ASTM F2737-11(2021)

(Specification)Standard Specification for Corrugated High Density Polyethylene (HDPE) Water Quality Units

Standard Specification for Corrugated High Density Polyethylene (HDPE) Water Quality Units

SCOPE

1.1 This specification covers materials, structural design, physical dimensions and manufacturing requirements for monolithic or sectional corrugated high density polyethylene (HDPE) water quality units with volumes greater than or equal to 86 ft3 or 640 gal (2400 L).

1.2 The corrugated HDPE water quality units are placed as offline or inline treatment devices along storm drain pipe lines to remove total suspended solids (TSS), heavy metals and phosphorous. Typical sources of pollutants include construction activity, automotive transportation related wear and debris items, refuse, landscaping debris, agricultural activities, and other similar by-products.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

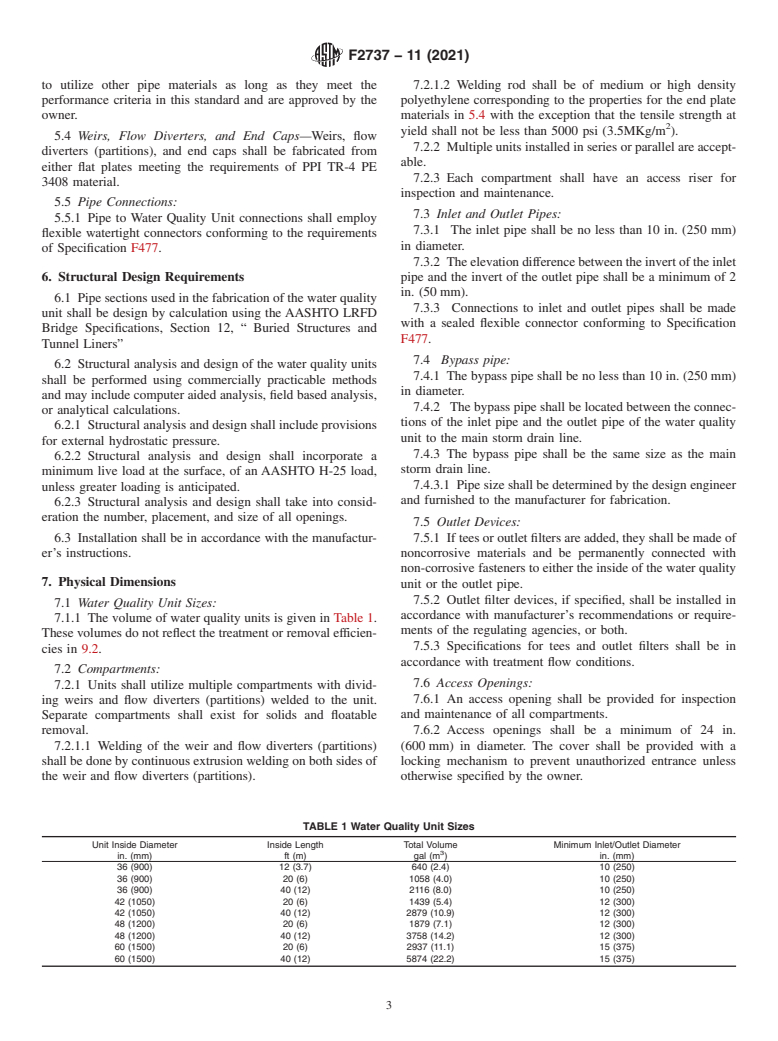

1.4 This specification covers horizontally laid corrugated HDPE water quality units as illustrated in Fig. 1.

FIG. 1 Horizontally Laid Corrugated HDPE Water Quality Units

HDPE water quality units contain three (3) chambers. A side inlet may be used in lieu of the end inlet and flow diverter when a full height longitudinal partition is constructed in the sediment chamber compartment to extend the particle travel length and isolate incoming flow from sediment build-up.

1.5 The following safety hazard caveat pertains only to the test methods portion, Section 9, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2737 −11 (Reapproved 2021) An American National Standard

Standard Specification for

Corrugated High Density Polyethylene (HDPE) Water Quality

1

Units

This standard is issued under the fixed designation F2737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers materials, structural design,

D1600 Terminology forAbbreviatedTerms Relating to Plas-

physical dimensions and manufacturing requirements for

tics

monolithic or sectional corrugated high density polyethylene

D3212 Specification for Joints for Drain and Sewer Plastic

(HDPE) water quality units with volumes greater than or equal

3 Pipes Using Flexible Elastomeric Seals

to 86 ft or 640 gal (2400 L).

D3350 Specification for Polyethylene Plastics Pipe and Fit-

1.2 The corrugated HDPE water quality units are placed as

tings Materials

offline or inline treatment devices along storm drain pipe lines

F412 Terminology Relating to Plastic Piping Systems

to remove total suspended solids (TSS), heavy metals and F477 Specification for Elastomeric Seals (Gaskets) for Join-

phosphorous. Typical sources of pollutants include construc- ing Plastic Pipe

F714 Specification for Polyethylene (PE) Plastic Pipe (DR-

tion activity, automotive transportation related wear and debris

PR) Based on Outside Diameter

items, refuse, landscaping debris, agricultural activities, and

F2306/F2306M Specification for 12 to 60 in. [300 to 1500

other similar by-products.

mm] Annular Corrugated Profile-Wall Polyethylene (PE)

1.3 The values stated in inch-pound units are to be regarded

Pipe and Fittings for Gravity-Flow Storm Sewer and

as standard. The values given in parentheses are mathematical

Subsurface Drainage Applications

conversions to SI units that are provided for information only 3

2.2 Plastic Pipe Institute:

and are not considered standard.

PPI TR-4 PPI Listing of Hydrostatic Design Basis (HDB),

Pressure Design Basis (PDB), and Minimum Required

1.4 This specification covers horizontally laid corrugated

Strength (MRS) Ratings for Thermoplastic Plastic Pipes

HDPE water quality units as illustrated in Fig. 1.

4

2.3 AASHTO Standard

1.5 The following safety hazard caveat pertains only to the

LDFD Bridge Design Specifications

test methods portion, Section 9, of this specification. This

standard does not purport to address all of the safety concerns,

3. Terminology

if any, associated with its use. It is the responsibility of the user

3.1 For definitions of terms relating to plastics, see Termi-

of this standard to establish appropriate safety, health, and

nology F412 and abbreviations are in accordance with Termi-

environmental practices and determine the applicability of

nology D1600, unless otherwise specified.

regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

1.6 This international standard was developed in accor-

3.2.1 access opening, n—a hole in the top or crown of the

dance with internationally recognized principles on standard-

water quality unit for access to the interior for inspection,

ization established in the Decision on Principles for the

cleaning and removing of sediment, hydrocarbons, floating

Development of International Standards, Guides and Recom-

debris, and pollutants without personnel entry.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic the ASTM website.

3

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

Based Pipe. Irving, TX 75062, http://www.plasticpipe.org.

4

Current edition approved July 1, 2021. Published August 2021. Originally Available from American Association of State Highway and Transportation

approved in 2010. Last previous edition approved in 2017 as F2737–11(2017). Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

DOI:10.1520/F2737–11R21. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.