ASTM D3342-90(2000)e1

(Test Method)Standard Test Method for Dispersion Stability of New (Unused) Rolling Oil Dispersions in Water

Standard Test Method for Dispersion Stability of New (Unused) Rolling Oil Dispersions in Water

SCOPE

1.1 This test method covers determination of the dispersion stability of dispersions of rolling oils in water. It is applicable to oils whose water dispersions are stable under moderate agitation, but which show at least some separation upon standing quiescent for 1/2 h, by rising of the oil particles.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.2, A2.1 and A2.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D3342–90(Reapproved 2000)

Standard Test Method for

Dispersion Stability of New (Unused) Rolling Oil

Dispersions in Water

This standard is issued under the fixed designation D 3342; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial corrections were made throughout in April 2000.

1. Scope similar situation is encountered with aluminum rolling mills,

but significant differences in designated settling times be

1.1 This test method covers determination of the dispersion

required outside the parameter of times used herein. Precision

stability of dispersions of rolling oils in water. It is applicable

data have only been obtained relative to metastable dispersions

to oils whose water dispersions are stable under moderate

for steel mill rolling oils.

agitation, but which show at least some separation upon

standing quiescent for ⁄2 h, by rising of the oil particles.

5. Apparatus

1.2 The values stated in SI units are to be regarded as the

5.1 Mixing Beaker , 5800 mL capacity, made of stainless

standard.

steel, modified as shown in Annex A2.

1.3 This standard does not purport to address all of the

5.2 Combination Agitator and Temperature Control

safety concerns, if any, associated with its use. It is the

Devcice .

responsibility of the user of this standard to establish appro-

5.3 Babcock Centrifuge Bottles —The 165-mm cream test

priate safety and health practices and determine the applica-

bottle, with 5 mL-neck permitting oil concentration readings

bility of regulatory limitations prior to use. For specific hazard

from0to10 %ispreferred.Thesebottlesshouldbemarkedfor

statements, see 6.2, A2.1 and A2.5.

filling to the 50–mL level which will normally be found close

2. Referenced Documents to the junction of body and neck. Sulfonation bottles may also

be used.

2.1 ASTM Standards:

5.4 Centrifuge, capable of whirling the Babcock bottles at

D 1126 Test Methods for Hardness in Water

sufficient speed to give a clean separation of oil and water

D 1293 Test Methods for pH of Water

under the test conditions. A centrifuge giving a relative

3. Summary of Test Method

centrifugal force (rcf) of 5009 at the bottle tips has been found

to give good separations in 10 min.

3.1 The rolling oil is dispersed in a standard test water, in a

5.5 To calculate the rpm required to achieve the stated rcf,

standard container, under standard conditions of time, agita-

use the following formula:

tion, and concentration. When the agitation is stopped, the

resulting decrease in oil concentration at a specified point near

rpm 5 1335 rcf/d (1)

=

thebottomofthecontainerismeasuredatcertaintimeintervals

where:

and plotted.

rcf = relative centrifugal force,

4. Significance and Use d = diameter of swing measured between tips of oppo-

site tubes when in rotating position, mm, and

4.1 Each steel rolling mill and operation is particular as to

rpm = revolutions per minute.

the degree of stability of dispersion required to effect maxi-

5.6 Stop Watch, or similar timing device.

mum efficiency of lubrication and cooling. This test method is

designed to differentiate between coolants for this use. A

Fisher beaker #2-584F, or equivalent, has been found satisfactory for this

This test method is under the jurisdiction of ASTM Committee D02 on purpose.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee The Porta-temp, available from the Precision Scientific Co., or equivalent, has

D02.L on Industrial Lubricants. been found satisfactory for this purpose.

Current edition approved May 25, 1990. Published July 1990. The Fisher cream test bottle No. 12–705 or sulfonation bottle No. 6-904, or

Annual Book of ASTM Standards, Vol 11.01. equivalent, have been found satisfactory for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D3342–90 (2000)

6. Reagents divided by 5 equals the percent oil. If this result is not close to

5 %, the results are suspect until repeat runs verify the

6.1 Buffered Synthetic Hard Water, prepared in accordance

reproducibility of the discrepancy. Significant amounts of

with Annex A2.

water soluble compounds in the oil sample might explain low

6.2 Sulfuric Acid, 30 vol % in water. Lower acid concen-

concentrations, for example. If, by the end of the 30 min

trations may be used if clean separations are obtained

agitation period, any significant amount of free oil or inverted

(Warning—Sulfuric acid is poison, corrosive, and a strong

emulsion remains floating on the surface without being repeat-

oxidizer.).

edly drawn down into the water layer, the oil is probably too

difficult to disperse for the test method to be applicable.

7. Procedure

8.2 For each sample taken after agitation was stopped,

7.1 The flow rate of the combination agitator and tempera-

calculate the amount of oil found as a percent of the amount

ture control device should be between 3500 and 4500 mL/min.

found in the sample.

The flow rate should be measured with a piece of 6.35-mm

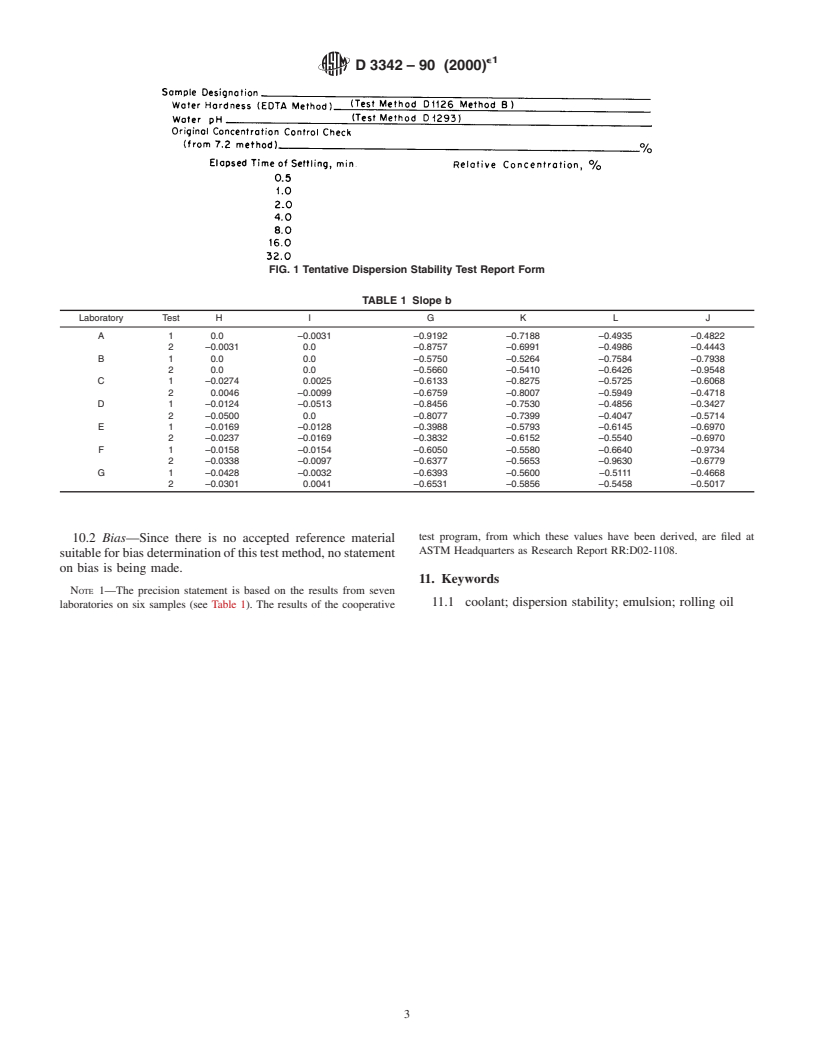

8.3 A single number used to describe the rolling oil emul-

inside diameter bore plastic tubing temporarily attached to the

sion stability is the slope of a straight line, fit by the method of

pump outlet and removed after this measurement. During the

least squares, to the base ten logarithms of both time, in

test, do not use attachments such as tubing, stopcocks, pinch

minutes, and the measured concentrations in percent. In

clamps, etc. on the pump outlet.

practice, to avoid taking the of zero, use the concentration plus

7.2 Add 4275 mL of test water to the beaker, install the

1%.

agitator-temperature control device, and adjust it for 60°C

8.4 The estimate of the Slope b, for an experimental trial is

temperature.When the water reaches this temperature, add 225

easily obtained by completing the following worksheet.

mL of the rolling oil to be tested. (The oil sample should be

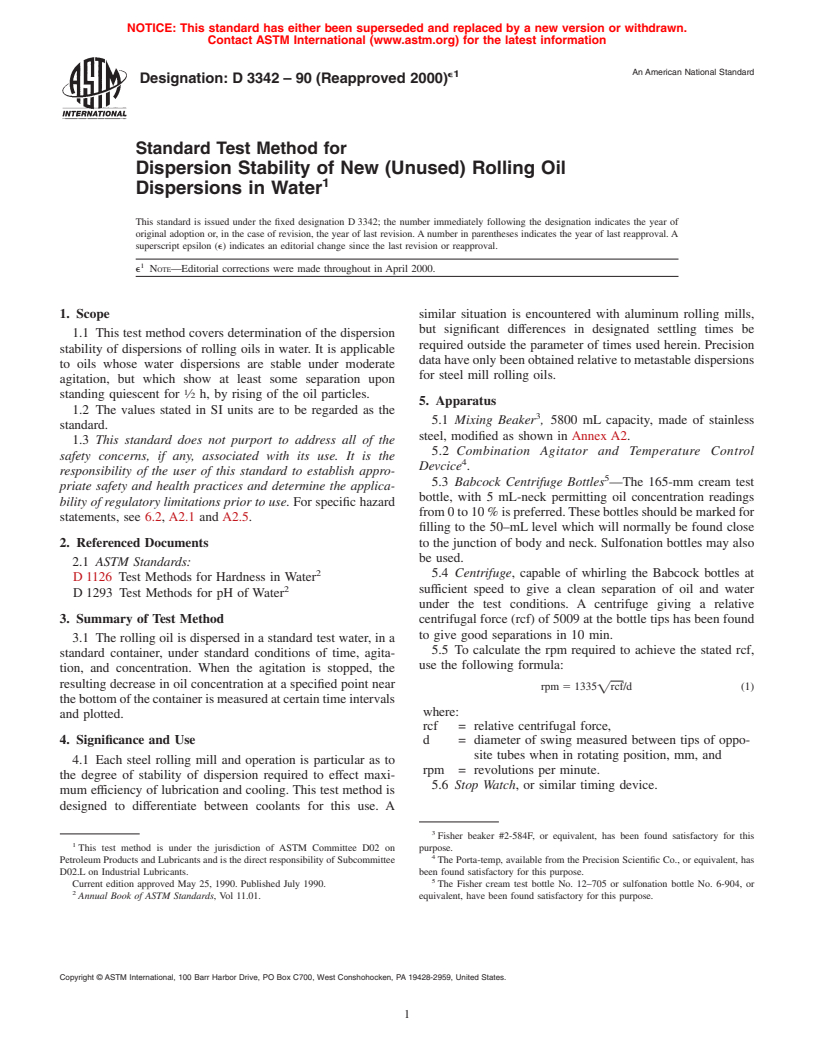

Log Time

sufficiently agitated to assure complete mixing of oil compo-

Log Concentration+1%

nents. With most materials, sufficient heat to melt all of the Time Actual Coded (X) (Y) XY

components will also be required, however, at no time should

0.5 −0.30103 −0.90309

1.0 0.0 −0.60206

the temperature exceed 60°C.) Continue controlled tempera-

2.0 0.30103 −0.30103

ture agitation for 30 min.

4.0 0.60206 0.0

7.3 While agitation continues, fill one Babcock bottle for an

8.0 0.90309 0.30103

16.0 1.20412 0.60206

emulsion concentration control test, as follows: Open the pinch

32.0 1.50515 0.90309

clamp on the beaker sample tap for 2 to 3 s. Discard about 20

mLof emulsion to flush the tap, and attempt to come as cleanly

8.5 Enter the log of the test result plus 1 on the appropriate

aspossibletotheend.Closethepinchclamp,placethehosetip

line. Form the product of each coded time ( X) and the

in a Babcock bottle, and fill i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.