ASTM E161-17

(Specification)Standard Specification for Electroformed Material and Test Sieves

Standard Specification for Electroformed Material and Test Sieves

ABSTRACT

This specification covers the requirements for design and construction of electroformed sieves. These sieves are used to perform particle-size distribution analysis and in preparing narrowly designated particle-size fractions. They may also be used as reference standards when suitably calibrated. The material used in the manufacture of the sieve sheet shall be nickel or a metal suitable for electrodeposition in a firm crystalline structure. The sheet shall have square or round openings with straight uniform sides and smooth, flat surfaces except for a slight bevel along the edges of the openings. Frames for precision electroformed sieves shall be made from non-corrosive material such as brass or stainless steel, and constructed in such a manner as to be rigid.

SCOPE

1.1 This specification covers the technical requirements for design and construction of electroformed sieves and sieve material. These sieves are used to perform particle-size analysis and in preparing narrowly designated particle -size fractions. They may also be used as reference standards when suitably certified. The method of certifying these sieves is included in Annex A1.

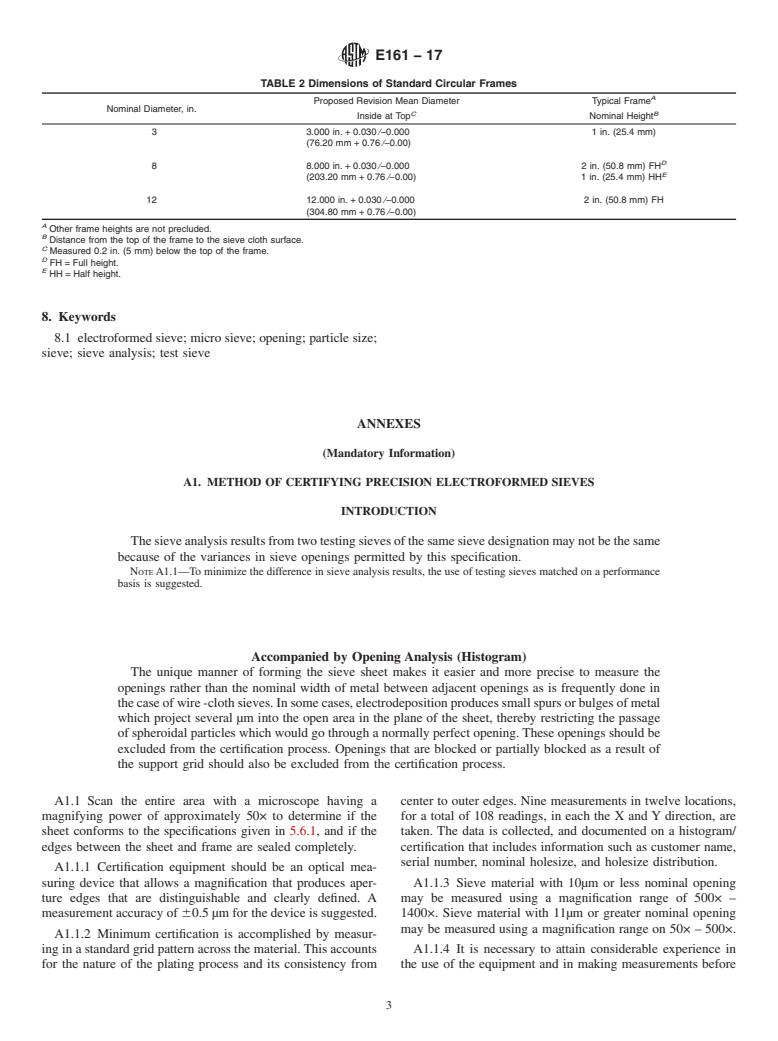

1.2 The values stated in SI units shall be considered standard for the dimensions of the electroformed mesh openings and the size of the line width in the electroformed mesh. The values stated in inch-pound units shall be considered standard with regard to the sieve frames and to lines per unit length, as in Table 1. The values given in parentheses are mathematical conversions that are provided for informational purposes only, and are not considered standard. (A) These nominal size openings are from the preferred number series R40/3 and R10. (Openings on apertures 32 μm and less are series R10.) These standard designations correspond to the values for test sieve apertures recommended by the International Organization for Standardization (ISO). These sizes are typical, other opening sizes are available.(B) Because of their greater durability in routine testing, sieves made close to the minimum limit are normally supplied. Sieves made close to the maximum limit may be obtained only on special order but are preferable from the standpoint of logical progression and better test completion time.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E161 −17

Standard Specification for

1

Electroformed Material and Test Sieves

This standard is issued under the fixed designation E161; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 45-µm (No. 325) Sieve

E11Specification forWovenWireTest Sieve Cloth andTest

1.1 This specification covers the technical requirements for

Sieves

design and construction of electroformed sieves and sieve

E323Specification for Perforated-Plate Sieves for Testing

material. These sieves are used to perform particle-size analy-

Purposes

sis and in preparing narrowly designated particle -size frac-

E1638Terminology Relating to Sieves, Sieving Methods,

tions. They may also be used as reference standards when

and Screening Media

suitably certified. The method of certifying these sieves is

included in Annex A1.

3. Terminology

1.2 The values stated in SI units shall be considered

3.1 Definitions—For definitions of related terms, refer to

standard for the dimensions of the electroformed mesh open-

Terminology E1638.

ings and the size of the line width in the electroformed mesh.

3.2 Definitions of Terms Specific to This Standard:

The values stated in inch-pound units shall be considered

3.2.1 electroformed material, n—electrodeposited grid ma-

standard with regard to the sieve frames and to lines per unit

terial consisting of precision openings used as the separation

length, as in Table 1. The values given in parentheses are

media for electroformed sieves.

mathematical conversions that are provided for informational

3.2.2 electroformed sieves, n—see test sieve (electro-

purposes only, and are not considered standard.

formed).

1.3 This standard does not purport to address all of the

3.2.3 non-standard frames (electroformed), n—sieveframes

safety concerns, if any, associated with its use. It is the

other than as specified in accordance with Table 2 that may be

responsibility of the user of this standard to establish appro-

circular, square, rectangular, or non-metal.

priate safety, health, and environmental practices and deter-

3.2.3.1 Discussion—Theframeshallhavetheelectroformed

mine the applicability of regulatory limitations prior to use.

material permanently attached.

1.4 This international standard was developed in accor-

3.2.4 support grid, n—conductive metal screen fused to the

dance with internationally recognized principles on standard-

sieve material.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.2.5 test sieve (electroformed), n—asievemanufacturedby

mendations issued by the World Trade Organization Technical

mounting electroformed material in a frame, designed for use

Barriers to Trade (TBT) Committee.

in particle size analysis by sieving.

4. Ordering Information

2. Referenced Documents

2

4.1 Orders for items under this specification include the

2.1 ASTM Standards:

following information as necessary:

C430Test Method for Fineness of Hydraulic Cement by the

4.1.1 Name of material (electroformed sieve or electro-

formed sieve material),

1 4.1.2 ASTM designation (Specification E161),

ThisspecificationisunderthejurisdictionofASTMCommitteeE29onParticle

and Spray Characterization and is the direct responsibility of Subcommittee E29.01

4.1.3 Quantity of each item, and

onSieves,SievingMethods,andScreeningMediaonSieves,SievingMethods,and

4.1.4 Standard sieve designation.

Screening Media.

4.1.4.1 Nominal opening size in micrometres (Table 1,

Current edition approved Dec. 15, 2017. Published January 2018. Originally

Column 1), and

approved in 1960. Last previous edition approved in 2012 as E161–12. DOI:

10.1520/E0161-17.

4.1.4.2 Aperture geometry.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.5 For testing sieves in standard circular frames:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.5.1 Nominal sieve frame diameter, and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.1.5.2 Nominal sieve frame height.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E161−17

TABLE 1 Sample Dimensions, Permissible Variations and Limits

5.6 Extraneous metal formed in or near the corners which

for Precision Electroformed Sieves

does not restrict the passage of a spheroidal particle shall be

Limits,

disregarded. Limitations on extraneous metal/repaired a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E161 − 12 E161 − 17

Standard Specification for

Precision Electroformed Electroformed Material and Test

1

Sieves

This standard is issued under the fixed designation E161; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

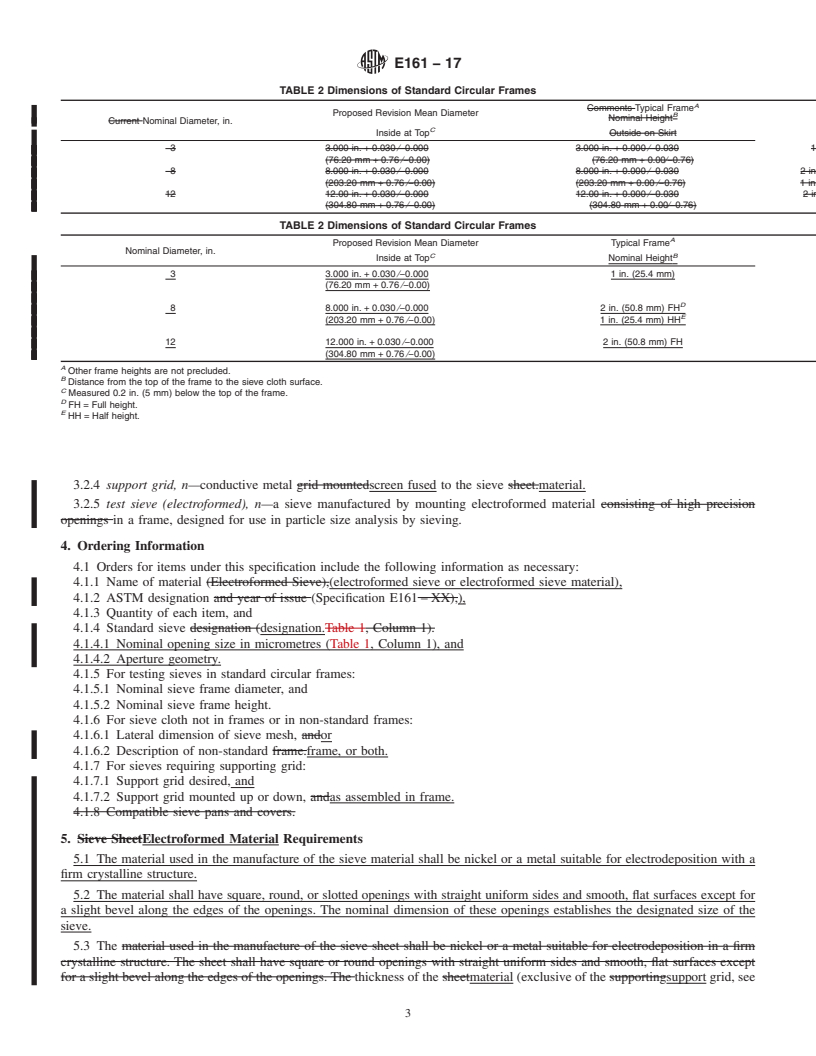

1.1 This specification covers the technical requirements for design and construction of electroformed sieves. sieves and sieve

material. These sieves are used to perform particle-size distribution analysis and in preparing narrowly designated particle-size

particle -size fractions. They may also be used as reference standards when suitably calibrated. Acertified. The method of

calibratingcertifying these sieves is included in Annex A1.

2

NOTE 1—Complete instructions and procedures on the use and calibration of testing sieves are contained in ASTM Manual 32. This publication also

contains a list of all published ASTM Standards on sieve analysis procedures for specific materials or industries.

1.2 The sieve analysis results from two testing sieves of the same sieve designation may not be the same because of the

variances in sieve opening permitted by this specification. To minimize the differences in sieve analysis results, the use of testing

sieves matched on a performance basis is suggested.

NOTE 2—For other types of sieves, see Specifications E11 and E323.

1.2 The values stated in SI units shall be considered standard for the dimensions of the electroformed mesh openings and the

size of the wires line width in the electroformed mesh. The values stated in inch-pound units shall be considered standard with

regard to the sieve frames.frames and to lines per unit length, as in Table 1. The values given in parentheses are mathematical

conversions that are provided for informational purposes only, and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C430 Test Method for Fineness of Hydraulic Cement by the 45-μm (No. 325) Sieve

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E323 Specification for Perforated-Plate Sieves for Testing Purposes

E1638 Terminology Relating to Sieves, Sieving Methods, and Screening Media

4

2.2 ISO Standard:

ISO 565 Test sieves—Metal Wire Cloth, Perforated Plate and Electroformed Sheet-Nominal Aperture Sizes

3. Terminology

3.1 Definitions—For definitions of related terms, refer to Terminology E1638.

3.2 Definitions of Terms Specific to This Standard:

1

This specification is under the jurisdiction of ASTM Committee E29 on Particle and Spray Characterization and is the direct responsibility of Subcommittee E29.01 on

Sieves, Sieving Methods, and Screening Media on Sieves, Sieving Methods, and Screening Media.

Current edition approved April 1, 2012Dec. 15, 2017. Published May 2012January 2018. Originally approved in 1960. Last previous edition approved in 20102012 as

E161 – 00 (2010).E161 – 12. DOI: 10.1520/E0161-12.10.1520/E0161-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E161 − 17

3.2.1 electroformed material, n—electrodeposited grid material consisting of precision openings used as the base materialsepa-

ration media for electroformed sieves.

3.2.2 electroformed sieves, n—see test sieve (electroformed).

3.2.3 non-standard frames (electroformed), n—sieve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.