ASTM D7085-04(2018)

(Guide)Standard Guide for Determination of Chemical Elements in Fluid Catalytic Cracking Catalysts by X-ray Fluorescence Spectrometry (XRF)

Standard Guide for Determination of Chemical Elements in Fluid Catalytic Cracking Catalysts by X-ray Fluorescence Spectrometry (XRF)

SIGNIFICANCE AND USE

4.1 The chemical composition of fresh FCC catalyst and equilibrium FCC catalyst is a predictor of catalyst performance. The analysis of catalyst fines also provides information on the performance of the FCC unit and the fines collection device(s).

4.2 The chemical composition of equilibrium FCC catalyst is a measure of the hazardous nature or toxicity of the material for purposes of disposal or secondary use.

SCOPE

1.1 This guide covers several comparable procedures for the quantitative chemical analysis of up to 29 elements in fluid catalytic cracking (FCC) catalyst by X-ray fluorescence spectrometry (XRF). Additional elements may be added.

1.2 This guide is applicable to fresh FCC catalyst, equilibrium FCC catalyst, spent FCC catalyst, and FCC catalyst fines.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3.1 The units of ppm (mg/kg) are used instead of wt% in Tables X2.3-X2.5 for reporting concentration of certain elements because of industry convention and because most of these elements are present at trace levels.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7085 − 04 (Reapproved 2018)

Standard Guide for

Determination of Chemical Elements in Fluid Catalytic

Cracking Catalysts by X-ray Fluorescence Spectrometry

(XRF)

This standard is issued under the fixed designation D7085; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Dispersive X-Ray Fluorescence (XRF) Systems (With-

drawn 2008)

1.1 Thisguidecoversseveralcomparableproceduresforthe

C1118 Guide for Selecting Components for Wavelength-

quantitative chemical analysis of up to 29 elements in fluid

Dispersive X-Ray Fluorescence (XRF) Systems (With-

catalytic cracking (FCC) catalyst by X-ray fluorescence spec-

drawn 2011)

trometry (XRF). Additional elements may be added.

D1977 Test Method for Nickel and Vanadium in FCC

1.2 This guide is applicable to fresh FCC catalyst, equilib- Equilibrium Catalysts by Hydrofluoric/Sulfuric Acid De-

composition and Atomic Spectroscopic Analysis

rium FCC catalyst, spent FCC catalyst, and FCC catalyst fines.

E1172 Practice for Describing and Specifying a Wavelength

1.3 The values stated in SI units are to be regarded as

Dispersive X-Ray Spectrometer

standard. No other units of measurement are included in this

E1361 Guide for Correction of Interelement Effects in

standard.

X-Ray Spectrometric Analysis

1.3.1 The units of ppm (mg/kg) are used instead of wt% in

E1621 Guide for ElementalAnalysis by Wavelength Disper-

Tables X2.3-X2.5 for reporting concentration of certain ele-

sive X-Ray Fluorescence Spectrometry

ments because of industry convention and because most of

E1622 Practice for Correction of Spectral Line Overlap in

these elements are present at trace levels.

Wavelength-Dispersive X-Ray Spectrometry (Withdrawn

2006)

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Summary of Guide

responsibility of the user of this standard to establish appro-

3.1 The test specimen is prepared with a clean, uniform, flat

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. surface. Two commonly used test methods of preparing test

specimens are listed: briquetting a powder (Test Method A,

1.5 This international standard was developed in accor-

Sections8–15) and fusing a powder into a glass bead (Test

dance with internationally recognized principles on standard-

Method B, Sections16–23). This surface of the fused or

ization established in the Decision on Principles for the

briquetted specimen is irradiated with a primary source of X

Development of International Standards, Guides and Recom-

rays. The secondary X rays produced in the specimen are

mendations issued by the World Trade Organization Technical

characteristic of the chemical elements present in the speci-

Barriers to Trade (TBT) Committee.

men.TwotypesofXRFinstrumentationmaybeusedtocollect

and process the X-ray spectra. Using a wavelength-dispersive

2. Referenced Documents

X-ray spectrometer, the secondary X rays produced in the

2.1 ASTM Standards:

specimen are dispersed according to their wavelength by

C982 Guide for Selecting Components for Energy-

means of crystals or synthetic multilayers. The X-ray intensi-

ties are measured by detectors set at selected wavelengths and

recorded as counts (number of X rays impinging on the

detector per unit time). Concentrations of the elements are

This guide is under the jurisdiction ofASTM Committee D32 on Catalysts and

is the direct responsibility of Subcommittee D32.03 on Chemical Composition.

determined from the measured intensities using calibration

Current edition approved Nov. 1, 2018. Published December 2018. Originally

curves prepared from suitable reference materials. Using an

ɛ1

approved in 2004. Last previous edition approved in 2010 as D7085 – 04(2010) .

energy-dispersive X-ray spectrometer, the secondary X rays

DOI:10.1520/D7085-04R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7085 − 04 (2018)

producedinthespecimenaresenttoadetectorwheretheentire 6.1.2 Non-Wetting Agents, such as lithium or ammonium

X-ray spectrum is electronically sorted according to the X-ray iodide, are frequently added to the flux, as are oxidizing agents

energy and processed into counts using a multichannel ana- such as lithium, potassium, or ammonium nitrate. Take care

lyzer. The principal advantages of the wavelength-dispersive that adding non-wetting or oxidizing reagents does not cause

X-ray spectrometer are resolution and detection limit. The spectral interference with the analytes of interest.

principal advantages of the energy-dispersive X-ray spectrom-

6.2 Reagents for Pressed Pellet Techniques:

eter are speed and a generally lower equipment cost.

6.2.1 Heavy Absorber, barium or hafnium oxides are com-

monly used as heavy absorbers, if that technique is applied.

4. Significance and Use

6.2.2 Binders, required for the pressed powder technique.

4.1 The chemical composition of fresh FCC catalyst and

These should not contribute any spectral interference. Micro-

equilibrium FCC catalyst is a predictor of catalyst perfor-

crystalline wax or cellulose with negligible levels of sodium or

mance.The analysis of catalyst fines also provides information

potassium are suitable.

on the performance of the FCC unit and the fines collection

6.3 Detector Gas, for a wavelength dispersive system. The

device(s).

typical gas for the flow-proportional counter is P-10: 10 %

4.2 The chemical composition of equilibrium FCC catalyst

methane and 90 % argon.

is a measure of the hazardous nature or toxicity of the material

6.4 2-propanol, ACS reagent grade.

for purposes of disposal or secondary use.

6.5 Calibration References, commercially available stan-

5. Apparatus

dard or certified reference materials or locally prepared mix-

tures from ultra high purity materials that include the elements

5.1 X-ray Spectrometer, wavelength or energy-dispersive

of interest in the concentration ranges expected in unknown

system equipped with a vacuum sample chamber. Refer to

samples.

Guide C982, Guide C1118, and Practice E1172 for information

on specifying XRF systems.

6.6 Standard Solutions, 10 000 µg⁄mL of nickel and

10 000 µg⁄mL of vanadium.

5.2 Muffle Furnace, capable of operating at 600 °C.

5.3 Hot Plate, capable of maintaining a constant 200 °C.

7. Procedure

5.4 Porcelain Dishes, of a suitable size for calcining 50-g

7.1 Prepare specimens using either a pressed powder or a

sample aliquots.

fusion technique.

5.5 Vacuum Oven, capable of maintaining 60 °C. This is

7.2 Prepare calibration standards using the same techniques

required only if catalyst fines are to be analyzed.

and reagents that will be used with the unknown samples.

5.6 Vacuum Desiccators, useful for storing fusion beads or

7.2.1 Calibration standards can be prepared from previously

pressed pellets.

analyzed samples where the accuracy and precision of the

5.7 Fusion Equipment:

analysisisknown.Thisisthetypicalcalibrationmethodforthe

5.7.1 Fusion Furnace or Fluxing Device, capable of oper- pressed powder technique. Up to 100 analyzed standards may

ating at 1100 °C.

be required for a full range calibration for 29 elements using

5.7.2 Fusion Crucibles and Molds, graphite or plati- the pressed powder technique.

num–5 % gold alloy, sized to match the specimen holder of the

7.2.2 Synthetic standards can be prepared from reagent-

X-ray spectrometer.

grade chemicals, analyzed samples, and certified reference

materials. This is the typical calibration method for the fusion

5.8 Pressed Pellet Equipment:

technique.

5.8.1 Grinders or Pulverizers, manual (such as agate,

mullite,alumina,tungstencarbide,orboroncarbidemortarand

7.3 Several tables, listed in Appendix X1, provide operating

pestle)orautomated(typicallywithatungstencarbidegrinding

information on the requirements necessary to establish a

vessel). Avoid steel grinding vessels.

pressed powder method for 29 elements in equilibrium FCC

5.8.2 Mixer Mill, useful for blending ground sample and

catalyst.

binder prior to preparing a pressed powder specimen.

5.8.3 Mixing Vials, sized to match the mixer mill.

TEST METHODS

5.8.4 Briquetting Press, capable of maintaining a reproduc-

ible pressure of at least 25 000 psi. This is required only if the

Test Method A—Pressed Powder

pressed powder method is utilized. Match mold size to the

specimenholderoftheX-rayspectrometer.Typicalsizesare25

8. Scope

to 40 mm.

8.1 A test method example is provided for the analysis of

nickel and vanadium in equilibrium FCC catalyst using either

6. Reagents

a wavelength or an energy-dispersive X-ray spectrometer and

6.1 Reagents for Fusion Techniques:

test specimens prepared by the pressed pellet technique.

6.1.1 Fluxes, lithium borates or carbonates or mixtures, of

ultrahigh purity. 8.2 This technique can be extended to other elements.

D7085 − 04 (2018)

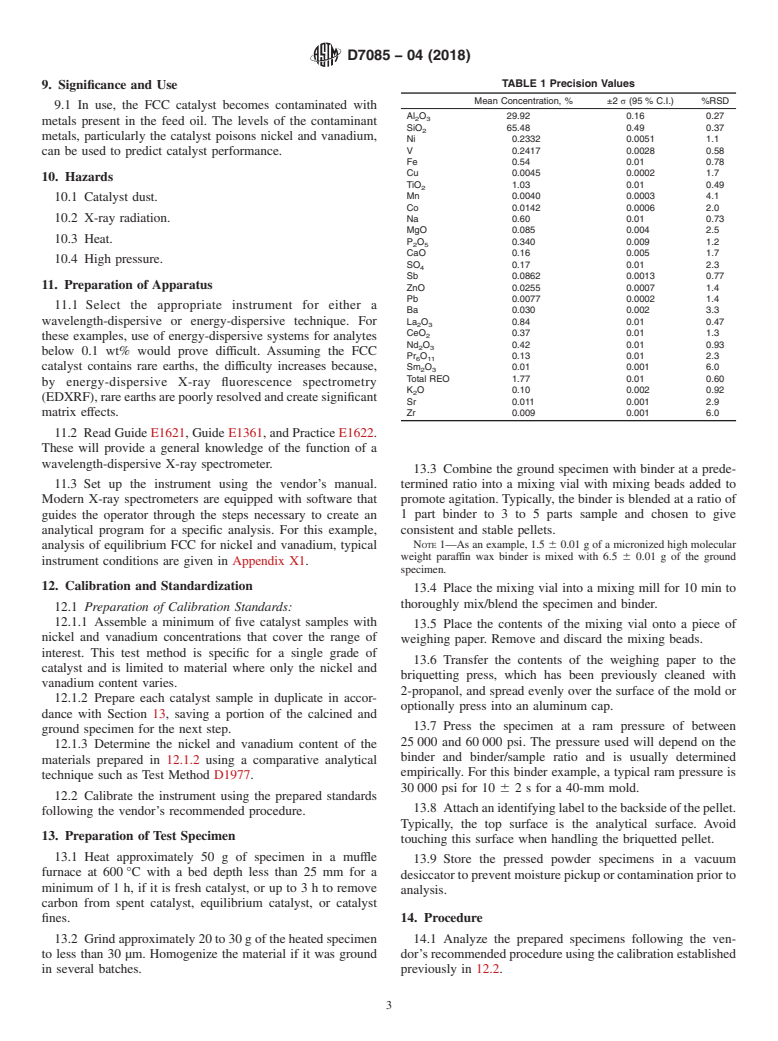

TABLE 1 Precision Values

9. Significance and Use

Mean Concentration, % ±2 σ (95 % C.I.) %RSD

9.1 In use, the FCC catalyst becomes contaminated with

Al O 29.92 0.16 0.27

2 3

metals present in the feed oil. The levels of the contaminant

SiO 65.48 0.49 0.37

metals, particularly the catalyst poisons nickel and vanadium,

Ni 0.2332 0.0051 1.1

V 0.2417 0.0028 0.58

can be used to predict catalyst performance.

Fe 0.54 0.01 0.78

Cu 0.0045 0.0002 1.7

10. Hazards

TiO 1.03 0.01 0.49

Mn 0.0040 0.0003 4.1

10.1 Catalyst dust.

Co 0.0142 0.0006 2.0

10.2 X-ray radiation. Na 0.60 0.01 0.73

MgO 0.085 0.004 2.5

10.3 Heat.

P O 0.340 0.009 1.2

2 5

CaO 0.16 0.005 1.7

10.4 High pressure.

SO 0.17 0.01 2.3

Sb 0.0862 0.0013 0.77

11. Preparation of Apparatus

ZnO 0.0255 0.0007 1.4

Pb 0.0077 0.0002 1.4

11.1 Select the appropriate instrument for either a

Ba 0.030 0.002 3.3

wavelength-dispersive or energy-dispersive technique. For La O 0.84 0.01 0.47

2 3

CeO 0.37 0.01 1.3

these examples, use of energy-dispersive systems for analytes

Nd O 0.42 0.01 0.93

2 3

below 0.1 wt% would prove difficult. Assuming the FCC

Pr O 0.13 0.01 2.3

6 11

catalyst contains rare earths, the difficulty increases because, Sm O 0.01 0.001 6.0

2 3

Total REO 1.77 0.01 0.60

by energy-dispersive X-ray fluorescence spectrometry

K O 0.10 0.002 0.92

(EDXRF),rareearthsarepoorlyresolvedandcreatesignificant

Sr 0.011 0.001 2.9

matrix effects. Zr 0.009 0.001 6.0

11.2 Read Guide E1621, Guide E1361, and Practice E1622.

These will provide a general knowledge of the function of a

wavelength-dispersive X-ray spectrometer.

13.3 Combine the ground specimen with binder at a prede-

11.3 Set up the instrument using the vendor’s manual. termined ratio into a mixing vial with mixing beads added to

promote agitation. Typically, the binder is blended at a ratio of

Modern X-ray spectrometers are equipped with software that

guides the operator through the steps necessary to create an 1 part binder to 3 to 5 parts sample and chosen to give

consistent and stable pellets.

analytical program for a specific analysis. For this example,

NOTE 1—As an example, 1.5 6 0.01 g of a micronized high molecular

analysis of equilibrium FCC for nickel and vanadium, typical

weight paraffin wax binder is mixed with 6.5 6 0.01 g of the ground

instrument conditions are given in Appendix X1.

specimen.

12. Calibration and Standardization

13.4 Place the mixing vial into a mixing mill for 10 min to

thoroughly mix/blend the specimen and binder.

12.1 Preparation of Calibration Standards:

12.1.1 Assemble a minimum of five catalyst samples with

13.5 Place the contents of the mixing vial onto a piece of

nickel and vanadium concentrations that cover the range of

weighing paper. Remove and discard the mixing beads.

interest. This test method is specific for a single grade of

13.6 Transfer the contents of the weighing paper to the

catalyst and is limited to material where only the nickel and

briquetting press, which has been previously cleaned with

vanadium content varies.

2-propanol, and spread evenly over the surface of the mold or

12.1.2 Prepare each catalyst sample in duplicate in accor-

optionally press into an aluminum cap.

dance with Section 13, saving a portion of the calcined and

13.7 Press the specimen at a ram pressure of between

ground specimen for the next step.

25 000 and 60 000 psi. The pressure used will depend on the

12.1.3 Determine the nickel and vanadium content of the

binder and binder/sample ratio and is usually determined

materials prepared in 12.1.2 using a comparative analytical

empirically. For this binder example, a typical ram pressure is

technique such as Test Method D1977.

30 000 psi for 10 6 2 s for a 40-mm mold.

12.2 Calibrate the instrument using the prepared standards

13.8 Attachanidentifyinglabeltothebacksideofthepellet.

following the vendor’s recommended procedure.

Typically, the top surface is the analytical surface. Avoid

13. Preparation of Test Specimen

touching this surface when handling the briquetted pellet.

13.1 Heat approximately 50 g of specimen in a muffle

13.9 Store the pressed powder specimens in a vacuum

furnace at 600 °C with a bed depth less than 25 mm for a

desiccatortopreventmoisturepickuporcontaminationpriorto

minimum of 1 h, if it is fresh catalyst, or up to3hto remove

analysis.

carbon from spent catalyst, equilibrium catalyst, or catalyst

fines. 14. Procedure

13.2 Grind approximately 20 to 30 g of the heated specimen 14.1 Analyze the prepared specimens following the ven-

to less than 30 µm. Homogenize the material if it was ground dor’srecommendedprocedureusingthecalibrationestablished

in several batches. previously in 12.2.

D7085 − 04 (2018)

15. Precision and Bias 20.2.1 Obtain 50 g of the fresh FCC catalyst and heat at

600 °C with a bed depth less than 25 mm for at least 2 h in a

15.1 The precision values listed in Table 1 were obtained

muffle furnace. Cool and store in a desiccator.

from one sample of equilibrium FCC catalyst, prepared and

20.2.2 Prepare two standard solutions at 1000

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.