ASTM A833-19

(Test Method)Standard Test Method for Indentation Hardness of Metallic Materials by Comparison Hardness Testers

Standard Test Method for Indentation Hardness of Metallic Materials by Comparison Hardness Testers

SIGNIFICANCE AND USE

4.1 The comparative hardness test is an empirical dynamic indentation hardness test. Comparative hardness tests provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, heat treatment condition, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

4.2 Comparative hardness testing at a specific location on a test part may not represent the physical characteristics of the whole test part or end product.

SCOPE

1.1 This test method covers the determination of indentation hardness of metallic materials using comparison hardness testers.

1.2 This test method applies only to those portable comparison hardness testers that use test bars that have been standardized according to Test Method E10 as a basis for comparison.

1.3 Calibration of test bars, used for comparison to determine hardness numbers, is also covered by this test method.

1.4 The impression force used during comparison hardness testing is normally an impact load applied by striking a hammer on the appropriate areas as outlined in the manufacturer's instructions.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A833 − 19

Standard Test Method for

Indentation Hardness of Metallic Materials by Comparison

1

Hardness Testers

This standard is issued under the fixed designation A833; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

1.1 Thistestmethodcoversthedeterminationofindentation

E10 Test Method for Brinell Hardness of Metallic Materials

hardness of metallic materials using comparison hardness

E177 Practice for Use of the Terms Precision and Bias in

testers.

ASTM Test Methods

1.2 This test method applies only to those portable compari-

E691 Practice for Conducting an Interlaboratory Study to

son hardness testers that use test bars that have been standard-

Determine the Precision of a Test Method

ized according to Test Method E10 as a basis for comparison.

3. Terminology

1.3 Calibration of test bars, used for comparison to deter-

mine hardness numbers, is also covered by this test method. 3.1 Definitions:

3.1.1 test bar, n—that part of the testing apparatus which is

1.4 The impression force used during comparison hardness

used to determine a comparable hardness used in calculation of

testing is normally an impact load applied by striking a

test part hardness.

hammer on the appropriate areas as outlined in the manufac-

3.1.2 test part, n—the item for which a hardness test

turer’s instructions.

determination is being performed.

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Significance and Use

standard.

4.1 The comparative hardness test is an empirical dynamic

1.6 This standard does not purport to address all of the

indentation hardness test. Comparative hardness tests provide

safety problems, if any, associated with its use. It is the

useful information about metallic materials. This information

responsibility of the user of this standard to establish appro-

maycorrelatetotensilestrength,wearresistance,ductility,heat

priate safety, health, and environmental practices and deter-

treatment condition, or other physical characteristics of metal-

mine the applicability of regulatory limitations prior to use.

licmaterials,andmaybeusefulinqualitycontrolandselection

1.7 This international standard was developed in accor-

of materials.

dance with internationally recognized principles on standard-

4.2 Comparative hardness testing at a specific location on a

ization established in the Decision on Principles for the

test part may not represent the physical characteristics of the

Development of International Standards, Guides and Recom-

whole test part or end product.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5. Apparatus

2. Referenced Documents 5.1 Comparison hardness testers are used principally for

2

testing articles that are too large or unwieldy to be tested in the

2.1 ASTM Standards:

usual types of testing machines, for testing parts of fixed

structures, or for testing under any conditions that require that

1 the indenting force be applied in a direction other than vertical.

This test method is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

5.1.1 Required equipment includes an apparatus that con-

A01.13 on Mechanical and Chemical Testing and Processing Methods of Steel

tains the impression ball and a slot or spacing to insert the test

Products and Processes.

bar, a structure to apply the impact (anvil), and an impacting

Current edition approved Nov. 1, 2019. Published December 2019. Originally

tool, normally a hammer. This apparatus is designed to allow a

approved in 1984. Last previous edition approved in 2017 as A833 – 17. DOI:

10.1520/A0833-19.

ball impression to be produced on the standard rod simultane-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ously with one produced on the piece to be tested. Comparison

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of the impression diameters together with the hardness of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. test bar is used to determine hardness of the test part.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700

...

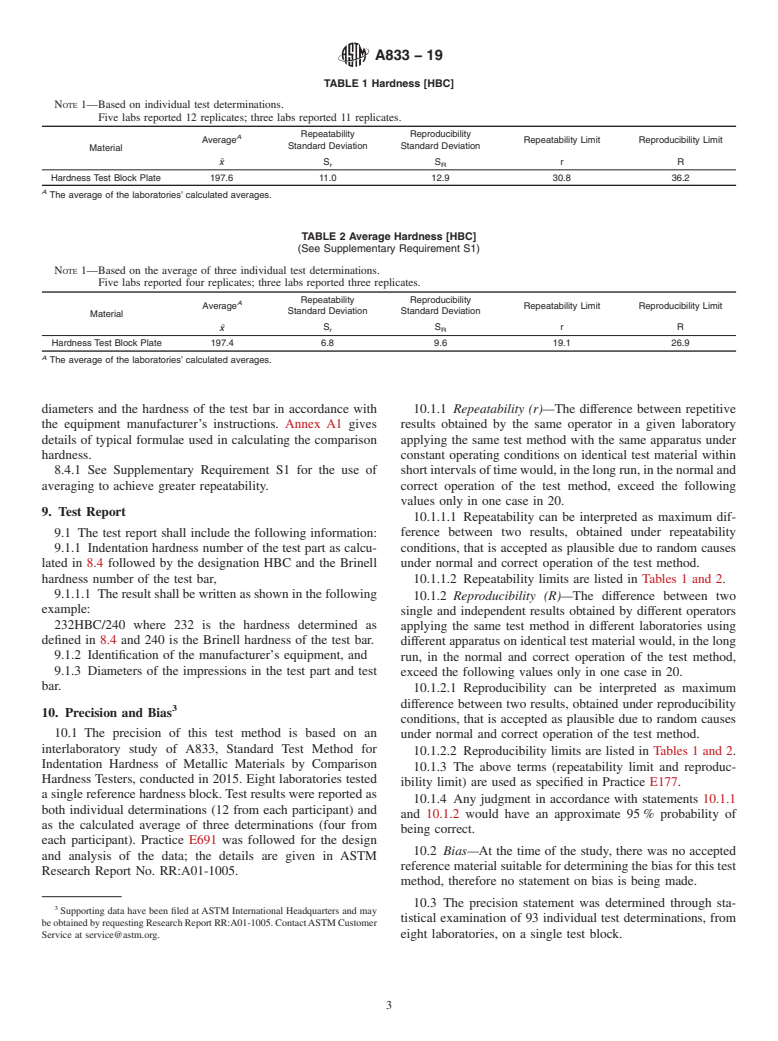

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A833 − 17 A833 − 19

Standard Test Method for

Indentation Hardness of Metallic Materials by Comparison

1

Hardness Testers

This standard is issued under the fixed designation A833; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of indentation hardness of metallic materials using comparison hardness testers.

1.2 This test method applies only to those portable comparison hardness testers that use test bars that have been standardized

according to Test Method E10 as a basis for comparison.

1.3 Calibration of test bars, used for comparison to determine hardness numbers, is also covered by this test method.

1.4 The impression force used during comparison hardness testing is normally an impact load applied by striking a hammer on

the appropriate areas as outlined in the manufacturer’s instructions.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

E10 Test Method for Brinell Hardness of Metallic Materials

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 test bar, n—that part of the testing apparatus which is used to determine a comparable hardness used in calculation of test

part hardness.

3.1.2 test part, n—the item for which a hardness test determination is being performed.

4. Significance and Use

4.1 The comparative hardness test is an empirical dynamic indentation hardness test. Comparative hardness tests provide useful

information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, heat treatment

condition, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

4.2 Comparative hardness testing at a specific location on a test part may not represent the physical characteristics of the whole

test part or end product.

1

This test method is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved Nov. 1, 2017Nov. 1, 2019. Published December 2017November 2019. Originally approved in 1984. Last previous edition approved in 20142017

as A833 – 08aA833 – 17.(2014). DOI: 10.1520/A0833-17.10.1520/A0833-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

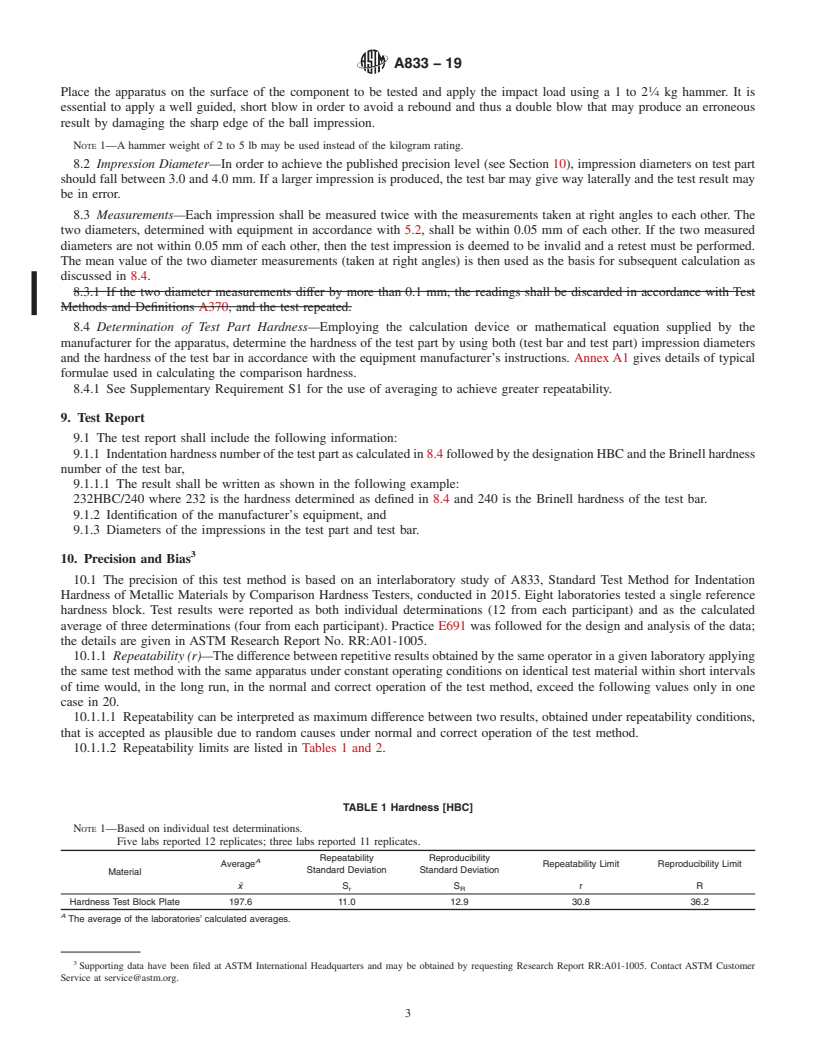

A833 − 19

5. Apparatus

5.1 Comparison hardness testers are used principally for testing articles that are too large or unwieldy to be tested in the usual

types of testing machines, for testing parts of fixed structures, or for testing under any conditions that require that the indenting

force be applied in a direction other than vertical.

5.1.1 Required equipment includes an apparatus that contains the impression ball and a slot or spacing to insert the test bar, a

structure to apply the impact (anvil), and an impacting tool, normally a hammer. This apparatus is desig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.