ASTM C1518-04

(Specification)Standard Specification for Precured Elastomeric Silicone Joint Sealants

Standard Specification for Precured Elastomeric Silicone Joint Sealants

ABSTRACT

This specification describes the properties of applied, flat shaped precured elastomeric silicone joint sealants that bridge joint openings and are adhered to joint substrates utilizing a liquid applied silicone adhesive sealant to seal building openings such as panel joints, metal flashing joints, or other building openings in place of conventional liquid applied sealants. Seals are applied in three different configurations, as follows: as a bridge joint, the seal is applied flat on the surface to cover a joint opening; as a beveled bridge joint, the seal is applied on the beveled edge of a substrate to bridge a joint opening.; as a U-joint, the seal is applied in a U-configuration within a joint. Seals are classified into Movement Classes on the basis of movement capability, and Tear Class on the basis of tear propagation. Seals should adhere to specified requirements as to stability, color and texture, application, adhesion and cohesion, and movement, modulus, and tear characteristics.

SCOPE

1.1 Precured elastomeric silicone joint sealants, hereinafter referred to as seal, are manufactured in flat, cured, extruded shapes and are primarily used to span joint openings in construction. This specification describes the properties of applied, flat shaped precured elastomeric silicone joint sealants, hereinafter referred to as applied seal, that bridge joint openings and are adhered to joint substrates utilizing a liquid applied silicone adhesive sealant, specified by the manufacturer, hereinafter referred to as adhesive to construction substrates, to seal building openings such as panel joints, metal flashing joints, or other building openings in place of conventional liquid applied sealants.

1.2 Seals are applied in three different configurations:

1.2.1 As a bridge joint, the seal is applied flat on the surface to cover a joint opening. See Fig. 1.

1.2.2 As a beveled bridge joint, the seal is applied on the beveled edge of a substrate to bridge a joint opening. See Fig. 2.

1.2.3 As a U-joint, the seal is applied in a U-configuration within a joint. See Fig. 3.

1.3 This specification is for a flat extruded shape. A three-dimensional shape used at a joint cross section or termination is being considered for future inclusion in the specification.

1.4 An applied seal meeting the requirements of this specification shall be designated by the manufacturer as to movement class and tear class as described in Section 5.

1.5 The values stated in SI units are to be regarded as the standard. The values given in brackets are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1518 – 04

Standard Specification for

1

Precured Elastomeric Silicone Joint Sealants

This standard is issued under the fixed designation C 1518; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 Precured elastomeric silicone joint sealants, hereinafter 2.1 ASTM Standards:

referred to as seal, are manufactured in flat, cured, extruded C 717 Terminology of Building Seals and Sealants

shapes and are primarily used to span joint openings in C 1442 Practice for Conducting Test on Sealants Using

construction. This specification describes the properties of Artificial Weathering Apparatus

applied, flat shaped precured elastomeric silicone joint seal- C 1523 Test Method for Determining Modulus, Tear and

ants, hereinafter referred to as applied seal, that bridge joint Adhesion Properties of Precured Elastomeric Joint Seal-

openings and are adhered to joint substrates utilizing a liquid ants

applied silicone adhesive sealant, specified by the manufac- D 1566 Terminology Relating to Rubber

turer, hereinafter referred to as adhesive to construction sub- G 113 Terminology Relating to Natural and Artificial

strates, to seal building openings such as panel joints, metal Weathering Tests of Nonmetallic Materials

flashing joints, or other building openings in place of conven-

3. Terminology

tional liquid applied sealants.

1.2 Seals are applied in three different configurations: 3.1 Definitions:

3.1.1 Refer to Terminology C 717 for definitions of the

1.2.1 As a bridge joint, the seal is applied flat on the surface

to cover a joint opening. See Fig. 1. following terms used in this specification: cohesive failure,

adhesive failure, elastomeric, elongation, joint, modulus,

1.2.2 As a beveled bridge joint, the seal is applied on the

beveled edge of a substrate to bridge a joint opening. See Fig. primer, seal, sealant, substrate.

3.1.2 Refer to Terminology G 113 for definitions related to

2.

1.2.3 As a U-joint, the seal is applied in a U-configuration artificial weathering.

3.1.3 Refer to Terminology D 1566 for tear.

within a joint. See Fig. 3.

1.3 This specification is for a flat extruded shape. A three-

4. Significance and Use

dimensional shape used at a joint cross section or termination

4.1 This specification describes several classifications of

is being considered for future inclusion in the specification.

appliedsealsasdescribedinSection5.Thepurchaserordesign

1.4 An applied seal meeting the requirements of this speci-

professional shall recognize that not all materials meeting this

fication shall be designated by the manufacturer as to move-

specification are suitable for all applications and substrates. It

ment class and tear class as described in Section 5.

is essential, therefore, that the proper classification of the seal

1.5 The values stated in SI units are to be regarded as the

system is provided for the intended use. The test methods in

standard.Thevaluesgiveninbracketsareforinformationonly.

this specification relate to elastomeric performance, adhesion

1

This specification is under the jurisdiction of ASTM Committee C24 on

2

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.10 For referenced ASTM standards, visit the ASTM website, www.astm.org, or

on Specifications, Guides and Practices. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2004. Published May 2004. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 2002. Last previous edition approved in 2002 as C 1518 - 02. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

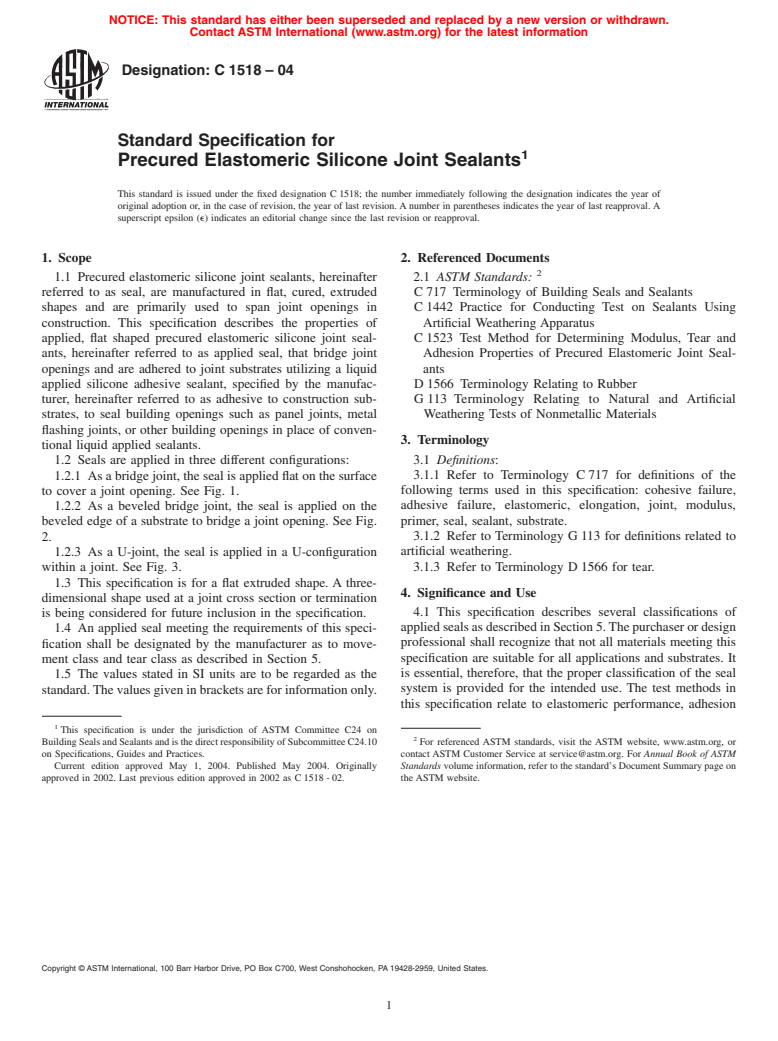

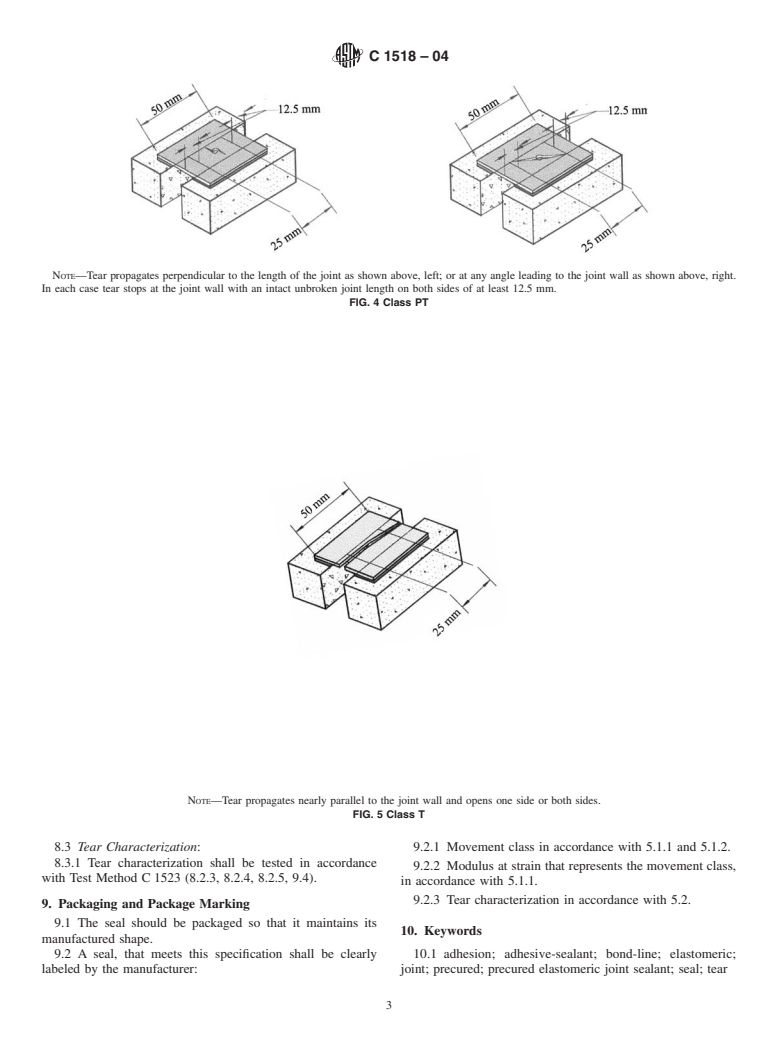

C1518–04

for 24 h; and three joint specimens to artificial weathering in

accordance with Practice C 1442 as described in Test Method

C 1523 (8.2.5) for a minimum of 2500 h. The exposure

duration shall be sufficient to produce a statistically significant

change of the property evaluated in a material known to give

poor performance when used in the application of interest.

After each type of conditioning, the specimen shall withstand

a strain and the holding time at that strain for one hour to X %

elongation, where X is 12.5 % or greater, in increments of

FIG. 1 Bridge Joint Configuration

12.5 % to max 200 %. (Test Method C 1523, 9.1)

5.1.2 Immediately following 5.1.1 the same specimen shall

withstand 10 movement cycles of X % elongation where X is

the percentage used in 5.1.1 and relaxation to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.