ASTM D4418-00(2016)

(Practice)Standard Practice for Receipt, Storage, and Handling of Fuels for Gas Turbines

Standard Practice for Receipt, Storage, and Handling of Fuels for Gas Turbines

SIGNIFICANCE AND USE

5.1 This practice provides the user of gas turbine fuel oils and the designer of gas turbine fuel systems with an appreciation of the effects of fuel contaminants and general methods of controlling such contaminants in gas turbine fuel systems.

5.2 This practice is general in nature and should not be considered a substitute for any requirement imposed by warranty of the gas turbine manufacturer, or by federal, state, or local government regulations.

5.3 Although it cannot replace a knowledge of local conditions or the use of good engineering and scientific judgment, this practice does provide guidance in development of individual fuel management systems for the gas turbine user.

SCOPE

1.1 This practice covers the receipt, storage, and handling of fuels for gas turbines, except for gas turbines used in aircraft. It is intended to provide guidance for the control of substances in a fuel that could cause deterioration of either the fuel system, or the gas turbine, or both.

1.2 This practice provides no guidance for either the selection of a grade of fuel, a topic covered by Specification D2880, or for the safety aspects of the fuel and fuel systems. For example, this practice does not address the spacings of storage tanks, loading and unloading facilities, etc., and procedures for dealing with the flammability and toxic properties of the fuels.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4418 − 00 (Reapproved 2016)

Standard Practice for

Receipt, Storage, and Handling of Fuels for Gas Turbines

This standard is issued under the fixed designation D4418; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6469 GuideforMicrobialContaminationinFuelsandFuel

Systems

1.1 Thispracticecoversthereceipt,storage,andhandlingof

fuels for gas turbines, except for gas turbines used in aircraft.

3. Terminology

It is intended to provide guidance for the control of substances

3.1 fuel entering the combustor(s)—this term is used to

inafuelthatcouldcausedeteriorationofeitherthefuelsystem,

designate the fuel that is actually burned in the gas turbine.

or the gas turbine, or both.

Fuel may actually be sampled at a point upstream from the

1.2 This practice provides no guidance for either the selec-

point of entry into the combustor(s), provided the sample is

tion of a grade of fuel, a topic covered by Specification D2880,

representative of the fuel actually entering the combustor(s).

or for the safety aspects of the fuel and fuel systems. For

3.2 fuel contaminants—in principle, are any fuel component

example, this practice does not address the spacings of storage

other than hydrocarbon oils. In the present context the con-

tanks, loading and unloading facilities, etc., and procedures for

taminants are foreign materials that make the fuel less suitable

dealing with the flammability and toxic properties of the fuels.

or even unsuitable for the intended use. The contaminants of

1.3 The values stated in SI units are to be regarded as the

primary interest are foreign materials introduced subsequent to

standard. The values given in parentheses are for information

the manufacture of specification quality fuel. Hence they are

only.

materials introduced in the distribution system (that is storage

1.4 This standard does not purport to address all of the tanks, pipelines, tank, trucks, barges, etc.), or in the user’s

storage and handling systems, or generated within these

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- systems (rust generated in steel pipes and tanks by moist fuel,

etc.). Contaminants may be soluble or insoluble in the fuel.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.3 dissolved and free water—water may be present in the

fuel as dissolved water or as “free” (undissolved) water, or

2. Referenced Documents

both. The free water may be fresh or saline. Fresh water may

2.1 ASTM Standards:

enter the fuel from steam coils in storage tanks, from conden-

D1500 Test Method forASTM Color of Petroleum Products

sation out of moisture-laden air, or from leaking cooling coils.

(ASTM Color Scale)

Saline water can enter the fuel during transportation in barges

D1796 Test Method for Water and Sediment in Fuel Oils by

or tankers.

the Centrifuge Method (Laboratory Procedure)

3.4 particulate solids—may enter a fuel from the air (sus-

D2274 Test Method for Oxidation Stability of Distillate Fuel

pended dirt and aerosols) or from the distribution and storage

Oil (Accelerated Method)

systems (rust, corrosion products, gasket debris, and so forth).

D2276 Test Method for Particulate Contaminant in Aviation

3.5 metallic compounds—metals may be present as metallic

Fuel by Line Sampling

compounds in the fuel as a natural result of the composition of

D2880 Specification for Gas Turbine Fuel Oils

the crude oil and of the refining process. However, unless

D4057 Practice for Manual Sampling of Petroleum and

special precautions are taken, additional metallic compounds

Petroleum Products

can be acquired during distribution and storage.Acommercial

1 product pipeline may contain residues of lead-containing

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom- gasoline that would then be dissolved by the gas turbine fuel.

mittee D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

Tank trucks, railroad tankcars, barges, and tankers may be

Current edition approved April 1, 2016. Published May 2016. Originally

inadequately cleaned and contain residues of past cargos.

approved in 1984. Last previous edition approved in 2011 as D4418 – 00(2011).

Acidic components in saline water salts in the fuel may react

DOI: 10.1520/D4418-00R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

with distribution and storage equipment.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.6 microbial slimes—may result when conditions are con-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ducive to the growth of microorganisms that are always

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4418 − 00 (2016)

present.The presence of free water is essential to the growth of devices is a function of particulate levels and size distributions

many of these microorganisms that grow in tank water bottoms in the fuel. High levels of particulates can lead to short cycle

and feed on nutrients in the water or on the hydrocarbons. times in the operation of filters, filter/separators, centrifuges,

andelectrostaticpurifiers.Sincesuchseparationdevicesdonot

4. Summary of Practice

remove all the particulates, certain quantities will be present in

4.1 The body of this practice defines the contaminants

the down-stream fuel.

frequently found in turbine fuel oils and discusses the sources

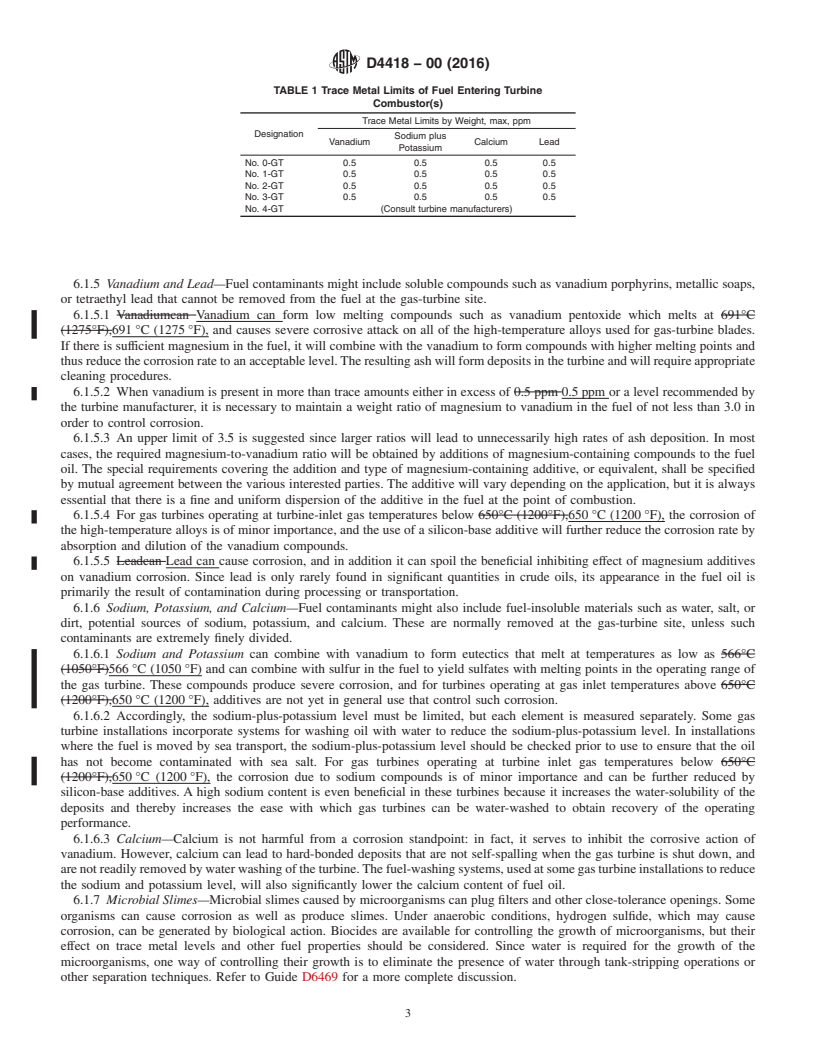

6.1.3 Trace metals refer both to those metals present as

and significance of such contaminants.

metallic compounds in solution and to metals present in

particulates like rust.They are dissolved or suspended either in

4.2 Annex A1 is a guide for the receipt, storage, and

the fuel hydrocarbons or in free water present in the fuel. The

handling of distillate gas turbine fuels, Grades 1-GTand 2-GT,

significance of several individual trace metals with respect to

in accordance with Specification D2880.

hot corrosion is discussed in 6.1.4 through 6.1.5. Although

4.3 Annex A2 is a guide for the receipt, storage, and

lower levels of trace metals in a fuel will promote longer

handling of gas turbine fuels, Grades 3-GT and 4-GT, that

turbineservicefromacorrosionstandpoint,thespecificationof

contain residual components.

excessively low levels may limit the availability of the fuel or

4.4 Annex A3 is a guide for the selection and storage of materially increase its cost. Table 1 suggests levels of trace

fuels intended for long-term storage, when such fuels are metals that would probably yield satisfactory service.

distillate fuels. 6.1.4 Ash is the noncombustible material in an oil. Ash

forming materials may be present in fuel oil in two forms: (1)

4.5 Annex A4 is a guide for gas turbine users who are

solid particles, and (2) oil- or water-soluble metallic com-

considering the use of fuels from alternative non-petroleum

pounds. The solid particles are for the most part the same

sources.

material that is designated as sediment in the water and

5. Significance and Use

sediment test. Depending on their size, these particles can

contributetowearinthefuelsystemandtopluggingofthefuel

5.1 This practice provides the user of gas turbine fuel oils

filterandthefuelnozzle.Thesolublemetalliccompoundshave

and the designer of gas turbine fuel systems with an apprecia-

little or no effect on wear or plugging, but they can contain

tion of the effects of fuel contaminants and general methods of

elements that produce turbine corrosion and deposits as de-

controlling such contaminants in gas turbine fuel systems.

scribed in 6.1.5.

5.2 This practice is general in nature and should not be

6.1.5 Vanadium and Lead—Fuel contaminants might in-

considered a substitute for any requirement imposed by war-

clude soluble compounds such as vanadium porphyrins, me-

ranty of the gas turbine manufacturer, or by federal, state, or

tallic soaps, or tetraethyl lead that cannot be removed from the

local government regulations.

fuel at the gas-turbine site.

5.3 Although it cannot replace a knowledge of local condi-

6.1.5.1 Vanadium can form low melting compounds such as

tions or the use of good engineering and scientific judgment,

vanadium pentoxide which melts at 691 °C (1275 °F), and

this practice does provide guidance in development of indi- causes severe corrosive attack on all of the high-temperature

vidual fuel management systems for the gas turbine user.

alloys used for gas-turbine blades. If there is sufficient magne-

sium in the fuel, it will combine with the vanadium to form

6. Significance of Contaminants

compounds with higher melting points and thus reduce the

6.1 Contamination levels in the fuel entering the combus-

corrosion rate to an acceptable level. The resulting ash will

tor(s) must be low for improved turbine life. Low contamina-

form deposits in the turbine and will require appropriate

tion levels in the fuel in the turbine’s in-plant fuel system are

cleaning procedures.

required to minimize corrosion and operating problems. Pro-

6.1.5.2 When vanadium is present in more than trace

viding fuel of adequate cleanliness to the gas turbine combus-

amounts either in excess of 0.5 ppm or a level recommended

tor(s) may require special actions by the user. These actions

by the turbine manufacturer, it is necessary to maintain a

mightincludespecialtransportationarrangementswiththefuel

weight ratio of magnesium to vanadium in the fuel of not less

supplier, particular care in on-site fuel storage and quality

than 3.0 in order to control corrosion.

control procedures, and establishment of on-site cleanup pro-

6.1.5.3 An upper limit of 3.5 is suggested since larger ratios

cedures.Eachofthefourclassesofcontaminantsdefinedin3.2

will lead to unnecessarily high rates of ash deposition. In most

has its own significance to system operation.

6.1.1 Water will cause corrosion of tanks, piping, flow

TABLE 1 Trace Metal Limits of Fuel Entering Turbine

dividers, and pumps. Corrosion or corrosion products in

Combustor(s)

close-tolerance devices, such as flow dividers, may cause

Trace Metal Limits by Weight, max, ppm

plugging and may stop flow to the turbines. Free water is

Designation

Sodium plus

Vanadium Calcium Lead

potentially corrosive in sulfur-containing fuels, it may be

Potassium

particularly corrosive. Free water may contain dissolved salts

No. 0-GT 0.5 0.5 0.5 0.5

that may be corrosive, and may encourage microbiological No. 1-GT 0.5 0.5 0.5 0.5

No. 2-GT 0.5 0.5 0.5 0.5

growth.

No. 3-GT 0.5 0.5 0.5 0.5

6.1.2 Particulate solids may shorten the life of fuel system

No. 4-GT (Consult turbine manufacturers)

components. Life of fuel pumps and of various close-tolerance

D4418 − 00 (2016)

cases, the required magnesium-to-vanadium ratio will be tions where the fuel is moved by sea transport, the sodium-

obtained by additions of magnesium-containing compounds to plus-potassium level should be checked prior to use to ensure

thefueloil.Thespecialrequirementscoveringtheadditionand that the oil has not become contaminated with sea salt. For gas

type of magnesium-containing additive, or equivalent, shall be turbines operating at turbine inlet gas temperatures below

specified by mutual agreement between the various interested

650 °C(1200 °F),thecorrosionduetosodiumcompoundsisof

parties. The additive will vary depending on the application, minor importance and can be further reduced by silicon-base

but it is always essential that there is a fine and uniform

additives. A high sodium content is even beneficial in these

dispersionoftheadditiveinthefuelatthepointofcombustion. turbines because it increases the water-solubility of the depos-

6.1.5.4 For gas turbines operating at turbine-inlet gas tem-

its and thereby increases the ease with which gas turbines can

peratures below 650 °C (1200 °F), the corrosion of the high- be water-washed to obtain recovery of the operating perfor-

temperature alloys is of minor importance, and the use of a

mance.

silicon-base additive will further reduce the corrosion rate by

6.1.6.3 Calcium—Calcium is not harmful from a corrosion

absorption and dilution of the vanadium compounds.

standpoint: in fact, it serves to inhibit the corrosive action of

6.1.5.5 Leadcancausecorrosion,andinadditionitcanspoil

vanadium. However, calcium can lead to hard-bonded deposits

the beneficial inhibiting effect of magnesium additives on

thatarenotself-spallingwhenthegasturbineisshutdown,and

vanadium corrosion. Since lead is only rarely found in signifi-

are not readily removed by water washing of the turbine. The

cant quantities in crude oils, its appearance in the fuel oil is

fuel-washing systems, used at some gas turbine installations to

primarily the result of contamination during processing or

reduce the sodium and potassium level, will also significantly

transportation.

lower the calcium content of fuel oil.

6.1.6 Sodium, Potassium, and Calcium—Fuel contaminants

6.1.7 Microbial Slimes—Microbial slimes caused by micro-

might also include fuel-insoluble materials such as water, salt,

organisms can plug filters and other close-tolerance openings.

or dirt, potential sources of sodium, potassium, and calcium.

Someorganismscancausecorrosionaswellasproduceslimes.

Thesearenormallyremovedatthegas-turbinesite,unlesssuch

Under anaerobic conditions, hydrogen sulfide, which may

contaminants are extremely finely divided.

cause corrosion, can be generated by biological action. Bio-

6.1.6.1 Sodium and Potassium can combine with vanadium

cides are available for controlling the growth of

to form eutectics that melt at temperatures as low as 566 °C

microorganisms, but their effect on trace metal levels and other

(1050 °F) and can combine with sulfur in the fuel to yield

fuel properties should be considered. Since water is required

sulfates with melting points in the operating range of the gas

for the growth of the microorganisms, one way of controlling

turbine. These compounds produce severe corrosion, and for

their growth is to eliminate the presence of water through

turbines operating at gas inlet temperatures above 650 °C

tank-stripping operations or other separation techniques. Refer

(1200 °F), additives are not yet in general use that control such

to Guide D6469 for a more complete discussion.

corrosion.

6.1.6.2 Accordingly, the sodium-

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4418 − 00 (Reapproved 2011) D4418 − 00 (Reapproved 2016)

Standard Practice for

Receipt, Storage, and Handling of Fuels for

Gas Turbines

This standard is issued under the fixed designation D4418; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the receipt, storage, and handling of fuels for gas turbines, except for gas turbines used in aircraft. It

is intended to provide guidance for the control of substances in a fuel that could cause deterioration of either the fuel system, or

the gas turbine, or both.

1.2 This practice provides no guidance for either the selection of a grade of fuel, a topic covered by Specification D2880, or

for the safety aspects of the fuel and fuel systems. For example, this practice does not address the spacings of storage tanks, loading

and unloading facilities, etc., and procedures for dealing with the flammability and toxic properties of the fuels.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1500 Test Method for ASTM Color of Petroleum Products (ASTM Color Scale)

D1796 Test Method for Water and Sediment in Fuel Oils by the Centrifuge Method (Laboratory Procedure)

D2274 Test Method for Oxidation Stability of Distillate Fuel Oil (Accelerated Method)

D2276 Test Method for Particulate Contaminant in Aviation Fuel by Line Sampling

D2880 Specification for Gas Turbine Fuel Oils

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D6469 Guide for Microbial Contamination in Fuels and Fuel Systems

3. Terminology

3.1 fuel entering the combustor(s)—this term is used to designate the fuel that is actually burned in the gas turbine. Fuel may

actually be sampled at a point upstream from the point of entry into the combustor(s), provided the sample is representative of the

fuel actually entering the combustor(s).

3.2 fuel contaminants—in principle, are any fuel component other than hydrocarbon oils. In the present context the

contaminants are foreign materials that make the fuel less suitable or even unsuitable for the intended use. The contaminants of

primary interest are foreign materials introduced subsequent to the manufacture of specification quality fuel. Hence they are

materials introduced in the distribution system (that is storage tanks, pipelines, tank, trucks, barges, etc.), or in the user’s storage

and handling systems, or generated within these systems (rust generated in steel pipes and tanks by moist fuel, etc.). Contaminants

may be soluble or insoluble in the fuel.

3.3 dissolved and free water—water may be present in the fuel as dissolved water or as “free” (undissolved) water, or both. The

free water may be fresh or saline. Fresh water may enter the fuel from steam coils in storage tanks, from condensation out of

moisture-laden air, or from leaking cooling coils. Saline water can enter the fuel during transportation in barges or tankers.

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

Current edition approved Oct. 1, 2011April 1, 2016. Published October 2011May 2016. Originally approved in 1984. Last previous edition approved in 20062011 as

D4418 – 00(2006).(2011). DOI: 10.1520/D4418-00R11.10.1520/D4418-00R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4418 − 00 (2016)

3.4 particulate solids—may enter a fuel from the air (suspended dirt and aerosols) or from the distribution and storage systems

(rust, corrosion products, gasket debris, and so forth).

3.5 metallic compounds—metals may be present as metallic compounds in the fuel as a natural result of the composition of the

crude oil and of the refining process. However, unless special precautions are taken, additional metallic compounds can be acquired

during distribution and storage. A commercial product pipeline may contain residues of lead-containing gasoline that would then

be dissolved by the gas turbine fuel. Tank trucks, railroad tankcars, barges, and tankers may be inadequately cleaned and contain

residues of past cargos. Acidic components in saline water salts in the fuel may react with distribution and storage equipment.

3.6 microbial slimes—may result when conditions are conducive to the growth of microorganisms that are always present. The

presence of free water is essential to the growth of many of these microorganisms that grow in tank water bottoms and feed on

nutrients in the water or on the hydrocarbons.

4. Summary of Practice

4.1 The body of this practice defines the contaminants frequently found in turbine fuel oils and discusses the sources and

significance of such contaminants.

4.2 Annex A1 is a guide for the receipt, storage, and handling of distillate gas turbine fuels, Grades 1-GT and 2-GT, in

accordance with Specification D2880.

4.3 Annex A2 is a guide for the receipt, storage, and handling of gas turbine fuels, Grades 3-GT and 4-GT, that contain residual

components.

4.4 Annex A3 is a guide for the selection and storage of fuels intended for long-term storage, when such fuels are distillate fuels.

4.5 Annex A4 is a guide for gas turbine users who are considering the use of fuels from alternative non-petroleum sources.

5. Significance and Use

5.1 This practice provides the user of gas turbine fuel oils and the designer of gas turbine fuel systems with an appreciation of

the effects of fuel contaminants and general methods of controlling such contaminants in gas turbine fuel systems.

5.2 This practice is general in nature and should not be considered a substitute for any requirement imposed by warranty of the

gas turbine manufacturer, or by federal, state, or local government regulations.

5.3 Although it cannot replace a knowledge of local conditions or the use of good engineering and scientific judgment, this

practice does provide guidance in development of individual fuel management systems for the gas turbine user.

6. Significance of Contaminants

6.1 Contamination levels in the fuel entering the combustor(s) must be low for improved turbine life. Low contamination levels

in the fuel in the turbine’s in-plant fuel system are required to minimize corrosion and operating problems. Providing fuel of

adequate cleanliness to the gas turbine combustor(s) may require special actions by the user. These actions might include special

transportation arrangements with the fuel supplier, particular care in on-site fuel storage and quality control procedures, and

establishment of on-site cleanup procedures. Each of the four classes of contaminants defined in 3.2 has its own significance to

system operation.

6.1.1 Waterwill Water will cause corrosion of tanks, piping, flow dividers, and pumps. Corrosion or corrosion products in

close-tolerance devices, such as flow dividers, may cause plugging and may stop flow to the turbines. Free water is potentially

corrosive in sulfur-containing fuels, it may be particularly corrosive. Free water may contain dissolved salts that may be corrosive,

and may encourage microbiological growth.

6.1.2 Particulate solidsmay solids may shorten the life of fuel system components. Life of fuel pumps and of various

close-tolerance devices is a function of particulate levels and size distributions in the fuel. High levels of particulates can lead to

short cycle times in the operation of filters, filter/separators, centrifuges, and electrostatic purifiers. Since such separation devices

do not remove all the particulates, certain quantities will be present in the down-stream fuel.

6.1.3 Trace metalsrefer metals refer both to those metals present as metallic compounds in solution and to metals present in

particulates like rust. They are dissolved or suspended either in the fuel hydrocarbons or in free water present in the fuel. The

significance of several individual trace metals with respect to hot corrosion is discussed in 6.1.4 through 6.1.5. Although lower

levels of trace metals in a fuel will promote longer turbine service from a corrosion standpoint, the specification of excessively

low levels may limit the availability of the fuel or materially increase its cost. Table 1 suggests levels of trace metals that would

probably yield satisfactory service.

6.1.4 Ashis Ash is the noncombustible material in an oil. Ashforming Ash forming materials may be present in fuel oil in two

forms: (1) solid particles, and (2) oil- or water-soluble metallic compounds. The solid particles are for the most part the same

material that is designated as sediment in the water and sediment test. Depending on their size, these particles can contribute to

wear in the fuel system and to plugging of the fuel filter and the fuel nozzle. The soluble metallic compounds have little or no effect

on wear or plugging, but they can contain elements that produce turbine corrosion and deposits as described in 6.1.5.

D4418 − 00 (2016)

TABLE 1 Trace Metal Limits of Fuel Entering Turbine

Combustor(s)

Trace Metal Limits by Weight, max, ppm

Designation

Sodium plus

Vanadium Calcium Lead

Potassium

No. 0-GT 0.5 0.5 0.5 0.5

No. 1-GT 0.5 0.5 0.5 0.5

No. 2-GT 0.5 0.5 0.5 0.5

No. 3-GT 0.5 0.5 0.5 0.5

No. 4-GT (Consult turbine manufacturers)

6.1.5 Vanadium and Lead—Fuel contaminants might include soluble compounds such as vanadium porphyrins, metallic soaps,

or tetraethyl lead that cannot be removed from the fuel at the gas-turbine site.

6.1.5.1 Vanadiumcan Vanadium can form low melting compounds such as vanadium pentoxide which melts at 691°C

(1275°F),691 °C (1275 °F), and causes severe corrosive attack on all of the high-temperature alloys used for gas-turbine blades.

If there is sufficient magnesium in the fuel, it will combine with the vanadium to form compounds with higher melting points and

thus reduce the corrosion rate to an acceptable level. The resulting ash will form deposits in the turbine and will require appropriate

cleaning procedures.

6.1.5.2 When vanadium is present in more than trace amounts either in excess of 0.5 ppm 0.5 ppm or a level recommended by

the turbine manufacturer, it is necessary to maintain a weight ratio of magnesium to vanadium in the fuel of not less than 3.0 in

order to control corrosion.

6.1.5.3 An upper limit of 3.5 is suggested since larger ratios will lead to unnecessarily high rates of ash deposition. In most

cases, the required magnesium-to-vanadium ratio will be obtained by additions of magnesium-containing compounds to the fuel

oil. The special requirements covering the addition and type of magnesium-containing additive, or equivalent, shall be specified

by mutual agreement between the various interested parties. The additive will vary depending on the application, but it is always

essential that there is a fine and uniform dispersion of the additive in the fuel at the point of combustion.

6.1.5.4 For gas turbines operating at turbine-inlet gas temperatures below 650°C (1200°F),650 °C (1200 °F), the corrosion of

the high-temperature alloys is of minor importance, and the use of a silicon-base additive will further reduce the corrosion rate by

absorption and dilution of the vanadium compounds.

6.1.5.5 Leadcan Lead can cause corrosion, and in addition it can spoil the beneficial inhibiting effect of magnesium additives

on vanadium corrosion. Since lead is only rarely found in significant quantities in crude oils, its appearance in the fuel oil is

primarily the result of contamination during processing or transportation.

6.1.6 Sodium, Potassium, and Calcium—Fuel contaminants might also include fuel-insoluble materials such as water, salt, or

dirt, potential sources of sodium, potassium, and calcium. These are normally removed at the gas-turbine site, unless such

contaminants are extremely finely divided.

6.1.6.1 Sodium and Potassium can combine with vanadium to form eutectics that melt at temperatures as low as 566°C

(1050°F)566 °C (1050 °F) and can combine with sulfur in the fuel to yield sulfates with melting points in the operating range of

the gas turbine. These compounds produce severe corrosion, and for turbines operating at gas inlet temperatures above 650°C

(1200°F),650 °C (1200 °F), additives are not yet in general use that control such corrosion.

6.1.6.2 Accordingly, the sodium-plus-potassium level must be limited, but each element is measured separately. Some gas

turbine installations incorporate systems for washing oil with water to reduce the sodium-plus-potassium level. In installations

where the fuel is moved by sea transport, the sodium-plus-potassium level should be checked prior to use to ensure that the oil

has not become contaminated with sea salt. For gas turbines operating at turbine inlet gas temperatures below 650°C

(1200°F),650 °C (1200 °F), the corrosion due to sodium compounds is of minor importance and can be further reduced by

silicon-base additives. A high sodium content is even beneficial in these turbines because it increases the water-solubility of the

deposits and thereby increases the ease with which gas turbines can be water-washed to obtain recovery of the operating

performance.

6.1.6.3 Calcium—Calcium is not harmful from a corrosion standpoint: in fact, it serves to inhibit the corrosive action of

vanadium. However, calcium can lead to hard-bonded deposits that are not self-spalling when the gas turbine is shut down, and

are not readily removed by water washing of the turbine. The fuel-washing systems, used at some gas turbine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.