ASTM D2996-01(2007)e1

(Specification)Standard Specification for Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

Standard Specification for Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

ABSTRACT

This specification covers machine-made reinforced thermosetting resin pressure pipe (RTRP) manufactured by the filament winding process. This specification does not include reinforced polymer mortar pipe (RPMP), which is another type of fiberglass pipe. The pipes are generally classified by type, grade, class, and hydrostatic design. In addition, a secondary cell classification system defines the basic mechanical properties of the pipe. The resins, reinforcements, colorants, fillers, and other materials, when combined as a composite structure, shall produce a pipe that shall meet the performance requirements of this specification. Materials shall be tested and the individual grades shall conform to the specified values of dimensions and tolerances, long-term static hydrostatic strength, long-term cyclic hydrostatic strength, short-term hydrostatic failure strength, longitudinal tensile properties, and stiffness factor.

SCOPE

1.1 This specification covers machine-made reinforced thermosetting resin pressure pipe (RTRP) manufactured by the filament winding process up to 24 in. nominal size. Included are a classification system and requirements for materials, mechanical properties, dimensions, performance, methods of test, and marking.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are provided for information purposes only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—The term "fiberglass pipe" as described in Section 3 of this specification applies to both reinforced thermosetting resin pipe (RTRP) and reinforced polymer mortar pipe (RPMP). This specification covers only reinforced thermosetting resin pipe (RTRP).

Note 2—This specification is applicable to RTRP where the ratio of outside diameter to wall thickness is 10:1 or more.

Note 3—There is no known ISO equivalent to this standard.

Note 4—For the purposes of this standard, polymer does not include natural polymers.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D2996 −01(Reapproved 2007) An American National Standard

Standard Specification for

Filament-Wound “Fiberglass’’ (Glass-Fiber-Reinforced

Thermosetting-Resin) Pipe

This standard is issued under the fixed designation D2996; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Note 3 was editorially updated in April 2007.

1. Scope* D883Terminology Relating to Plastics

D1598Test Method for Time-to-Failure of Plastic Pipe

1.1 Thisspecificationcoversmachine-madereinforcedther-

Under Constant Internal Pressure

mosetting resin pressure pipe (RTRP) manufactured by the

D1599Test Method for Resistance to Short-Time Hydraulic

filament winding process up to 24 in. nominal size. Included

Pressure of Plastic Pipe, Tubing, and Fittings

are a classification system and requirements for materials,

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

mechanical properties, dimensions, performance, methods of

tics

test, and marking.

D2105Test Method for Longitudinal Tensile Properties of

1.2 The values stated in inch-pound units are to be regarded

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-

as standard. The values given in parentheses are provided for

Resin) Pipe and Tube

information purposes only.

D2143 Test Method for Cyclic Pressure Strength of

1.3 The following safety hazards caveat pertains only to the Reinforced, Thermosetting Plastic Pipe

test method portion, Section 8, of this specification: This

D2310 Classification for Machine-Made “Fiberglass”

standard does not purport to address all of the safety problems, (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

if any, associated with its use. It is the responsibility of the user

D2412Test Method for Determination of External Loading

of this standard to establish appropriate safety and health Characteristics of Plastic Pipe by Parallel-Plate Loading

practices and determine the applicability of regulatory limita-

D2992Practice for Obtaining Hydrostatic or Pressure De-

tions prior to use. sign Basis for “Fiberglass” (Glass-Fiber-Reinforced

Thermosetting-Resin) Pipe and Fittings

NOTE 1—The term “fiberglass pipe” as described in Section 3 of this

D3567PracticeforDeterminingDimensionsof“Fiberglass”

specification applies to both reinforced thermosetting resin pipe (RTRP)

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

and reinforced polymer mortar pipe (RPMP). This specification covers

only reinforced thermosetting resin pipe (RTRP).

Fittings

NOTE 2—This specification is applicable to RTRP where the ratio of

F412Terminology Relating to Plastic Piping Systems

outside diameter to wall thickness is 10:1 or more.

NOTE 3—There is no known ISO equivalent to this standard.

3. Terminology

NOTE 4—For the purposes of this standard, polymer does not include

natural polymers.

3.1 Definitions:

3.1.1 General—Definitions are in accordance with Termi-

2. Referenced Documents

nologies D883 and F412 and abbreviations are in accordance

2.1 ASTM Standards:

with Terminology D1600, unless otherwise indicated. The

D618Practice for Conditioning Plastics for Testing

abbreviation for reinforced thermosetting resin pipe is RTRP.

D638Test Method for Tensile Properties of Plastics

3.2 Definitions of Terms Specific to This Standard:

3.2.1 coating—a resin layer, with or without filler or

reinforcement, or both, applied to the exterior surface of the

This specification is under the jurisdiction of ASTM Committee D20 on

pipe structural wall.

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

Plastic Piping Systems and Chemical Equipment.

3.2.2 fiberglass pipe—a tubular product containing glass-

Current edition approved March 1, 2007. Published April 2007. Originally

fiber reinforcements embedded in or surrounded by cured

approved in 1971. Last previous edition approved in 2001 as D2996–01. DOI:

10.1520/D2996-01R07E01.

thermosetting resin; the composite structure may contain

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

aggregate, granular or platelet fillers, thixotropic agents,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pigments, or dyes; thermoplastic or thermosetting liners or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. coatings may be included.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2996−01 (2007)

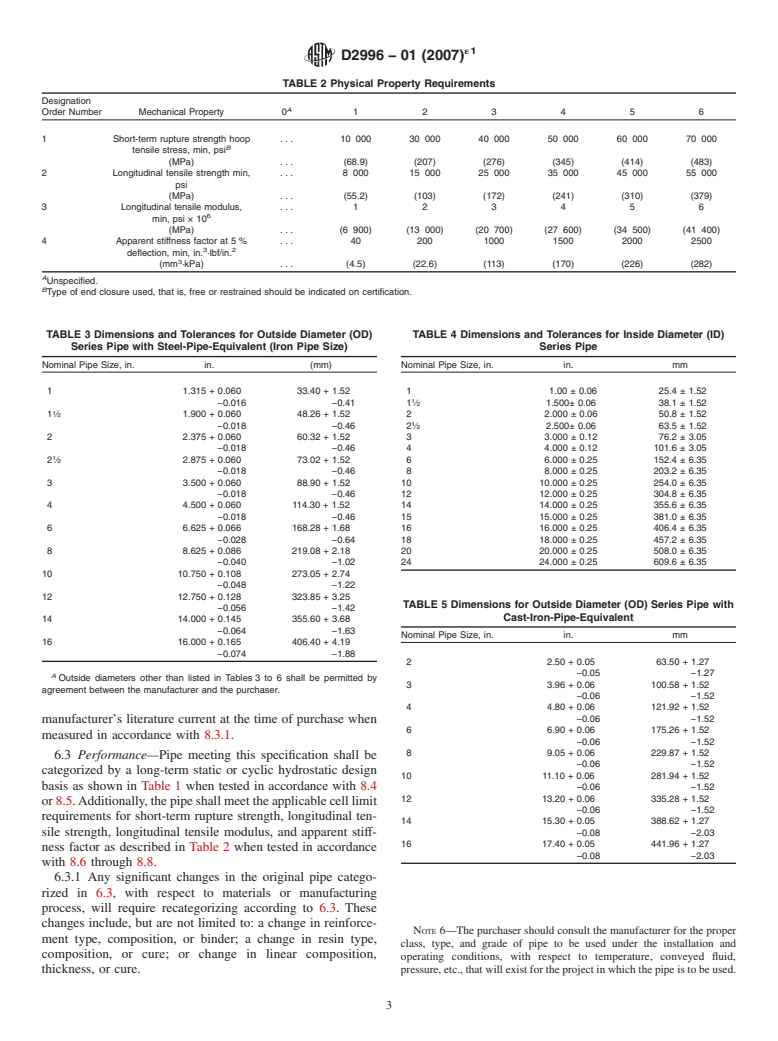

TABLE 1 Hydrostatic Design Basis Categories

3.2.3 filament winding—a process used to manufacture tu-

bulargoodsbywindingcontinuousfibrousglassstrandroving, Cyclic Test Method Static Test Method

or roving tape, saturated with liquid resin or preimpregnated Hoop Stress, psi Hoop Stress, psi

Designation (MPa) Designation (MPa)

with partially cured resin (subsequent heating may be required

to polymerize the resin system) onto the outside of a mandrel

A 2 500 (17.2) Q 5 000 (34.5)

in a predetermined pattern under controlled tension; the inside

B 3 150 (21.7) R 6 300 (43.4)

diameter (ID) of the pipe is fixed by the mandrel outside C 4 000 (27.6) S 8 000 (55.2)

D 5 000 (34.5) T 10 000 (68.9)

diameter and the outside diameter (OD) of the pipe is deter-

E 6 300 (43.4) U 12 500 (86.2)

minedbytheamountofmaterialthatiswoundonthemandrel.

F 8 000 (55.2) W 16 000 (110)

G 10 000 (68.9) X 20 000 (138)

3.2.4 liner—the inner portion of the wall at least 0.005 in.

H 12 500 (86.2) Y 25 000 (172)

(0.13mm)inthickness,asdeterminedin8.3.2,whichdoesnot

Z 31 500 (217)

contribute to the strength in the determination of the hydro-

static design basis.

3.2.5 reinforced polymer mortar pipe (RPMP)—a fiberglass

system may not be commercially available.

pipe with aggregate.

4.1.6 Designation Code—The pipe designation code shall

3.2.6 reinforced thermosetting resin pipe (RTRP)—a fiber-

consist of the abbreviation RTRP, followed by the type and

glass pipe without aggregate.

grade in Arabic numerals, the class and static or cyclic HDB

3.2.7 reinforced wall thickness—the total wall thickness

level in capital letters, the type of end closure used, and four

minus the liner or exterior coating thickness, or both.

Arabicnumbersidentifying,respectively,thecellclassification

designations of the short-term rupture strength, longitudinal

4. Classification

tensile strength, longitudinal tensile modulus, and apparent

stiffness of the pipe.

4.1 General—Pipemeetingthisspecificationisclassifiedby

Example: RTRP-11FA1-1334. Such a designation would

type, grade, class, and hydrostatic design basis in accordance

describe a filament-wound, glass-fiber reinforced, epoxy pipe

with Classification D2310 and by a secondary cell classifica-

having a reinforced epoxy liner; a cyclic pressure strength

tion system that defines the basic mechanical properties of the

exceeding 2500 psi (17.2 MPa) using free-end closures; a

pipe. These types, grades, classes, hydrostatic design basis

short-term rupture strength exceeding 10 000 psi (68.9 MPa);

categories, and cell classification designations are as follows:

a longitudinal tensile strength exceeding 25 000 psi (172

4.1.1 Types:—Type 1

MPa); a longitudinal tensile modulus exceeding3×10 psi

Filament wound.

(20.7 × 10 MPa); and an apparent stiffness factor exceeding

4.1.2 Grades:—Grade 1

3 2 3

1500 in. ·lbf/in. (170 mm ·kPa).

Glass fiber reinforced epoxy resin pipe.

Grade 2—Glass fiber reinforced polyester resin pipe.

5. Materials and Manufacture

Grade 7—Glass fiber reinforced furan resin pipe.

5.1 General—The resins, reinforcements, colorants, fillers,

4.1.3 Classes:—Class A

and other materials, when combined as a composite structure,

No liner.

shall produce a pipe that shall meet the performance require-

Class B—Polyester resin liner (nonreinforced).

ments of this specification.

Class C—Epoxy resin liner (nonreinforced).

Class E—Polyester resin liner (reinforced).

6. Physical Requirements

Class F—Epoxy resin liner (reinforced).

Class H—Thermoplastic resin liner (specify).

6.1 Workmanship—The pipe shall be free of all defects

Class I—Furan resin liner (reinforced).

including indentations, delaminations, bubbles, pinholes, for-

4.1.4 Hydrostatic Design Basis—Two methods of classify-

eign inclusions, and resin-starved areas which, due to their

ing the hydrostatic design basis of the pipe are provided. Pipe

nature, degree, or extent, detrimentally affect the strength and

meeting this specification may be classified using either the

serviceability of the pipe. The pipe shall be as uniform as

cyclic test method or the static test method, or both, and the

commercially practicable in color, opacity, and other physical

designations as shown in Table 1. Appendix X1 explains how

properties.Thepipeshallberoundandstraightandtheboreof

these design basis categories are to be used.

thepipeshallbesmoothanduniform.Allpipeendsshallbecut

4.1.4.1 Forpipesubjectedtoaxialorendloads,theeffectof

at right angles to the axis of the pipe and any sharp edges

these loads shall be represented in the HDB testing. In the

removed.

designation code, the numeral 1 shall immediately follow the

6.2 Dimensions and Tolerances:

HDB letter class if free-end type closures were used and the

6.2.1 Inside and Outside Diameter—The inside and outside

numeral 2 shall immediately follow the HDB letter class if

diameter and tolerances of pipe meeting these specifications

restrained-end type closures were used to establish the HDB.

shall conform to the requirements in one of the Tables 3-6,

4.1.5 Mechanical Properties—Table 2 presents a cell clas-

when determined in accordance with 8.3.1.

sification system for identifying the mechanical properties of

6.2.2 Wall Thickness—The minimum wall thickness of pipe

pipe covered by this specification.

furnished under this specification shall not at any point be less

NOTE5—Allpossiblecombinationscoveredbytheaboveclassification than 87.5% of the nominal wall thickness published in the

´1

D2996−01 (2007)

TABLE 2 Physical Property Requirements

Designation

A

Order Number Mechanical Property 0 123456

1 Short-term rupture strength hoop . . . 10 000 30 000 40 000 50 000 60 000 70 000

B

tensile stress, min, psi

(MPa) . . . (68.9) (207) (276) (345) (414) (483)

2 Longitudinal tensile strength min, . . . 8 000 15 000 25 000 35 000 45 000 55 000

psi

(MPa) . . . (55.2) (103) (172) (241) (310) (379)

3 Longitudinal tensile modulus, . 123456

min, psi × 10

(MPa) . . . (6 900) (13 000) (20 700) (27 600) (34 500) (41 400)

4 Apparent stiffness factor at 5 % . . . 40 200 1000 1500 2000 2500

3 2

deflection, min, in. ·lbf/in.

(mm ·kPa) . . . (4.5) (22.6) (113) (170) (226) (282)

A

Unspecified.

B

Type of end closure used, that is, free or restrained should be indicated on certification.

TABLE 3 Dimensions and Tolerances for Outside Diameter (OD) TABLE 4 Dimensions and Tolerances for Inside Diameter (ID)

Series Pipe with Steel-Pipe-Equivalent (Iron Pipe Size) Series Pipe

Nominal Pipe Size, in. in. (mm) Nominal Pipe Size, in. in. mm

1 1.315 + 0.060 33.40 + 1.52 1 1.00 ± 0.06 25.4 ± 1.52

−0.016 −0.41 1 ⁄2 1.500± 0.06 38.1 ± 1.52

1 ⁄2 1.900 + 0.060 48.26 + 1.52 2 2.000±0.06 50.8±1.52

−0.018 −0.46 2 ⁄2 2.500± 0.06 63.5 ± 1.52

2 2.375 + 0.060 60.32 + 1.52 3 3.000±0.12 76.2±3.05

−0.018 −0.46 4 4.000 ± 0.12 101.6 ± 3.05

2 ⁄2 2.875 + 0.060 73.02 + 1.52 6 6.000 ± 0.25 152.4 ± 6.35

−0.018 −0.46 8 8.000 ± 0.25 203.2 ± 6.35

3 3.500 + 0.060 88.90 + 1.52 10 10.000 ± 0.25 254.0 ± 6.35

−0.018 −0.46 12 12.000 ± 0.25 304.8 ± 6.35

4 4.500 + 0.060 114.30 + 1.52 14 14.000 ± 0.25 355.6 ± 6.35

−0.018 −0.46 15 15.000 ± 0.25 381.0 ± 6.35

6 6.625 + 0.066 168.28 + 1.68 16 16.000 ± 0.25 406.4 ± 6.35

−0.028 −0.64 18 18.000 ± 0.25 457.2 ± 6.35

8 8.625 + 0.086 219.08 + 2.18 20 20.000 ± 0.25 508.0 ± 6.35

−0.040 −1.02 24 24.000 ± 0.25 609.6 ± 6.35

10 10.750 + 0.108 273.05 + 2.74

−0.048 −1.22

12 12.750 + 0.128 323.85 + 3.25

TABLE 5 Dimensions for Outside Diameter (OD) Series Pipe with

−0.056 −1.42

Cast-Iron-Pipe-Equivalent

14 14.000 + 0.145 355.60 + 3.68

−0.064 −1.63

Nominal Pipe Size, in. in. mm

16 16.000 + 0.165 406.40 + 4.19

−0.074 −1.88

2 2.50 + 0.05 63.50 + 1.27

−0.05 −1.27

A

Outside diameters other than listed in Tables 3 to 6 shall be permitted by

3 3.96 + 0.06 100.58 + 1.52

agreement between the manufacturer and the purchaser.

−0.06 −1.52

4 4.80 + 0.06 121.92 + 1.52

−0.06 −1.52

manufacturer’s literature current at the time of purchase when

6 6.90 + 0.06 175.26 + 1.52

measured in accordance with 8.3.1.

−0.06 −1.52

8 9.05 + 0.06 229.87 + 1.52

6.3 Performance—Pipe meeting this specification shall be

−0.06 −1.52

categorized by a long-term static or cyclic hydrostatic design

10 11.10 + 0.06 281.94 + 1.52

basis as shown in Table 1 when tested in accordance with 8.4

−0.06 −1.52

12 13.20 + 0.06 335.28 + 1.52

or8.5.Additionally,thepipeshallmeettheapplicablecelllimit

−0.06 −1.52

requirements for short-term rupture strength, longitudinal ten-

14 15.30 + 0.05 388.62 + 1.27

sile strength, longitudinal tensile modulus, and apparent stiff- −0.08 −2.03

16 17.40 + 0.05 441.96 + 1.27

ness factor as described in Table 2 when tested in accordance

−0.08 −2.03

with 8.6 through 8.8.

6.3.1 Any significant changes in the original pipe catego-

rized in 6.3, with respect to materials or manufacturing

process, will require recategorizing according to 6.3. These

changes include, but are not limited to: a change in reinforce-

NOTE 6—The purchaser should consult the manufacturer for the proper

ment type, composition, or binder; a change in resin type,

class, type, and grade of pipe to be used under the installation and

composition, or cure; or change in linear composition,

operating conditions, with respect to temperature, conveyed fluid,

thickness, or cure. pressure,etc.,thatwillexistfortheprojectinwhichthepipeistobeused.

´1

D2996−01 (2007)

TABLE 6 Dimensions for Inside Diameter (ID) Series Pipe with

8.3.2 Liner Thickness—If the test specimens contain a liner,

Iron Pipe Size Equivalent

determine the average liner thickness in accordance with

Nominal Pipe Size, in. in. mm

Practice D3567.

8.4 Long-Term Cyclic Hydrostatic Strength—Determine in

2 2.25 + 0.05 57.15 + 1.27

−0.05 −1.27 accordancewithProcedureAofMethodD2992,followingTest

3 3.34 + 0.06 84.84 + 1.52

Method D2143.

−0.06 −1.52

4 4.37 + 0.06 111.00 + 1.52

8.5 Long-Term Static Hydrostatic Strength—Determine in

−0.06 −1.52

accordancewithProcedureBofMethodD2992,followingTest

6 6.43 + 0.06 163.32 + 1.52

Method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.