ASTM D5519-14

(Test Method)Standard Test Methods for Particle Size Analysis of Natural and Man-Made Riprap Materials

Standard Test Methods for Particle Size Analysis of Natural and Man-Made Riprap Materials

SIGNIFICANCE AND USE

5.1 Riprap is commonly used to prevent erosion of underlying materials due to the effects of rain runoff, wind, flowing water, or wave action. The particle size distribution (mass of particles) is an important physical characteristic of riprap, as discussed in Guide D6825. These test methods provide a gradation of the material graphically represented as percent finer than the particle mass. If a gradation can be established or accepted on the basis of only maximum and minimum particle sizes, then it may not be necessary to establish the complete gradation in accordance with these test methods.

5.2 These test methods can be used during evaluation of a potential source, as a means of product acceptance, or for assessment of existing installations. Method D is not recommended as a means of product acceptance.

5.3 Other characteristics of interest, such as particle shape, particle angularity, or visually evident rock durability characteristics may be determined during the performance of these test methods.

5.4 Interpretation of test results must consider the representativeness of the sample.

Note 2: The quality of the result produced by this standard is dependent upon the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself ensure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 These test methods cover the particle size and mass analysis of natural and man-made riprap and related materials, including filter stone or coarse bedding materials.

1.2 These test methods are generally intended for riprap and related materials. They are applicable for mixtures of stones screened from natural deposits, blast rock, processed materials from quarried rock, or recycled concrete. They are applicable for sizes 3 in. (75 mm) and above, with the upper size limited only by equipment available for handling and determining the mass of the individual particles.

1.3 Four alternate procedures are provided. There is a wide range in the level of effort and the precision of the test procedures. It is important for specifiers to indicate the test procedure. Test reports should clearly indicate which procedure was used.

Note 1: While conducting these test methods, it may be convenient to collect data on other attributes, such as the amount of slab pieces and deleterious materials.

1.4 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026, unless superseded by this standard.

1.4.1 For purposes of comparing measured or calculated value(s) with specified limits, the measured or calculated value(s) shall be rounded to the nearest decimal or significant digits in the specified limits.

1.4.2 The procedures used to specify how data are collected/recorded or calculated, in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analytical methods for engineering design.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

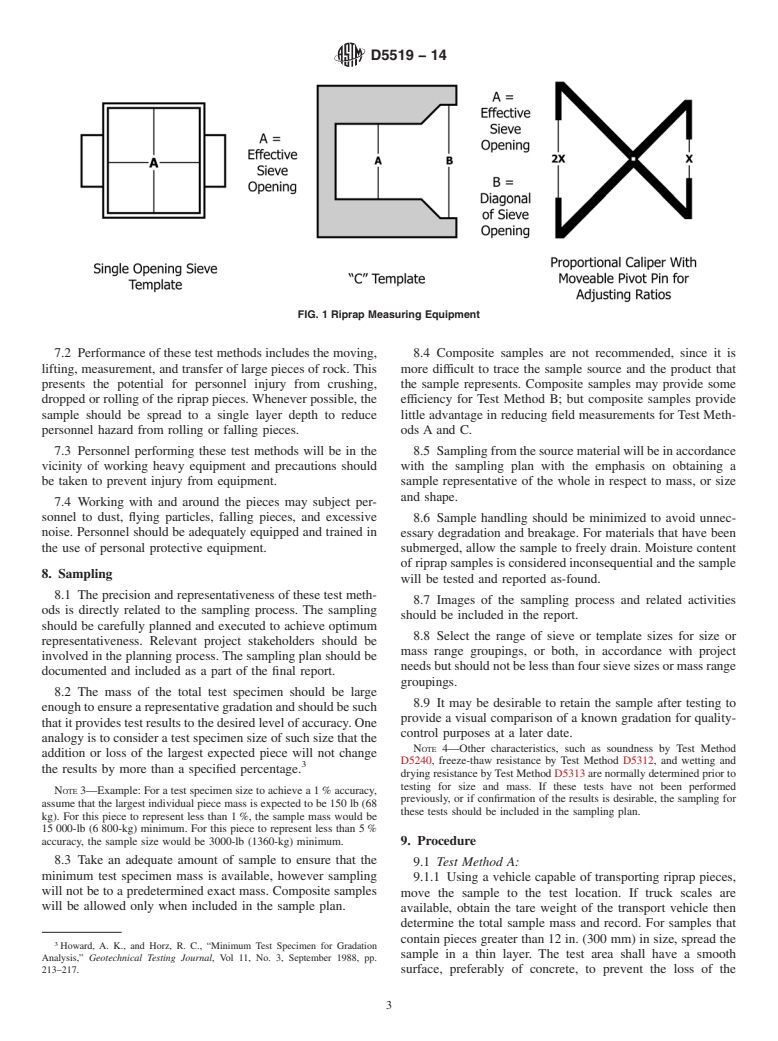

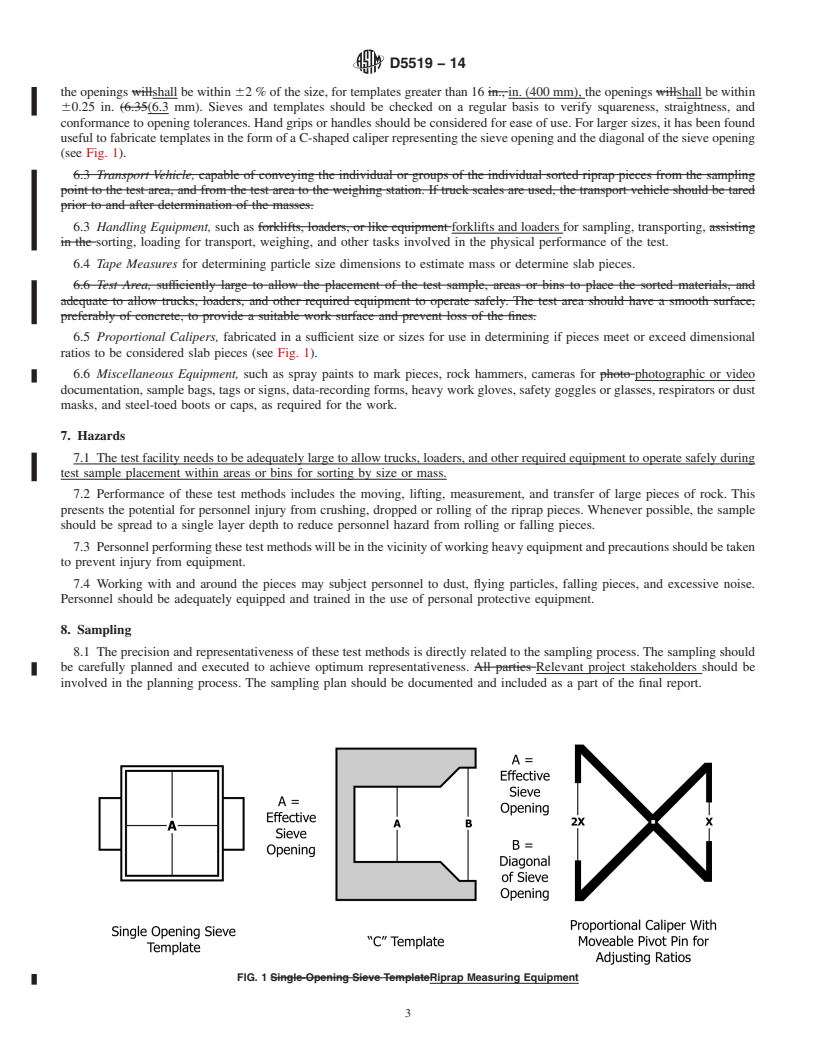

Designation: D5519 − 14

StandardTest Methods for

Particle Size Analysis of Natural and Man-Made Riprap

1

Materials

This standard is issued under the fixed designation D5519; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* of this standard to consider significant digits used in analytical

methods for engineering design.

1.1 These test methods cover the particle size and mass

analysis of natural and man-made riprap and related materials,

1.5 The values stated in inch-pound units are to be regarded

including filter stone or coarse bedding materials.

asthestandard.Thevaluesgiveninparenthesesaremathemati-

cal conversions to SI units that are provided for information

1.2 These test methods are generally intended for riprap and

only and are not considered standard.

related materials. They are applicable for mixtures of stones

screened from natural deposits, blast rock, processed materials 1.6 This standard does not purport to address all of the

from quarried rock, or recycled concrete. They are applicable

safety concerns, if any, associated with its use. It is the

for sizes 3 in. (75 mm) and above, with the upper size limited responsibility of the user of this standard to establish appro-

only by equipment available for handling and determining the

priate safety and health practices and determine the applica-

mass of the individual particles. bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 7.

1.3 Four alternate procedures are provided. There is a wide

range in the level of effort and the precision of the test

2. Referenced Documents

procedures. It is important for specifiers to indicate the test

2

procedure.Testreportsshouldclearlyindicatewhichprocedure

2.1 ASTM Standards:

was used.

C136 Test Method for Sieve Analysis of Fine and Coarse

NOTE 1—While conducting these test methods, it may be convenient to

Aggregates

collect data on other attributes, such as the amount of slab pieces and

D653 Terminology Relating to Soil, Rock, and Contained

deleterious materials.

Fluids

1.4 All observed and calculated values shall conform to the

D3740 Practice for Minimum Requirements for Agencies

guidelines for significant digits and rounding established in

Engaged in Testing and/or Inspection of Soil and Rock as

Practice D6026, unless superseded by this standard.

Used in Engineering Design and Construction

1.4.1 For purposes of comparing measured or calculated

D4992 Practice for Evaluation of Rock to be Used for

value(s) with specified limits, the measured or calculated

Erosion Control

value(s) shall be rounded to the nearest decimal or significant

D5240 Test Method for Testing Rock Slabs to Evaluate

digits in the specified limits.

Soundness of Riprap by Use of Sodium Sulfate or

1.4.2 Theproceduresusedtospecifyhowdataarecollected/

Magnesium Sulfate

recorded or calculated, in this standard are regarded as the

D5312 Test Method for Evaluation of Durability of Rock for

industry standard. In addition, they are representative of the

Erosion Control Under Freezing and Thawing Conditions

significant digits that generally should be retained. The proce-

D5313 Test Method for Evaluation of Durability of Rock for

dures used do not consider material variation, purpose for

Erosion Control Under Wetting and Drying Conditions

obtaining the data, special purpose studies, or any consider-

D6026 Practice for Using Significant Digits in Geotechnical

ations for the user’s objectives; and it is common practice to

Data

increase or reduce significant digits of reported data to be

D6825 Guide for Placement of Riprap Revetments

commensuratewiththeseconsiderations.Itisbeyondthescope

E11 Specification for Woven Wire Test Sieve Cloth and Test

Sieves

1

These test methods are under the jurisdiction ofASTM Committee D18 on Soil

and Rock and are the direct responsibility of Subcommittee D18.17 on Rock for

2

Erosion Control. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2014. Published November 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1994. Last previous edition approved in 2007 as D5519 – 07. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5519-14. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5519 − 14

NOTE 2—The quality of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5519 − 07 D5519 − 14

Standard Test Methods for

Particle Size Analysis of Natural and Man-Made Riprap

1

Materials

This standard is issued under the fixed designation D5519; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These test methods cover the particle size and mass analysis of natural and man-made riprap and related materials, including

filter stone or coarse bedding materials.

1.2 These test methods are generally intended for riprap and related materials. They are applicable for mixtures of stones

screened from natural deposits, blast rock, processed materials from quarried rock, or recycled concrete. They are applicable for

sizes 3 in. (75 mm) and above, with the upper size limited only by equipment available for handling and weighing the determining

the mass of the individual particles.

1.3 Four alternate procedures are provided. There is a wide range in the level of effort and the precision of the test procedures.

It is important for specifiers to indicate the test procedure. Test reports should clearly indicate which procedure was used.

NOTE 1—While conducting these test methods, it may be convenient to collect data on other attributes, such as the amount of slab pieces and deleterious

materials.

1.4 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice

D6026, unless superseded by this standard.

1.4.1 For purposes of comparing measured or calculated value(s) with specified limits, the measured or calculated value(s) shall

be rounded to the nearest decimal or significant digits in the specified limits.

1.4.2 The procedures used to specify how data are collected/recorded or calculated, in this standard are regarded as the industry

standard. In addition, they are representative of the significant digits that generally should be retained. The procedures used do not

consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives;

and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations.

It is beyond the scope of this standard to consider significant digits used in analytical methods for engineering design.

1.5 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units values

given in parentheses may be approximate.are mathematical conversions to SI units that are provided for information only and are

not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

C136 Test Method for Sieve Analysis of Fine and Coarse Aggregates

D422 Test Method for Particle-Size Analysis of Soils

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

D4992 Practice for Evaluation of Rock to be Used for Erosion Control

D5240 Test Method for Testing Rock Slabs to Evaluate Soundness of Riprap by Use of Sodium Sulfate or Magnesium Sulfate

1

These test methods are under the jurisdiction of ASTM Committee D18 on Soil and Rock and are the direct responsibility of Subcommittee D18.17 on Rock for Erosion

Control.

Current edition approved July 1, 2007Nov. 1, 2014. Published August 2007November 2014. Originally approved in 1994. Last previous edition approved in 20012007

as D5519 – 94 (2001).D5519 – 07. DOI: 10.1520/D5519-07.10.1520/D5519-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United Sta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.