ASTM F1817-17(2022)

(Test Method)Standard Test Method for Performance of Conveyor Ovens

Standard Test Method for Performance of Conveyor Ovens

SIGNIFICANCE AND USE

5.1 The energy input rate test and thermostat calibration are used to confirm that the conveyor oven is operating properly prior to further testing and to insure that all test results are determined at the same temperature.

5.2 Preheat energy and time can be useful to food service operators to manage power demands and to know how quickly the conveyor oven can be ready for operation.

5.3 Idle Energy Rate—This test provides a measure of an empty oven’s energy consumption and pilot energy during noncooking periods, at a typical cooking temperature setting. It also provides an indicator of the combined effectiveness of components of the oven’s design (for example, insulation, door seals, and combustion efficiency) that influence its energy consumption.

5.4 Cooking Energy Efficiency—A precise indicator of conveyor oven energy performance while cooking a typical food product under various loading conditions. If energy performance information is desired using a food product other than the specified test food, the test method could be adapted and applied. Energy performance information allows an end user to better understand the operating characteristics of a conveyor oven.

5.5 Production capacity information can help an end user to better understand the production capabilities of a conveyor oven as it is used to cook a typical food product and this could help in specifying the proper size and quantity of equipment. If production information is desired using a food product other than the specified test food, the test method could be adapted and applied.

SCOPE

1.1 This test method covers an evaluation of the energy consumption and cooking performance of conveyor ovens. The food service operator can use this evaluation to select a conveyor oven and understand its energy consumption.

1.2 This test method is applicable to gas and electric conveyor ovens.

1.3 The conveyor oven can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate and thermostat calibration (see 10.2),

1.3.2 Preheat energy consumption and time (see 10.3),

1.3.3 Idle energy rate (see 10.4),

1.3.4 Pilot energy rate (if applicable) (see 10.5), and

1.3.5 Cooking energy efficiency and production capacity (see 10.6).

1.4 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1817 − 17 (Reapproved 2022) An American National Standard

Standard Test Method for

1

Performance of Conveyor Ovens

This standard is issued under the fixed designation F1817; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers an evaluation of the energy 2.1 ASHRAE Documents:

consumptionandcookingperformanceofconveyorovens.The 2013ASHRAE Handbook of FundamentalsChapter 1, Psy-

chrometrics

food service operator can use this evaluation to select a

2014ASHRAE Handbook—Refrigeration Chapter 19Ther-

conveyor oven and understand its energy consumption.

mal Conductivity of Foods, page 9 (R19.9); Diffusivity of

1.2 This test method is applicable to gas and electric

foods, R19.17, and Enthalpy of foods R19.8

conveyor ovens.

ASHRAE Guideline 2-1986 (RA90)Engineering Analysis

of Experimental Data

1.3 The conveyor oven can be evaluated with respect to the

ASHRAE Guideline 2 2010 (RA 2014)Engineering Analy-

following (where applicable):

sis of Experimental Data

1.3.1 Energy input rate and thermostat calibration (see

2.2 Other Document:

10.2),

AOAC Procedure 984.25Moisture (Loss of Mass on Dry-

1.3.2 Preheat energy consumption and time (see 10.3), 3

ing) in Frozen French Fried Potatoes

1.3.3 Idle energy rate (see 10.4),

3. Terminology

1.3.4 Pilot energy rate (if applicable) (see 10.5), and

1.3.5 Cooking energy efficiency and production capacity 3.1 Definitions of Terms Specific to This Standard:

3.1.1 chamber stabilization pizzas, n—full cooking cavity

(see 10.6).

loadofnominal12in.pizzasloadedatbeginningofproduction

1.4 The values stated in inch-pound units are to be regarded

capacity test.

asstandard.Nootherunitsofmeasurementareincludedinthis

3.1.2 conveyor oven, n—an appliance that carries the food

standard.

product on a moving conveyor into and through a heated

1.5 This test method may involve hazardous materials,

chamber.The chamber may be heated by gas or electric forced

operations, and equipment. This standard does not purport to convection, radiant, or quartz tubes. Top and bottom heat may

be independently controlled.

address all of the safety concerns, if any, associated with its

use. It is the responsibility of the user of this standard to

3.1.3 cooking energy effıciency, n—quantity of energy im-

establish appropriate safety, health, and environmental prac-

parted to the specified food product, expressed as a percentage

tices and determine the applicability of regulatory limitations of energy consumed by the conveyor oven during the cooking

event.

prior to use.

1.6 This international standard was developed in accor- 3.1.4 cooking energy rate, n—average rate of energy con-

sumption (Btu/h or kW) during the cooking energy efficiency

dance with internationally recognized principles on standard-

tests.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.5 cooking stabilization pizzas, n—full cooking chamber

mendations issued by the World Trade Organization Technical

ofnominal12in.pizzascontinuouslyloadeddirectlyfollowing

Barriers to Trade (TBT) Committee.

the test pizzas. Pizzas keep the cooking chamber consistent

during the measured test pizzas.

1

This test method is under the jurisdiction of ASTM Committee F26 on Food

2

Service Equipment and is the direct responsibility of Subcommittee F26.06 on Available from American Society of Heating, Refrigerating, and Air-

Productivity and Energy Protocol. Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

Current edition approved May 1, 2022. Published June 2022. Originally 30329.

3

approved in 1997. Last previous edition approved in 2017 as F1817–17. DOI: Available from AOAC International, 2275 Research Blvd., Suite 300,

10.1520/F1817-17R22. Rockville, MD 20850-3250, http://www.aoac.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1817 − 17 (2022)

3.1.6 energy input rate, n—peak rate at which a conveyor 4.6 Cooking Uniformity—The uniformity of heating within

oven consumes energy (Btu/h or kW). the oven’s cavity is determined and reported based on the

product cooked temperature per cooking position and visual of

3.1.7 idle energy rate, n—the conveyor oven’s rate of

product appearance top and bottom.

energy consumption (kW or

...

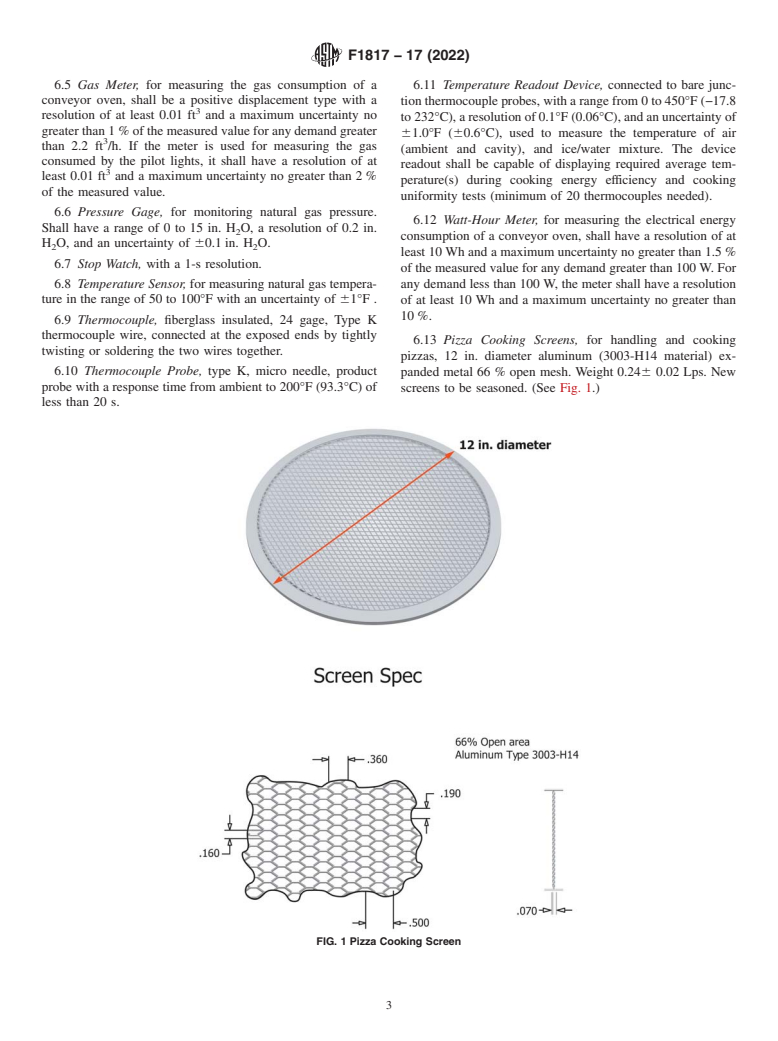

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.