ASTM D6865-04

(Classification)Standard Classification System for Acrylonitrile-Styrene-Acrylate (ASA) and Acrylonitrile-EPDM-Styrene (AES) Plastics and Alloys Molding and Extrusion Materials

Standard Classification System for Acrylonitrile-Styrene-Acrylate (ASA) and Acrylonitrile-EPDM-Styrene (AES) Plastics and Alloys Molding and Extrusion Materials

ABSTRACT

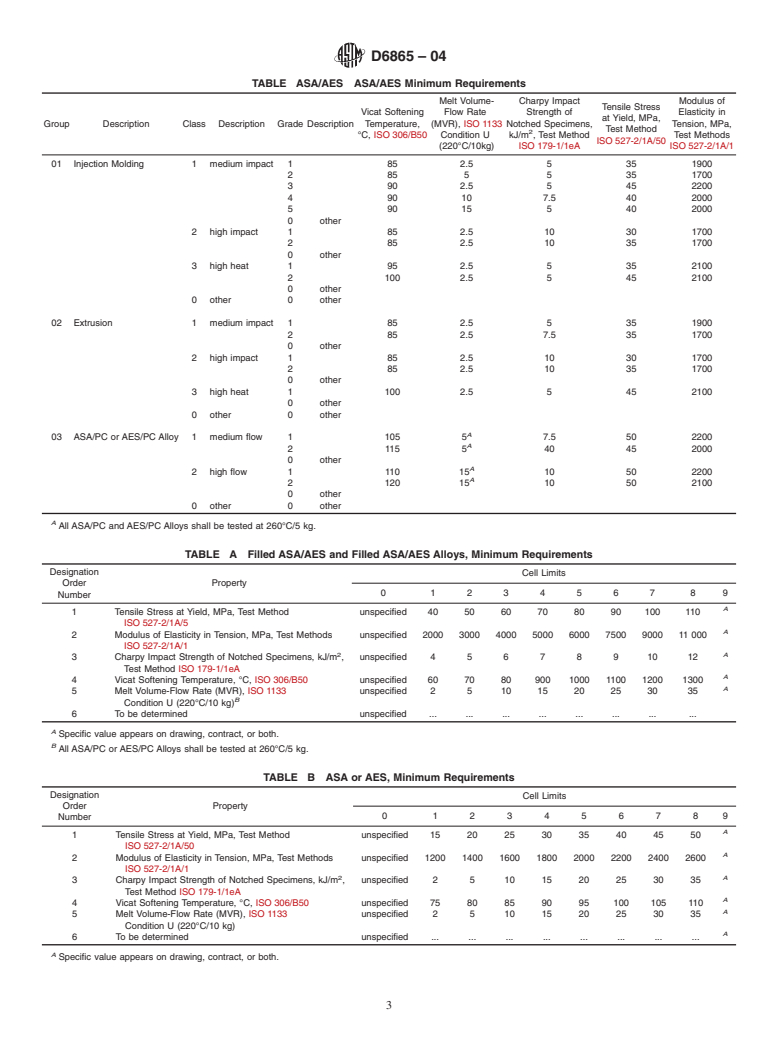

This specification covers acrylonitrile-styrene-acrylate (ASA) and acrylonitrile-EPDM-styrene (AES) plastics and alloys suitable for injection molding and extrusion. ASA and AES materials, and ASA and AES alloys are classified into groups according to their composition. These groups are subdivided into classes and grades: class 0, 1, 2, and 3; grade 0, 1, 2, 3, 4, and 5. The tensile stresses at yield, modulus of elasticity in tension, charpy impact strength, vicat softening temperature, and melt volume-flow rate shall be tested to meet the requirements prescribed.

SCOPE

1.1 This classification system covers ASA and AES materials, and ASA and AES alloys suitable for injection molding and extrusion. This classification system does not cover recycled ASA and AES materials, and recycled ASA and AES alloys.

1.2 The properties included in this standard are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications. These may be specified by using the suffixes as given in Section 5.

1.3 This classification system and subsequent line callout (specification) are intended to provide a means of calling out plastic materials used in the fabrication of end items or parts. It is not intended for the selection of materials. Material selection should be made by those having expertise in the plastic field after careful consideration of the design and the performance required of the part, the environment to which it will be exposed, the fabrication process to be employed, the costs involved, and the inherent properties of the material other than those covered by this standard.

Note 1—This classification system and ISO 6402 cover the same subject matter but are not technically equivalent.

1.4 The following precautionary caveat pertains only to the test method portion, Section , of this classification system: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6865 – 04

Standard Classification System for

Acrylonitrile–Styrene–Acrylate (ASA) and

Acrylonitrile–EPDM–Styrene (AES) Plastics and Alloys

Molding and Extrusion Materials

This standard is issued under the fixed designation D6865; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to

1.1 This classification system covers ASA and AES materi-

Plastics

als,andASAandAESalloyssuitableforinjectionmoldingand

D1999 Guide for Selection of Specimens and Test Param-

extrusion. This classification system does not cover recycled

eters from ISO/IEC Standards

ASA and AES materials, and recycled ASA and AES alloys.

D3892 Practice for Packaging/Packing of Plastics

1.2 The properties included in this standard are those

D4000 Classification System for Specifying Plastic Materi-

required to identify the compositions covered. There may be

als

other requirements necessary to identify particular character-

D5630 Test Method for Ash Content in Plastics

istics important to specialized applications. These may be

E29 Practice for Using Significant Digits in Test Data to

specified by using the suffixes as given in Section 5.

Determine Conformance with Specifications

1.3 This classification system and subsequent line callout

2.2 ISO Standards:

(specification) are intended to provide a means of calling out

ISO 179-1 Plastics—Determination of Charpy Impact

plastic materials used in the fabrication of end items or parts.

Strength—Part 1: Non-Instrumented Impact Test

It is not intended for the selection of materials. Material

ISO 291 Plastics—Standard Atmospheres for Conditioning

selection should be made by those having expertise in the

and Testing

plastic field after careful consideration of the design and the

ISO 294-1 Plastics—Injection Moulding Test Specimens of

performance required of the part, the environment to which it

ThermoplasticsMaterials—Part1:GeneralPrinciples,and

will be exposed, the fabrication process to be employed, the

Moulding of Multipurpose and Bar Test Specimens

costsinvolved,andtheinherentpropertiesofthematerialother

ISO 306 Plastics—Thermoplastic Materials— Determina-

than those covered by this standard.

tion of Vicat Softening Temperature (VST)

NOTE 1—This classification system and ISO 6402 cover the same

ISO 527 Plastics—Determination of Tensile Properties—

subject matter but are not technically equivalent.

Part 1: General Principles and —Part 2: Test Conditions

1.4 The following precautionary caveat pertains only to the

for Moulding and Extrusion Materials

test method portion, Section 11, of this classification system:

ISO 1133 Plastics—Determination of the Melt Mass Flow

This standard does not purport to address all of the safety

Rate (MFR) and the Melt Volume Flow Rate (MVR) of

concerns, if any, associated with its use. It is the responsibility

Thermoplastics

of the user of this standard to establish appropriate safety and

ISO 3451-1 Plastics—Determination of Ash—Part 1: Gen-

health practices and determine the applicability of regulatory

eral Methods

requirements prior to use.

ISO 6402 Plastics—Impact-Resistant Acrylonitrile/Styrene

(ASA, AES, ACS) Moulding and Extrusion materials,

2. Referenced Documents

Excluding Butadiene-Modified Materials—Part 1: Desig-

2.1 ASTM Standards:

nation System and Basis for Specification and —Part 2:

D618 Practice for Conditioning Plastics for Testing

Preparation of Test Specimens and Determination of

Properties

This classification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials.

Current edition approved March 1, 2004. Published April 2004. DOI: 10.1520/

D6865-04.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Withdrawn. The last approved version of this historical standard is referenced

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM on www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6865 – 04

3. Terminology the order as they appear in Tables A, B, or C. Although the

values listed are necessary to include the range of properties

3.1 Except for the terms defined below, the terminology

availableinexistingmaterials,usersshouldnotinferthatevery

used in this classification system is in accordance with Termi-

possible combination of the properties exists or can be ob-

nologies D883 and D1600.

tained.

4.2.3 When the grade of the basic material is not known, or

4. Classification

is not important, the use of the “o” grade classification shall be

4.1 ASA and AES materials, and ASA and AES alloys are

used for the reinforced materials in this system.

classified into groups according to their composition. These

NOTE 4—An example of this classification for a reinforced ASA/AES

groups are subdivided into classes and grades as shown in

material is given as follows. The designation ASA 0120G30A55130

Table ASA/AES.

would indicate the following material requirements:

NOTE 2—An example of this classification system is given as follows:

ASA 0120 = Acrylonitrile-styrene-acrylate, molding resin,

high impact, from Table ASA/AES,

The designation ASA0111 indicates the following:

G30 = Glass reinforced at 30 % nominal level,

ASA = acrylonitrile–styrene–acrylate, as found in Terminology

A = Cell Table A property requirements,

D1600,

5 = 80 MPa Tensile Stress at Yield, min,

01 = injection molding resin (group),

5 = 7500 MPa Modulus of Elasticity in Tension, min,

1 = medium impact (class), and

1=4kJ/m Charpy Impact Strength of Notched Specimens, min,

1 = requirements given in Table ASA/AES (grade).

3 = 90°C Vicat softening temperature, min, and

4.1.1 To facilitate incorporation of future or special materi- 0 = unspecified

als, the “other” category for class (0), and grade (0) is shown

If no properties are specified, the designation would be ASA

in TableASA/AES. The basic properties of these materials can

0120G30A00000.

be obtained from Table A, B, or C as they apply.

5. Suffixes

4.2 Reinforced, filled, and lubricated versions of ASA and

5.1 When additional requirements are needed that are not

AES materials, and ASA and AES alloys that are not in Table

covered by the basic requirements or cell-table requirements,

ASA/AES are classified in accordance with Table A, B, or C.

they shall be indicated through the use of suffixes.

Table ASA/AES is used to specify the group of the material

5.2 A list of suffixes can be found in Classification System

and Table A, B, or C is used to specify the property require-

D4000 (Table 3) and may be used for additional requirements

ments after the addition of reinforcements, pigments, fillers, or

as appropriate. Additional suffixes will be added to that

lubricants at the nominal level indicated (see 4.2.1).

standard as test methods and requirements are developed and

4.2.1 Reinforced versions of the basic materials are identi-

requested.

fied by a single letter that indicates the reinforcement used and

two digits that indicate the nominal quantity in percent by

6. General Requirements

weight. Thus, a letter designation G for glass-reinforced for

6.1 Basic requirements from the property tables or cell

percent of reinforcement, G33, specifies a filled material with

tables are always in effect unless superseded by specific suffix

a nominal glass level of 33 %. The reinforcement letter

requirements, which always take precedence.

designations and associated tolerance levels are shown in the

6.2 The plastics composition shall be uniform and shall

following table:

conform to the requirements specified herein.

Symbol Material Tolerance

C carbon and graphite fiber reinforced 62%

7. Detail Requirements

G glass-reinforced 62%

7.1 The materials shall conform to the requirements in

L lubricants (such as PTFE, graphite, depends upon material and

silicone, and molybdenum disulfide) process—to be specified

Tables ASA/AES, A, B, C, and suffix requirements as they

M mineral-reinforced 62%

apply.

R combinations of reinforcements or 63% for total reinforcement

7.2 For purposes of determining conformance, all specified

fillers, or both level

limits for a specification (line callout) based on this classifica-

tion system are absolute limits, as defined in Practice E29.

NOTE 3—This part of the classification system uses the percent of

reinforcements or additives, or both, in the callout of the modified basic 7.2.1 With the absolute method, an observed value or a

material. The types and percentages of reinforcements and additives

calculated value is not rounded, but is to be compared directly

should be shown on the supplier’s technical data sheet unless they are

with the limiting value. Conformance or nonconformance is

proprietary in nature. If necessary, additional callout of these reinforce-

based on this comparison.

ments and additives can be accomplished by use of the suffix part of the

system (see Section 5).

8. Sampling

4.2.2 Specific requirements for reinforced, filled, or lubri- 8.1 Sampling shall be statistic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.