ASTM F2657-07

(Test Method)Standard Test Method for Outdoor Weathering Exposure of Crosslinked Polyethylene (PEX) Tubing

Standard Test Method for Outdoor Weathering Exposure of Crosslinked Polyethylene (PEX) Tubing

SIGNIFICANCE AND USE

During shipment, storage and installation, PEX tubing may be exposed to UV radiation prior to being shielded from further exposure after installation. The effects of UV exposure on PEX tubing is determined by use of this test method. By first exposing specimens to solar UV radiation and subsequently testing specimens for oxidative resistance or stabilizer functionality, changes as a result of solar UV radiation exposure can be evaluated. This information can be used to determine the maximum allowable total UV exposure prior to permanent shielding provided by installation.

The results of short-term exposure tests can provide an indication of relative outdoor performance, but they should not be used to predict the absolute long-term performance of a material. The results of tests conducted for less than twelve months will depend on the particular season of the year in which they begin.

SCOPE

1.1 This test method describes the procedure for exposing crosslinked polyethylene (PEX) tubing produced in accordance with Specification F 876 to natural (sunlight) ultraviolet (UV) radiation and evaluating the effects of the exposure. This test method outlines the requirements for specimen size and preparation, exposure orientation, minimum UV exposure energy, post exposure testing and reporting.

Note 1—While other laboratory UV exposure systems are available, this test method relies on natural sunlight as the UV radiation source. Laboratory methods may be added in the future if testing confirms a correlation between natural sunlight and laboratory exposure.

1.2 PEX tubing is not designed for outdoor use. Data from short-term exposure testing per this test method can be used to judge the relative performance of PEX tubing stored outdoors for short periods of time prior to installation completely shielded from sunlight.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 The following precautionary caveat pertains only to the test method and post exposure testing portions, Sections 8 and 9 of this test method.This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F2657–07

Standard Test Method for

Outdoor Weathering Exposure of Crosslinked Polyethylene

(PEX) Tubing

This standard is issued under the fixed designation F2657; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1598 Test Method for Time-to-Failure of Plastic Pipe

Under Constant Internal Pressure

1.1 This test method describes the procedure for exposing

D1600 Terminology for Abbreviated Terms Relating to

crosslinkedpolyethylene(PEX)tubingproducedinaccordance

Plastics

with Specification F876 to natural (sunlight) ultraviolet (UV)

F412 Terminology Relating to Plastic Piping Systems

radiation and evaluating the effects of the exposure. This test

F876 Specification for Crosslinked Polyethylene (PEX)

method outlines the requirements for specimen size and

Tubing

preparation, exposure orientation, minimum UV exposure

F2023 Test Method for Evaluating the Oxidative Resistance

energy, post exposure testing and reporting.

of Crosslinked Polyethylene (PEX) Tubing and Systems to

NOTE 1—While other laboratory UV exposure systems are available,

Hot Chlorinated Water

this test method relies on natural sunlight as the UV radiation source.

G147 Practice for Conditioning and Handling of Nonmetal-

Laboratory methods may be added in the future if testing confirms a

lic Materials for Natural and Artificial Weathering Tests

correlation between natural sunlight and laboratory exposure.

1.2 PEX tubing is not designed for outdoor use. Data from

3. Terminology

short-term exposure testing per this test method can be used to

3.1 Definitions—Definitions are in accordance with Termi-

judge the relative performance of PEX tubing stored outdoors

nology F412 and abbreviations are in accordance with Termi-

for short periods of time prior to installation completely

nology D1600, unless otherwise indicated.

shielded from sunlight.

3.2 Definitions of Terms Specific to This Standard:

1.3 The values stated in SI units are to be regarded as

3.2.1 nominal exposure time period, n—the number of

standard. The values given in parentheses are mathematical

months corresponding to the measured TUV as defined in

conversions to inch-pound units that are provided for informa-

Table 1.

tion only and are not considered standard.

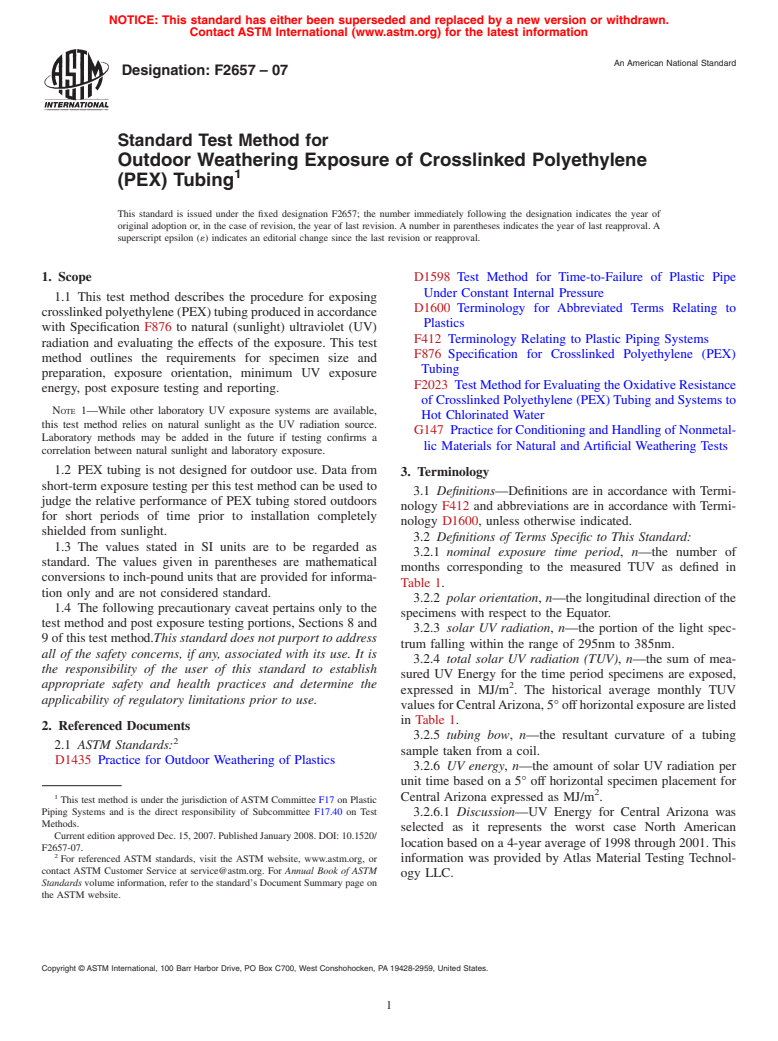

3.2.2 polar orientation, n—the longitudinal direction of the

1.4 The following precautionary caveat pertains only to the

specimens with respect to the Equator.

test method and post exposure testing portions, Sections 8 and

3.2.3 solar UV radiation, n—the portion of the light spec-

9 of this test method.This standard does not purport to address

trum falling within the range of 295nm to 385nm.

all of the safety concerns, if any, associated with its use. It is

3.2.4 total solar UV radiation (TUV), n—the sum of mea-

the responsibility of the user of this standard to establish

sured UV Energy for the time period specimens are exposed,

appropriate safety and health practices and determine the 2

expressed in MJ/m . The historical average monthly TUV

applicability of regulatory limitations prior to use.

valuesforCentralArizona,5°offhorizontalexposurearelisted

in Table 1.

2. Referenced Documents

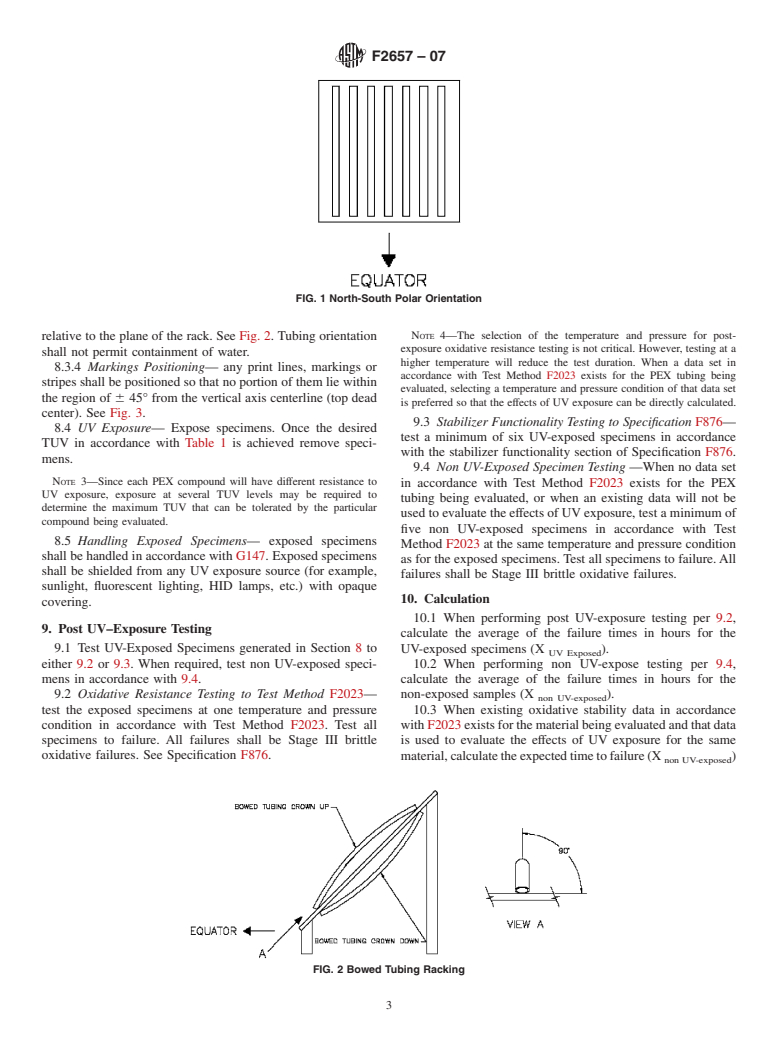

3.2.5 tubing bow, n—the resultant curvature of a tubing

2.1 ASTM Standards:

sample taken from a coil.

D1435 Practice for Outdoor Weathering of Plastics

3.2.6 UV energy, n—the amount of solar UV radiation per

unit time based on a 5° off horizontal specimen placement for

Central Arizona expressed as MJ/m .

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

3.2.6.1 Discussion—UV Energy for Central Arizona was

Methods.

selected as it represents the worst case North American

Current edition approved Dec. 15, 2007. Published January 2008. DOI: 10.1520/

location based on a 4-year average of 1998 through 2001. This

F2657-07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or information was provided by Atlas Material Testing Technol-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ogy LLC.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2657–07

A

TABLE 1 Total UV (TUV) Energy per Monthly Time Period

6.2 Specimen Rack—Specimen racks shall be in accordance

Nominal Exposure TUV Solar Radiation Highest Consecutive with Practice D1435 and shall allow for vertical mounting of

Time Period MJ/m UV Month Range

samples free of torsional or tensile stress. The rack shall

1 month 40 June

position the exposed surface of the specimens at a tilt angle in

2 months 80 May-June

the range of 5° to 45° inclusive.

3 months 119 May-July

6.3 Backing— specimens shall be tested un-backed.

4 months 154 May-August

5 months 187 April-August

6.4 UV Energy Measurement Equipment— UV radiation

6 months 218 April-September

shall be measured using an Ultraviolet Radiometer conforming

7 months 246 March-September

8 months 270 March-October to the requirements of Practice D1435. Radiometer shall be

9 months 289 February-October

mounted in the same attitude as the exposed samples.

10 months 307 February-November

11 months 324 January-November

12 months 339 January-December 7. Sampling and Specimen Preparation

A

Solar UV radiation is based on CentralArizona 5° off horizontal for the 4 year

7.1 Sampling—specimens shall be representative of the

periodof1998through2001asreportedbyAtlasandTestingandTechnologyLLC.

product/material being evaluated. Select a sufficient amount of

tubing to satisfy the testing requirements. Specimens can be

4. Summary of Test Method

straight or can have a bow when cut from a coil.

4.1 PEX tubing specimens are exposed to solar UV radia-

7.2 Test Specimen Size—PEX tubing specimens shall be of

tion for a period of time and then removed. The exposed

nominal size ⁄2 in., SDR 9, and shall be a minimum of 380

specimens are then tested in accordance with one of the

mm (15 in.) in length for the UV exposure portion of this

following methods:

method.

4.2 Potable Water Applications—UV exposed specimens

7.3 Number of Test Specimens:

are tested at one temperature and pressure condition in accor-

7.3.1 Post Exposure Testing to Test Method F2023—when a

dance with Test Method F2023 to determine the average time

complete data set exists for the PEX material being evaluated

to failure. The average time to failure for the UV-exposed

toTest Method F2023 and that data will be used for calculation

specimens is then compared to the average time to failure of

in accordance with 10.4, a minimum of five specimens are

non UV-exposed specimens of the same PEX material or to the

required. When no data set exists for the PEX material being

predicted time to failure for the same material based on a

evaluated to Test Method F2023, or the existing data set will

completeTestMethodF2023dataset.Thepercentagedecrease

notbeusedforcalculationinaccordancewith10.4,aminimum

in the average time to failure for the UV exposed specimens

of ten specimens are required, five for UV exposure and five

and the TUV of the exposure are reported.

for the non UV-exposed portion of this method.

4.3 Non-Potable Water Applications— PEX tubing for non-

7.3.2 Post-Exposure Testing to Stabilizer Functionality—a

potable water applications is post-exposure tested in accor-

minimum of six specimens are required when stabilizer func-

dance with 4.2 or, alternately, tested in accordance with the

tionality is used for post UV exposure testing.

stabilizer functionality test in Specification F876. The pass or

NOTE 2—The minimum specimen requirements are based on a single

fail result of the stabilizer functionality test and theTUVof the

Nominal Exposure Time Period (NETP) for the material being evaluated.

exposure are reported.

When the expected NETP for the material is unknown, additional

specimens may be UV exposed for various levels of NETP and post-

5. Significance and Use

exposure test data can be evaluated against non-UV exposed data.

5.1 During shipment, storage and installation, PEX tubing

may be exposed to UV radiation prior to being shielded from

8. Procedure

further exposure after installation. The effects of UV exposure

8.1 Required Specimens—obtain sufficient specimens in

on PEX tubing is determined by use of this test method. By

accordance with Section 7.

first exposing specimens to solar UV radiation and subse-

8.2 Preparation—condition and prepare specimens in ac-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.