ASTM A1035/A1035M-07

(Specification)Standard Specification for Deformed and Plain, Low-carbon, Chromium, Steel Bars for Concrete Reinforcement

Standard Specification for Deformed and Plain, Low-carbon, Chromium, Steel Bars for Concrete Reinforcement

ABSTRACT

This specification covers low-carbon, chromium, steel bars, deformed and plane for concrete reinforcement in cut lengths and coils. The bars shall be rolled from properly identified heats of mold cast or strand cast steel using the basic oxygen, electric-furnace, or open-hearth process. Heat analysis shall be performed wherein steel materials shall conform to required chemical compositions of carbon, chromium, manganese, nitrogen, phosphorus, sulfur, and silicon. Steel specimens shall also undergo deformations test, tensile test, and bend test. Steel specimens shall conform to required values of tensile strength, yield strength, stress, and elongation. Final products shall be marked by a tag.

SCOPE

1.1 This specification covers low-carbon, chromium, steel bars, deformed and plain for concrete reinforcement in cut lengths and coils. The standard sizes and dimensions of deformed bars and their number designations are given in Table 1. The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.2 Bars are of two minimum yield strength levels as defined in 9.2: namely, 100 000 psi [690 MPa], and 120 000 [830 MPa] designated as Grade 100 [690] and Grade 120 [830], respectively.

Note 1 Designers need to be aware that typical design standards limit the design strength to 80 000 psi [550 MPa], except for prestressing steel and for spiral transverse reinforcement. Members reinforced with bars with yield strengths that are considerably above 80 000 psi [550 MPa] may exhibit behavior that differs from that expected of conventional reinforced concrete members or may require special detailing to ensure adequate performance at service and factored loads.

1.3 Deformed bars shall have a minimum yield strength and other tensile properties in accordance with Table 2. Hot-rolled plain rounds in sizes up to and including 2.25 in. [57.2 mm] in diameter in coils or cut lengths when specified for dowels, spirals, structural ties or bar supports shall be furnished under this specification and shall also meet the tensile properties requirements of Table 2. Ductility properties for plain rounds shall be those of the nearest smaller nominal diameter deformed bar size in . Requirements covering deformation dimensions and marking are not applicable to plain rounds.

Welding of the material in this specification should be approached with caution since no specific provisions have been included to enhance its weldability. When this steel is to be welded, a welding procedure suitable for the chemical composition and intended use or service should be used.

1.4 This specification is applicable for orders in either inch-pound units (as Specification A 1035) or in SI units (as Specification A 1035M).

1.5 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A1035/A1035M – 07

Standard Specification for

Deformed and Plain, Low-carbon, Chromium, Steel Bars for

1

Concrete Reinforcement

This standard is issued under the fixed designation A1035/A1035M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.4 This specification is applicable for orders in either

inch-pound units (as Specification A1035) or in SI units (as

1.1 This specification covers low-carbon, chromium, steel

Specification A1035M).

bars, deformed and plain for concrete reinforcement in cut

1.5 The values stated in either inch-pound units or SI units

lengths and coils. The standard sizes and dimensions of

are to be regarded as standard. Within the text, the SI units are

deformed bars and their number designations are given in

shown in brackets. The values stated in each system are not

Table 1. The text of this specification references notes and

exact equivalents; therefore, each system must be used inde-

footnotes which provide explanatory material. These notes and

pendentlyoftheother.Combiningvaluesfromthetwosystems

footnotes (excluding those in tables and figures) shall not be

may result in nonconformance with the specification.

considered as requirements of the specification.

1.2 Bars are of two minimum yield strength levels as

2. Referenced Documents

defined in 9.2: namely, 100 000 psi [690 MPa], and 120 000

2

2.1 ASTM Standards:

[830 MPa] designated as Grade 100 [690] and Grade 120

A6/A6M SpecificationforGeneralRequirementsforRolled

[830], respectively.

Structural Steel Bars, Plates, Shapes, and Sheet Piling

NOTE 1—Caution: Designers need to be aware that typical design

A370 Test Methods and Definitions for Mechanical Testing

standards limit the design strength to 80 000 psi [550 MPa], except for

of Steel Products

prestressing steel and for spiral transverse reinforcement. Members

A510 Specification for General Requirements for Wire

reinforced with bars with yield strengths that are considerably above

Rods and Coarse Round Wire, Carbon Steel

80 000 psi [550 MPa] may exhibit behavior that differs from that expected

A700 PracticesforPackaging,Marking,andLoadingMeth-

of conventional reinforced concrete members or may require special

detailing to ensure adequate performance at service and factored loads.

ods for Steel Products for Shipment

A751 Test Methods, Practices, andTerminology for Chemi-

1.3 Deformed bars shall have a minimum yield strength and

cal Analysis of Steel Products

other tensile properties in accordance with Table 2. Hot-rolled

E29 Practice for Using Significant Digits in Test Data to

plain rounds in sizes up to and including 2.25 in. [57.2 mm] in

Determine Conformance with Specifications

diameter in coils or cut lengths when specified for dowels,

3

2.2 U.S. Military Standard:

spirals, structural ties or bar supports shall be furnished under

3

MIL STD-129 Marking for Shipment and Storage

this specification and shall also meet the tensile properties

3

2.3 U.S. Federal Standard:

requirements of Table 2. Ductility properties for plain rounds

3

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

shall be those of the nearest smaller nominal diameter de-

formedbarsizeinTable2.Requirementscoveringdeformation

3. Terminology

dimensions and marking are not applicable to plain rounds.

3.1 Definitions of Terms Specific to This Standard:

NOTE 2—Welding of the material in this specification should be

3.1.1 deformations, n—protrusions on a deformed bar.

approached with caution since no specific provisions have been included

3.1.2 deformed bar, n—steel bar with protrusions; a bar that

to enhance its weldability. When this steel is to be welded, a welding

is intended for use as reinforcement in reinforced concrete

procedure suitable for the chemical composition and intended use or

construction.

service should be used.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.05 on Steel Reinforcement. the ASTM website.

3

Current edition approved March 1, 2007. Published March 2007. Originally AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

approved in 2004. Last previous edition approved in 2006 asA1035/A1035M – 06. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. Or visit: http://

DOI: 10.1520/A1035_A1035M-07. assist.daps.dla.mil/

...

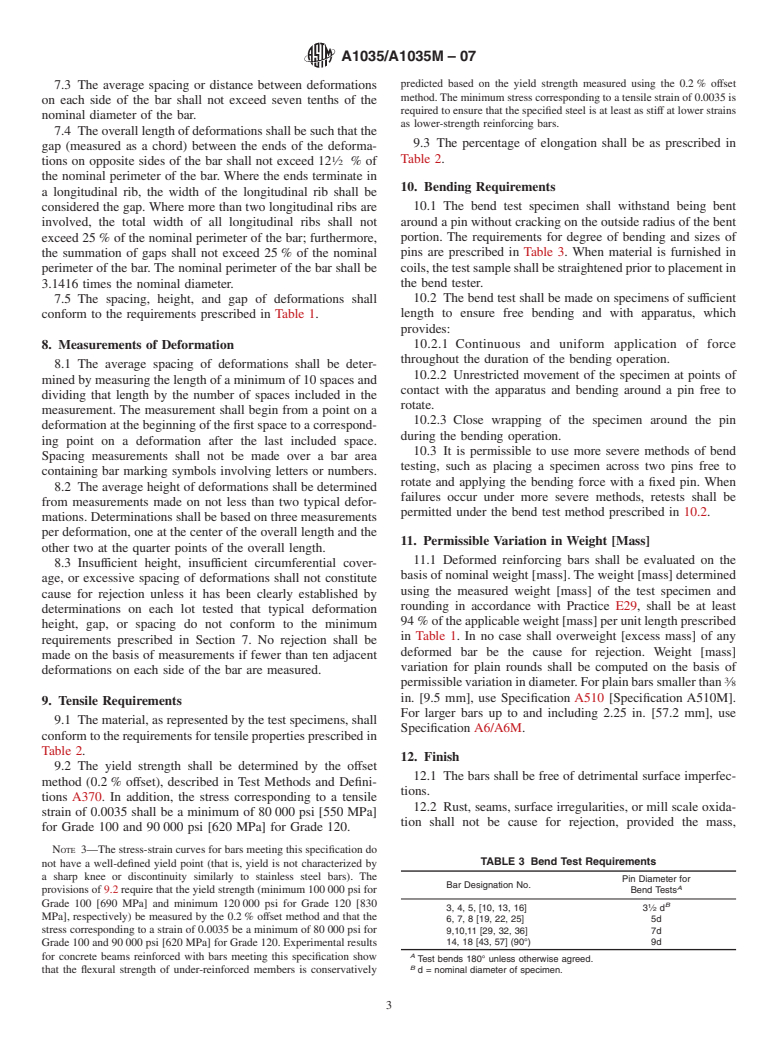

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.