ASTM F37-06(2019)

(Test Method)Standard Test Methods for Sealability of Gasket Materials

Standard Test Methods for Sealability of Gasket Materials

SIGNIFICANCE AND USE

4.1 These test methods are designed to compare gasket materials under controlled conditions and to provide a precise measure of leakage rate.

4.2 These test methods are suitable for measuring leakage rates as high as 6 L/h and as low as 0.3 mL/h. In many cases, “zero” leakage may not be attainable.

4.3 These test methods evaluate leakage rates after time periods that are typically 5 to 30 min under load. Holding a gasket material under load for extended time periods may give different results.

4.4 If the fluid being used in the test causes changes, such as swelling, in the gasket material, then unpredictable results may be obtained.

SCOPE

1.1 These test methods provide a means of evaluating the sealing properties of sheet and solid form-in-place gasket materials at room temperature. Test Method A is restricted to liquid leakage measurements, whereas Test Method B may be used for both liquid and gas leakage measurements.

1.2 These test methods are suitable for evaluating the sealing characteristics of a gasket material under different compressive flange loads. The test method may be used as an acceptance test when the producer and user have agreed to specific test conditions for the following parameters: test medium, internal pressure on medium, and flange load on gasket specimens.

1.3 These test methods use a small-diameter narrow-width gasket as the test specimen under relatively low gasket loads and relatively low pressures. Test Method F2378 is another sealability test method that uses a larger gasket specimen and higher internal pressures and flange loads.

1.4 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (For specific hazard or warning statements, or both, see 5.2.11, Section 6, 6.3, 8.2.4, 11.3.2, and 11.4.2.)

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F37 − 06 (Reapproved 2019)

Standard Test Methods for

1

Sealability of Gasket Materials

This standard is issued under the fixed designation F37; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 These test methods provide a means of evaluating the

D471 Test Method for Rubber Property—Effect of Liquids

sealing properties of sheet and solid form-in-place gasket

D2000 Classification System for Rubber Products in Auto-

materials at room temperature. Test Method A is restricted to

motive Applications

liquid leakage measurements, whereas Test Method B may be

E691 Practice for Conducting an Interlaboratory Study to

used for both liquid and gas leakage measurements.

Determine the Precision of a Test Method

1.2 These test methods are suitable for evaluating the

F38 Test Methods for Creep Relaxation of a Gasket Material

sealing characteristics of a gasket material under different

F104 Classification System for Nonmetallic Gasket Materi-

compressive flange loads. The test method may be used as an

als

acceptance test when the producer and user have agreed to

F2378 Test Method for Sealability of Sheet, Composite, and

specific test conditions for the following parameters: test

Solid Form-in-Place Gasket Materials

3

medium, internal pressure on medium, and flange load on

2.2 ANSI Standard:

gasket specimens.

B57.1 Compressed Gas Cylinder Valve Outlet and Inlet

Connections

1.3 These test methods use a small-diameter narrow-width

2.3 ASTM Adjuncts:

gasket as the test specimen under relatively low gasket loads

4

Leakage Test Fixtures

and relatively low pressures. Test Method F2378 is another

sealability test method that uses a larger gasket specimen and

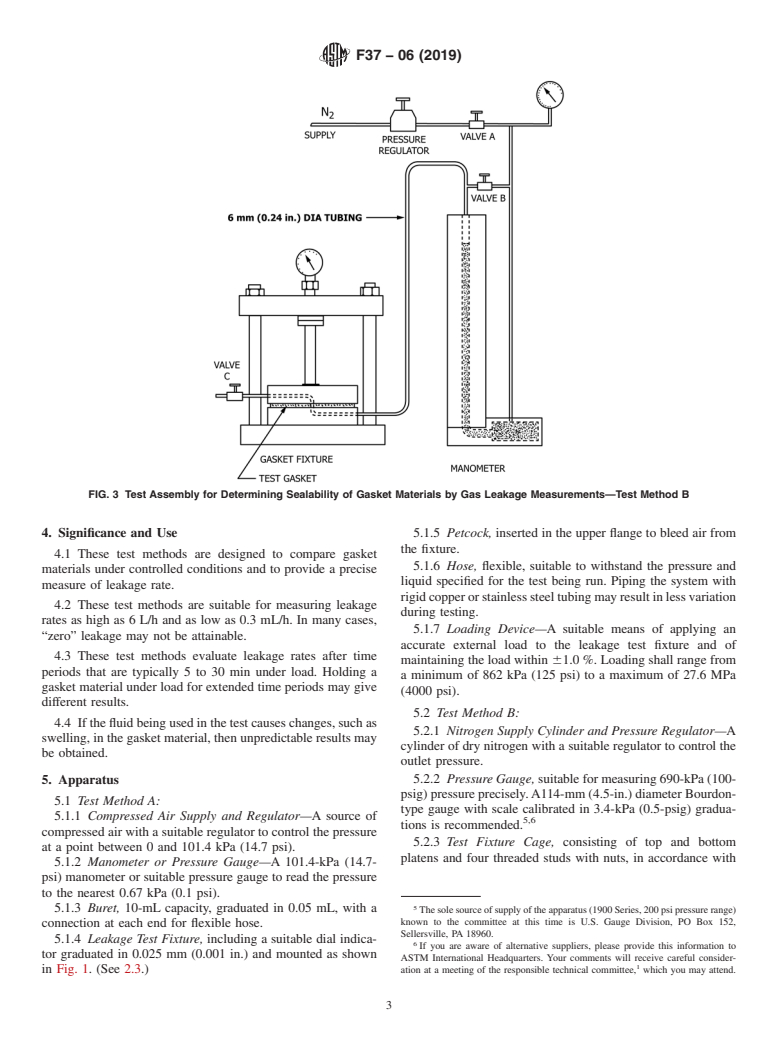

3. Summary of Test Methods

higher internal pressures and flange loads.

3.1 Both test methods utilize a test specimen compressed

1.4 The values stated in SI units are to be regarded as the

betweenthesurfacesoftwosmoothsteelflangefaces.Afterthe

standard. The values in parentheses are for information only.

specified flange load is applied, the test medium is introduced

into the center of the annular gasket compressed between the

1.5 This standard does not purport to address all of the

flangesandthespecifiedpressureisappliedtothemedium.For

safety concerns, if any, associated with its use. It is the

liquid sealability tests (Test MethodsAand B), Reference Fuel

responsibility of the user of this standard to establish appro-

A (see Test Method D471, Motor Fuel Section of Annex) is

priate safety, health, and environmental practices and deter-

recommended and the leakage rate is measured by a change in

mine the applicability of regulatory limitations prior to use.

the level of a sight-glass located in the line upstream from the

(For specific hazard or warning statements, or both, see 5.2.11,

gasket testing fixture. Nitrogen is the recommended gas for the

Section 6, 6.3, 8.2.4, 11.3.2, and 11.4.2.)

gas sealability test (Test Method B) and the leakage rate is

1.6 This international standard was developed in accor-

measured by a change in the level of a water manometer

dance with internationally recognized principles on standard-

located in the line upstream from the gasket testing fixture.

ization established in the Decision on Principles for the

3.1.1 Test MethodAuses a test fixture (Fig. 1) by which an

Development of International Standards, Guides and Recom-

external load is transferred into the fixture to produce a

mendations issued by the World Trade Organization Technical

compressive force on the gasket specimen.

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

These test methods are under the jurisdiction of ASTM Committee F03 on Standards volume information, refer to the standard’s Document Summary page on

Gaskets and are the direct responsibility of Subcommittee F03.10 on Composite the ASTM website.

3

Gaskets. Available from American National Standards Institute, 11 W. 42nd St., 13th

Current edition approved May 1, 2019. Published June 2019. Originally Floor, New York, NY 10036.

4

approved in 1962. Last previous edition approved in 2013 as F37 – 06 (2013). DOI: Available from ASTM International Headquarters. Order Adjunct No.

10.1520/F0037-06R19. A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.