ASTM C1523-02

(Test Method)Standard Test Method for Determining Modulus, Tear and Adhesion Properties of Precured Elastomeric Joint Sealants

Standard Test Method for Determining Modulus, Tear and Adhesion Properties of Precured Elastomeric Joint Sealants

SCOPE

1.1 This test method describes a laboratory procedure for measuring modulus, tear, joint movement ability and adhesion properties of applied, Precured Elastomeric Joint Sealants, hereinafter referred to as "applied seal" and if not applied, hereinafter referred to as "seal," on portland cement mortar as a standard substrate and or other substrates. It tests these properties after dry, wet, frozen, heat aged or artificially weather-aged conditionings, or both.

1.2 The values stated in SI units are to be regarded as the standard. Other values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The committee with jurisdiction over this standard is not aware of any similar standard published by another committee or organization.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1523 – 02

Standard Test Method for

Determining Modulus, Tear and Adhesion Properties of

Precured Elastomeric Joint Sealants

This standard is issued under the fixed designation C 1523; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method describes a laboratory procedure for 3.1 Definitions—Refer to Terminology C 717 for definitions

measuring modulus, tear, joint movement ability and adhesion of the following terms used in this test method: adhesive

properties of applied, Precured Elastomeric Joint Sealants, failure, cohesive failure, primer, modulus, and to Terminology

hereinafter referred to as “applied seal” and if not applied, D 1566 for tear and to Terminology G 113 for definitions

hereinafter referred to as “seal,” on portland cement mortar as related to artificial weathering.

a standard substrate and or other substrates. It tests these

4. Summary of Test Method

properties after dry, wet, frozen, heat aged or artificially

weather-aged conditionings, or both. 4.1 Model joints are prepared, the seal is adhered to the

substrate utilizing an adhesive sealant specified by the manu-

1.2 The values stated in SI units are to be regarded as the

standard. Other values given in parentheses are provided for facturer, hereinafter referred to as adhesive, then exposed to a

variety of conditionings such as heat, cold, artificial weathering

information only.

1.3 This standard does not purport to address all of the or water immersion. A specific set of specimens can go through

each conditioning or separate specimens can be used for each

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- conditioning. After exposure the test specimens are subjected

to an elongation (strain) and held at this elongation for as long

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. as is desired. The elongation (joint expansion) is performed

with a tensometer to obtain tensile-forces during the pull. One

1.4 The committee with jurisdiction over this standard is not

aware of any similar standard published by another committee aspect of the test has the applied seal cut in the middle of the

joint and then elongated and the degree of tear propagation

or organization.

noted. After the initial strain the samples can be subjected to

2. Referenced Documents

cycles of repeated strain. The samples can also be tested to

2.1 ASTM Standards: destruction. The movement test and tear test can be done on

C 717 Terminology of Building Seals and Sealants separate sets of test specimens or done sequentially with the

C 1375 Guide for Substrates Used in Testing Building Seals same test specimen.

and Sealants

2 5. Significance and Use

D 1566 Terminology Relating to Rubber

5.1 Seals are manufactured in flat extruded shapes and are

G 113 Terminology Relating to Natural and Artificial

Weathering Tests of Nonmetallic Materials primarily used to span joint openings. The seal is adhered to

construction substrates utilizing a liquid applied adhesive, to

G 151 Practice for Exposing Nonmetallic Materials in Ac-

celerated Test Devices That Use Laboratory Light seal building openings such as panel joints, metal flashing

joints or other joints in place of conventional liquid applied

Sources

G 154 Practice for Operating Fluorescent Light Apparatus sealants. In actual use, failure of an applied seal in an active

joint is usually manifested by cohesive failure of the seal;

for UV Exposure of Nonmetallic Materials

G 155 Practice for Operating Xenon Arc Light Apparatus adhesive failure between the adhesive and the substrate;

adhesive failure between the adhesive and the seal; cohesive

for Exposure of Nonmetallic Materials

failure of the substrate or tear propagation parallel to the joint

length.

5.2 This test method can be used for testing the adhesion of

This test method is under the jurisdiction of ASTM Committee C24 on Building

Seals and Sealants and is the direct responsibility of Subcommittee C24.32 on

the adhesive to the substrate and to the seal, tensile load at

Chemically Curing Sealants.

various strains and tear resistance at various strains after the

Current edition approved Feb. 10, 2002. Published May 2002.

Annual Book of ASTM Standards,Vol

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1523

FIG. 1 Standard Substrate Test Specimen Assemblies

load on the specimen at a rate of 50 6 5 mm (2.0 6 0.20

in.)/min., and with a recording chart to show load strain values

(tensile modulus).

6.1.1 Fixed Member—A fixed or essentially stationary

member carrying one grip.

6.1.2 Movable Member—A movable member carrying one

grip.

6.1.3 Grips—The grips should be suitable to firmly grasp

the test fixture that holds the test specimen.

6.1.4 Grip Fixture—A fixture capable of being held by the

FIG. 2 Beveled Bridge Joint Configuration

grips and furnishing a tensile force to the sealant specimen.

6.2 Spatulas, for use in applying the adhesive.

6.3 Caulking Gun, for extruding adhesive from cartridges.

6.4 Primer, if applicable.

6.5 Adhesive.

6.6 Seal.

6.7 Spacer—Pieces of rigid material that help to maintain a

joint opening of 12 mm (0.5 in.) while preparing the test

specimen.

6.8 Substrates—2 substrate samples are required for each

test specimen. The substrate sample size shall be determined

FIG. 3 U-joint Configuration

by the size of the test machine grips, yet they must be of a size

to allow the application of a 50 65mm(2 6 0.2 in.) long seal.

6.9 Freezer, −18 6 2°C (0 6 3.6°F).

6.10 Oven,70 6 2°C (158 6 3.6°F).

6.11 Apparatus, in accordance with Practice G 151 and

G 154, or G 155 and C 1442.

6.12 Stencil Knife, or similar instrument (5 mm cutting

width).

7. Test Specimen

7.1 The standard joint configuration used in this test method

shall be the bridge joint application as shown in Fig. 1.

NOTE 1—Other joint configurations such as beveled bridge joint appli-

FIG. 4 Test Specimen Showing 5 mm Cut in the Middle of the

cation and/or U-joint application in place or in addition to the standard

Seal for Tear Propagation Testing

joint configuration may be specified for the test with the seal sample.

While the beveled bridge joint application (Fig. 2) is similar in function

specimens are exposed to wet, cold, hot and artificial weath-

and the calculation of test values to the standard joint configuration,

ering conditionings. All or some of these properties are

different considerations have to be taken into account with the U-joint

experienced on actual job sites.

application (Fig. 3): (1) The actual joint opening of 12 mm (0.5 in.) will

be reduced by the thickness of the seal and the adhesive, and (2) The size

6. Apparatus and Materials

of the unbonded loop of the seal determines to a great extend the flexibility

6.1 Tensile Testing Machine, capable of producing a tensile and expandability of the seal (Fig. 3).

C 1523

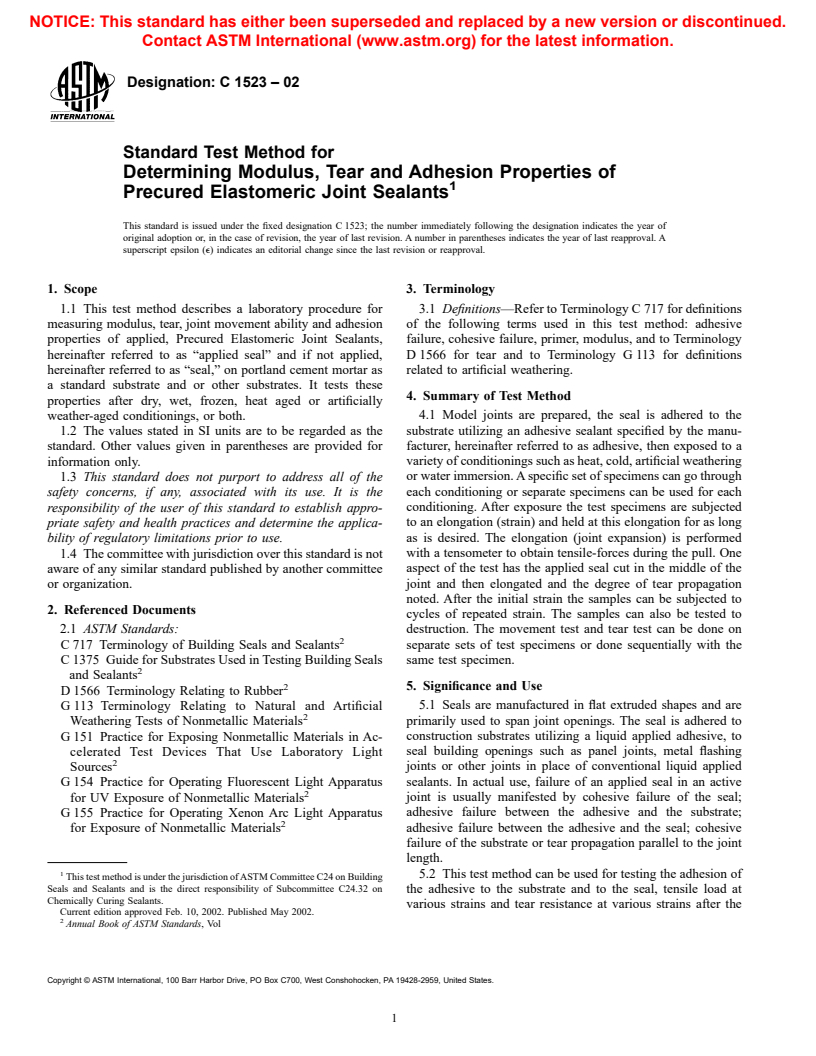

Tear propagates perpendicular to the length of the joint as shown above, left; or at any angle leading to the joint wall as shown above, right. In each case tear stops

at the joint wall with an intact unbroken joint length on both sides of at least 12.5 mm.

FIG. 5 Partial Tear

NOTE 4—Care must be taken to bring the adhesive neatly to the edge of

the test block and extra adhesive should be cleaned of the bridging section

of the seal.

NOTE 5—Three test specimen assemblies per condition should be

prepared for each substrate and each desired test(s) (Modulus/Adhesion or

Tear, or both). It may be beneficial to prepare three extra specimen

assemblies in the event one or more samples are unusable.

8. Conditioning

8.1 Condition (cure or set up time for adhesive) specimens

for 21 days (or for a shorter time if indicated by the manufac-

turer) at standard conditions of 23 6 2°C (73.4 6 3.6°F) and

50 6 5 % relative humidity.

8.2 Following completion of the cure or set up of the

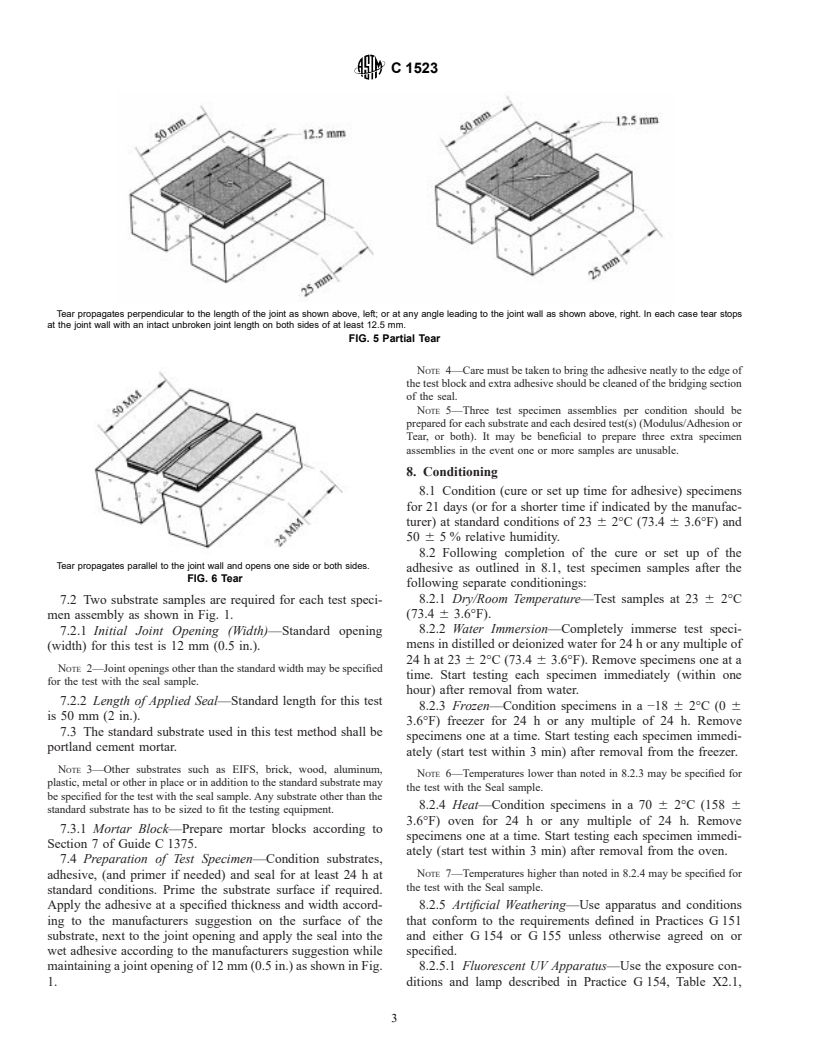

Tear propagates parallel to the joint wall and opens one side or both sides.

adhesive as outlined in 8.1, test specimen samples after the

FIG. 6 Tear

following separate conditionings:

8.2.1 Dry/Room Temperature—Test samples at 23 6 2°C

7.2 Two substrate samples are required for each test speci-

(73.4 6 3.6°F).

men assembly as shown in Fig. 1.

8.2.2 Water Immersion—Completely immerse test speci-

7.2.1 Initial Joint Opening (Width)—Standard opening

mens in distilled or deionized water for 24 h or any multiple of

(width) for this test is 12 mm (0.5 in.).

24hat23 6 2°C (73.4 6 3.6°F). Remove specimens one at a

NOTE 2—Joint openings other than the standard width may be specified

time. Start testing each specimen immediately (within one

for the test with the seal sample.

hour) after removal from water.

7.2.2 Length of Applied Seal—Standard length for this test

8.2.3 Frozen—Condition specimens in a −18 6 2°C (0 6

is 50 mm (2 in.).

3.6°F) freezer for 24 h or any multiple of 24 h. Remove

7.3 The standard substrate used in this test method shall be

specimens one at a time. Start testing each specimen immedi-

portland cement mortar.

ately (start test within 3 min) after removal from the freezer.

NOTE 3—Other substrates such as EIFS, brick, wood, aluminum,

NOTE 6—Temperatures lower than noted in 8.2.3 may be specified for

plastic, metal or other in place or in addition to the standard substrate may

the test with the Seal sample.

be specified for the test with the seal sample. Any substrate other than the

8.2.4 Heat—Condition specimens in a 70 6 2°C (158 6

standard substrate has to be sized to fit the testing equipment.

3.6°F) oven for 24 h or any multiple of 24 h. Remove

7.3.1 Mortar Block—Prepare mortar blocks according to

specimens one at a time. Start testing each specimen immedi-

Section 7 of Guide C 1375.

ately (start test within 3 min) after removal from the oven.

7.4 Preparation of Test Specimen—Condition substrates,

NOTE 7—Temperatures higher than noted in 8.2.4 may be specified for

adhesive, (and primer if needed) and seal for at least 24 h at

the test with the Seal sample.

standard conditions. Prime the substrate surface if re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.