ASTM E2302-03a(2009)

(Test Method)Standard Test Method for Measurement of the Luminance Coefficient Under Diffuse Illumination of Pavement Marking Materials Using a Portable Reflectometer

Standard Test Method for Measurement of the Luminance Coefficient Under Diffuse Illumination of Pavement Marking Materials Using a Portable Reflectometer

SIGNIFICANCE AND USE

The quality of the stripe for visibility in daylight or under road lighting is determined by the luminance coefficient under diffuse illumination, Qd, and depends on the materials used, age, and wear pattern. These conditions shall be observed and noted by the user.

Under the same conditions of illumination and viewing, higher levels of Qd correspond to higher levels of lightness.

Reflectivity of pavement (road) markings degrade with traffic wear and require periodic measurement to ensure that sufficient line visibility is provided to drivers.

For a given viewing distance, measurements of Qd made with a reflectometer having a geometry corresponding to that distance are a good indicator of the visual ranking of material measured.

specified by CEN, the measurement geometry of the instrument is based on a viewing distance of 30 m and an eye height of 1.2 m.

It shall be the responsibility of the user to employ an instrument having the specified co-viewing angle.

SCOPE

1.1 This test method covers measurement of the luminance coefficient under diffuse illumination of horizontal pavement markings, such as traffic stripes and surface symbols, and pavement surfaces, in a particular viewing direction using a portable reflectometer.

Note 1—The luminance coefficient under diffuse illumination is a measure of the reflection of horizontal pavement markings and pavement surfaces in a particular viewing direction in daylight or under road lighting. Diffuse illumination approximates daylight illumination from the overcast sky, and road lighting as an average of locations on the pavement surface.

1.2 The co-viewing angle of the reflectometer affects the readings. As specified by the European Committee for Standardization (CEN), the co-viewing angle shall be 2.29°.

1.3 This test method is intended to be used for field measurement of pavement markings and pavement surfaces but may be used to measure the performance of materials on sample panels before placing the marking material in the field.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2302 −03a(Reapproved 2009)

Standard Test Method for

Measurement of the Luminance Coefficient Under Diffuse

Illumination of Pavement Marking Materials Using a Portable

Reflectometer

This standard is issued under the fixed designation E2302; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standard:

CEN EN 1436Road Marking Materials—Road Marking

1.1 This test method covers measurement of the luminance

Performance for Road Users

coefficient under diffuse illumination of horizontal pavement

markings, such as traffic stripes and surface symbols, and

3. Terminology

pavement surfaces, in a particular viewing direction using a

3.1 The terminology used in this test method generally

portable reflectometer.

agrees with that used in Terminology E284.

NOTE 1—The luminance coefficient under diffuse illumination is a

measure of the reflection of horizontal pavement markings and pavement

3.2 Definitions:

surfaces in a particular viewing direction in daylight or under road

3.2.1 luminance coeffıcient under diffuse illumination; Qd,

lighting.Diffuseilluminationapproximatesdaylightilluminationfromthe

overcastsky,androadlightingasanaverageoflocationsonthepavement n—the ratio of luminance, L, in a particular viewing direction,

surface.

of a projected surface to the illuminance of diffuse

illumination, E, at the surface on the plane of the surface,

1.2 The co-viewing angle of the reflectometer affects the

-2 -1

expressed in candelas per square metre per lux (cd·m ·lx ).

readings. As specified by the European Committee for Stan-

3.2.1.1 Discussion—Qd has a range from zero up to a

dardization (CEN), the co-viewing angle shall be 2.29°.

-2 -1

maximum of 1/π = approximately 0.318 cd·m ·lx . For

1.3 This test method is intended to be used for field

convenience, the units used commonly are millicandelas per

measurementofpavementmarkingsandpavementsurfacesbut -2 -1

square metre per lux (mcd·m ·lx ) providing a range from

may be used to measure the performance of materials on -2 -1

zero up to 1000/π = approximately 318 mcd·m ·lx .

sample panels before placing the marking material in the field.

3.2.2 co-viewing angle, a, n—theanglebetweentheplaneof

1.4 This standard does not purport to address all of the

the pavement marking surface and the observation axis.

safety concerns, if any, associated with its use. It is the

3.2.3 portable reflectometer, n—a hand-held instrument that

responsibility of the user of this standard to establish appro-

can be used in the field or laboratory for measurement of

priate safety and health practices and determine the applica-

luminance coefficient under diffuse illumination.

bility of regulatory limitations prior to use.

3.2.4 instrument standard, n—working standard used to

standardize the portable reflectometer.

2. Referenced Documents

2.1 ASTM Standards:

4. Summary of Test Method

E284Terminology of Appearance

4.1 This test method involves the use of commercial por-

E809Practice for Measuring Photometric Characteristics of

table reflectometers for determining the luminance coefficient

Retroreflectors

under diffuse illumination in a particular viewing direction of

horizontal coatings materials used in pavement markings.

4.2 The co-viewing angle is fixed at 2.29°.

This test method is under the jurisdiction of ASTM Committee E12 on Color

and Appearance and is the direct responsibility of Subcommittee E12.10 on

4.3 The reflectometers use an external panel or other instru-

Retroreflection.

ment standard of known luminance coefficient under diffuse

Current edition approved Aug. 1, 2009. Published September 2009. Originally

illumination, Qd.

approved in 2003. Last previous edition approved in 2003 as E2302–03a. DOI:

10.1520/E2302-03AR09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from European Committee for Standardization (CEN), 36 rue de

the ASTM website. Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2302−03a (2009)

4.4 The portable reflectometer is placed directly over the 6.2.3 The diffuse illumination may be approximated by

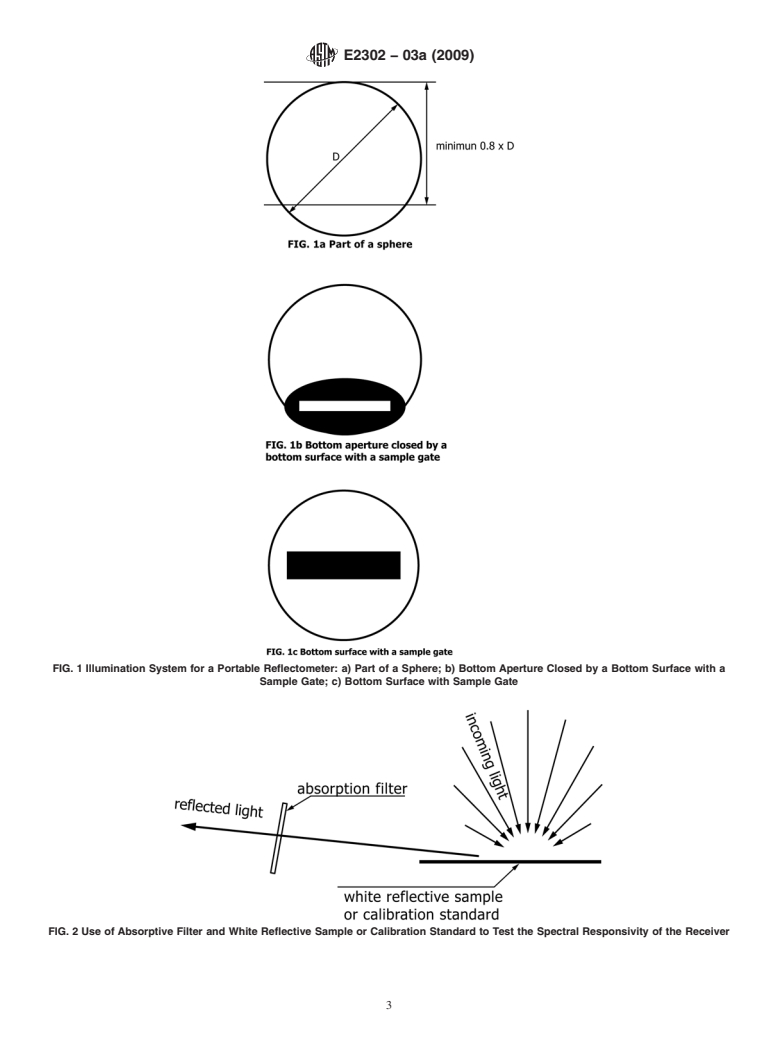

pavement marking to be measured, ensuring that the measure- reflection from the interior surface of sphere or other shape or

ment area of the reflectometer fits within the width of the by other means. Enough testing shall be carried out to verify

stripe, and the reading displayed by the reflectometer is that flux received on the sample is approximately homoge-

recorded. neous. For measurements from all positions in the sample gate

and in all directions, using a collection cone of an included

4.5 Readings shall be taken for the direction of traffic.

angle of 8 degrees the ratio of the smallest to the largest

Readings shall be taken for each direction of traffic separately

measurement shall be minimum 0.8. The test shall be carried

for centerlines.

out with the sample gate open, and shall be repeated with the

sample gate closed by a reflecting surface of white, matt finish

5. Significance and Use

with suitable openings to allow for the measurements.

5.1 The quality of the stripe for visibility in daylight or

6.2.3.1 The case of illumination by a sphere with a bottom

under road lighting is determined by the luminance coefficient

aperture is shown in Fig. 1. For this arrangement sample gate

under diffuse illumination, Qd, and depends on the materials

should not be larger than necessary in view of the illuminated

used,age,andwearpattern.Theseconditionsshallbeobserved

area needed in accordance with 6.4 and should stop at a

and noted by the user.

distance before the sphere surface opposing the observation

5.2 Under the same conditions of illumination and viewing,

direction.Inorderthatreflectioninthesamplesurfaceshallnot

higher levels of Qd correspond to higher levels of lightness.

distort the uniformity of luminance of the interior sphere

surface, the remaining part of the sphere, after introducing the

5.3 Reflectivity of pavement (road) markings degrade with

bottom aperture, shall be minimum 0.8×D, where D is the

traffic wear and require periodic measurement to ensure that

diameterofthesphere.Inthiscase,thetestof6.2.3needsonly

sufficient line visibility is provided to drivers.

to be applied with the sample gate open.

5.4 Foragivenviewingdistance,measurementsofQdmade

6.2.4 The sphere may be approximated by other shapes, but

with a reflectometer having a geometry corresponding to that

enough testing shall be carried out to verify that interior

distance are a good indicator of the visual ranking of material

surfaces have approximately constant luminance. The ratio of

measured.

the smallest to the largest luminance of interior surfaces shall

5.5 specified by CEN, the measurement geometry of the

be minimum 0.8, when measured in different directions

instrument is based on a viewing distance of 30 m and an eye

through different locations at the sample gate.The test shall be

height of 1.2 m.

carried out with the sample gate open, and shall be repeated

with the sample gate closed by a reflecting surface of white,

5.6 It shall be the responsibility of the user to employ an

matt finish with suitable openings to allow for the measure-

instrument having the specified co-viewing angle.

ments.

6. Apparatus

6.3 Receiver Requirements:

6.3.1 Thereceivershallhavesufficientsensitivityandrange

6.1 Portable Reflectometer:

to accommodate luminance coefficient in diffuse illumination

6.1.1 Thereflectometershallbeportable,withthecapability

expected in use, typically from 1 to close to the maximum of

to be placed on various horizontal pavement markings in

-2 -1

approximately 318 mcd·m ·lx .

different locations.

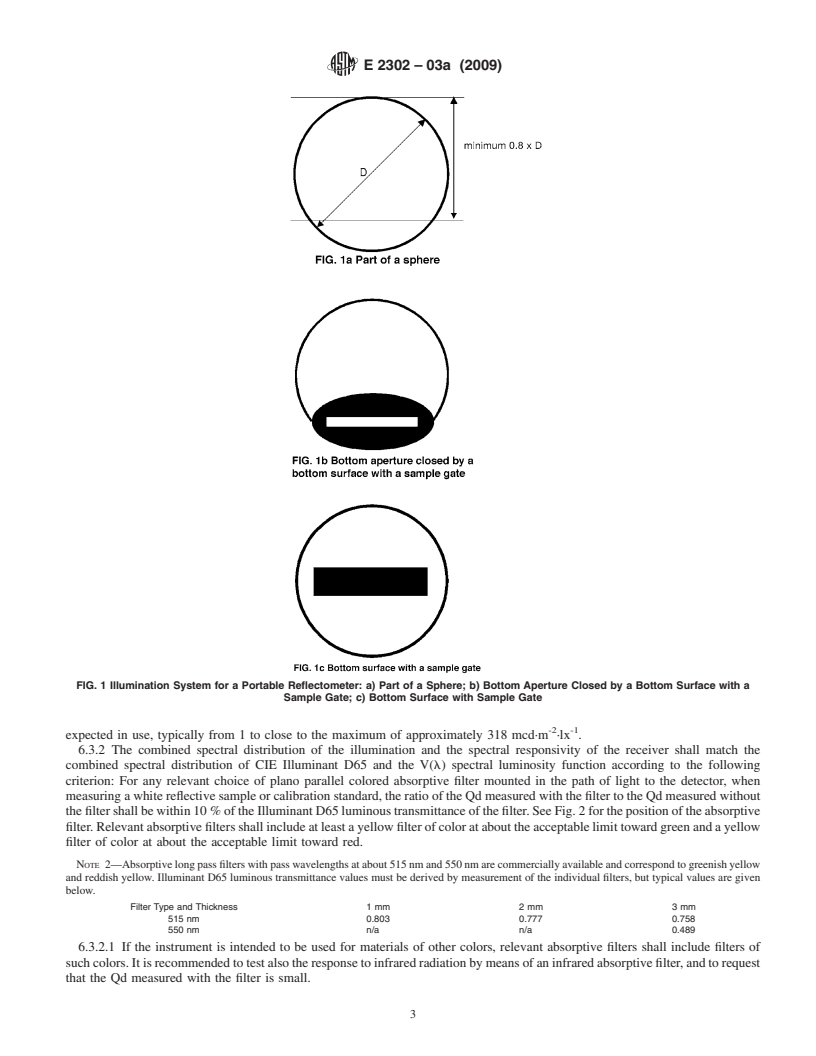

6.3.2 The combined spectral distribution of the illumination

6.1.2 The reflectometer shall be constructed so that place-

and the spectral responsivity of the receiver shall match the

ment on the highway pavement markings will preclude any

combined spectral distribution of CIE Illuminant D65 and the

straylightenteringthemeasurementareaoftheinstrumentand

V(λ) spectral luminosity function according to the following

affecting the reading. This may be done by shielding against

criterion: For any relevant choice of plano parallel colored

stray light, or by subtraction of the stray light reading, or both.

absorptive filter mounted in the path of light to the detector,

Alternatively, the reflectometer shall produce a warning signal

when measuring a white reflective sample or calibration

when stray light could affect the reading.

standard, the ratio of the Qd measured with the filter to the Qd

6.1.3 For the convenience of the user, a marking shall be

measured without the filter shall be within 10% of the

placed on the instrument to permit it to be aligned with the

Illuminant D65 luminous transmittance of the filter. See Fig. 2

directionoftraffic,ortheinstrumentdesignshallitselfindicate

for the position of the absorptive filter. Relevant absorptive

the measuring direction in an obvious manner.

filters shall include at least a yellow filter of color at about the

6.2 Illumination System Requirements:

acceptable limit toward green and a yellow filter of color at

6.2.1 The illumination system shall provide diffuse

about the acceptable limit toward red.

illumination, which can be obtained by indirect illumination

NOTE 2—Absorptive long pass filters with pass wavelengths at about

through a sample gate from a photometric sphere of interior

515 nm and 550 nm are commercially available and correspond to

white, matt finish.

greenish yellow and reddish yellow. Illuminant D65 luminous transmit-

6.2.2 The illumination system shall have compensation for

tance values must be derived by measurement of the individual filters, but

the increase of illumination caused by interreflection between

typical values are given below.

a sample surface and the interior surfaces of the illumination

Filter Type and Thickness 1 mm 2 mm 3 mm

system, for instance by means of a reading of the illuminance 515 nm 0.803 0.777 0.758

550 nm n/a n/a 0.489

at a location close to the sample gate.

E2302−03a (2009)

FIG. 1Illumination System for a Portable Reflectometer: a) Part of a Sphere; b) Bottom Aperture Closed by a Bottom Surface with a

Sample Gate; c) Bottom Surface with Sample Gate

FIG. 2Use of Absorptive Filter and White Reflective Sample or Calibration Standard to Test the Spectral Responsivity of the Receiver

E2302−03a (2009)

FIG. 3Optics Geometry Diagram for Portable Reflectometer: a) Angle and Aperture for Non-Collimating Portable Reflectometer; b)

Angle and Aperture for Collimating Portable Reflectometer

6.3.2.1 If the instrument is intended to be used for materials vertical directions. For a collimated instrument, the frame

ofothercolors,relevantabsorptivefiltersshallincludefiltersof shown in Fig. 4 can also be used to test the aperture angle,

such colors. It is recommended to test also the response to when the targets indicate maximum dimensions.

infraredradiationbymeansofaninfraredabsorptivefilter,and

NOTE 5—The maximum receiver aperture dimensions are in agreement

to request that the Qd measured with the filter is small.

with CEN EN 1436.

NOTE3—Somecombinationsoflightsourcesanddetectorstendtogive

6.3.5 The combined stability of the output of the light

response to infrared radiation. An absorptive long pass filter with pass

source and the receiver shall be such that readings will not

wavelength at about 715 nm is suitable. The Qd measured with the filter

-2 -1 change more than 61% after 10 s when the reflectometer is in

insertedshouldtheoreticallybezero,butavaluefrom−3to3mcd·m ·lx

contact with the pavement marking and ready to measure.

is acceptable.

6.3.6 The linearity of the reflectometer photometric scale

6.3.3 The receiver may be either at optical infinity or at a

over the range of readings expected shall be within 2%.

finite distance from the measurement area, and the co-viewing

Correction factors may be used to ensure a linear response. A

angle shall be 2.29 6 0.05° as determined from the center of

method for determining linearity is found in Annex A2 of

the measurement area. See Fig. 3 for a diagram of the optics

Practice E809.

geometry. The co-viewing angle can be tested with light

6.3.7 The reflectometer shall have a zero-adjust control, or

through the aperture stop at the detector, using a frame with

an auto-zero function.

pinholes and targets as shown in Fig. 4. For a non-collimated

instrument, the pinholes shall be at a location corresponding to

6.4 Measurement Geometry:

the center of the measurement field.

6.4.1 The detected area shall either be fully included within

the illuminated area (called arrangementA) or the illuminated

NOTE4—Tosendlightthroughtheaperturestopatthedetectorinvolves

opening of the reflectometer, which should be done according to instruc- area shall be fully included within the detected area (called

tions by the manufacturer of the reflectometer.

arrangement B).

6.3.4 As determined from the center of the measurement

NOTE6—ArrangementAisadvantageoustoarrangementBinthesense

area, the aperture of the receiver shall not be larger than a

that it leads to less variation of the measured Qd value with small tilts of

square subtending 20 min of arc (0.33°) in both horizontal and the reflectometer that are unavoidable in practical field measurements.

E2302−03a (2009)

FIG. 4Frame with Pinholes and Targets for Alternative Testing of the Co-viewing Angle and the Aperture for Only the Collimated Instru-

ments

6.4.2 The smaller of the two areas, detected or illuminated ment standard with a known and reproducible luminance

area, is the measurement area and shall be at least 50 cm . See coefficient under diffuse illumination measured at the same

Fig. 5 for a method of testing this area.

geometry as used in the portable reflectometer.The instrument

standard shall be standardized with diffuse illumination from

NOTE7—TheplatementionedinFig.5needsinmostcasestobeaglass

an indirectly illuminated photometric sphere of sufficient

plate with a diffuse upper surface, so that the area can be studied from the

underside. dimensions, with the datum mark indicated on the standard.

The instrument standard shall have a sta

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2302–03a Designation: E 2302 – 03a (Reapproved 2009)

Standard Test Method for

Measurement of the Luminance Coefficient Under Diffuse

Illumination of Pavement Marking Materials Using a Portable

Reflectometer

This standard is issued under the fixed designation E2302; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers measurement of the luminance coefficient under diffuse illumination of horizontal pavement

markings, such as traffic stripes and surface symbols, and pavement surfaces, in a particular viewing direction using a portable

reflectometer.

NOTE 1—The luminance coefficient under diffuse illumination is a measure of the reflection of horizontal pavement markings and pavement surfaces

in a particular viewing direction in daylight or under road lighting. Diffuse illumination approximates daylight illumination from the overcast sky, and

road lighting as an average of locations on the pavement surface.

1.2 Theco-viewingangleofthereflectometeraffectsthereadings.AsspecifiedbytheEuropeanCommitteeforStandardization

(CEN), the co-viewing angle shall be 2.29°.

1.3 Thistestmethodisintendedtobeusedforfieldmeasurementofpavementmarkingsandpavementsurfacesbutmaybeused

to measure the performance of materials on sample panels before placing the marking material in the field.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E284 Terminology of Appearance

E809 Practice for Measuring Photometric Characteristics of Retroreflectors

2.2 Other Standard:

CEN EN 1436 Road Marking Materials—Road Marking Performance for Road Users

3. Terminology

3.1 The terminology used in this test method generally agrees with that used in Terminology E284.

3.2 Definitions:

3.2.1 luminance coeffıcient under diffuse illumination; Qd, n—the ratio of luminance, L, in a particular viewing direction, of a

projected surface to the illuminance of diffuse illumination, E, at the surface on the plane of the surface, expressed in candelas per

-2 -1

square metre per lux (cd·m ·lx ).

-2 -1

3.2.1.1 Discussion—Qd has a range from zero up to a maximum of 1/p = approximately 0.318 cd·m ·lx . For convenience,

-2 -1

the units used commonly are millicandelas per square metre per lux (mcd·m ·lx ) providing a range from zero up to 1000/p =

-2 -1

approximately 318 mcd·m ·lx .

3.2.2 co-viewing angle, a, n—the angle between the plane of the pavement marking surface and the observation axis.

3.2.3 portable reflectometer, n—ahand-heldinstrumentthatcanbeusedinthefieldorlaboratoryformeasurementofluminance

coefficient under diffuse illumination.

3.2.4 instrument standard, n—working standard used to standardize the portable reflectometer.

ThistestmethodisunderthejurisdictionofASTMCommitteeE12onColorandAppearanceandisthedirectresponsibilityofSubcommitteeE12.10onRetroreflection.

Current edition approved Dec.Aug. 1, 2003.2009. Published December 2003.September 2009. Originally approved in 2003. Last previous edition approved in 2003 as

E2302–03a.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from European Committee for Standardization, Central Secretariat (CEN), rue de Stassart 36, B1050 Brussels, Belgium.

Available from European Committee for Standardization (CEN), 36 rue de Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 2302 – 03a (2009)

4. Summary of Test Method

4.1 This test method involves the use of commercial portable reflectometers for determining the luminance coefficient under

diffuse illumination in a particular viewing direction of horizontal coatings materials used in pavement markings.

4.2 The co-viewing angle is fixed at 2.29°.

4.3 The reflectometers use an external panel or other instrument standard of known luminance coefficient under diffuse

illumination, Qd.

4.4 Theportablereflectometerisplaceddirectlyoverthepavementmarkingtobemeasured,ensuringthatthemeasurementarea

of the reflectometer fits within the width of the stripe, and the reading displayed by the reflectometer is recorded.

4.5 Readings shall be taken for the direction of traffic. Readings shall be taken for each direction of traffic separately for

centerlines.

5. Significance and Use

5.1 The quality of the stripe for visibility in daylight or under road lighting is determined by the luminance coefficient under

diffuse illumination, Qd, and depends on the materials used, age, and wear pattern. These conditions shall be observed and noted

by the user.

5.2 Under the same conditions of illumination and viewing, higher levels of Qd correspond to higher levels of lightness.

5.3 Reflectivity of pavement (road) markings degrade with traffic wear and require periodic measurement to ensure that

sufficient line visibility is provided to drivers.

5.4 For a given viewing distance, measurements of Qd made with a reflectometer having a geometry corresponding to that

distance are a good indicator of the visual ranking of material measured.

5.5 specified by CEN, the measurement geometry of the instrument is based on a viewing distance of 30 m and an eye height

of 1.2 m.

5.6 It shall be the responsibility of the user to employ an instrument having the specified co-viewing angle.

6. Apparatus

6.1 Portable Reflectometer:

6.1.1 The reflectometer shall be portable, with the capability to be placed on various horizontal pavement markings in different

locations.

6.1.2 The reflectometer shall be constructed so that placement on the highway pavement markings will preclude any stray light

entering the measurement area of the instrument and affecting the reading. This may be done by shielding against stray light, or

by subtraction of the stray light reading, or both.Alternatively, the reflectometer shall produce a warning signal when stray light

could affect the reading.

6.1.3 For the convenience of the user, a marking shall be placed on the instrument to permit it to be aligned with the direction

of traffic, or the instrument design shall itself indicate the measuring direction in an obvious manner.

6.2 Illumination System Requirements:

6.2.1 The illumination system shall provide diffuse illumination, which can be obtained by indirect illumination through a

sample gate from a photometric sphere of interior white, matt finish.

6.2.2 The illumination system shall have compensation for the increase of illumination caused by interreflection between a

sample surface and the interior surfaces of the illumination system, for instance by means of a reading of the illuminance at a

location close to the sample gate.

6.2.3 The diffuse illumination may be approximated by reflection from the interior surface of sphere or other shape or by other

means. Enough testing shall be carried out to verify that flux received on the sample is approximately homogeneous. For

measurements from all positions in the sample gate and in all directions, using a collection cone of an included angle of 8 degrees

the ratio of the smallest to the largest measurement shall be minimum 0.8.The test shall be carried out with the sample gate open,

and shall be repeated with the sample gate closed by a reflecting surface of white, matt finish with suitable openings to allow for

the measurements.

6.2.3.1 ThecaseofilluminationbyaspherewithabottomapertureisshowninFig.1.Forthisarrangementsamplegateshould

not be larger than necessary in view of the illuminated area needed in accordance with 6.4 and should stop at a distance before

the sphere surface opposing the observation direction. In order that reflection in the sample surface shall not distort the uniformity

of luminance of the interior sphere surface, the remaining part of the sphere, after introducing the bottom aperture, shall be

minimum 0.83D, where D is the diameter of the sphere. In this case, the test of 6.2.3 needs only to be applied with the sample

gate open.

6.2.4 The sphere may be approximated by other shapes, but enough testing shall be carried out to verify that interior surfaces

have approximately constant luminance. The ratio of the smallest to the largest luminance of interior surfaces shall be minimum

0.8, when measured in different directions through different locations at the sample gate. The test shall be carried out with the

sample gate open, and shall be repeated with the sample gate closed by a reflecting surface of white, matt finish with suitable

openings to allow for the measurements.

6.3 Receiver Requirements:

6.3.1 The receiver shall have sufficient sensitivity and range to accommodate luminance coefficient in diffuse illumination

E 2302 – 03a (2009)

FIG. 1 Illumination System for a Portable Reflectometer: a) Part of a Sphere; b) Bottom Aperture Closed by a Bottom Surface with a

Sample Gate; c) Bottom Surface with Sample Gate

-2 -1

expected in use, typically from 1 to close to the maximum of approximately 318 mcd·m ·lx .

6.3.2 The combined spectral distribution of the illumination and the spectral responsivity of the receiver shall match the

combined spectral distribution of CIE Illuminant D65 and the V(l) spectral luminosity function according to the following

criterion: For any relevant choice of plano parallel colored absorptive filter mounted in the path of light to the detector, when

measuringawhitereflectivesampleorcalibrationstandard,theratiooftheQdmeasuredwiththefiltertotheQdmeasuredwithout

thefiltershallbewithin10%oftheIlluminantD65luminoustransmittanceofthefilter.SeeFig.2forthepositionoftheabsorptive

filter.Relevantabsorptivefiltersshallincludeatleastayellowfilterofcoloratabouttheacceptablelimittowardgreenandayellow

filter of color at about the acceptable limit toward red.

NOTE 2—Absorptivelongpassfilterswithpasswavelengthsatabout515nmand550nmarecommerciallyavailableandcorrespondtogreenishyellow

and reddish yellow. Illuminant D65 luminous transmittance values must be derived by measurement of the individual filters, but typical values are given

below.

Filter Type and Thickness 1 mm 2 mm 3 mm

515 nm 0.803 0.777 0.758

550 nm n/a n/a 0.489

6.3.2.1 If the instrument is intended to be used for materials of other colors, relevant absorptive filters shall include filters of

suchcolors.Itisrecommendedtotestalsotheresponsetoinfraredradiationbymeansofaninfraredabsorptivefilter,andtorequest

that the Qd measured with the filter is small.

E 2302 – 03a (2009)

FIG. 2 Use of Absorptive Filter and White Reflective Sample or Calibration Standard to Test the Spectral Responsivity of the Receiver

NOTE 3—Some combinations of light sources and detectors tend to give response to infrared radiation. An absorptive long pass filter with pass

-2 -1

wavelength at about 715 nm is suitable. The Qd measured with the filter inserted should theoretically be zero, but a value from −3 to 3 mcd·m ·lx is

acceptable.

6.3.3 The receiver may be either at optical infinity or at a finite distance from the measurement area, and the co-viewing angle

shall be 2.29 6 0.05° as determined from the center of the measurement area. See Fig. 3 for a diagram of the optics geometry.

The co-viewing angle can be tested with light through the aperture stop at the detector, using a frame with pinholes and targets

as shown in Fig. 4. For a non-collimated instrument, the pinholes shall be at a location corresponding to the center of the

measurement field.

FIG. 3 Optics Geometry Diagram for Portable Reflectometer: a) Angle and Aperture for Non-Collimating Portable Reflectometer; b)

Angle and Aperture for Collimating Portable Reflectometer

E 2302 – 03a (2009)

FIG. 4 Frame with Pinholes and Targets for Alternative Testing of the Co-viewing Angle and the Aperture for Only the Collimated

Instruments

NOTE 4—To send light through the aperture stop at the detector involves opening of the reflectometer, which should be done according to instructions

by the manufacturer of the reflectometer.

6.3.4 As determined from the center of the measurement area, the aperture of the receiver shall not be larger than a square

subtending 20 min of arc (0.33°) in both horizontal and vertical directions. For a collimated instrument, the frame shown in Fig.

4 can also be used to test the aperture angle, when the targets indicate maximum dimensions.

NOTE 5—The maximum receiver aperture dimensions are in agreement with CEN EN 1436.

6.3.5 The combined stability of the output of the light source and the receiver shall be such that readings will not change more

than 61% after 10 s when the reflectometer is in contact with the pavement marking and ready to measure.

6.3.6 The linearity of the reflectometer photometric scale over the range of readings expected shall be within 2%. Correction

factors may be used to ensure a linear response. A method for determining linearity is found in Annex A2 of Practice E809.

6.3.7 The reflectometer shall have a zero-adjust control, or an auto-zero function.

6.4 Measurement Geometry:

6.4.1 The detected area shall either be fully included within the illuminated area (called arrangementA) or the illuminated area

shall be fully included within the detected area (called arrangement B).

NOTE 6—ArrangementAis advantageous to arrangement B in the sense that it leads to less variation of the measured Qd value with small tilts of the

reflectometer that are unavoidable in practical field measurements.

6.4.2 The smaller of the two areas, detected or illuminated area, is the measurement area and shall be at least 50 cm . See Fig.

5 for a method of testing this area.

NOTE 7—The plate mentioned in Fig. 5 needs in most cases to be a glass plate with a diffuse upper surface, so that the area can be studied from the

underside.

6.4.3 The larger of the two areas,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.