ASTM D7674-14a(2021)

(Test Method)Standard Test Method for Hexane/Petroleum Ether Extract in Wet Blue and Wet White

Standard Test Method for Hexane/Petroleum Ether Extract in Wet Blue and Wet White

SIGNIFICANCE AND USE

4.1 This test method measures the amount of solvent-soluble (hexane or petroleum ether) materials in wet blue and wet white.

SCOPE

1.1 This test method covers the quantitative extraction of all types of wet blue and wet white with hexane or petroleum ether.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7674 − 14a (Reapproved 2021)

Standard Test Method for

1

Hexane/Petroleum Ether Extract in Wet Blue and Wet White

This standard is issued under the fixed designation D7674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope analysis. The prepared specimen is extracted with solvent.

Another specimen from the same sample is also analyzed for

1.1 This test method covers the quantitative extraction of all

moisture content in accordance with Test Method D6658.

types of wet blue and wet white with hexane or petroleum

Following completion of the extraction process, the extract is

ether.

dried, then cooled and weighed. The extract is reported as

1.2 The values stated in SI units are to be regarded as the

extractables on a moisture-free basis.

standard. The values given in parentheses are for information

only.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 This test method measures the amount of solvent-

safety concerns, if any, associated with its use. It is the

soluble (hexane or petroleum ether) materials in wet blue and

responsibility of the user of this standard to establish appro-

wet white.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 5. Apparatus

For a specific hazard statement, see Section 7.

5.1 Analytical Balance.

1.4 This international standard was developed in accor-

5.2 Extraction Apparatus—Soxhlet, consisting of a boiling

dance with internationally recognized principles on standard-

flask, extraction tube, and condenser. Alternate Extraction

ization established in the Decision on Principles for the

Apparatus: Soxtec-type system consisting of an extraction unit

Development of International Standards, Guides and Recom-

and a control unit.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 5.3 ForcedCirculatingAirOven,capableofmaintainingthe

specified temperature.

2. Referenced Documents

5.4 Electric Hot Plate (or steam bath).

2

2.1 ASTM Standards:

5.5 Extraction Thimbles, fat-free: cellulose,Alundum, glass

D3495 Test Method for Hexane Extraction of Leather

microfiber, or fritted glass.

D6658 Test Method for Volatile Matter (Moisture) of Wet

Blue by Oven Drying

5.6 Absorbent Cotton, fat-free, or glass wool.

D6659 Practice for Sampling and Preparation of Wet Blue

6. Reagents and Materials

and Wet White for Physical and Chemical Tests

E177 Practice for Use of the Terms Precision and Bias in

6.1 Hexane, ACS Reagent Grade, or

ASTM Test Methods

6.2 Petroleum Ether, ACS Reagent Grade.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

7. Hazards

3. Summary of Test Method

7.1 All reagents and chemicals should be handled with care.

Before using any chemical, read and follow all safety precau-

3.1 A specimen is analyzed as received in wet state, diced;

tions and instructions on the manufacturers’ label or MSDS

or pre-dried at the determined setting then ground prior to

(Material Safety Data Sheet).

1

This test method is under the jurisdiction ofASTM Committee D31 on Leather

8. Sampling

and is the direct responsibility of Subcommittee D31.02 on Wet Blue.

Current edition approved Sept. 1, 2021. Published October 2021. Originally

8.1 The wet blue or wet white shall be sampled in accor-

approved in 2010 as E7674-10. Last previous edition approved in 2014 as

dance with Test Method D6659.

E7674-14a. DOI: 10.1520/D7674-14AR21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

9. Procedure

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on NOTE 1—Two sample conditions are listed below. Both sample condi-

the ASTM website. tions produce acceptable results (See Precision and Bias section).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

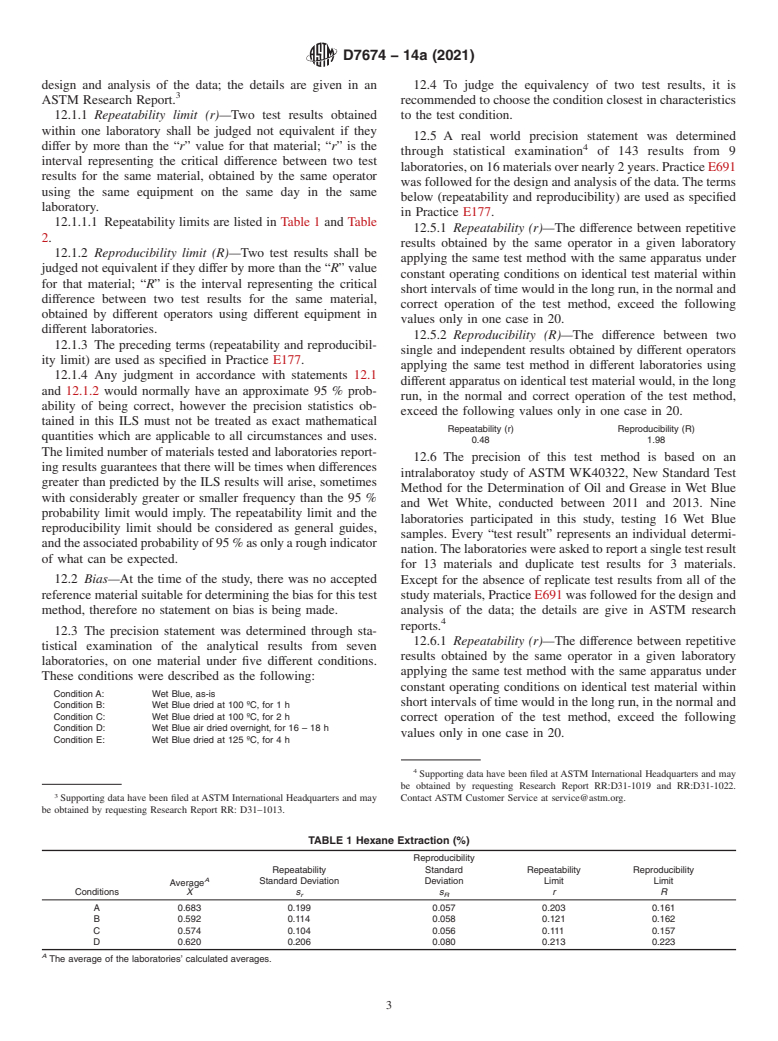

D7674 − 14a (2021)

9.1 Condition A—As received in wet state, diced (prepared petroleum ether or hexane. Place the loaded thimble in the

per Test Method D6659 Method A). Soxtec-type apparatus. Extract the sample by using the Soxtec-

9.1.1 Weigh out specimen for both moisture and hexane/

type boiling cycle for 45-50 min, followed by a rinse cycle of

petroleum e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.