ASTM D1240-14

(Test Method)Standard Test Methods for Rosin Acids Content of Pine Chemicals, Including Rosin, Tall Oil, and Related Products

Standard Test Methods for Rosin Acids Content of Pine Chemicals, Including Rosin, Tall Oil, and Related Products

SIGNIFICANCE AND USE

4.1 This is a revision of the method for measuring rosin acids content combines the three major ways of determining the rosin acids content of pine chemicals products into a single method.

4.1.1 For materials containing less than 15 % rosin, the modified Glidden procedure has gained acceptance. For materials containing more than 15 % rosin the modified Wolfe Method is preferred. The modified Wolfe and modified Glidden procedures differ only in their details. They have been combined here into a single procedure. This procedure can be run using either a potentiometer or an internal indicator to determine the end point of the titration. Use of a potentiometer is preferred and is the referee method. Use of an internal indicator is the principal alternative method. They will be referred to as the Potentiometric Method and the Internal Indicator Method.

SCOPE

1.1 These test methods cover the determination of rosin acids in tall oil, tall oil fatty acid, tall oil rosin, and other pine chemicals products.

1.2 These test methods may not be applicable to adducts or derivatives of rosin, fatty acid, or other pine chemicals products.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

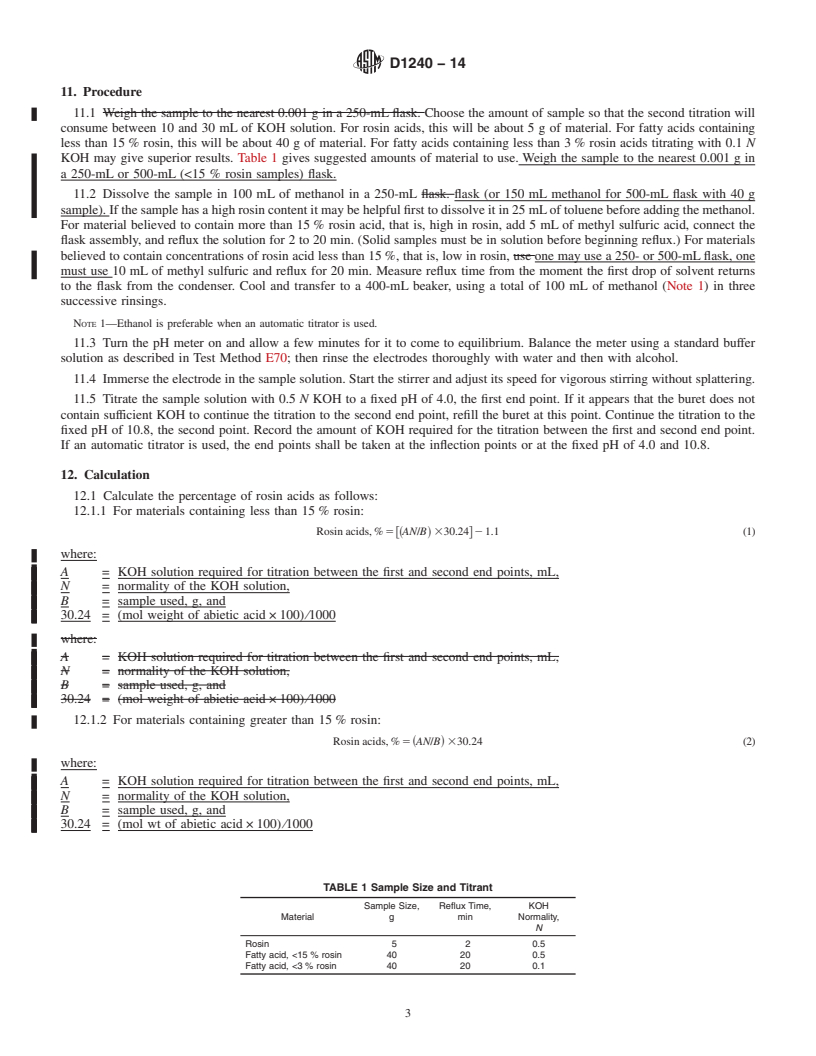

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1240 − 14

Standard Test Methods for

Rosin Acids Content of Pine Chemicals, Including Rosin,

1

Tall Oil, and Related Products

This standard is issued under the fixed designation D1240; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope by selective esterification of fatty acids to form butyl esters

followed by titration of the unreacted rosin acids.

1.1 These test methods cover the determination of rosin

acids in tall oil, tall oil fatty acid, tall oil rosin, and other pine

4. Significance and Use

chemicals products.

4.1 This is a revision of the method for measuring rosin

1.2 These test methods may not be applicable to adducts or

acids content combines the three major ways of determining

derivatives of rosin, fatty acid, or other pine chemicals prod-

the rosin acids content of pine chemicals products into a single

ucts.

method.

1.3 The values stated in SI units are to be regarded as the

4.1.1 For materials containing less than 15% rosin, the

standard. The values given in parentheses are for information

modified Glidden procedure has gained acceptance. For mate-

only.

rials containing more than 15% rosin the modified Wolfe

Methodispreferred.ThemodifiedWolfeandmodifiedGlidden

1.4 This standard does not purport to address all of the

procedures differ only in their details. They have been com-

safety concerns, if any, associated with its use. It is the

bined here into a single procedure. This procedure can be run

responsibility of the user of this standard to establish appro-

using either a potentiometer or an internal indicator to deter-

priate safety and health practices and determine the applica-

mine the end point of the titration. Use of a potentiometer is

bility of regulatory limitations prior to use.

preferredandistherefereemethod.Useofaninternalindicator

2. Referenced Documents

is the principal alternative method. They will be referred to as

2

the Potentiometric Method and the Internal Indicator Method.

2.1 ASTM Standards:

D1585Test Methods for Fatty Acids Content of Naval

5. Reagents

Stores, Including Rosin, Tall Oil, and Related Products

E70Test Method for pH of Aqueous Solutions With the

5.1 Purity of Reagents—Reagent grade chemicals shall be

Glass Electrode

used in all tests. Unless otherwise indicated, it is intended that

E177Practice for Use of the Terms Precision and Bias in all reagents shall conform to the specifications of the Commit-

ASTM Test Methods

tee onAnalytical Reagents of theAmerican Chemical Society

3

E691Practice for Conducting an Interlaboratory Study to where such specifications are available. Other grades may be

Determine the Precision of a Test Method

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

3. Summary of Test Method

accuracy of the determination.

3.1 The rosin acids content is determined by one of two

5.2 Unless otherwise indicated, references to water shall be

procedures; by selective esterification of fatty acids to form

understood to mean deionized or distilled water.

methylestersfollowedbytitrationoftheunreactedrosinacids,

6. Preparation of Sample

1

These test methods are under the jurisdiction of ASTM Committee D01 on 6.1 Homogeneous liquid materials may be used without

Paint and Related Coatings, Materials, and Applications and are the direct

further preparation.

responsibility of Subcommittee D01.34 on Pine Chemicals and Hydrocarbon

Resins.

Current edition approved July 1, 2014. Published August 2014. Originally

3

approved in 1952. Last previous edition approved in 2012 as D1240–12. DOI: Reagent Chemicals, American Chemical Society Specifications, American

10.1520/D1240-14. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1240 − 14

6.2 Nonhomogeneous liquid materials should be heated frequently, either potentiometrically or colorimetrically, using

until they are homogeneous, then a portion ta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1240 − 12 D1240 − 14

Standard Test Methods for

Rosin Acids Content of Pine Chemicals, Including Rosin,

1

Tall Oil, and Related Products

This standard is issued under the fixed designation D1240; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the determination of rosin acids in tall oil, tall oil fatty acid, tall oil rosin, and other pine chemicals

products.

1.2 These test methods may not be applicable to adducts or derivatives of rosin, fatty acid, or other pine chemicals products.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1585 Test Methods for Fatty Acids Content of Naval Stores, Including Rosin, Tall Oil, and Related Products

E70 Test Method for pH of Aqueous Solutions With the Glass Electrode

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1 The rosin acids content is determined by one of two procedures; by selective esterification of fatty acids to form methyl

esters followed by titration of the unreacted rosin acids, by selective esterification of fatty acids to form butyl esters followed by

titration of the unreacted rosin acids.

4. Significance and Use

4.1 This is a revision of the method for measuring rosin acids content combines the three major ways of determining the rosin

acids content of pine chemicals products into a single method.

4.1.1 For materials containing less than 15 % rosin, the modified Glidden procedure has gained acceptance. For materials

containing more than 15 % rosin the modified Wolfe Method is preferred. The modified Wolfe and modified Glidden procedures

differ only in their details. They have been combined here into a single procedure. This procedure can be run using either a

potentiometer or an internal indicator to determine the end point of the titration. Use of a potentiometer is preferred and is the

referee method. Use of an internal indicator is the principal alternative method. They will be referred to as the Potentiometric

Method and the Internal Indicator Method.

5. Reagents

5.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.34 on Pine Chemicals and Hydrocarbon Resins.

Current edition approved Nov. 1, 2012July 1, 2014. Published December 2012August 2014. Originally approved in 1952. Last previous edition approved in 20062012

as D1240 – 02 (2006).D1240 – 12. DOI: 10.1520/D1240-12.10.1520/D1240-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1240 − 14

3

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

5.2 Unless otherwise indicated, references to water shall be understood to mean deionized or distilled water.

6. Preparation of Sample

6.1 Homogeneous liquid materials may be used without further preparation.

6.2 Nonhomogeneous liquid materials should be heated until they are homogeneous, then a portion taken for analysis.

6.3 Solid samples are subject to surface oxidat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.