ASTM F496-08

(Specification)Standard Specification for In-Service Care of Insulating Gloves and Sleeves

Standard Specification for In-Service Care of Insulating Gloves and Sleeves

ABSTRACT

This specification covers the in-service care, inspection, testing, and use voltage of insulating gloves and sleeves for protection from electrical shock. Gloves and sleeves covered under this specification are designated as type I or type II; class 00, class 0, class 1, class 2, class 3, or class 4. Type I - nonresistant to ozone, made from a high-grade cis-1,4-polyisoprene rubber compound of natural or synthetic origin, properly vulcanized, and type II - ozone resistant, made of any elastomer or combination of elastomeric compounds. The recommended sequence of inspection and testing of gloves and sleeves at an electrical testing facility are: check-in, washing, and preliminary inspection; repair; electrical test; drying; final inspection; record-keeping and marking; and powdering, pairing, and packing for storage or shipment. Electrical testing shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers the in-service care, inspection, testing, and use voltage of insulating gloves and sleeves for protection from electrical shock.

1.2 The values stated in SI units are to be regarded as the standard. See IEEE/ASTM SI 10.

1.3 The following safety hazards caveat pertains only to the test method portion, Sections 6 and 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific warning statement, see 7.2.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F496 −08

StandardSpecification for

1

In-Service Care of Insulating Gloves and Sleeves

ThisstandardisissuedunderthefixeddesignationF496;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This specification covers the in-service care, inspection,

3.1 Compliance with this specification should continue to

testing, and use voltage of insulating gloves and sleeves for

provide personnel with insulating gloves and sleeves of known

protection from electrical shock.

and acceptable quality after initial acceptance in accordance

with Specifications D120 and D1051.The specifications herein

1.2 The values stated in SI units are to be regarded as the

are to be considered as minimum requirements.

standard. See IEEE/ASTM SI-10.

3.2 A margin of safety shall be provided between the

1.3 The following safety hazards caveat pertains only to the

test method portion, Sections 6 and 7, of this specification.This maximum use voltage and the voltage at which the gloves and

sleeves are retested. The relationship between retest voltage

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user andmaximumusevoltageatwhichtheglovesandsleevesshall

be used is shown in Table 1.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

3.2.1 When work is not being performed on energized

tions prior to use.For a specific warning statement, see 7.2.

conductors or equipment, or both, any contact with energized

conductors or equipment, or both, would be limited to the

2. Referenced Documents

phase-to-ground potential. If gloves are the only protection

2

used in such operations, the phase-to-ground voltage to which

2.1 ASTM Standards:

the gloves may be exposed shall be limited to the maximum

D120 Specification for Rubber Insulating Gloves

use voltage of that class glove as listed in Table 1.

D1051 Specification for Rubber Insulating Sleeves

D2865 Practice for Calibration of Standards and Equipment

3.3 The user of these types of protective equipment shall be

for Electrical Insulating Materials Testing

knowledgeable of and instructed in the correct and safe

F696 Specification for Leather Protectors for Rubber Insu-

inspection and use of such equipment.

lating Gloves and Mittens

F819 Terminology Relating to Electrical Protective Equip-

4. Terminology

ment for Workers

4.1 Definitions:

F1236 Guide for Visual Inspection of Electrical Protective

4.1.1 ozone—a very active form of oxygen that may be

Rubber Products

produced by corona, arcing, or ultraviolet rays.

2.2 ANSI Standards:

C 39.5 Safety Requirements for Electrical and Electronic 4.1.2 For definitions of other terms, refer to Terminology

3

F819.

Measuring and Controlling Instrumentation

IEEE/ASTM SI-10 Standard for Use of the International

2

5. Classification

System of Units (SI): The Modern Metric System

5.1 Gloves and sleeves covered under this specification are

designated as Type I or Type II; Class 00, Class 0, Class 1,

1

This specification is under the jurisdiction of ASTM Committee F18 on

Class 2, Class 3, or Class 4.

Electrical Protective Equipment for Workers and is the direct responsibility of

5.1.1 Type I, nonresistant to ozone, made from a high-grade

Subcommittee F18.15 on Worker Personal Equipment.

Current edition approved Oct. 1, 2008. Published November 2008. Originally

cis-1,4-polyisoprene rubber compound of natural or synthetic

approved in 1977. Last previous edition approved in 2006 as F496 – 06. DOI:

origin, properly vulcanized.

10.1520/F0496-08.

2 5.1.2 Type II, ozone resistant, made of any elastomer or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM combination of elastomeric compounds.

Standards volume information, refer to the standard’s Document Summary page on

5.1.3 The electrical properties correspond to those shown in

the ASTM website.

3

Table 1. The class designations are those specified in Specifi-

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. cations D120 and D1051.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

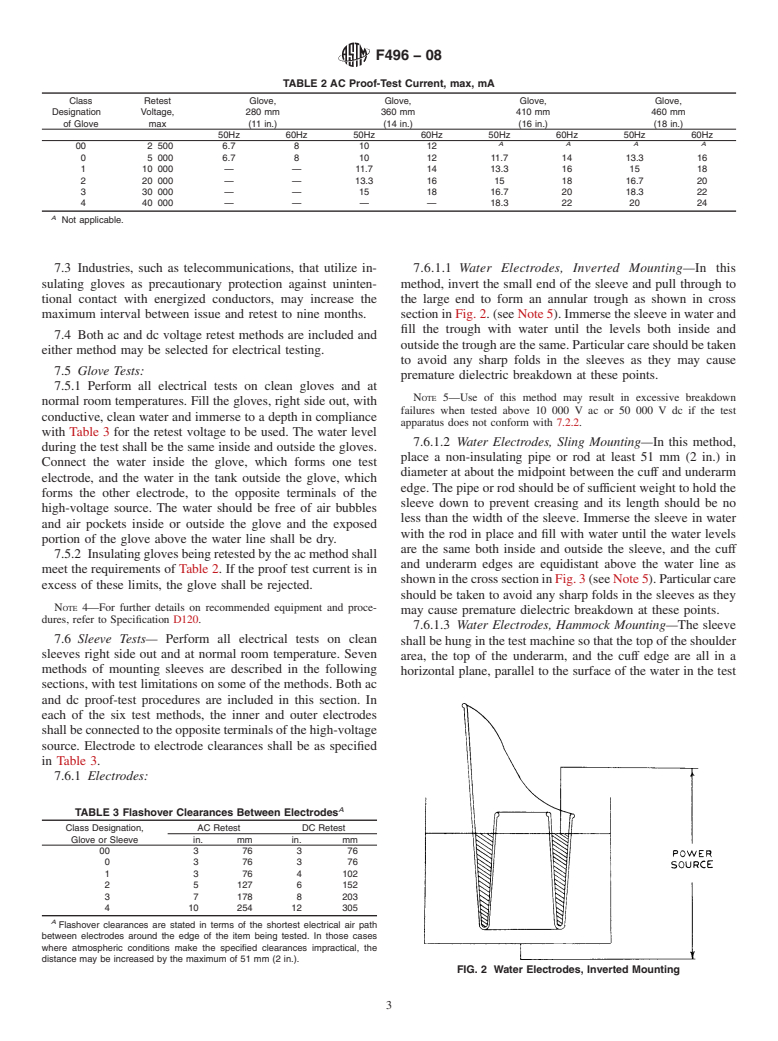

F496−08

TABLE 1 Voltage Requirements

Maximum

Maximum AC AC Retest DC Retest

Class Designation DC Use

Use Voltage Voltage

of Glove or Sleeve Voltage

Voltage rms, V rms, V avg, V

avg, V

00 500 2

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F 496–06 Designation: F 496 – 08

Standard Specification for

1

In-Service Care of Insulating Gloves and Sleeves

This standard is issued under the fixed designation F 496; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the in-service care, inspection, testing, and use voltage of insulating gloves and sleeves for

protection from electrical shock.

1.2 The values stated in SI units are to be regarded as the standard. See IEEE/ASTM SI 10.

1.3 The following safety hazards caveat pertains only to the test method portion, Sections 6 and 7, of this specification. This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use. For a specific warning statement, see 7.2.

2. Referenced Documents

2

2.1 ASTM Standards:

D 120 Specification for Rubber Insulating Gloves

D 1051 Specification for Rubber Insulating Sleeves

D 2865 Practice for Calibration of Standards and Equipment for Electrical Insulating Materials Testing

F 696 Specification for Leather Protectors for Rubber Insulating Gloves and Mittens

F 819 Terminology Relating to Electrical Protective Equipment for Workers

F 1236 Guide for Visual Inspection of Electrical Protective Rubber Products

2.2 ANSI Standards:

3

C 39.5 Safety Requirements for Electrical and Electronic Measuring and Controlling Instrumentation

2

IEEE/ASTM SI-10 Standard for Use of the International System of Units (SI): The Modern Metric System

3. Significance and Use

3.1 Compliance with this specification should continue to provide personnel with insulating gloves and sleeves of known and

acceptable quality after initial acceptance in accordance with Specifications D 120 and D 1051. The specifications herein are to be

considered as minimum requirements.

3.2 A margin of safety shall be provided between the maximum use voltage and the voltage at which the gloves and sleeves

are retested. The relationship between retest voltage and maximum use voltage at which the gloves and sleeves shall be used is

shown in Table 1.

3.2.1 When work is not being performed on energized conductors or equipment, or both, any contact with energized conductors

or equipment, or both, would be limited to the phase-to-ground potential. If gloves are the only protection used in such operations,

the phase-to-ground voltage to which the gloves may be exposed shall be limited to the maximum use voltage of that class glove

as listed in Table 1.

3.3 The user of these types of protective equipment shall be knowledgeable of and instructed in the correct and safe inspection

and use of such equipment.

4. Terminology

4.1 Definitions:

4.1.1 ozone—a very active form of oxygen that may be produced by corona, arcing, or ultraviolet rays.

4.1.2 For definitions of other terms, refer to Terminology F 819.

1

This specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.15 on Worker Personal Equipment.

´1

Current edition approved May 1, 2006. Published May 2006. Originally approved in 1977. Last previous edition approved in 2002 as F496–02a .

Current edition approved Oct. 1, 2008. Published November 2008. Originally approved in 1977. Last previous edition approved in 2006 as F 496 – 06.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

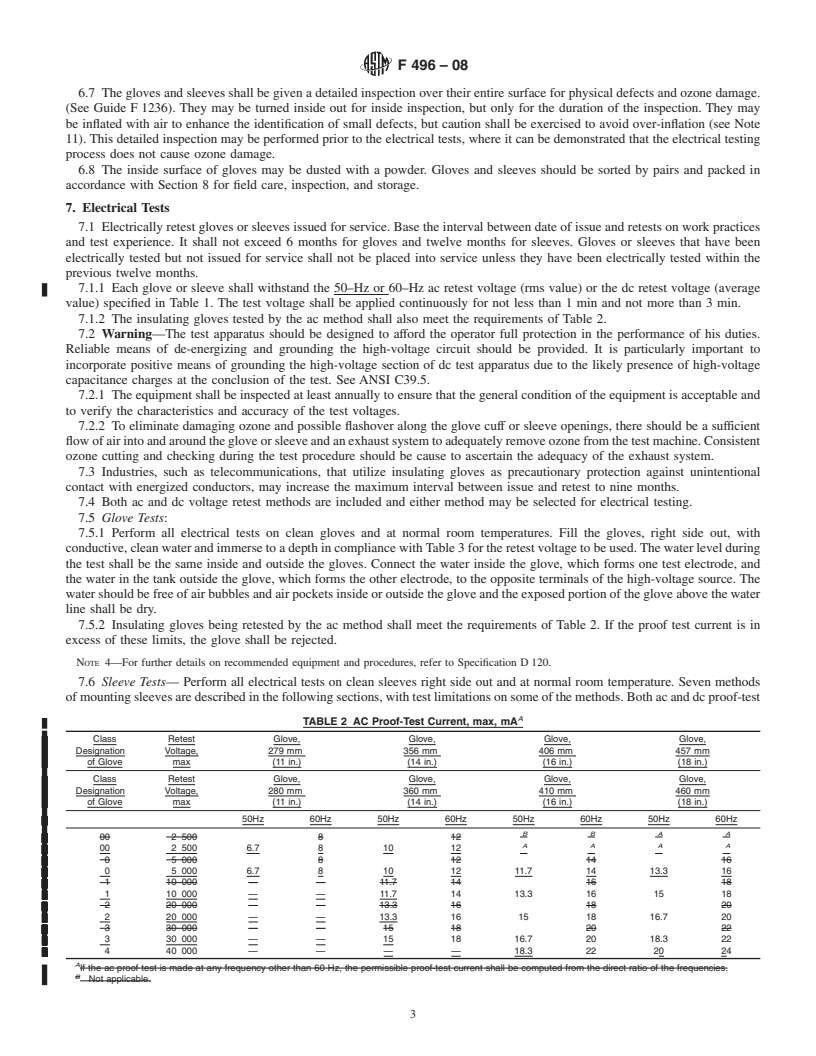

F 496–08

TABLE 1 Voltage Requirements

Maximum

Maximum AC AC Retest DC Retest

Class Designation DC Use

Use Voltage Voltage

of Glove or Sleeve Voltage

Voltage rms, V rms, V avg, V

avg, V

00 500 2 500 750 10 000

0 1 000 5 000 1 500 20 000

1 7 500 10 000 11 250 40 000

2 17 000 20 000 25 500

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.