ASTM D6710-02(2012)

(Guide)Standard Guide for Evaluation of Hydrocarbon-Based Quench Oil

Standard Guide for Evaluation of Hydrocarbon-Based Quench Oil

SIGNIFICANCE AND USE

The significance and use of each test method will depend on the system in use and the purpose of the test method listed under Section 6. Use the most recent editions of the test methods.

SCOPE

1.1 This guide covers information without specific limits, for selecting standard test methods for testing hydrocarbon-based quench oils for quality and aging.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6710 − 02 (Reapproved 2012)

Standard Guide for

Evaluation of Hydrocarbon-Based Quench Oil

This standard is issued under the fixed designation D6710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ucts by Hydrometer Method

D4052Test Method for Density, Relative Density, and API

1.1 This guide covers information without specific limits,

Gravity of Liquids by Digital Density Meter

for selecting standard test methods for testing hydrocarbon-

D4530Test Method for Determination of Carbon Residue

based quench oils for quality and aging.

(Micro Method)

1.2 This standard does not purport to address all of the

D6200Test Method for Determination of Cooling Charac-

safety concerns, if any, associated with its use. It is the

teristics of Quench Oils by Cooling Curve Analysis

responsibility of the user of this standard to establish appro-

D6304Test Method for Determination of Water in Petro-

priate safety and health practices and determine the applica-

leum Products, Lubricating Oils, and Additives by Cou-

bility of regulatory limitations prior to its use.

lometric Karl Fischer Titration

2.2 ISO Standards:

2. Referenced Documents

ISO 9950Industrial Quenching Oils—Determination of

2.1 ASTM Standards:

Cooling Characteristics—Nickel-Alloy Probe Test

D91Test Method for Precipitation Number of Lubricating

Method, 1995-95-01

Oils

3. Terminology

D92Test Method for Flash and Fire Points by Cleveland

Open Cup Tester

3.1 Definitions of Terms Specific to This Standard:

D94Test Methods for Saponification Number of Petroleum

Products Quench Processing

D95Test Method for Water in Petroleum Products and 3.1.1 austenitization, n—heatingasteelcontaininglessthan

Bituminous Materials by Distillation the eutectoid concentration of carbon (about 0.8 mass %) to a

D189Test Method for Conradson Carbon Residue of Petro- temperaturejustabovetheeutectoidtemperaturetodecompose

leum Products the pearlite microstructure to produce a face-centered cubic

(fcc) austenite-ferrite mixture.

D445Test Method for Kinematic Viscosity of Transparent

andOpaqueLiquids(andCalculationofDynamicViscos-

3.1.2 dragout, n—solutioncarriedoutofabathonthemetal

ity)

being quenched and associated handling equipment.

D482Test Method for Ash from Petroleum Products

3.1.3 martempering, n—cooling steel from the austenitiza-

D524Test Method for Ramsbottom Carbon Residue of

tion temperature to a temperature just above the start of

Petroleum Products

mertensite transformation (M ) for a time sufficient for the

s

D664Test Method for Acid Number of Petroleum Products

temperature to equalize between the surface and the center of

by Potentiometric Titration

the steel, at which point the steel is removed from the quench

D974Test Method for Acid and Base Number by Color-

bath and air cooled as shown in Fig. 1. (1)

Indicator Titration

3.1.4 protective atmosphere, n—any atmosphere that will

D1298Test Method for Density, Relative Density, or API

inhibit oxidation of the metal surface during austenitization, or

Gravity of Crude Petroleum and Liquid Petroleum Prod-

it may be used to protect the quenching oil, which may be an

inert gas such as nitrogen or argon or a gas used for a heat

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

treating furnace.

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

3.1.5 quench media, n—any medium, either liquid (water,

mittee D02.L0.06 on Non-Lubricating Process Fluids.

Current edition approved April 15, 2012. Published May 2012. Originally

oil, molten salt, or lead, aqueous solutions of water-soluble

approved in 2001. Last previous edition approved in 2007 as D6710–02(2007).

DOI: 10.1520/D6710-02R12.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6710 − 02 (2012)

FIG. 1 (a) Conventional Quenching Cycle; (b) Martempering

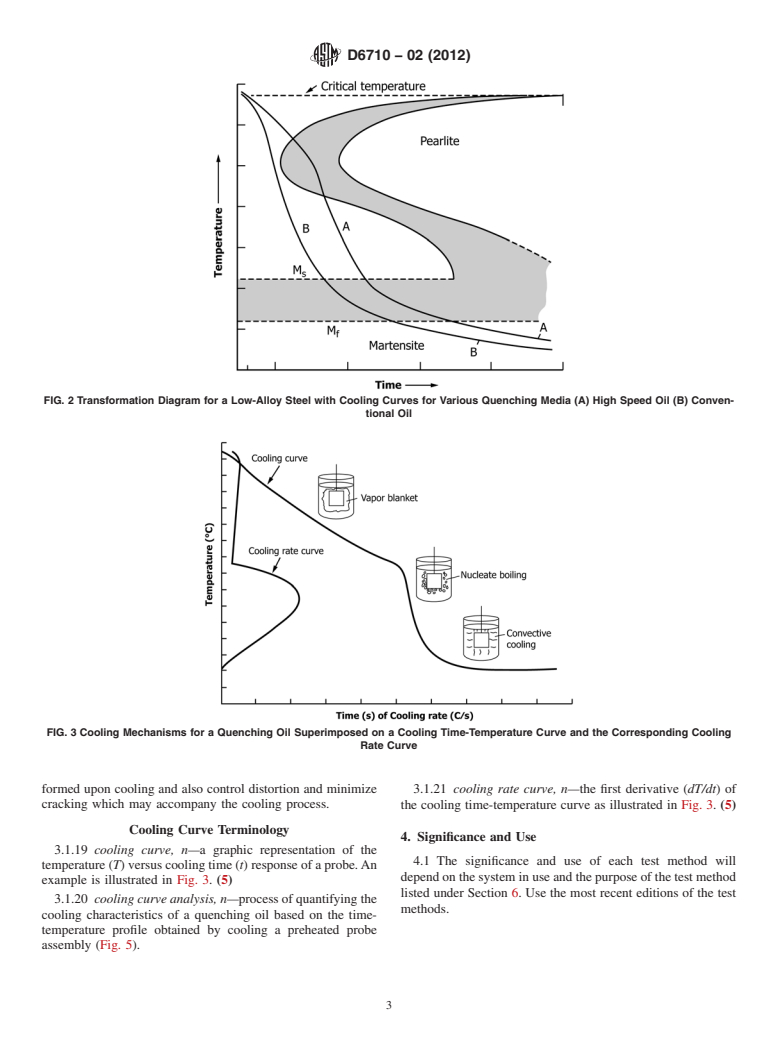

polymers or salt-brines) or gas or combinations of liquid and 3.1.12 nucleate boiling, n—upon continued cooling, the

gas (air at atmospheric pressure, or pressurized nitrogen, vapor blanket that initially forms around the hot metal col-

helium,hydrogen)suchasair-waterspray,usedtofacilitatethe lapses and a nucleate boiling process, the fastest cooling

cooling of metal in such a way as to achieve the desired portionofthequenchingprocess,occursasillustratedinFig.3.

physical properties or microstructure.

3.1.13 vapor blanket cooling, n—See full-film boiling

3.1.6 quench severity, n—the ability of a quenching oil to

(3.1.10).

extract heat from a hot metal traditionally defined by the

3.1.14 wettability, n—when a heated metal, such as the

quenching speed (cooling rate) at 1300°F (705°C) which was

probe illustrated in Fig. 5, is immersed into a quenching

related to a Grossmann H-Value or Quench Severity Factor

medium, the cooling process shown in Fig. 6 occurs by initial

(H-Factor).(2)

vapor blanket formation followed by collapse, at which point

3.1.7 quenching, n—cooling process from a suitable el-

the metal surface is wetted by the quenching medium. (4)

evated temperature used to facilitate the formation of the

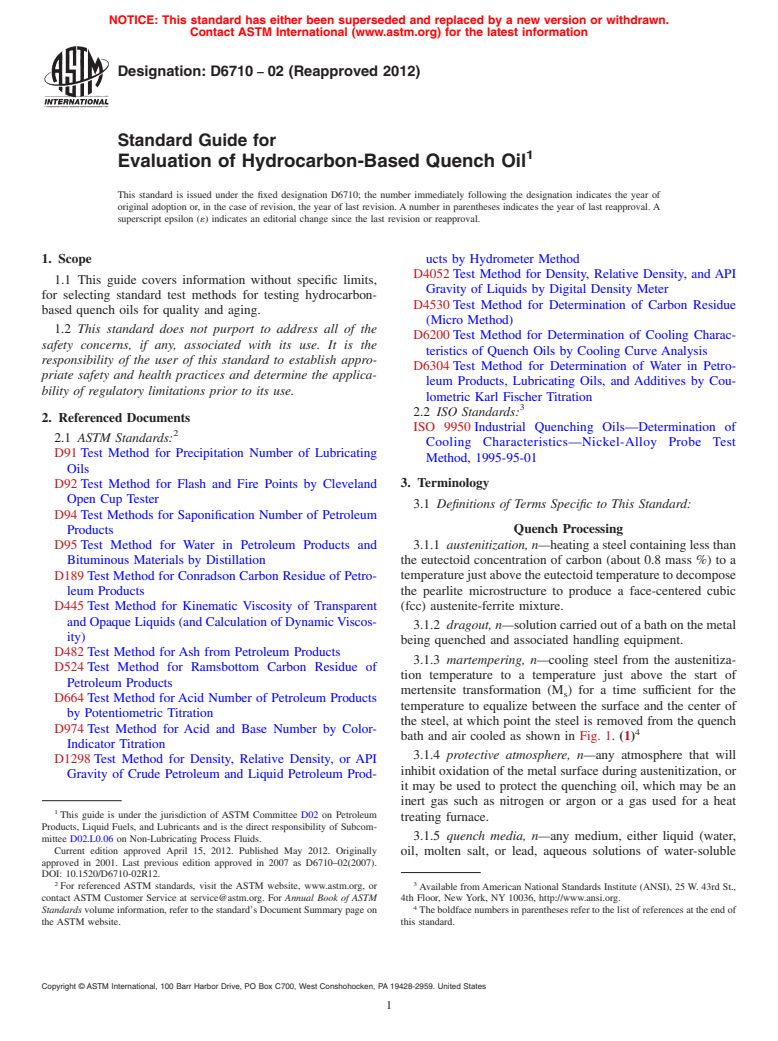

desired microstructure and properties of a metal as shown in Quench Oil Classification

Fig. 2.

3.1.15 accelerated quenching oil, n—also referred to as a

3.1.8 transformation temperature, n—characteristic tem-

fast or high-speed oil, these are oils that contain additions that

peratures that are important in the formation of martensitic

facilitate collapse of the vapor blanket surrounding the hot

microstructure as illustrated in Fig. 2;A – equilibrium

e metal immediately upon immersion into the quenching oil, as

austenitization phase change temperature; M – temperature at

s shown in Fig. 3.

which transformation of austenite to martensite starts during

3.1.16 conventional quenching oil, n—also called slow oils,

cooling; and M – temperature at which transformation of

f

these oils typically exhibit substantial film-boiling

austenite to martensite is completed during cooling.

characteristics, commonly referred to as vapor blanket cooling

Cooling Mechanisms due to relatively stable vapor blanket formation, illustrated

mechanistically in Fig. 2.

3.1.9 convective cooling, n—after continued cooling, the

interfacial temperature between the cooling metal surface and

3.1.17 marquenching oils, n—also referred to as mar-

the quenching oil will be less than the boiling point of the oil,

quenching oils or hot oils, these oils are typically used at

at which point cooling occurs by a convective cooling process

temperatures between 95 to 230°C (203 to 446°F) and are

as illustrated in Fig. 3.

usually formulated to optimize oxidative and thermal stability

by the addition of antioxidants and because they are used at

3.1.10 full-film boiling, n—upon initial immersion of hot

relatively high temperatures, a protective or non-oxidizing

steel into a quench oil, a vapor blanket surrounds the metal

environment is often employed, which permits much higher

surface as shown in Fig. 3. This is full-film boiling also

use temperatures than open-air conditions.

commonly called vapor blanket cooling.

3.1.11 Leidenfrost temperature, n—the characteristic tem- 3.1.18 quenching oil, n—although usually derived from a

perature where the transition from full-film boiling (vapor petroleum oil, they may also be derived from natural oils such

blanket cooling) to nucleate boiling occurs which is indepen- as vegetable oils or synthetic oils such as poly(alpha olefin).

dent of the initial temperature of the metal being quenched as They are used to mediate heat transfer from a heated metal,

illustrated in Fig. 4. (3) such as austenitized steel, to control the microstructure that is

D6710 − 02 (2012)

FIG. 2 Transformation Diagram for a Low-Alloy Steel with Cooling Curves for Various Quenching Media (A) High Speed Oil (B) Conven-

tional Oil

FIG. 3 Cooling Mechanisms for a Quenching Oil Superimposed on a Cooling Time-Temperature Curve and the Corresponding Cooling

Rate Curve

formed upon cooling and also control distortion and minimize 3.1.21 cooling rate curve, n—the first derivative (dT/dt)of

cracking which may accompany the cooling process.

the cooling time-temperature curve as illustrated in Fig. 3. (5)

Cooling Curve Terminology

4. Significance and Use

3.1.19 cooling curve, n—a graphic representation of the

4.1 The significance and use of each test method will

temperature(T)versuscoolingtime(t)responseofaprobe.An

dependonthesysteminuseandthepurposeofthetestmethod

example is illustrated in Fig. 3. (5)

listed under Section 6. Use the most recent editions of the test

3.1.20 cooling curve analysis, n—processofquantifyingthe

methods.

cooling characteristics of a quenching oil based on the time-

temperature profile obtained by cooling a preheated probe

assembly (Fig. 5).

D6710 − 02 (2012)

FIG. 4 Leidenfrost Temperature and its Independence of the Initial Temperature of the Metal Being Quenched

NOTE 1—Measurements are nominal. (From Test Method D6200.)

FIG. 5 Probe Details and Probe Assembly

5. Sampling 5.1.1.2 Sampling Position—For each system, the sample

shall be taken from the same position each time that system is

5.1 SamplingUniformity—Flowisneveruniforminagitated

sampled. The sample shall be taken at the point of maximum

quench tanks. There is always variation of flow rate and

flow turbulence. The position in the tank where the sample is

turbulence from top to bottom and across the tank.This means

taken shall be recorded.

that there may be significant variations of particulate contami-

5.1.1.3 Sampling Valves—If a sample is taken from a

nationincludingsludgefromoiloxidationandmetalscale.For

sampling valve, then sufficient quenching oil should be taken

uniform sampling, a number of sampling recommendations

and discarded to ensure that the sampling valve and associated

have been developed.

piping has been flushed, before the sample is taken.

5.1.1 Sampling Recommendations:

5.1.1.1 Minimum Sampling Time—The circulation pumps 5.1.1.4 Sampling From Tanks With No Agitation—If

shall be in operation for at least 1 h prior to taking a sample samplesaretobetakenfrombulkstoragetankoraquenchtank

from a quench system. withnoagitation,thensamplesshallbetakenfromthetopand

D6710 − 02 (2012)

FIG. 6 Actual Cooling Process and Movement of the Wetting Front on a Metal Surface During a Quenching Process

bottomofthebulksystemorquenchtank.Ifthisisnotpossible 40°C (104°F) for conventional or accelerated oils and also at

and the sample can only be taken from the top, then the 100°C (212°F) for martempering oils.

laboratory report shall state that the results represent a sample

6.1.2 Flash Point and Fire Point (Test Method D92)—Use

taken from the top of the bulk system or quench tank and may

of a quench oil in an open system with no protective atmo-

not be representative of the total system.

sphere shall be at least 60 to 65°C lower than its actual open

5.1.1.5 Effect of Quenching Oil Addition as Make-Up Due

cup flash point to minimize the potential for fire. General

to Dragout—It is important to determine the quantity and

guidelines have been developed for use-temperatures of a

frequency of new quenchant additions, as large additions of

quench oil relative to its flash point.

new quench oil will have an effect on the test results, in

NOTE 1—There are various manufacturer-dependent guidelines for

particular the cooling curve. If a sample was taken just after a

relating the suitability for use of a used quenching oil with respect to its

large addition of new quench oil, this shall be taken into

flash point and they shall be followed. In the absence of such guidelines,

consideration when interpreting the cooling curve of this oil

it is recommended that the use temperature of a quenching oil in an open

sample.

system with no protective atmosphere shall be more than 60 to 65°C (140

5.1.1.6 Sampling Containers—Samplesshallbecollectedin

to 149°F) below its actual open-cup flash point. In closed systems where

aprotectiveatmosphereisused,theusetemperatureoftheusedquenching

newcontainers.Undernocircumstancesshallusedbeverageor

oilshallbeatleast35°C(95°F)lowerthanitsactualopen-cupflashpoint.

food containers be used because of the potential for fluid

contamination and leakage.

6.1.3 Density (Test Methods D1298 and D4052)—The den-

sity of materials of similar volatility is dependent on the

6. Recommended Test Procedures

chemical composition, and in the case of quenching oils, the

type of basestock used in formulation. The oxidative stability

6.1 Performance-Related Physical and Chemical Proper-

ties: of quenching oils is also dependent on similar chemical

6.1.1 Kinematic Viscosity, (Test Method D445)—Theperfor- composition trends, and thus density (or relative density) is an

mance of a quench oil is dependent on its viscosity, which indirect indicator of oxidative stability. Density (or relative

varies with temperature and oil deterioration during continued density) is measured at, or converted to, a standard reference

temperature,normallyeither15°Cor60/60°F,andtheseshould

use. Increased oil viscosity typically results in decreased heat

transfer rates. (6) Oil viscosity varies with temperature which be quoted alongside the result.

affects heat transfer rates throughout the process.

6.1.3.1 Test Method D1298 uses a hydrometer plus ther-

6.1.1.1 The flow velocity of a quench oil depends on both

mometer for measurement while Test Method D4052 uses a

viscosityandtemperature.Somequenchoilsareusedathigher

digital density meter based on an oscillating U-tube.

temperatures, such as martempering oils, also known as

NOTE 2—Density or relative density are of limited value in the

hot-oils.Although the viscosity of a martempering oil may not

assessment of quality of a quenching oil.

fluctuate substantially at elevated temperatures, the oil may

become almost solid upon cooling. Thus, the viscosity- 6.2 Aged Fluid Properties

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.