feb. 1, 2016. Published March 2016. Originally

approved in 1980. Last previous edition approved in 2015 as F667/F667M–15.

NOTE1—ClassBpigmentsmaybesubstitutedforClassCprovidedthat

DOI: 10.1520/F0667_F0667-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on DLA Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA

the ASTM website. 19111-5094 http://quicksearch.dla.mil/

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F667/F667M−16

ultraviolet protection is acceptable to the publisher as satisfactory for the

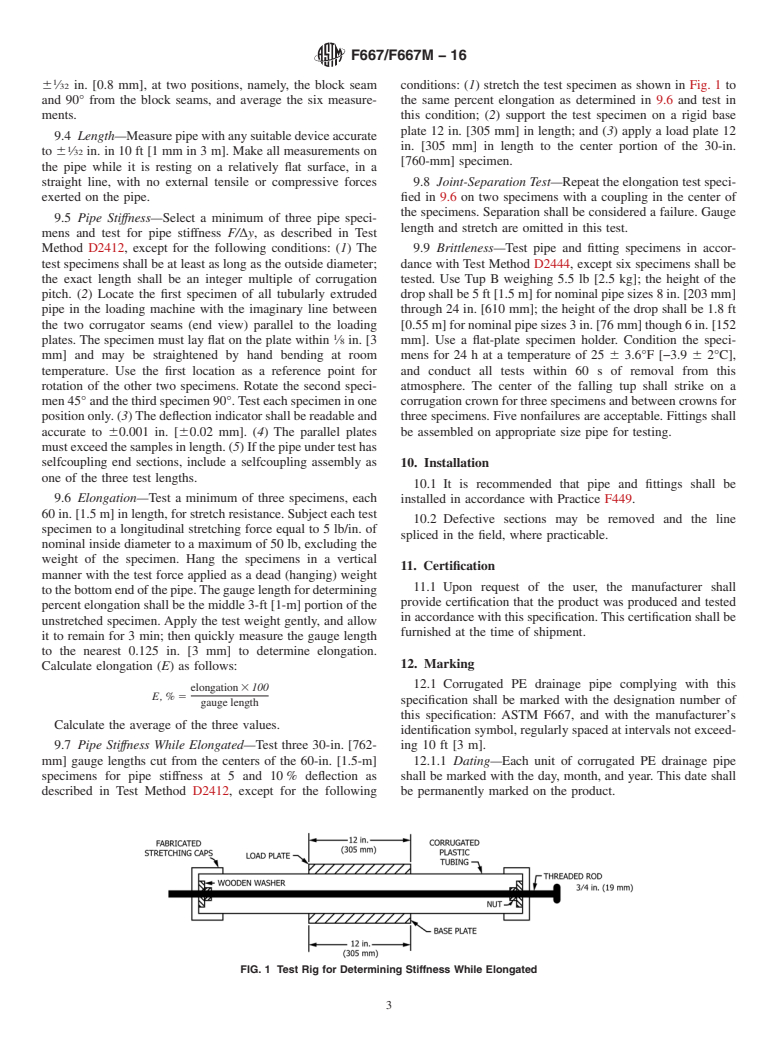

7.5 Elongation—Continuously extruded pipe that elongates

intended use.

more than 5%, but less than 10%, when tested in accordance

5.2 Rework Material—Clean rewor

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F667/F667M − 15 F667/F667M − 16

Standard Specification for

1

3 through 24 in. Corrugated Polyethylene Pipe and Fittings

This standard is issued under the fixed designation F667/F667M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers requirements and test methods for materials, workmanship, dimensions, perforations, pipe

stiffness, elongation, joint separation resistance, quality of extruded polyethylene, brittleness, bond, and marking of corrugated

polyethylene (PE) pipe and fittings. It covers nominal sizes 3 in. [76 mm], 4 in. [102 mm], 5 in. [127 mm] 6 in. [152 mm], 8 in.

[203 mm], 10 in. [254 mm], 12 in. [305 mm], 15 in. [381 mm], 18 in. [457 mm], and 24 in. [610 mm].

1.2 This specification covers tubularly extruded, spirally laminated, and rotationally molded corrugated polyethylene pipe.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

F412 Terminology Relating to Plastic Piping Systems

F449 Practice for Subsurface Installation of Corrugated Polyethylene Pipe for Agricultural Drainage or Water Table Control

3

2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

3

2.3 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

3. Terminology

3.1 Definitions—Definitions used in this specification are in accordance with Terminology F412, unless otherwise noted.

3.2 Definitions:

3.2.1 split—any break or crack that extends through the wall.

3.2.2 crease—a deformation that cannot be removed like a dent: generally associated with wall buckling.

4. Significance and Use

4.1 Corrugated PE pipe and fittings are intended for underground applications where soil provides support to their flexible walls.

Their major use is to collect or convey drainage water, or both.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land Drainage.

Current edition approved April 15, 2015Feb. 1, 2016. Published May 2015March 2016. Originally approved in 1980. Last previous edition approved in 20122015 as

F667 – 12.F667/F667M – 15. DOI: 10.1520/F0667_F0667-15.10.1520/F0667_F0667-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.DLA

Document Services Building 4/D 700 Robbins Avenue Philadelphia, PA 19111-5094 http://quicksearch.dla.mil/

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F667/F667M − 16

4.2 Exclusions from Recommended Use:

4.2.1 Exposure to flame at any time,

4.2.2 Permanent exposure to sunlight or weathering, or both, and

4.2.3 Exposure to chemicals, other than those normally found in ground water, whose compatibility with the tubing and fittings

is not known.

5. Materials

5.1 Basic Materials—Compounds used in the manufacture of corrugated PE drainage pipe and fittings s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.