ASTM C1427-07e1

(Specification)Standard Specification for Extruded Preformed Flexible Cellular Polyolefin Thermal Insulation in Sheet and Tubular Form

Standard Specification for Extruded Preformed Flexible Cellular Polyolefin Thermal Insulation in Sheet and Tubular Form

ABSTRACT

This specification covers the standard for two grades of extruded preformed flexible cellular polyolefin thermal insulation. Physical properties of preformed flexible cellular polyofelin thermal insulation which are mandatory for thermal design are also covered. Properties such as density and coefficient of thermal expansion (CTE) have been deemed nonmandatory for thermal design. The thermal insulation shall comply with physical requirements. Such physical requirements include thermal conductivity, water vapor permeability, and linear shrinkage and shall be determined by test methods specified here.

SCOPE

1.1 This specification covers two grades of extruded preformed flexible cellular polyolefin thermal insulation. Grade 1 is for operating temperatures from –150°F to 200°F (–101°C to 93°C). Grade 2 is for operating temperatures from –297°F to 250°F (–182°C to 121°C). For specific applications, the actual temperature limit shall be agreed upon between the manufacturer and the purchaser.

1.2 The use of thermal insulation materials covered by this specification are governed by codes and standards that address fire performance. Contact manufacturer for specific performance of product at the intended use thickness.

1.3 This specification covers the physical properties of preformed flexible cellular polyolefin thermal insulation, which have been deemed mandatory for thermal design. Physical properties such as density and coefficient of thermal expansion (CTE) have been deemed nonmandatory for thermal design. Nonmandatory physical properties have been included in Appendix X1 for information purposes only.

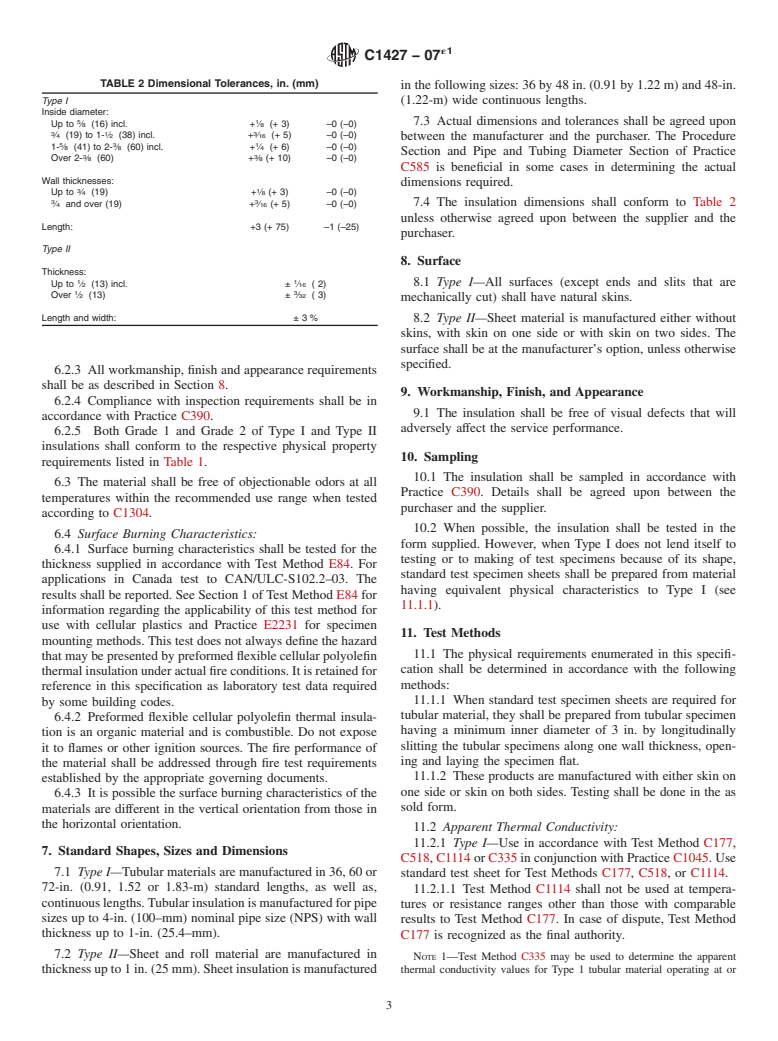

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:C1427 −07

StandardSpecification for

Extruded Preformed Flexible Cellular Polyolefin Thermal

1

Insulation in Sheet and Tubular Form

This standard is issued under the fixed designation C1427; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Sections 1.4 and 1.5 were editorially revised in April 2010.

1. Scope 2. Referenced Documents

2

1.1 This specification covers two grades of extruded 2.1 ASTM Standards:

preformed flexible cellular polyolefin thermal insulation. C168 Terminology Relating to Thermal Insulation

Grade 1 is for operating temperatures from –150°F to 200°F C177 Test Method for Steady-State Heat Flux Measure-

(–101°C to 93°C). Grade 2 is for operating temperatures from ments and Thermal Transmission Properties by Means of

–297°F to 250°F (–182°C to 121°C). For specific applications, the Guarded-Hot-Plate Apparatus

the actual temperature limit shall be agreed upon between the C209 Test Methods for Cellulosic Fiber Insulating Board

manufacturer and the purchaser. C335 Test Method for Steady-State Heat Transfer Properties

of Pipe Insulation

1.2 The use of thermal insulation materials covered by this

C390 Practice for Sampling and Acceptance of Thermal

specification are governed by codes and standards that address

Insulation Lots

fire performance. Contact manufacturer for specific perfor-

C411 Test Method for Hot-Surface Performance of High-

mance of product at the intended use thickness.

Temperature Thermal Insulation

1.3 This specification covers the physical properties of

C447 Practice for Estimating the Maximum Use Tempera-

preformed flexible cellular polyolefin thermal insulation,

ture of Thermal Insulations

which have been deemed mandatory for thermal design.

C518 Test Method for Steady-State Thermal Transmission

Physical properties such as density and coefficient of thermal

Properties by Means of the Heat Flow Meter Apparatus

expansion (CTE) have been deemed nonmandatory for thermal

C534 Specification for Preformed Flexible Elastomeric Cel-

design. Nonmandatory physical properties have been included

lular Thermal Insulation in Sheet and Tubular Form

in Appendix X1 for information purposes only.

C585 Practice for Inner and Outer Diameters of Thermal

Insulation for Nominal Sizes of Pipe and Tubing

1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical C1045 Practice for Calculating Thermal Transmission Prop-

erties Under Steady-State Conditions

conversions to SI units that are provided for information only

and are not considered standard. C1058 Practice for Selecting Temperatures for Evaluating

and Reporting Thermal Properties of Thermal Insulation

1.5 This standard does not purport to address all of the

C1114 Test Method for Steady-State Thermal Transmission

safety concerns, if any, associated with its use. It is the

Properties by Means of the Thin-Heater Apparatus

responsibility of the user of this standard to establish appro-

C1303 Test Method for Predicting Long-Term Thermal Re-

priate safety and health practices and determine the applica-

sistance of Closed-Cell Foam Insulation

bility of regulatory limitations prior to use.

C1304 Test Method for Assessing the Odor Emission of

Thermal Insulation Materials

D883 Terminology Relating to Plastics

1

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on

2

Organic and Nonhomogeneous Inorganic Thermal Insulations. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2007. Published December 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 2004 as C1427 - 04. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1427-07E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

C1427−07

D1622 Test Method for Apparent Density of Rigid Cellular 4.2.2 Grade 2 (crosslinked)—Use temperature –297°F to

Plastics 250°F (–182°C to 121°C).

D1667 Specification for Flexible Cellular Materials—Poly

5. Material

(Vinyl Chloride) Foam (Closed-Cell)

D3575 Test Methods for Flexible Cellular Materials Made

5.1 These products shall be extruded flexible cellular poly-

From Olefin Polymers

olefin materials.

E84 Test Method for Surface Burning Characteristics of

5.2 These product

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.