ASTM B533-85(2004)

(Test Method)Standard Test Method for Peel Strength of Metal Electroplated Plastics

Standard Test Method for Peel Strength of Metal Electroplated Plastics

SIGNIFICANCE AND USE

The force required to separate a metallic coating from its plastic substrate is determined by the interaction of several factors: the generic type and quality of the plastic molding compound, the molding process, the process used to prepare the substrate for electroplating, and the thickness and mechanical properties of the metallic coating. By holding all others constant, the effect on the peel strength by a change in any one of the above listed factors may be noted. Routine use of the test in a production operation can detect changes in any of the above listed factors.

The peel test values do not directly correlate to the adhesion of metallic coatings on the actual product.

When the peel test is used to monitor the coating process, a large number of plaques should be molded at one time from a same batch of molding compound used in the production moldings to minimize the effects on the measurements of variations in the plastic and the molding process.

SCOPE

1.1 This test method gives two procedures for measuring the force required to peel a metallic coating from a plastic substrate. One procedure (Procedure A) utilizes a universal testing machine and yields reproducible measurements that can be used in research and development, in quality control and product acceptance, in the description of material and process characteristics, and in communications. The other procedure (Procedure B) utilizes an indicating force instrument that is less accurate and that is sensitive to operator technique. It is suitable for process control use.

1.2 The tests are performed on standard molded plaques. This method does not cover the testing of production electroplated parts.

1.3 The tests do not necessarily measure the adhesion of a metallic coating to a plastic substrate because in properly prepared test specimens, separation usually occurs in the plastic just beneath the coating-substrate interface rather than at the interface. It does, however, reflect the degree that the process is controlled.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Endorsed by American

Designation:B533–85 (Reapproved 2004) Electroplaters’ Society

Endorsed by National

Association of Metal Finishers

Standard Test Method for

Peel Strength of Metal Electroplated Plastics

This standard is issued under the fixed designation B533; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope coating. The coated plaque is either tested as is, or it is

conditioned by a low-temperature bake and then tested. The

1.1 Thistestmethodgivestwoproceduresformeasuringthe

coating is cut through to the plastic substrate in a way that

force required to peel a metallic coating from a plastic

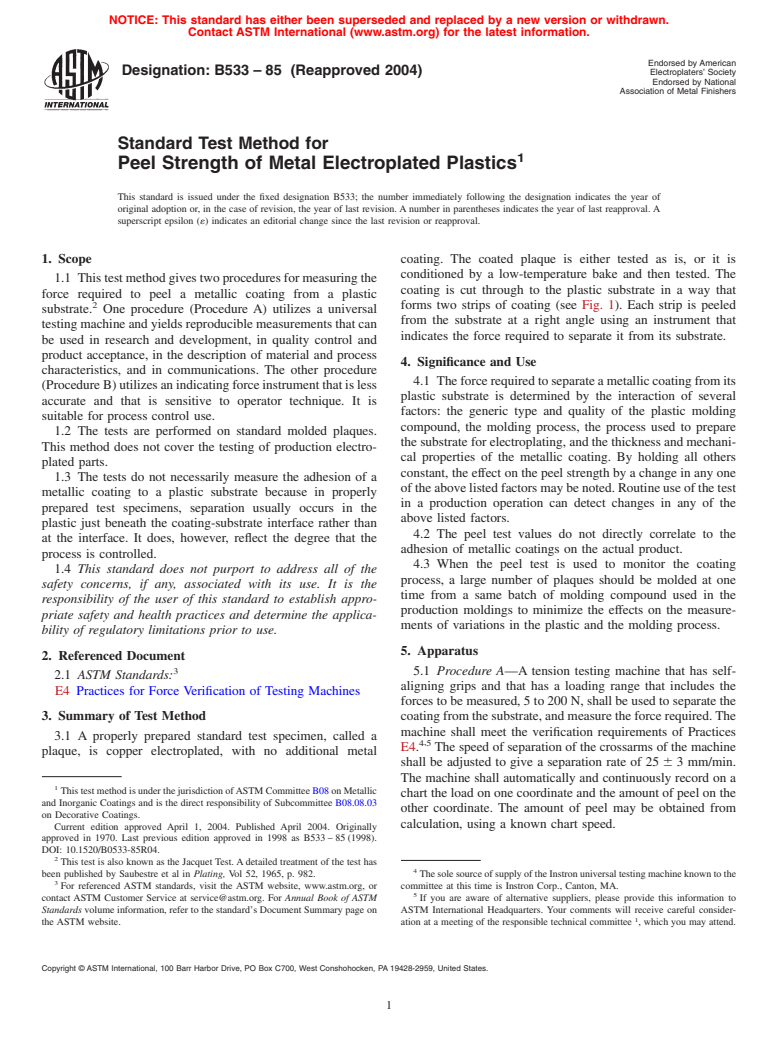

forms two strips of coating (see Fig. 1). Each strip is peeled

substrate. One procedure (Procedure A) utilizes a universal

from the substrate at a right angle using an instrument that

testingmachineandyieldsreproduciblemeasurementsthatcan

indicates the force required to separate it from its substrate.

be used in research and development, in quality control and

product acceptance, in the description of material and process

4. Significance and Use

characteristics, and in communications. The other procedure

4.1 Theforcerequiredtoseparateametalliccoatingfromits

(ProcedureB)utilizesanindicatingforceinstrumentthatisless

plastic substrate is determined by the interaction of several

accurate and that is sensitive to operator technique. It is

factors: the generic type and quality of the plastic molding

suitable for process control use.

compound, the molding process, the process used to prepare

1.2 The tests are performed on standard molded plaques.

the substrate for electroplating, and the thickness and mechani-

This method does not cover the testing of production electro-

cal properties of the metallic coating. By holding all others

plated parts.

constant, the effect on the peel strength by a change in any one

1.3 The tests do not necessarily measure the adhesion of a

oftheabovelistedfactorsmaybenoted.Routineuseofthetest

metallic coating to a plastic substrate because in properly

in a production operation can detect changes in any of the

prepared test specimens, separation usually occurs in the

above listed factors.

plastic just beneath the coating-substrate interface rather than

4.2 The peel test values do not directly correlate to the

at the interface. It does, however, reflect the degree that the

adhesion of metallic coatings on the actual product.

process is controlled.

4.3 When the peel test is used to monitor the coating

1.4 This standard does not purport to address all of the

process, a large number of plaques should be molded at one

safety concerns, if any, associated with its use. It is the

time from a same batch of molding compound used in the

responsibility of the user of this standard to establish appro-

production moldings to minimize the effects on the measure-

priate safety and health practices and determine the applica-

ments of variations in the plastic and the molding process.

bility of regulatory limitations prior to use.

5. Apparatus

2. Referenced Document

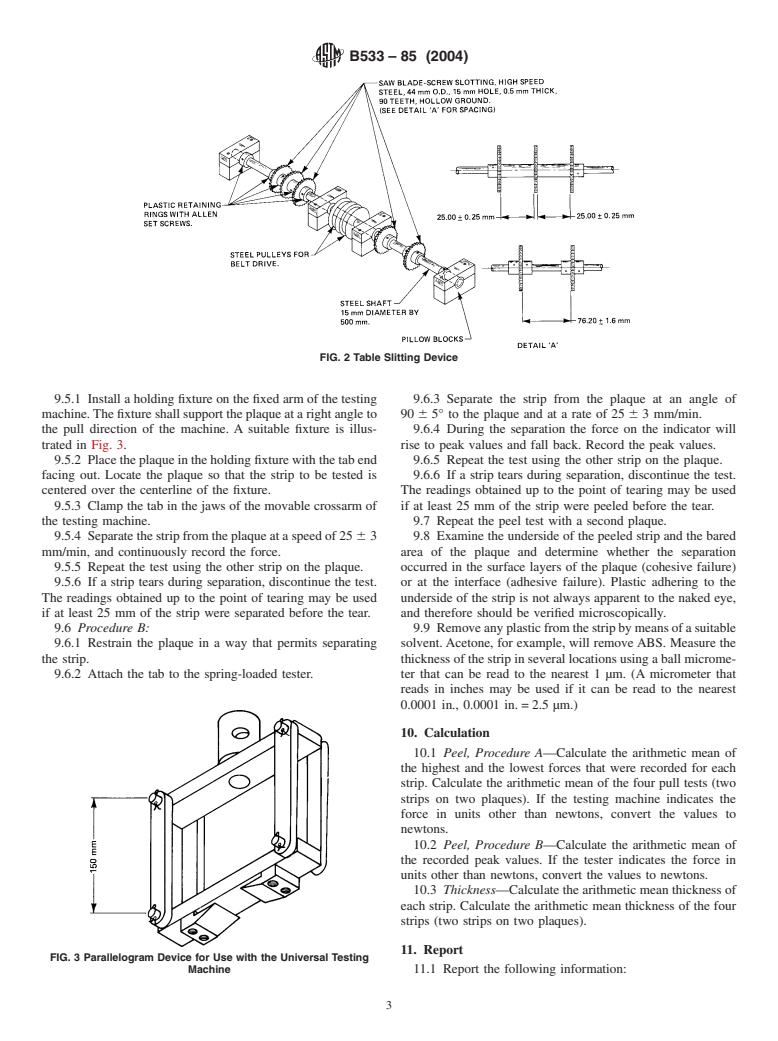

3 5.1 Procedure A—A tension testing machine that has self-

2.1 ASTM Standards:

aligning grips and that has a loading range that includes the

E4 Practices for Force Verification of Testing Machines

forces to be measured, 5 to 200 N, shall be used to separate the

3. Summary of Test Method coatingfromthesubstrate,andmeasuretheforcerequired.The

machine shall meet the verification requirements of Practices

3.1 A properly prepared standard test specimen, called a

,

4 5

E4. The speed of separation of the crossarms of the machine

plaque, is copper electroplated, with no additional metal

shall be adjusted to give a separation rate of 25 6 3 mm/min.

The machine shall automatically and continuously record on a

ThistestmethodisunderthejurisdictionofASTMCommitteeB08onMetallic

chart the load on one coordinate and the amount of peel on the

and Inorganic Coatings and is the direct responsibility of Subcommittee B08.08.03

other coordinate. The amount of peel may be obtained from

on Decorative Coatings.

calculation, using a known chart speed.

Current edition approved April 1, 2004. Published April 2004. Originally

approved in 1970. Last previous edition approved in 1998 as B533 – 85 (1998).

DOI: 10.1520/B0533-85R04.

This test is also known as the Jacquet Test.Adetailed treatment of the test has

been published by Saubestre et al in Plating, Vol 52, 1965, p. 982. The sole source of supply of the Instron universal testing machine known to the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or committee at this time is Instron Corp., Canton, MA.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM If you are aware of alternative suppliers, please provide this information to

Standards volume information, refer to the standard’s Document Summary page on ASTM International Headquarters. Your comments will receive careful consider-

the ASTM website. ation at a meeting of the responsible technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B533–85 (2004)

FIG. 1 Plaque

5.2 Procedure B—A spring-loaded, force-indicating instru- 9.2 Clean, activate, and electroplate the plaques as speci-

ment with a measurement range that includes the force to be fied. The thickness of the metallic coating in the test area (see

measured, 5 to 200 N, shall be used to measure the force Fig. 1) shall be 40 6 4 µm.

required to separate the coating. The indicated force shall be

NOTE 3—Itisnecessarytohaveaductilecoppercoatingtoperformthis

accurate to 610 %.

test. The thickness and uniformity of thickness of the metallic coating

directly influence the peel strength; therefore, in order to standardize this

6. Sampling

test, the coating thickness is specified. If a different coating thickness is

used, the results will not be comparable to other test results. It may be

6.1 A sampling procedure is not applicable to this test

necessary to use shielding during plating to obtain the required coating

method.

thickness uniformity.

9.3 Cut through the coating along the dashed lines shown in

7. Test Specimen

Fig. 1, and also along the centerline so as to produce two

7.1 Perform the test using a flat, molded plastic plaque such

parallel strips of coating that are 25.00 6 0.25 mm wide and

as shown in Fig. 1. Plaque dimensions may vary up to 610 %

approximately 75 mm long.

provided that the edges of slit peel strips are not closer than 11

mm from any plaque edge.

NOTE 4—Following are methods that can be used to cut the coating:

(a) Slit the coating with a milling machine equipped with a slitting

,

5 7

8. Conditioning

saw. Operate the saw at a peripheral speed of 300 mm/s and a feed of

5 mm/s.

8.1 Condition th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.