ASTM F3191-16

(Practice)Standard Practice for Field Determination of Substrate Water Absorption (Porosity) for Substrates to Receive Resilient Flooring

Standard Practice for Field Determination of Substrate Water Absorption (Porosity) for Substrates to Receive Resilient Flooring

SIGNIFICANCE AND USE

5.1 The ability of a substrate surface to readily absorb water is a key indicator in determining how to correctly install many types of flooring adhesives, primers, self-leveling underlayments, and other products. Several flooring industry publications such as CRI’s Carpet Installation Standard, RFCI’s Recommended Installation Practice for Homogenous Sheet Flooring, Fully-Adhered, as well as most flooring, adhesive, primer, and underlayment manufacturers reference substrate surface porosity criteria in their application instructions since this directly impacts the spread rate of directly applied material, the open time, and other critical installation factors.

5.2 Installing flooring products over low or non-absorptive (sometimes referred to as “non-porous”) substrates such as densely machine-troweled concrete, mature and well-hydrated concrete, existing resilient flooring, polymer terrazzo and others may require adjustments to the surface preparation method or product selection to ensure a successful installation.

5.3 Use this practice to obtain a qualitative assessment of substrate water absorption (porosity) and whether or not that substrate should be regarded as porous/absorptive or non-porous/non-absorptive as these terms relate to the installation of resilient floor coverings, adhesives, self-leveling underlayments, primers, and other products. This practice will produce results directly applicable to determining appropriate surface preparation requirements in accordance with manufacturer’s specifications, but it is in no way meant to replace published manufacturer’s literature regarding the determination of substrate water absorption (porosity) and the impact such has, if any, on substrate preparation requirements and on the installation of their respective materials.

5.4 Substrates that evidence immediate absorption, are chalky or dusty, or have varying degrees of absorption may require priming or other additional surface preparation prior to subseq...

SCOPE

1.1 This practice covers the determination of whether or not a substrate surface, in lieu of written instruction from a product manufacturer, is considered porous or non-porous prior to the installation of resilient flooring materials.

1.2 Although carpet tiles, carpet, wood flooring, coatings, films, paints, self-leveling and trowel-grade underlayments, primers, and other associated products are not specifically intended to be included in the category of resilient floor coverings, the procedures included in this practice may be useful for assessing the substrate water absorption for substrates to receive such materials.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 6 on Hazards.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3191 − 16

Standard Practice for

Field Determination of Substrate Water Absorption

1

(Porosity) for Substrates to Receive Resilient Flooring

This standard is issued under the fixed designation F3191; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 Carpet and Rug Institute (CRI) Standard:

CRI Carpet Installation Standard

1.1 This practice covers the determination of whether or not

4

2.3 Resilient Floor Covering Institute (RFCI) Standards:

a substrate surface, in lieu of written instruction from a product

Recommended Work Practices for Removal of Resilient

manufacturer, is considered porous or non-porous prior to the

Floor Coverings

installation of resilient flooring materials.

Recommended Installation Practice for Homogenous Sheet

1.2 Although carpet tiles, carpet, wood flooring, coatings,

Flooring, Fully-Adhered

films, paints, self-leveling and trowel-grade underlayments,

3. Terminology

primers, and other associated products are not specifically

intended to be included in the category of resilient floor

3.1 Definitions:

coverings, the procedures included in this practice may be

3.1.1 See Terminology F141 for definitions of the terms:

useful for assessing the substrate water absorption for sub-

substrate, above-grade (suspended), on-grade, below grade,

strates to receive such materials.

concrete, and resilient flooring.

3.1.2 See Test Method F1869 for definition of service

1.3 The values stated in inch-pound units are to be regarded

temperature and relative humidity.

as standard. The values given in parentheses are mathematical

3.1.3 See Terminology C125 for definition of absorption.

conversions to SI units that are provided for information only

3.2 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.2.1 absorption, n—the process by which a liquid is drawn

1.4 This standard does not purport to address all of the

into and tends to fill permeable pores in a porous solid body

safety concerns, if any, associated with its use. It is the

(Terminology C125).

responsibility of the user of this standard to establish appro-

3.2.2 absorption rate, n—critical factor in determining how

priate safety and health practices and determine the applica-

to install many directly applied adhesives, determined by the

bility of regulatory limitations prior to use. Some specific

amount of time necessary for one droplet of water to be

hazards statements are given in Section 6 on Hazards.

absorbed with increasing length of time for absorption indicat-

ing a less absorptive, less porous, substrate surface.

2. Referenced Documents

2

4. Summary of Practice

2.1 ASTM Standards:

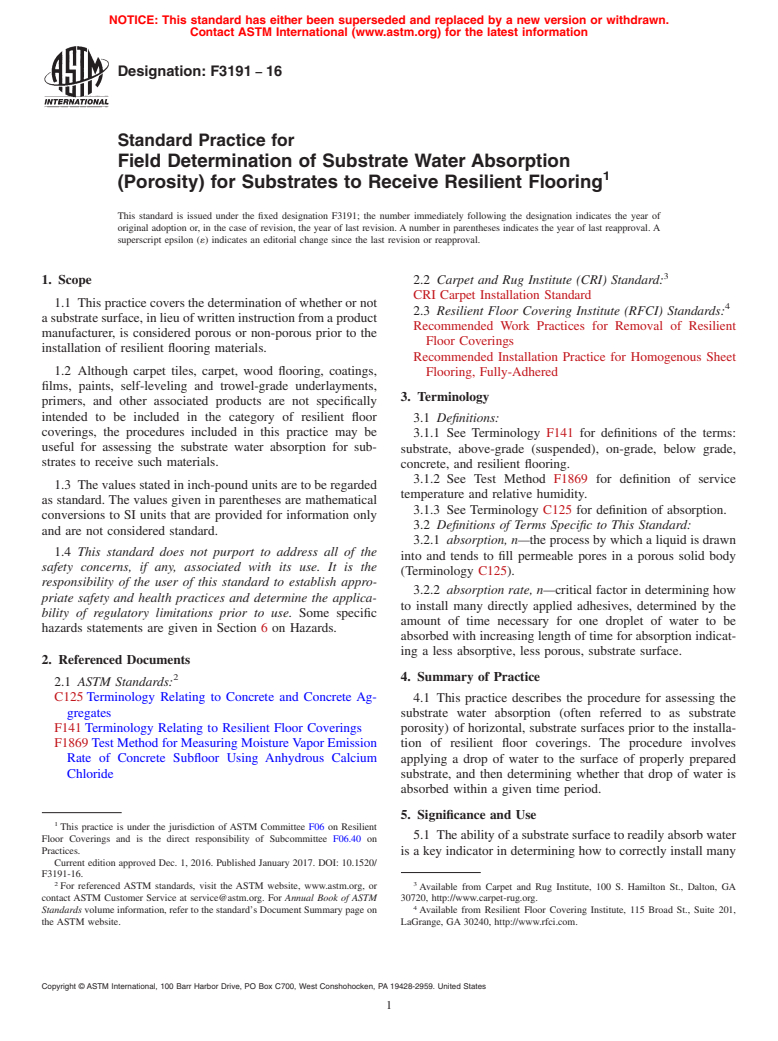

C125 Terminology Relating to Concrete and Concrete Ag- 4.1 This practice describes the procedure for assessing the

gregates substrate water absorption (often referred to as substrate

F141 Terminology Relating to Resilient Floor Coverings porosity) of horizontal, substrate surfaces prior to the installa-

F1869 Test Method for Measuring Moisture Vapor Emission

tion of resilient floor coverings. The procedure involves

Rate of Concrete Subfloor Using Anhydrous Calcium applying a drop of water to the surface of properly prepared

Chloride

substrate, and then determining whether that drop of water is

absorbed within a given time period.

5. Significance and Use

1

This practice is under the jurisdiction of ASTM Committee F06 on Resilient

5.1 The ability of a substrate surface to readily absorb water

Floor Coverings and is the direct responsibility of Subcommittee F06.40 on

Practices.

is a key indicator in determining how to correctly install many

Current edition approved Dec. 1, 2016. Published January 2017. DOI: 10.1520/

F3191-16.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Carpet and Rug Institute, 100 S. Hamilton St., Dalton, GA

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 30720, http://www.carpet-rug.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from Resilient Floor Covering Institute, 115 Broad St., Suite 201,

the ASTM website. LaGrange, GA 30240, http://www.rfci.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3191 − 16

types of flooring adhesives, primers, self-leveling may be required to control worker exposure to respirable

underlayments, and other products. Several flooring industry crystalline silica produced from drilling concrete. Inhalation of

publications s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.