ASTM C1287-95(2001)

(Test Method)Standard Test Method for Determination of Impurities in Uranium Dioxide by Inductively Coupled Plasma Mass Spectrometry

Standard Test Method for Determination of Impurities in Uranium Dioxide by Inductively Coupled Plasma Mass Spectrometry

SCOPE

1.1 This test method covers the determination of 61 elements in uranium dioxide samples by inductively coupled plasma mass spectrometry (ICP-MS). The elements are listed in Table 1 along with their lower reporting limits.

1.2 Similar levels of these elements in other uranic compounds can also be determined if they are treated and converted to the same uranium concentration solution.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific warning statement, see Note 1. Note 1—The ICP-MS is a source of intense ultra-violet radiation from the radio frequency induced plasma. Protection from radio frequency radiation and UV radiation is provided by the instrument under normal operation.

1.4 The test method for the additional elements boron, sodium, silicon, phosphorus, potassium, and calcium is given in Appendix X1.

1.5 The test method for technetium-99 is given in Appendix X2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1287 – 95 (Reapproved 2001)

Standard Test Method for

Determination of Impurities in Uranium Dioxide by

Inductively Coupled Plasma Mass Spectrometry

This standard is issued under the fixed designation C 1287; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Less Than 5 % U

D 1193 Specification for Reagent Water

1.1 This test method covers the determination of 61 ele-

ments in uranium dioxide samples by inductively coupled

3. Summary of Test Method

plasma mass spectrometry (ICP-MS). The elements are listed

3.1 The sample is dissolved in acid. A fixed quantity of

in Table 1 along with their lower reporting limits.

internal standard is added to monitor and correct for signal

1.2 Similar levels of these elements in other uranic com-

instability. The level of impurities in the solution is measured

pounds can also be determined if they are treated and converted

by ICP-MS. Customized software calculates the concentration

to the same uranium concentration solution.

of each element.

1.3 This standard does not purport to address all of the

3.2 Uranium-concentration-matched standard solutions are

safety concerns, if any, associated with its use. It is the

used to calibrate the ICP-MS instrument. The calibration is

responsibility of the user of this standard to establish appro-

,

4 5

linear up to at least 0.2 μg/ml (100 μg/g U) for each analyte.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For a specific

4. Significance and Use

warning statement, see Note 1.

4.1 This test method is capable of measuring the elements in

NOTE 1—Warning: The ICP-MS is a source of intense ultra-violet

Table 1, some of which are required by Specifications C 753,

radiation from the radio frequency induced plasma. Protection from radio

C 776, C 787, C 788, C 967 and C 996.

frequency radiation and UV radiation is provided by the instrument under

normal operation.

5. Apparatus

1.4 The test method for the additional elements boron,

5.1 ICP-MS, controlled by computer and fitted with the

sodium, silicon, phosphorus, potassium, and calcium is given

associated software and peripherals.

in Appendix X1.

5.2 Autosampler, with tube racks and disposable plastic

1.5 The test method for technetium-99 is given in Appendix

sample tubes compatible with 5.1 (optional).

X2.

5.3 Variable Micropipettes:

5.3.1 10 μL to 100 μL capacity.

2. Referenced Documents

5.3.2 100 μL to 1000 μL capacity.

2.1 ASTM Standards:

5.3.3 1000 μL to 10.00 mL capacity.

C 753 Specification for Nuclear-Grade, Sinterable Uranium

5.4 Volumetric Flasks:

Dioxide Powder

5.4.1 50 mL capacity—polypropylene.

C 776 Specification for Sintered Uranium Dioxide Pellets

5.4.2 100 mL capacity—polypropylene.

C 787 Specification for Uranium Hexafluoride for Enrich-

5.4.3 1 L capacity—glass.

ment

5.5 Platinum Dish—100 mL capacity.

C 788 Specification for Nuclear-Grade Uranyl Nitrate So-

5.6 Silica Beaker—250 mL capacity.

lution

C 967 Specification for Uranium Ore Concentrate

C 996 Specification for Uranium Hexafluoride Enriched to Annual Book of ASTM Standards, Vol 11.01.

“ICP-MS Versus Conventional Methods for the Analysis of Trace Impurities in

Nuclear Fuel,” by Allenby, P., Clarkson, A. S., Makinson, P. R., presented at 2nd

This test method is under the jurisdiction of ASTM Committee C26 on Nuclear Surrey Conference on Plasma Source Mass Spectrometry, Guildford, UK, July

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of 1987.

Test. “Trace Metals in NBL Uranium Standard CRM 124 Using ICP-MS,” by

Current edition approved Sept. 10, 1995. Published November 1995. Originally Aldridge, A. J., Clarkson, A. S., Makinson, P. R., Dawson, K. W., presented at 1st

published as C 1287 – 94. Last previous edition C 1287 – 94. Durham International Conference on Plasma Source Mass Spectrometry, Durham,

UK, September 1988.

Annual Book of ASTM Standards, Vol 12.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1287

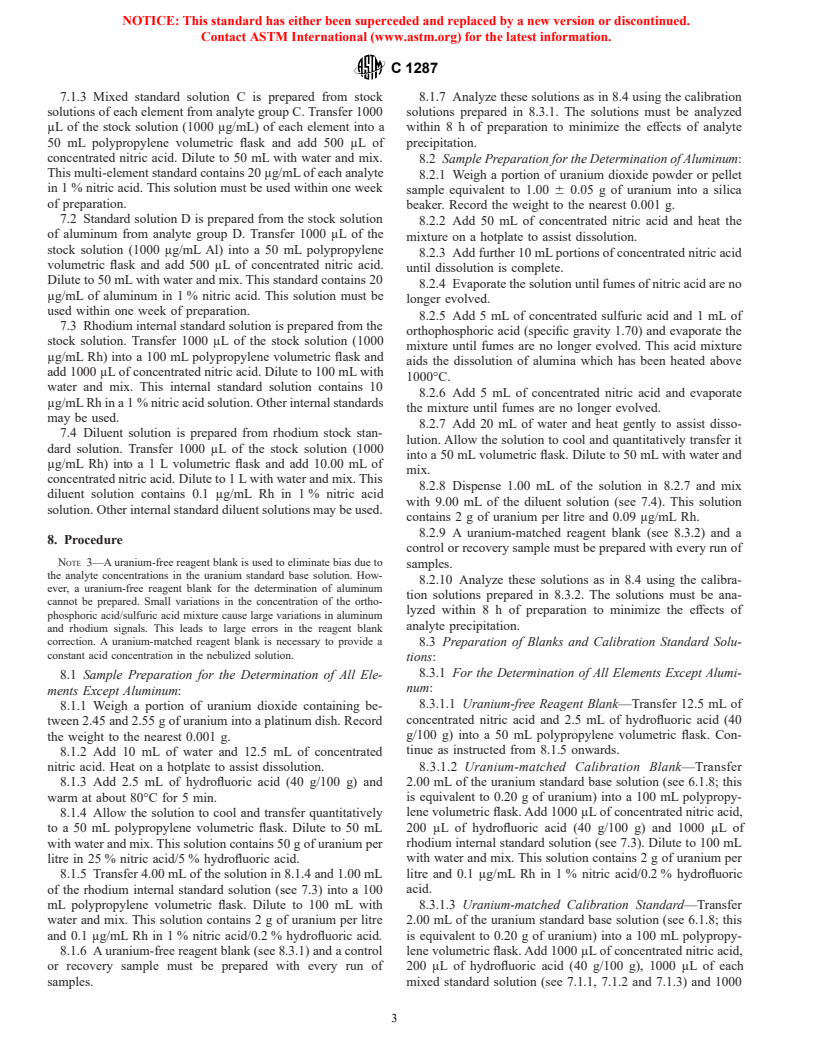

TABLE 1 Reporting Limits of Impurity Elements in Uranium

5.7 Watch Glasses—75 mm diameter.

Dioxide

6. Reagents

NOTE 1—Acquisition time = 10 s/isotope using peak jump mode.

6.1 The sensitivity of the ICP-MS technique requires the use

NOTE 2—103 Rh was used as an internal standard.

NOTE 3—The LRL is based on the within run standard deviation (S )of of ultra high purity reagents in order to be able to obtain the

b

20 uranium-matched blank determinations for each analyte. This limit

low levels of detection. All the reagents below are ultra high

equals 4 3 S , rounded up to a preferred value in the series 1, 1.5, 2, 3, 4,

b

purity grade unless otherwise stated:

6, multiplied or divided by the appropriate integer power of ten.

6.1.1 Element stock standards at 1000 μg/mL for all the

NOTE 4—The upper reporting limit can be increased by extending the

elements in Table 1.

calibration to 10 μg/mL (5000 μg/g U) if the ICP-MS used has an extended

6.1.2 Hydrofluoric acid (40 g/100 g).

dynamic range (EDR) accessory.

6.1.3 Nitric acid (specific gravity 1.42)—Concentrated ni-

Upper Reporting

Mass Analyte Lower Reporting

tric acid (HNO ).

Analyte Limit

Used Group Limit (LRL), μg/g U

(URL), μg/g U

6.1.4 Orthophosphoric acid (specific gravity 1.70).

Lithium 7 A 0.01 100 6.1.5 Rhodium Stock Solution (1000 μg/mL Rh)—

Beryllium 9 A 0.04 100

Commercially available solution (see Note 2).

Magnesium 24 A 4 100

Aluminum 27 D 2 1000

NOTE 2—Rhodium stock solution is commercially available supplied

Scandium 45 A 4 100

with a certificate of analysis for the element and a full range of trace

Titanium 48 B 0.2 100

impurities. The solutions are prepared by the manufacturer using a variety

Vanadium 51 B 0.04 100

of media designed to keep each element in solution for a minimum of one

Chromium 52 B 0.1 100

Manganese 55 A 0.1 100 year.

Iron 56 A 15 100

6.1.6 Sulfuric acid (specific gravity 1.84)—Concentrated

Cobalt 59 A 0.02 100

Nickel 60 A 0.4 100 sulfuric acid (H SO ).

2 4

Copper 65 A 0.2 100

6.1.7 Uranium Standard Base Solution—Uranyl nitrate so-

Zinc 66 A 0.3 100

lution to Specification C 788, of known uranium (100 g/L) and

Gallium 69 A 0.04 100

Germanium 74 A 0.2 100

aluminum content (# 2 μg/g U). The total metallic impurity

Arsenic 75 A 0.2 100

(TMI) content must not exceed 50 μg/g U and no individual

Selenium 82 A 3 100

analyte must exceed 10 μg/g U.

Rubidium 85 A 0.06 100

Strontium 88 A 0.06 100

6.1.8 Purity of Water—Unless otherwise indicated, refer-

Yttrium 89 A 0.04 100

ences to water shall be understood to mean reagent water

Zirconium 90 B 0.02 100

conforming to Specification D 1193, Type I.

Niobium 93 B 0.01 100

Molybdenum 95 B 0.04 100

7. Standards

Ruthenium 102 B 0.02 100

Palladium 106 B 0.2 100

7.1 Three separate mixed standard solutions (A, B and C)

Silver 107 A 0.1 100

are prepared to prevent the precipitation of some elements (as

Cadmium 111 A 0.03 100

Indium 115 A 0.04 100

insoluble chlorides, fluorides etc.; see Table 1 for details of the

Tin 116 B 0.04 100

analyte groups). Analyte group A contains element stock

Antimony 121 B 0.02 100

solutions prepared in HNO or HNO /HF, analyte group B

Tellurium 130 B 0.4 100

3 3

Caesium 133 A 0.06 100

contains element stock solutions prepared in HCl or HCl/HF,

Barium 138 A 0.02 100

and analyte group C contains the rare earth element stock

Lanthanum 139 C 0.1 100

Cerium 140 C 0.01 100 solutions. The mixed standard solutions should be prepared to

Praseodymium 141 C 0.01 100

contain only the analytes of interest. Other combinations of

Neodymium 146 C 0.01 100

mixed standard solutions may be prepared to minimize the

Samarium 149 C 0.01 100

precipitation of the analytes.

Europium 151 C 0.01 100

Gadolinium 158 C 0.01 100

7.1.1 Mixed standard solution A is prepared from stock

Terbium 159 C 0.01 100

solutions of each element from analyte group A. Transfer 1000

Dysprosium 163 C 0.01 100

Holmium 165 C 0.01 100 μL of the stock solution (1000 μg/mL) of each element into a

Erbium 166 C 0.01 100

50 mL polypropylene volumetric flask and add 500 μL of

Thulium 169 C 0.01 100

concentrated nitric acid. Dilute to 50 mL with water and mix.

Ytterbium 174 C 0.01 100

Lutetium 175 C 0.01 100 This multi-element standard contains 20 μg/mL of each analyte

Hafnium 178 B 0.01 100

in 1 % nitric acid. This solution must be used on the day of

Tantalum 181 B 0.01 100

preparation.

Tungsten 184 B 0.01 100

Rhenium 187 A 0.02 100 7.1.2 Mixed standard solution B is prepared from stock

Osmium 190 B 0.2 100

solutions of each element from analyte group B. Transfer 1000

Iridium 193 B 0.2 100

μL of the stock solution (1000 μg/mL) of each element into a

Platinum 195 B 0.2 100

Gold 197 B 0.06 100 50 mL polypropylene volumetric flask and add 500 μL of

Mercury 202 A 0.4 100

concentrated nitric acid. Dilute to 50 mL with water and mix.

Thallium 205 A 0.02 100

This multi-element standard contains 2 μg/mL of each analyte

Lead 208 A 0.02 100

Bismuth 209 A 0.03 100 in 1 % nitric acid. This solution must be used within one week

Thorium 232 B 0.01 100

of preparation.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1287

7.1.3 Mixed standard solution C is prepared from stock 8.1.7 Analyze these solutions as in 8.4 using the calibration

solutions of each element from analyte group C. Transfer 1000 solutions prepared in 8.3.1. The solutions must be analyzed

μL of the stock solution (1000 μg/mL) of each element into a within8hof preparation to minimize the effects of analyte

50 mL polypropylene volumetric flask and add 500 μL of precipitation.

concentrated nitric acid. Dilute to 50 mL with water and mix. 8.2 Sample Preparation for the Determination of Aluminum:

This multi-element standard contains 20 μg/mL of each analyte

8.2.1 Weigh a portion of uranium dioxide powder or pellet

in 1 % nitric acid. This solution must be used within one week

sample equivalent to 1.00 6 0.05 g of uranium into a silica

of preparation.

beaker. Record the weight to the nearest 0.001 g.

7.2 Standard solution D is prepared from the stock solution

8.2.2 Add 50 mL of concentrated nitric acid and heat the

of aluminum from analyte group D. Transfer 1000 μL of the

mixture on a hotplate to assist dissolution.

stock solution (1000 μg/mL Al) into a 50 mL polypropylene

8.2.3 Add further 10 mL portions of concentrated nitric acid

volumetric flask and add 500 μL of concentrated nitric acid.

until dissolution is complete.

Dilute to 50 mL with water and mix. This standard contains 20

8.2.4 Evaporate the solution until fumes of nitric acid are no

μg/mL of aluminum in 1 % nitric acid. This solution must be

longer evolved.

used within one week of preparation.

8.2.5 Add 5 mL of concentrated sulfuric acid and 1 mL of

7.3 Rhodium internal standard solution is prepared from the

orthophosphoric acid (specific gravity 1.70) and evaporate the

stock solution. Transfer 1000 μL of the stock solution (1000

mixture until fumes are no longer evolved. This acid mixture

μg/mL Rh) into a 100 mL polypropylene volumetric flask and

aids the dissolution of alumina which has been heated above

add 1000 μL of concentrated nitric acid. Dilute to 100 mL with

1000°C.

water and mix. This internal standard solution contains 10

8.2.6 Add 5 mL of concentrated nitric acid and evaporate

μg/mL Rh in a 1 % nitric acid solution. Other internal standards

the mixture until fumes are no longer evolved.

may be used.

8.2.7 Add 20 mL of water and heat gently to assist disso-

7.4 Diluent solution is prepared from rhodium stock stan-

lution. Allow the solution to cool and quantitatively transfer it

dard solution. Transfer 1000 μL of the stock solution (1000

into a 50 mL volumetric flask. Dilute to 50 mL with water and

μg/mL Rh) intoa1L volumetric flask and add 10.00 mL of

mix.

concentrated nitric acid. Dilute to 1 L with water and mix. This

8.2.8 Dispense 1.00 mL of the solution in 8.2.7 and mix

diluent solution contains 0.1 μg/mL Rh in 1 % nitric acid

with 9.00 mL of the diluent solution (see 7.4). This solution

solution. Other internal standard diluent solutions may be used.

contains2gof uranium per litre and 0.09 μg/mL Rh.

8.2.9 A uranium-matched reagent blank (see 8.3.2) and a

8. Procedure

control or recovery sample must be prepared with every run of

NOTE 3—A uranium-free reagent blank is used to eliminate bias due to

samples.

the analyte concentrations in the uranium standard base solution. How-

8.2.10 Analyze these solutions as in 8.4 using the calibra-

ever, a uranium-free reagent blank for the determination of aluminum

tion solutions prepared in 8.3.2. The solutions must be ana-

cannot be prepared. Small variations in the concentration of the ortho-

lyzed within8hof preparation to minimize the effects of

phosphoric acid/sulfuric acid mixture cause large variations in aluminum

analyte precipitation.

and rhodium signals. This leads to large errors in the reagent blank

correction. A uranium-matched reagent blank is necessary to provide a 8.3 Preparation of Blanks and Calibration Standard Solu-

constant acid concentration in the nebulized solution.

tions:

8.3.1 For the Determination of All Elements Except Alumi-

8.1 Sample Preparation for the Determination of All Ele-

num:

ments Except Aluminum:

8.3.1.1 Uranium-free Reagent Blank—Transfer 12.5 mL of

8.1.1 Weigh a portion of uranium dioxide containing be-

concentrated nitric acid and 2.5 mL of hydrofluoric acid (40

tween 2.45 and 2.55 g of uranium into a platinum dish. Record

g/100 g) into a 50 mL polypropylene volumetric flask. Con-

the weight to the nearest 0.001 g.

tinue as instructed from 8.1.5 onwards.

8.1.2 Add 10 mL of water and 12.5 mL of concentrated

8.3.1.2 Uranium-matched Calibration Blank—Transfer

nitric acid. Heat on a hotplate to assist dissolution.

8.1.3 Add 2.5 mL of hydrofluoric acid (40 g/100 g) and 2.00 mL of the uranium standard base solution (see 6.1.8; this

is equivalent to 0.20 g of uranium) into a 100 mL polypropy-

warm at about 80°C for 5 min.

8.1.4 Allow the solution to cool and transfer quantitatively lene volumetric flask. Add 1000 μL of concentrated nitric acid,

200 μL of hydrofluoric acid (40 g/100 g) and 1000 μL of

to a 50 mL polypropylene volumetric fl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.