ASTM F1504-02

(Specification)Standard Specification for Folded Poly(Vinyl Chloride) (PVC) Pipe for Existing Sewer and Conduit Rehabilitation

Standard Specification for Folded Poly(Vinyl Chloride) (PVC) Pipe for Existing Sewer and Conduit Rehabilitation

ABSTRACT

This specification covers the material, dimensional, and requirements and corresponding test methods for folded poly(vinyl chloride) (PVC) pipes suitable for the rehabilitation of existing nonpressure sewers and conduits, wherein the folded PVC pipe is inserted into, and then expanded to conform to the wall of, the original conduit forming a new pipe-within-a-pipe structure. This specification does not include pipes manufactured from reprocessed, recycled, or reclaimed PVC. Appropriately sampled specimens shall be tested, and shall thereby conform accordingly to specified requirements for flattening resistance, impact strength, stiffness, extrusion quality by acetone immersion and heat reversion, flexural modulus of elasticity, and rounded pipe diameter and wall thickness.

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, flattening resistance, impact resistance, pipe stiffness, extrusion quality, and a form of marking for folded (vinyl chloride) (PVC) pipe for existing sewer and conduit rehabilitation.

1.2 Pipe produced to this specification is for use in non-pressure sewer and conduit rehabilitation where the folded PVC pipe is inserted into and then expanded to conform to the wall of the original conduit forming a new structural pipe-within-a-pipe.

Note 1—An ASTM specification for the installation of folded PVC pipe is under preparation and will be referenced in this specification when published.

1.3 This specification includes pipe made only from materials specified in Section . This specification does not include pipe manufactured from reprocessed, recycled, or reclaimed PVC.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are provided for information only.

1.5 The following precautionary statement pertains to the test method portion only, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1504 – 02

Standard Specification for

Folded Poly(Vinyl Chloride) (PVC) Pipe for Existing Sewer

1

and Conduit Rehabilitation

This standard is issued under the fixed designation F1504; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

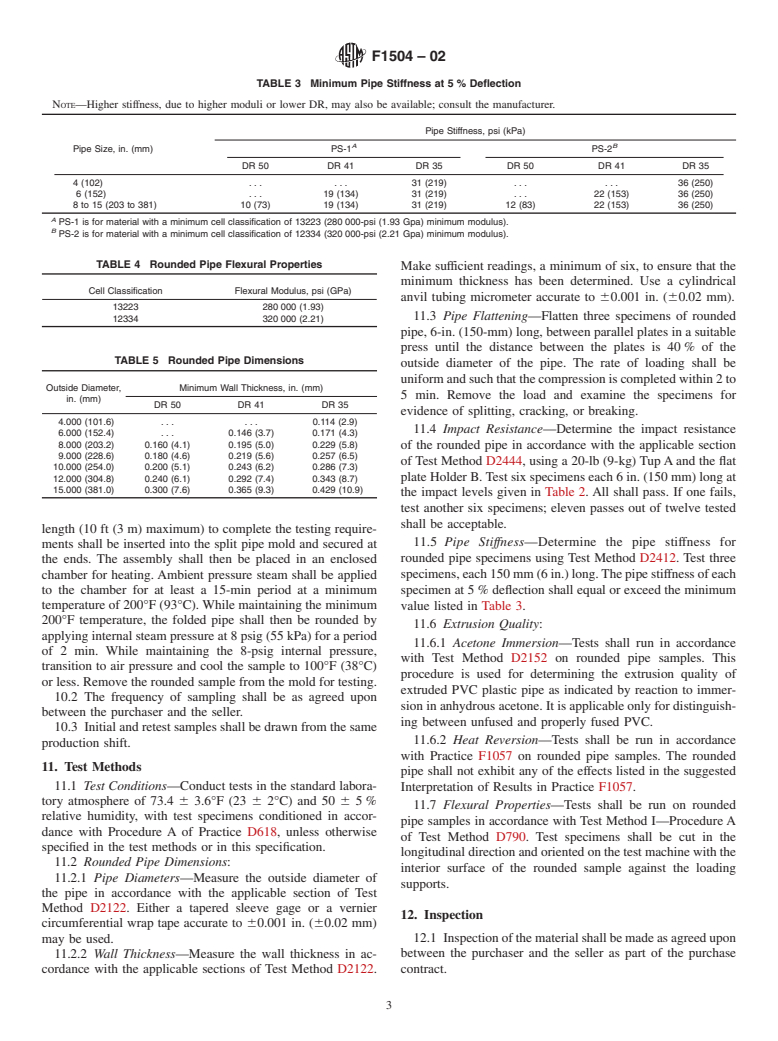

1. Scope D790 Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materials

1.1 This specification covers requirements and test methods

D1600 Terminology for Abbreviated Terms Relating to

for materials, dimensions, workmanship, flattening resistance,

Plastics

impact resistance, pipe stiffness, extrusion quality, and a form

D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

of marking for folded (vinyl chloride) (PVC) pipe for existing

Compounds and Chlorinated Poly(Vinyl Chloride)

sewer and conduit rehabilitation.

(CPVC) Compounds

1.2 Pipe produced to this specification is for use in non-

D2122 Test Method for Determining Dimensions of Ther-

pressure sewer and conduit rehabilitation where the folded

moplastic Pipe and Fittings

PVC pipe is inserted into and then expanded to conform to the

D2152 Test Method for Adequacy of Fusion of Extruded

wall of the original conduit forming a new structural pipe-

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

within-a-pipe.

Acetone Immersion

NOTE 1—An ASTM specification for the installation of folded PVC

D2412 Test Method for Determination of External Loading

pipe is under preparation and will be referenced in this specification when

Characteristics of Plastic Pipe by Parallel-Plate Loading

published.

D2444 Test Method for Determination of the Impact Resis-

1.3 This specification includes pipe made only from mate-

tance of Thermoplastic Pipe and Fittings by Means of a

rials specified in Section 6. This specification does not include

Tup (Falling Weight)

pipe manufactured from reprocessed, recycled, or reclaimed

F412 Terminology Relating to Plastic Piping Systems

PVC.

F1057 Practice for Estimating the Quality of Extruded Poly

1.4 The values stated in inch-pound units are to be regarded

(Vinyl Chloride) (PVC) Pipe by the Heat Reversion Tech-

as the standard. The SI units given in parentheses are provided

nique

for information only.

2.2 Federal Standard:

1.5 The following precautionary statement pertains to the 3

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

test method portion only, Section 11, of this specification: This

2.3 Military Standard:

standard does not purport to address all of the safety concerns, 3

MIL-STD-129 Marking for Shipment and Storage

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health 3. Terminology

practices and determine the applicability of regulatory limita-

3.1 General—Abbreviations used in this specification are in

tions prior to use.

accordance with Terminology D1600 and definitions are in

accordancewithTerminologyF412unlessotherwiseindicated.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2

2.1 ASTM Standards:

3.2.1 folded pipe—pipe that has been manufactured in a

D618 Practice for Conditioning Plastics for Testing

folded shape or that is subsequently folded for use in existing

sewer and conduit rehabilitation. See Fig. 1.

1 3.2.2 rounded pipe—A rounded pipe is a sample for test

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

purposes formed when the folded pipe has been inserted into a

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

Trenchless Plastic Pipeline Technology.

circular casing pipe and expanded with heat and pressure to fit

Current edition approved Sept. 10, 2002. Published December 2002. Originally

tightly to the casing pipe taking a circular cross section, in

´1

published as F1504 – 94. Last previous edition F1504 – 97 . DOI: 10.1520/F1504-

accordance with Section 10. See Fig. 1.

02.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1504 – 02

material meets the requirements of 6.1 and that the pipe

produced meets all the requirements of this specifi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.