ASTM A840/A840M-00

(Specification)Standard Specification for Fully Processed Magnetic Lamination Steel

Standard Specification for Fully Processed Magnetic Lamination Steel

SCOPE

1.1 This specification covers cold-rolled carbon steel coils or strip used in the fully processed condition in magnetic lamination applications.

1.2 This steel is produced to specified maximum core-loss values and is intended primarily for commercial power frequency (50- and 60-Hz) applications in magnetic devices. Desirable core-loss and permeability characteristics are developed during mill processing, so further heat treatment by the purchaser is not necessary for most uses.

1.3 Fully processed magnetic lamination steels are flat-rolled low carbon iron alloys having 1 % maximum silicon and 0.4 % maximum aluminum.

1.4 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 840/A 840M – 00

Standard Specification for

Fully Processed Magnetic Lamination Steel

ThisstandardisissuedunderthefixeddesignationA840/A840M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 719 Test Method for Lamination Factor of Magnetic

Materials

1.1 This specification covers cold-rolled carbon steel coils

or strip used in the fully processed condition in magnetic

3. Terminology

lamination applications.

3.1 The terms and symbols used in this specification are

1.2 This steel is produced to specified maximum core-loss

defined in Terminology A340.

values and is intended primarily for commercial power fre-

quency (50- and 60-Hz) applications in magnetic devices.

4. Classification

Desirable core-loss and permeability characteristics are devel-

4.1 The fully processed magnetic lamination steel types

oped during mill processing, so further heat treatment by the

described by this specification are as shown in Table 1.

purchaser is not necessary for most uses.

1.3 Fully processed magnetic lamination steels are flat-

5. Ordering Information

rolledlowcarbonironalloyshaving1%maximumsiliconand

5.1 Ordersformaterialunderthisspecificationshallinclude

0.4% maximum aluminum.

as much of the following information as necessary to describe

1.4 The values stated in customary (cgs-emu and inch-

the desired material adequately:

pound) units are to be regarded as standard. The values given

5.1.1 ASTM specification number.

in parentheses are mathematical conversions to SI units, which

5.1.2 Name of material (fully processed magnetic lamina-

are provided for information only and are not considered

tion steel).

standard.

5.1.3 ASTM core-loss type number.

5.1.4 Thickness, width and length (if in cut lengths instead

2. Referenced Documents

of coils).

2.1 ASTM Standards:

5.1.5 Total weight of ordered item.

A34/A34M Practice for Sampling and Procurement Test-

2 5.1.6 Limitations in coil size or lift weights.

ing of Magnetic Materials

5.1.7 End Use—The purchaser shall disclose as much

A 340 Terminology of Symbols and Definitions Relating to

2 pertinent information as possible about the intended applica-

Magnetic Testing

tion to enable the supplier to provide material characteristics

A 343 Test Method forAlternating-Current Magnetic Prop-

most suitable for specific fabricating practices.

ertiesofMaterialsatPowerFrequenciesUsingWattmeter-

5.1.8 Special requirements or exceptions to the provisions

Ammeter-Voltmeter Method and 25-cm Epstein Test

2 of this specification.

Frame

A 664 Practice for the Identification of Standard Electrical-

6. Manufacture

and Lamination-Steel Grades in ASTM Specifications

6.1 Melting Practice:

A700 PracticesforPackaging,MarkingandLoadingMeth-

6.1.1 These fully processed magnetic lamination steels may

ods for Steel Products for Domestic Shipment

be made by basic oxygen, electric furnace, or other steelmak-

ing practices.

1 6.1.2 Thesesteelstypicallycontainlessthan0.03%carbon.

This specification is under the jurisdiction of ASTM Committee A06 on

6.1.3 The addition of silicon, aluminum, manganese, and

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

Materials Specifications.

phosphorus may be used to enhance punchability and improve

Current edition approved Oct. 10, 2000. Published December 2000. Originally

magnetic properties by increasing electrical resistivity. The

e1

published as A840–85. Last previous edition A840–91 (1996) .

alloy additions are usually restricted such that the density of

Annual Book of ASTM Standards, Vol 03.04.

3 3

Annual Book of ASTM Standards, Vol 01.05. these steels is maintained above 7.825 g/cm (7825 kg/m ).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 840/A 840M

A B C

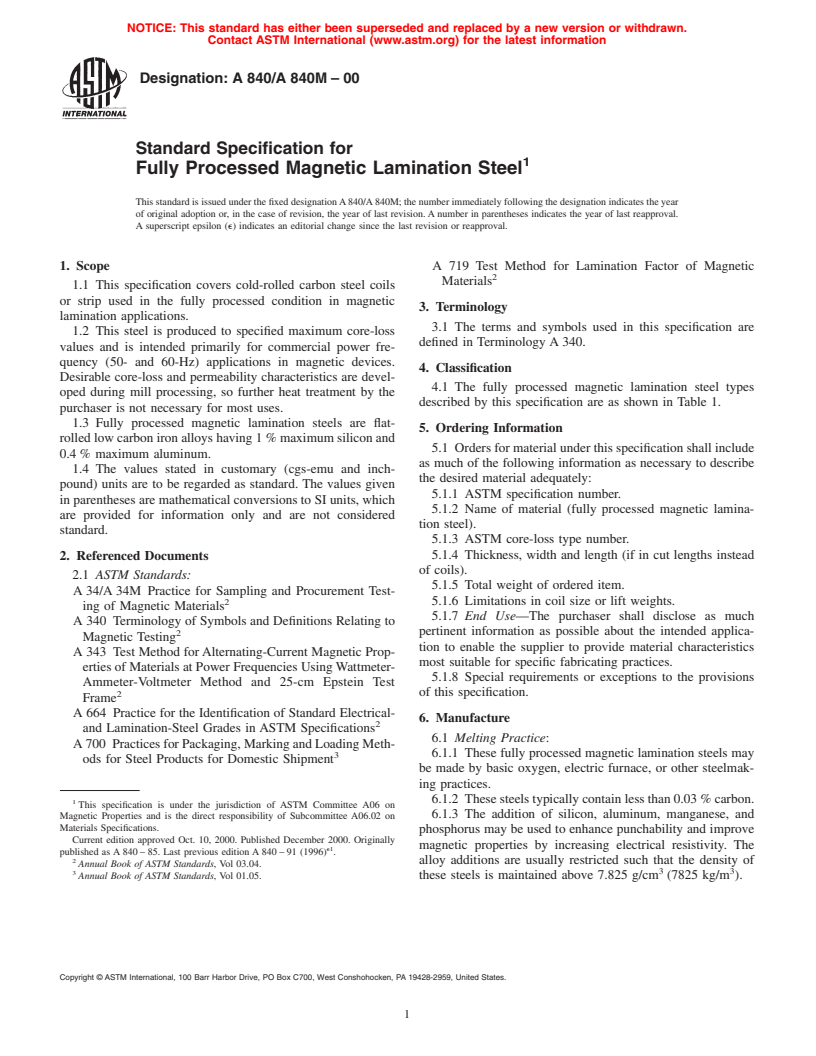

TABLE 1 Core-Loss Types and Maximum Core-Loss Values at 15 kG (1.5 T) and 60 Hz for As-Sheared Epstein Specimens

Strip Thickness, Maximum Core Loss

Typical Relative Peak

A

ASTM Core-Loss Type

Permeability

in. (mm) W/lb (W/kg)

47C550 0.0185 (0.47) 5.50 (12.13) 1150

47C600 6.00 (13.23) 1300

64C700 0.025 (0.64) 7.00 (15.43) 1250

64C750 7.50 (16.53) 1400

A

See Practice A 644.

B

Maximum core losses at 15 kG (1.5 T) and 50 Hz are 0.79 times maximum core loss at 60 Hz.

C

One half of the strips cut parallel to and one half of the strips cut perpendicular to the rolling direction.

6.1.4 Residual elements such as copper, nickel, chromium, 9. Dimensions and Permissible Variations

molybdenum, and tin should be held as low as practicable.

9.1 Thickness—Specified thickness should be one of the

6.1.5 The producer is not required to report chemical

common thicknesses as follows:

composition of each lot except where a clear need for such

Thickness, in. (mm)

information has been shown. In such cases, the analyses to be

0.0185 (0.47)

reported shall be negotiated between the manufacturer and the

0.025 (0.64)

purchaser.

6.2 Typical Processing: 9.2 Thickness Variations—The average thickness of the

material supplied shall be as close as possible to the ordered

6.2.1 Processing sequence for fully processed magnetic

lamination steel comprises hot rolling, pickling, cold rolling, thickness. Measurements made with a contacting micrometer

atpointsnocloserthan ⁄8in.(10mm)fromtheedgeofasheet

and annealing.

6.2.2 Themillannealingoperationistypicallynondecarbur- or coil of specified width shall not differ from the specified

thickness by more than the value (which include taper) shown

izing or partially decarburizing, resulting in a finished product

that can be prone to magnetic aging depending on the carbon in Table 2.

9.3 Taper—The rolling of flat rolled coils inherently pro-

content.

6.2.3 Unless otherwise specified, these steels are supplied duces an edge which is thinner than the rest of the coil width.

This characteristic is termed tapered edge or feather or gamma

with a smooth surface finish in the as-annealed condition. The

and occurs primarily within 1 or 2 in. (25 or 50 mm) from the

requiredsurfacetextureisimpartedfromtherollsurfacetothe

as-rollededgeofthematerial.Thethicknessvariationinvolved

steel surface during cold rolling.

inedgetapersometimesisthemajorportionofthetotaloverall

6.3 When changes in the manufacture of the material are

believed to exert possible significant effects upon the user’s thickness variation permitted in 9.2. It may be expected that in

the case of edge slit coils, the following limits on the

fabricating practices and upon the magnetic performance to be

obtained in the specified end use, the manufacturer shall notify differencesinthicknessmeasuredwithinthefirst2in.(50mm)

or less from either edge of the ordered width will apply:

the purchaser before shipment is made to provide opportunity

to evaluate the effects.

Ordered Thickness, Maximum Taper,

in. (mm) in. (mm)

7. Magnetic Properties

0.0185 0.47 0.0012 0.030

7.1 Core losses are guaranteed and shall conform to the

0.025 0.64 0.0014 0.036

limits given in Table 1.

More restricted taper tolerances or tolerances on mill edge

7.2 Permeabilitydependsonalloycompositionandprocess-

coils shall be negotiated between the manufacturer and the

ing. Relative peak permeability is a dimensionless quantity

purchaser.

which is the same in all unit systems. Typical relative peak

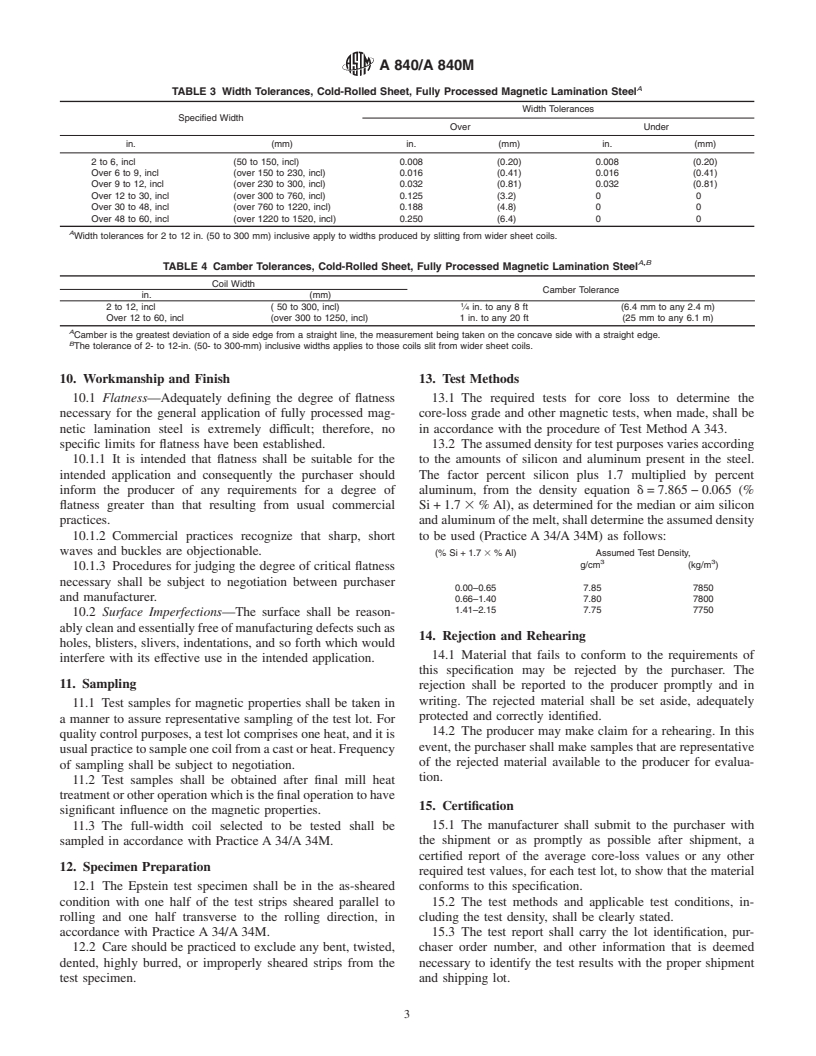

9.4 Width Tolerances—Maximum deviations from the or-

permeability values are found in Table 1.

dered width shall be as shown in Table 3.

7.3 Note that fully processed electrical steels do not nor-

9.5 Camber—Camber is the greatest deviation of a side

mally need a user anneal. Therefore, care must be taken to

edge from a straight line, the measurement being taken on th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.