ASTM D5780-95(2002)

(Test Method)Standard Test Method for Individual Piles in Permafrost Under Static Axial Compressive Load

Standard Test Method for Individual Piles in Permafrost Under Static Axial Compressive Load

SIGNIFICANCE AND USE

This test method will provide a relationship between time to failure, creep rate, and displacement to failure for specific failure loads at specific test temperatures as well as a relationship between creep rate and applied load at specific test temperatures for loads less than failure loads.

Pile design for specific soil temperatures may be controlled by either limiting long-term stress to below long-term strength or by limiting allowable settlement over the design life of the structure. It is the purpose of this test method to provide the basic information from which the limiting strength or long-term settlement may be evaluated by geotechnical engineers.

Data derived from pile tests at specific ground temperatures that differ from the design temperatures must be corrected to the design temperature by the use of data from additional pile tests, laboratory soil strength tests, or published correlations, if applicable, to provide a suitable means of correction.

For driven piles or grouted piles, failure will occur at the pile/soil interface. For slurried piles, failure can occur at either the pile/slurry interface or the slurry/soil interface, depending on the strength and deformation properties of the slurry material and the adfreeze bond strength. Location of the failure surface must be taken into account in the design of the test program and in the interpretation of the test results. Dynamic loads must be evaluated separately.

SCOPE

1.1 This test method covers procedures for testing individual vertical piles to determine response of the pile to static compressive load applied axially to the pile. This test method is applicable to all deep foundation units in permafrost that function in a manner similar to piles regardless of their method of installation. This test method is divided into the following sections: SectionReferenced Documents2 Terminology3 Significance and Use4 Installation of Test Piles5Apparatus for Applying Loads6Apparatus for Measuring Movements 7Safety Requirements8Loading Procedures9Standard Test Procedures10 Procedures for Measuring Pile Movements 11Report12 Precision and Bias13Keywords14

Note 1—Apparatus and procedures designated "optional" are to be required only when included in the project specifications or if not specified, may be used only with the approval of the engineer responsible for the foundation design. The word "shall" indicates a mandatory provision and "should" indicates a recommended or advisory provision. Imperative sentences indicate mandatory provisions. Notes, illustrations, and appendixes included herein are explanatory or advisory.

Note 2—This test method does not include the interpretation of test results or the application of test results to foundation design. See Appendix X1 for comments regarding some of the factors influencing the interpretation of test results. A qualified geotechnical engineer should interpret the test results for predicting pile performance and capacity.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D5780–95 (Reapproved 2002)

Standard Test Method for

Individual Piles in Permafrost Under Static Axial

Compressive Load

This standard is issued under the fixed designation D5780; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Thistestmethodhasbeenpreparedtocovermethodsofaxialloadtestingofpilesinpermafrost.The

provisions permit the introduction of more detailed requirements and procedures when required to

satisfy the objectives of the test program. The procedures herein produce a relationship between

applied load and pile settlement for conditions of ground temperature at the time of test. The results

may be interpreted to establish long-term load capacity of piles in permafrost.

1. Scope 1.2 The values stated in inch-pound units are to be regarded

as the standard. The SI units given in parentheses are for

1.1 This test method covers procedures for testing indi-

information only.

vidual vertical piles to determine response of the pile to static

1.3 This standard does not purport to address all of the

compressive load applied axially to the pile. This test method

safety concerns, if any, associated with its use. It is the

is applicable to all deep foundation units in permafrost that

responsibility of the user of this standard to establish appro-

functioninamannersimilartopilesregardlessoftheirmethod

priate safety and health practices and determine the applica-

of installation. This test method is divided into the following

bility of regulatory limitations prior to use. Specific precau-

sections:

tionary statements are given in Section 8.

Section

Referenced Documents 2

2. Referenced Documents

Terminology 3

Significance and Use 4 2

2.1 ASTM Standards:

Installation of Test Piles 5

D653 Terminology Relating to Soil, Rock, and Contained

Apparatus for Applying Loads 6

Apparatus for Measuring Movements 7

Fluids

Safety Requirements 8

2.2 ANSI Standard:

Loading Procedures 9

B30.1 Safety Code for Jacks

Standard Test Procedures 10

Procedures for Measuring Pile Movements 11

Report 12

3. Terminology

Precision and Bias 13

3.1 Definitions:

Keywords 14

3.1.1 Thestandarddefinitionsoftermsandsymbolsrelating

NOTE 1—Apparatus and procedures designated “optional” are to be

to soil and rock mechanics is Terminology D653.

required only when included in the project specifications or if not

3.2 Definitions of Terms Specific to This Standard:

specified, may be used only with the approval of the engineer responsible

for the foundation design. The word “shall” indicates a mandatory 3.2.1 adfreeze bond strength—the strength of the bond

provision and “should” indicates a recommended or advisory provision.

developed between frozen soil and the surface of the pile.

Imperative sentences indicate mandatory provisions. Notes, illustrations,

3.2.2 base load—a load equivalent to the design load

and appendixes included herein are explanatory or advisory.

adjusted for test pile geometry and expected ground tempera-

NOTE 2—This test method does not include the interpretation of test

ture.

results or the application of test results to foundation design. See

3.2.3 creep load—that load applied to measure a rate of

Appendix X1 for comments regarding some of the factors influencing the

displacement.

interpretation of test results. A qualified geotechnical engineer should

interpret the test results for predicting pile performance and capacity.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Rock and is the direct responsibility of Subcommittee D18.19 on Frozen Soils and Standards volume information, refer to the standard’s Document Summary page on

Rock. the ASTM website.

Current edition approved Sept. 10, 1995. Published January 1996. DOI: Available from American National Standards Institute, 25 W. 43rd St., 4th

10.1520/D5780-95R02. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5780–95 (2002)

3.2.4 creep load increment—an incremental load applied to the pile/slurry interface or the slurry/soil interface, depending

apiletodeterminetherateofdisplacementat10%ofafailure on the strength and deformation properties of the slurry

load or at 100% of a design load. materialandtheadfreezebondstrength.Locationofthefailure

3.2.5 design active layer—the maximum depth of annual surface must be taken into account in the design of the test

thaw anticipated surrounding the pile under design conditions. program and in the interpretation of the test results. Dynamic

3.2.6 failure (in piles)—pile displacement that is occurring loads must be evaluated separately.

at an increasing rate with time under the action of a constant

5. Installation of Test Pile(s)

load, incremental pile displacement that is increasing for

5.1 Install the test pile according to the procedures and

uniform time increments, or a creep rate which exceeds 100%

specifications used for the installation of the production piles.

of the design creep rate when loaded to 100% of the design

load.

NOTE 3—Because the pile behavior will be influenced by the soil type,

3.2.7 failure load—that load applied to a pile to cause

temperature,icecontent,andporewatersalinity,theengineermustensure

failure to occur. that adequate information is available for soil/ice conditions at the

construction site to determine their effect on the pile performance (that is,

3.2.8 failure load increment—the load increment applied to

test pile should be installed in the same condition as the production

a pile that causes failure within a specified time period.

piles—preferably at the same site).

3.2.9 freezeback—for the purpose of this test method, free-

5.2 The design and installation of the test pile shall address

zeback shall be defined as the attainment of a subfreezing

theeffectsofendbearing,asopposedtotheshearresistanceon

temperature at each ground temperature measuring point lo-

the shaft of the pile. Address end bearing by measuring its

cated below the design active layer, which have attained

effect, eliminating its effect, or accounting for its effect

equilibrium with the surrounding soil.

analytically. Measure end bearing by attaching a load cell to

3.2.10 ice-poor—frozen soil with a high solids concentra-

the tip of the pile prior to installation or by attaching a series

tion whose behavior is characterized mainly by soil particle

of strain gages along the length of the pile prior to installation.

contacts.

Eliminate end bearing by attaching a compressible layer to the

3.2.11 ice-rich—frozen soil with a moderate to low solids

tip of the pile prior to installation or by providing a void

concentration whose behavior is characterized by ice particle

beneath the tip of the pile.

contacts.

5.3 Install thermistors or other temperature-measuring de-

3.2.12 pile, driven—a pile driven into the ground with an

vicesadjacenttothetestpiletodeterminethegroundtempera-

impact or vibratory pile hammer.

tureprofileadjacenttothepile.Measuregroundtemperaturein

3.2.13 pile, grouted—a pile placed in an oversized, pre-

frozengroundataminimumofthreelocationsalongthelength

drilled hole and backfilled with a sand, cement grout.

ofpile;forpileslongerthan10ft(3m),itisrecommendedthat

3.2.14 pile, slurried—a pile placed in an oversized, pre-

ground temperatures be measured at 5-ft (1.5-m) depth inter-

drilled hole and backfilled with a soil/water slurry.

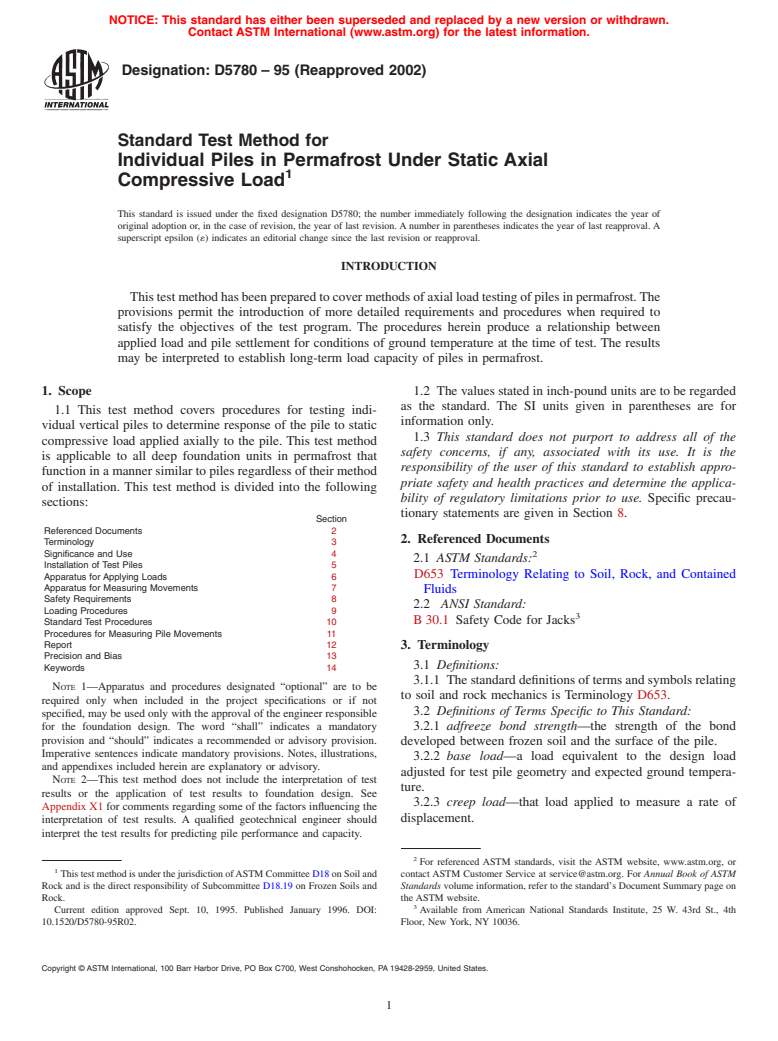

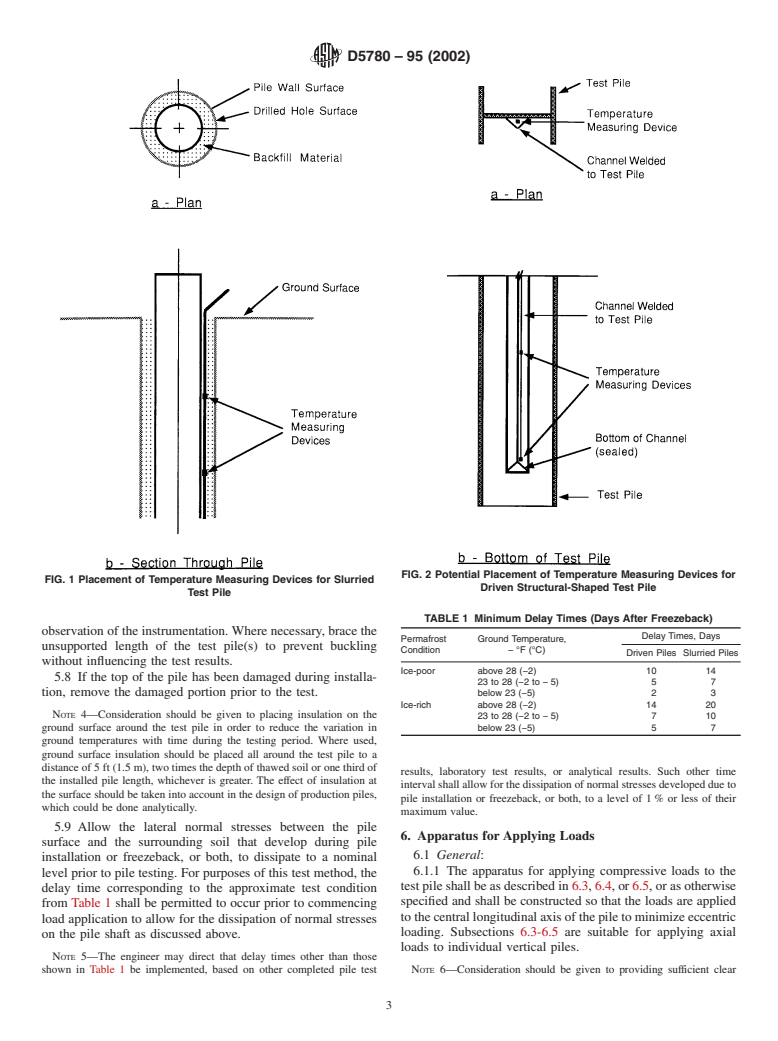

vals. Install the temperature-measuring devices in contact with

3.2.15 subfreezing temperature—anytemperaturebelowthe

the exterior pile surface; for slurried piles, installation may be

actualfreezingtemperatureofthesoilwatercombinationbeing

as shown in Fig. 1; for driven piles, installation may be as

used.

shown in Fig. 2.

3.2.16 time to failure—the total time from the start of the

5.4 Measure ground temperatures periodically using the

current test load increment to the point at which failure begins

installed temperature-measuring devices to determine when

to occur.

freezeback occurs.

4. Significance and Use

5.5 Where freezeback of soils adjacent to the pile is aided

4.1 This test method will provide a relationship between bythecirculationofcoldairorliquidcoolant,discontinuesuch

time to failure, creep rate, and displacement to failure for coolingwhenthemeasuredgroundtemperaturesbecomeequal

specific failure loads at specific test temperatures as well as a to the desired ground temperature for the pile test; significant

relationshipbetweencreeprateandappliedloadatspecifictest overcooling shall not be permitted to occur. When freezeback

temperatures for loads less than failure loads. of soils adjacent to the test piles is aided by a designed cooling

4.2 Pile design for specific soil temperatures may be con- system, such designed cooling system shall also be applied in

trolled by either limiting long-term stress to below long-term a similar manner to all reaction piles to ensure freezeback of

strengthorbylimitingallowablesettlementoverthedesignlife the reaction piles.

of the structure. It is the purpose of this test method to provide 5.6 Isolate the surface of the test pile from the surrounding

the basic information from which the limiting strength or soil or ice over the depth of the design active layer. This may

long-term settlement may be evaluated by geotechnical engi- beaccomplishedbyusingasleeveorcasing.Forslurriedpiles,

neers. a greased wrapping or other technique that will essentially

4.3 Data derived from pile tests at specific ground tempera- eliminate the transfer of shear forces between the pile and the

turesthatdifferfromthedesigntemperaturesmustbecorrected surrounding soil/ice in the design active layer may be used.

to the design temperature by the use of data from additional 5.7 Where feasible, excavate the immediate area of the test

pile tests, laboratory soil strength tests, or published correla- pile or fill to the proposed finished grade elevation. Cut off test

tions, if applicable, to provide a suitable means of correction. piles or build up to the proper grade necessary to permit

4.4 Fordrivenpilesorgroutedpiles,failurewilloccuratthe construction of the load-application apparatus, placement of

pile/soil interface. For slurried piles, failure can occur at either the necessary testing and instrumentation equipment, and

D5780–95 (2002)

FIG. 2 Potential Placement of Temperature Measuring Devices for

FIG. 1 Placement of Temperature Measuring Devices for Slurried

Driven Structural-Shaped Test Pile

Test Pile

TABLE 1 Minimum Delay Times (Days After Freezeback)

observation of the instrumentation.Where necessary, brace the

Delay Times, Days

Permafrost Ground Temperature,

unsupported length of the test pile(s) to prevent buckling

Condition − °F (°C)

Driven Piles Slurried Piles

without influencing the test results.

Ice-poor above 28 (−2) 10 14

5.8 If the top of the pile has been damaged during installa-

23 to 28 (−2 to − 5) 5 7

tion, remove the damaged portion prior to the test. below 23 (−5) 2 3

Ice-rich above 28 (−2) 14 20

NOTE 4—Consideration should be given to placing insulation on the

23 to 28 (−2 to − 5) 7 10

ground surface around the test pile in order to reduce the variation in below 23 (−5) 5 7

ground temperatures with time during the testing period. Where used,

ground surface insulation should be placed all around the test pile to a

distance of 5 ft (1.5 m), two times the depth of thawed soil or one third of

results, laboratory test results, or analytical results. Such other time

the installed pile length, whichever is greater. The effect of insulation at

intervalshallallowforthedissipationofnormalstressesdevelopeddueto

the surface should be taken into account in the design of production piles,

pile installation or freezeback, or both, to a level of 1% or less of their

which could be done analytically.

maximum value.

5.9 Allow the lateral normal stresses between the pile

6. Apparatus for Applying Loads

surface and the surrounding soil that develop during pile

6.1 General:

installation or freezeback, or both, to dissipate to a nominal

6.1.1 The apparatus for applying compressive loads to the

level prior to pile testing. For purposes of this test method, the

testpileshallbeasdescribedin6.3,6.4,or6.5,orasotherwise

delay time corresponding to the approximate test condition

specified and shall be constructed so that the loads are applied

from Table 1 shall be permitted to occur prior to commencing

tothecentrallongitudinalaxisofthepiletominimizeeccentric

load application to allow for the dissipation of normal stresses

loading. Subsections 6.3-6.5 are suitable for applying axial

on the pile shaft as discussed above.

loads to individual vertical piles.

NOTE 5—The engineer may direct that delay times other than those

shown in Table 1 be implemented, based on other completed pile test NOTE 6—Consideration should be given to providing sufficient clear

D5780–95 (2002)

spacebetweenthepilecapandthegroundsurfacetoeliminateanysupport

series of tests in a test program to provide an accuracy of less

of the cap by the soil. A properly constructed steel grillage may serve as

than 1% of the applied load. Calibrate the hydraulic jack(s)

an adequate pile cap for testing purposes.

over its complete range of ram travel for increasing and

6.1.2 For testing an individual pile, center a steel-bearing

decreasing applied loads at a temperature within the air

plate(s) on the pile and set perpendicular to the longitudinal temperaturerangeexpectedtooccurduringtheloadtest.Iftwo

axis of the pile. It shall be of sufficient thickness to prevent it

or more jacks are to be used to apply the test load, they shall

from bending under the loads involved (but not less than 2 in. beofthesameramdiameter,connectedtoacommonmanifold

(50 mm) thick). The size of the test plate shall be not less than

and pressure gage, and operated by a single hydraulic pump.

the size of the pile top nor less than the area covered by the

NOTE 7—Where tests will be carried out in subfreezing fluctuating air

base(s) of the hydraulic jack(s).

temperatures, it is recommended that thermal insulation be applied to the

6.1.3 For tests on precast or cast-in-place concrete piles, set

hydraulic jack, the hydraulic lines, and other components of the loading

the test plate, when used, in high-strength quick-setting grout.

system.

For

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.