ASTM C982-88(1997)e1

(Guide)Standard Guide for Selecting Components for Energy-Dispersive X-Ray Fluorescence (XRF) Systems

Standard Guide for Selecting Components for Energy-Dispersive X-Ray Fluorescence (XRF) Systems

SCOPE

1.1 This guide describes the components for an energy-dispersive X-ray fluorescence (XRF) system for materials analysis. It can be used as a reference in the apparatus section of test methods for energy-dispersive X-ray fluorescence analyses of nuclear materials.

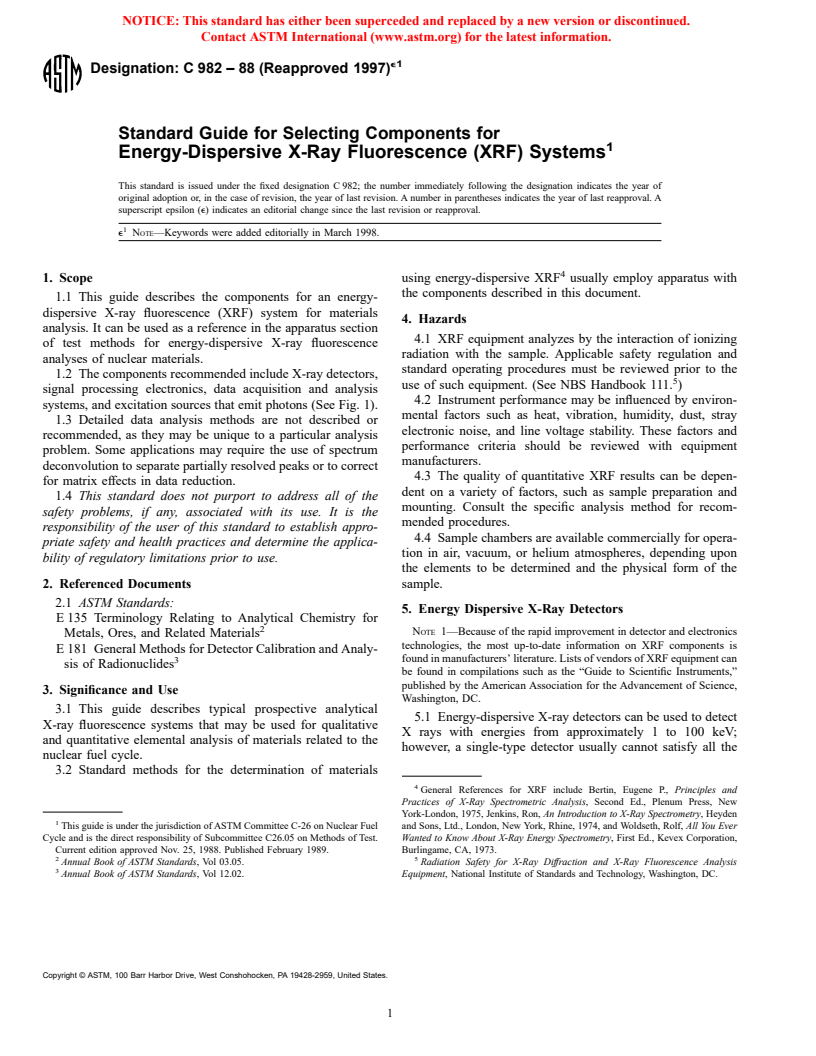

1.2 The components recommended include X-ray detectors, signal processing electronics, data acquisition and analysis systems, and excitation sources that emit photons (See Fig. 1).

1.3 Detailed data analysis methods are not described or recommended, as they may be unique to a particular analysis problem. Some applications may require the use of spectrum deconvolution to separate partially resolved peaks or to correct for matrix effects in data reduction.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 982 – 88 (Reapproved 1997)

Standard Guide for Selecting Components for

Energy-Dispersive X-Ray Fluorescence (XRF) Systems

This standard is issued under the fixed designation C 982; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in March 1998.

1. Scope using energy-dispersive XRF usually employ apparatus with

the components described in this document.

1.1 This guide describes the components for an energy-

dispersive X-ray fluorescence (XRF) system for materials

4. Hazards

analysis. It can be used as a reference in the apparatus section

4.1 XRF equipment analyzes by the interaction of ionizing

of test methods for energy-dispersive X-ray fluorescence

radiation with the sample. Applicable safety regulation and

analyses of nuclear materials.

standard operating procedures must be reviewed prior to the

1.2 The components recommended include X-ray detectors,

use of such equipment. (See NBS Handbook 111. )

signal processing electronics, data acquisition and analysis

4.2 Instrument performance may be influenced by environ-

systems, and excitation sources that emit photons (See Fig. 1).

mental factors such as heat, vibration, humidity, dust, stray

1.3 Detailed data analysis methods are not described or

electronic noise, and line voltage stability. These factors and

recommended, as they may be unique to a particular analysis

performance criteria should be reviewed with equipment

problem. Some applications may require the use of spectrum

manufacturers.

deconvolution to separate partially resolved peaks or to correct

4.3 The quality of quantitative XRF results can be depen-

for matrix effects in data reduction.

dent on a variety of factors, such as sample preparation and

1.4 This standard does not purport to address all of the

mounting. Consult the specific analysis method for recom-

safety problems, if any, associated with its use. It is the

mended procedures.

responsibility of the user of this standard to establish appro-

4.4 Sample chambers are available commercially for opera-

priate safety and health practices and determine the applica-

tion in air, vacuum, or helium atmospheres, depending upon

bility of regulatory limitations prior to use.

the elements to be determined and the physical form of the

2. Referenced Documents sample.

2.1 ASTM Standards:

5. Energy Dispersive X-Ray Detectors

E 135 Terminology Relating to Analytical Chemistry for

NOTE 1—Because of the rapid improvement in detector and electronics

Metals, Ores, and Related Materials

technologies, the most up-to-date information on XRF components is

E 181 General Methods for Detector Calibration and Analy-

found in manufacturers’ literature. Lists of vendors of XRF equipment can

sis of Radionuclides

be found in compilations such as the “Guide to Scientific Instruments,”

published by the American Association for the Advancement of Science,

3. Significance and Use

Washington, DC.

3.1 This guide describes typical prospective analytical

5.1 Energy-dispersive X-ray detectors can be used to detect

X-ray fluorescence systems that may be used for qualitative

X rays with energies from approximately 1 to 100 keV;

and quantitative elemental analysis of materials related to the

however, a single-type detector usually cannot satisfy all the

nuclear fuel cycle.

3.2 Standard methods for the determination of materials

General References for XRF include Bertin, Eugene P., Principles and

Practices of X-Ray Spectrometric Analysis, Second Ed., Plenum Press, New

York-London, 1975, Jenkins, Ron, An Introduction to X-Ray Spectrometry, Heyden

This guide is under the jurisdiction of ASTM Committee C-26 on Nuclear Fuel and Sons, Ltd., London, New York, Rhine, 1974, and Woldseth, Rolf, All You Ever

Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of Test. Wanted to Know About X-Ray Energy Spectrometry, First Ed., Kevex Corporation,

Current edition approved Nov. 25, 1988. Published February 1989. Burlingame, CA, 1973.

2 5

Annual Book of ASTM Standards, Vol 03.05. Radiation Safety for X-Ray Diffraction and X-Ray Fluorescence Analysis

Annual Book of ASTM Standards, Vol 12.02. Equipment, National Institute of Standards and Technology, Washington, DC.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 982

Reprinted by permission of Kevex Corporation, Burlingame, CA.

FIG. 1 Function Block Diagram of XES System

requirements of efficiency and energy resolution over such a proportional counters, may be used in certain applications in

wide energy range. which the high resolution of the semiconductor detectors is not

5.2 The energy resolution (Terminology E 135) of a detector required.

is usually specified by the FWHM (full width at half maxi- 5.6 All types of X-ray detectors have entrance windows of

mum) of the full energy peak of an X ray (or g ray) of a a low-Z material (for example, Be on solid-state detectors or

particular energy and at a specified count rate. The FWTM (full plastic film on gas-filled counters) to minimize X-ray absorp-

width at one-tenth maximum) of the full-energy peak or the tion.

peak-to-background ratio, or both, may also be specified.

6. Signal Processing Electronics

“High resolution” (small values of FWHM) detectors are

6.1 The bias power supply required to operate X-ray detec-

required to separate X rays of similar energy emitted by

different elements. tors must be capable of delivering sufficient high voltage and

5.3 The dimension of the detector “active volume” is current for the particular detector. The power shall be regulated

usually specified for X-ray detection applications, allowing the and have ripple and noise content below the 10-mV level.

efficiency of the device for detecting a particular energy X ray 6.2 A preamplifier converts the charge pulse caused by an

to be estimated. ionizing event in the detector to a voltage signal. It must also

5.4 XRF analysis systems requiring high-resolution detec- minimize electronic noise that would degrade the spectrum

tors employ semiconductor (“solid state”) detectors. resolution. The preamplifier is typically charge sensitive and

5.4.1 Lithium-drifted silicon, Si(Li), detectors are usually uses a field-effect transistor. The noise content, gain, and

used for applications requiring the detection of X rays from 1 count-rate capability must be compatible with the particular

to 40 keV. Si(Li) resolution is commonly specified at 5.9 keV detector and application. “Resistive feedback” and “pulsed-

and 1000 cps. Resolutions of 145 to 160 eV (FWHM) are optical feedback” are two types of preamplifier techniques

typical. suitable for high-resolution spectroscopy. The preamplifier is

5.4.2 Germanium, Ge, detectors or lithium-drifted germa- usually supplied as an integral part of the detector, and the

nium, Ge(Li), detectors are usually employed to detect X rays detector manufacturer should be consulted to determine a

in the high-energy region of the X-ray spectrum. Ge resolution suitable preamplifier.

is commonly specified at 122 keV and 1000 cps when the 6.3 A shaping amplifier is used to integrate the preamplifier

detector is to be used for X-ray detection. Resolutions of 500 pulse for a well-defined duration, differentiate the pulse to

eV (FWHM) are typical. provide an acceptable shape, and amplify the pulse to an

appropriate voltage. Typical shaping times vary from 1 to 40 μs

5.4.3 Both Ge(Li) and Si(Li) detectors must be operated at

77°K (liquid nitrogen temperature). Si(Li) detectors can be depending on the detector count rate and the required energy

resolution. Amplifier outputs are approximately ten volts maxi-

stored at room temperature. Germanium detectors must be

stored at 77°K (Standard E 181). mum. The amplification factor is variable so that the output

5.4.4 Improvements in technology can extend the useful pulse height spectrum corresponds to the desired range of

energy range of a particular detector type or result in the X-ray energies. Most shaping amplifiers provide power to the

development of new detector materials. Manufacturers should preamplifier. High-resolution amplifiers are equipped with

be consulted for the latest information. adjustments for signal shaping to optimize the resolution at a

5.5 Scintillation detectors such as NaI(T1), or gas-filled given rate. Some high-resolution amplifiers are equipped with

N

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.