ASTM B407-08

(Specification)Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

ABSTRACT

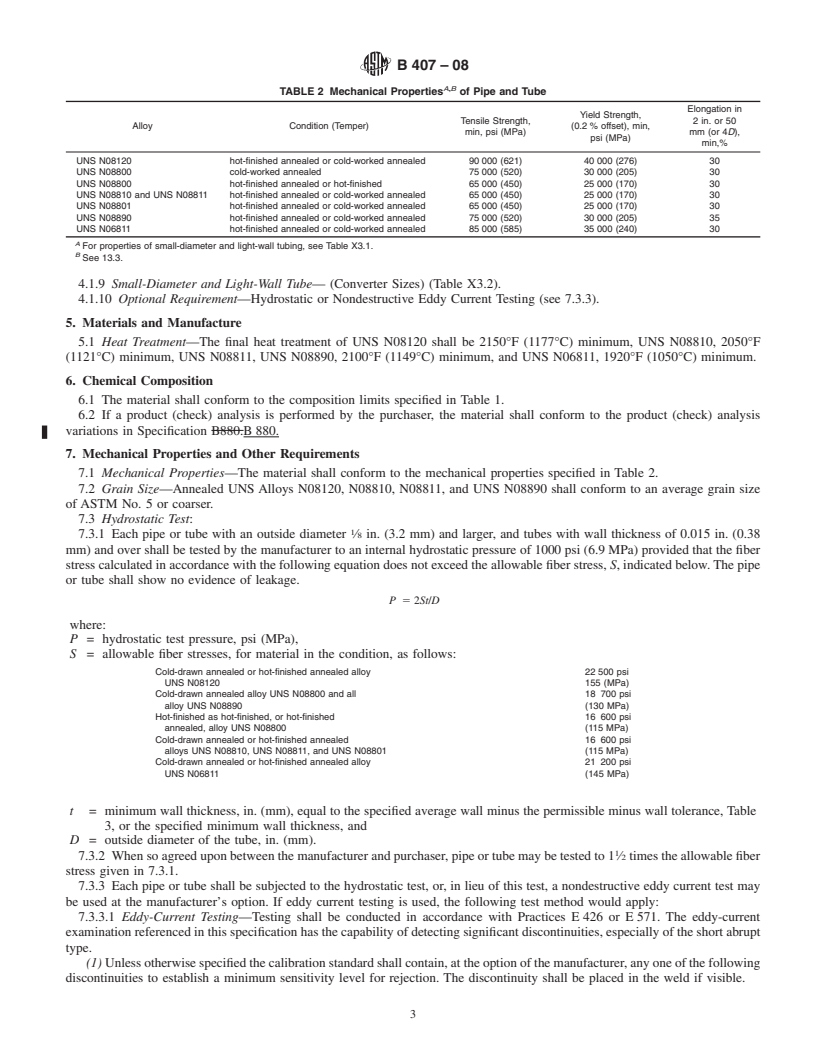

This specification covers the standard requirements for nickel-iron-chromium alloy which include UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and UNS N06811 in the form of cold-worked and hot-finished annealed seamless pipe and tube. The materials shall be heat treated at certain annealing temperatures and shall conform to the chemical composition limits for nickel, chromium, iron, manganese, carbon, copper, silicon, sulfur, aluminum, titanium, columbium, molybdenum, niobium, tantalum, phosphorus, tungsten, cobalt, nitrogen, and boron. Planimetric method of measurement and tension test shall be conducted in full tubular size, longitudinal strip, or round specimens in the direction of fabrication to determine the grain size and mechanical properties, respectively. These materials shall conform to the specified grain size, yield strength, tensile strength, and elongation requirements. Each pipe or tube shall be subjected to hydrostatic or nondestructive eddy-current tests to determine the allowable fiber stress and to detect significant discontinuities such as drilled hole and transverse tangential notch. The cold-drawn material shall be commercially straight, uniform in quality and temper, smooth, and free of bends, kinks, and other injurious imperfections.

SCOPE

1.1 This specification covers UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and UNS N06811 in the form of cold-worked and hot-finished annealed seamless pipe and tube. Alloys UNS N08800 and UNS N06811 are normally employed in service temperatures up to and including 1100°F (593°C). Alloys UNS N08120, UNS N08810, UNS N08811, and UNS N08890 are normally employed in service temperatures above 1100°F (593°C) where resistance to creep and rupture is required, and they are annealed to develop controlled grain size for optimum properties in this temperature range.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 13, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 407 – 08

Standard Specification for

1

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

This standard is issued under the fixed designation B 407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E29 Practice for Using Significant Digits in Test Data to

2 Determine Conformance with Specifications

1.1 This specification covers UNS N08120, UNS N08800,

E112 Test Methods for Determining Average Grain Size

UNSN08801,UNSN08810,UNSN08811,UNSN08890,and

E 140 Hardness ConversionTables for Metals Relationship

UNS N06811 in the form of cold-worked and hot-finished

Among Brinell Hardness, Vickers Hardness, Rockwell

annealed seamless pipe and tube. Alloys UNS N08800 and

Hardness, Superficial Hardness, Knoop Hardness, and

UNS N06811 are normally employed in service temperatures

Scleroscope Hardness

up to and including 1100°F (593°C). Alloys UNS N08120,

E 426 Practice for Electromagnetic (Eddy-Current) Exami-

UNS N08810, UNS N08811, and UNS N08890 are normally

nation of Seamless and Welded Tubular Products, Austen-

employed in service temperatures above 1100°F (593°C)

itic Stainless Steel and Similar Alloys

where resistance to creep and rupture is required, and they are

E 571 Practice for Electromagnetic (Eddy-Current) Exami-

annealed to develop controlled grain size for optimum proper-

nation of Nickel and Nickel Alloy Tubular Products

ties in this temperature range.

E 1473 Test Methods for Chemical Analysis of Nickel,

1.2 The values stated in inch-pound units are to be regarded

Cobalt, and High-Temperature Alloys

as the standard. The values given in parentheses are for

information only.

3. Terminology

1.3 The following safety hazards caveat pertains only to the

3.1 Definitions:

test method portion, Section 13, of this specification. This

3.1.1 average diameter, n—average of the maximum and

standard does not purport to address all of the safety concerns,

minimum outside diameters, or the maximum and minimum

if any, associated with its use. It is the responsibility of the user

inside diameters, as determined at any one cross section of the

of this standard to become familiar with all hazards including

tube.

those identified in the appropriate Material Safety Data Sheet

3.1.2 pipe, n—seamless tube conforming to the particular

(MSDS) for this product/material as provided by the manufac-

dimensions commercially known as standard pipe sizes (see

turer, to establish appropriate safety and health practices, and

Table X3.1).

determine the applicability of regulatory limitations.

3.1.3 tube, n—hollow product of round or any other cross

2. Referenced Documents section having a continuous periphery.

3

2.1 ASTM Standards:

4. Ordering Information

B 880 SpecificationforGeneralRequirementsforChemical

4.1 Orders for material to this specification should include

Check Analysis Limits for Nickel, Nickel Alloys and

information with respect to the following:

Cobalt Alloys

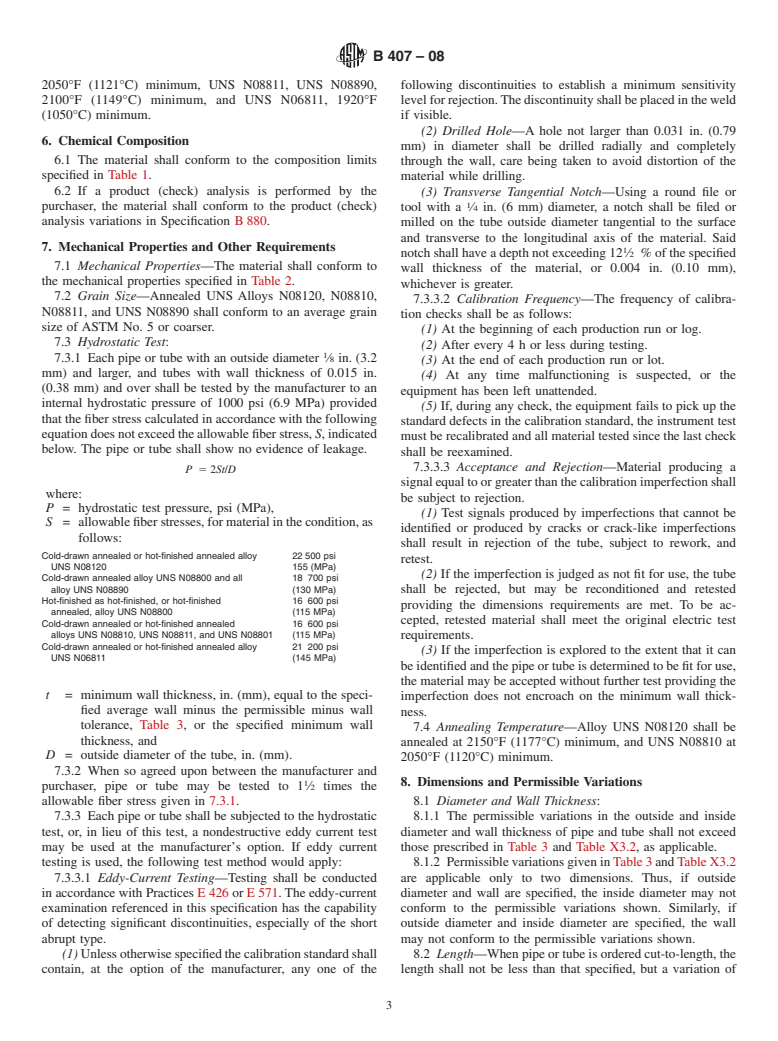

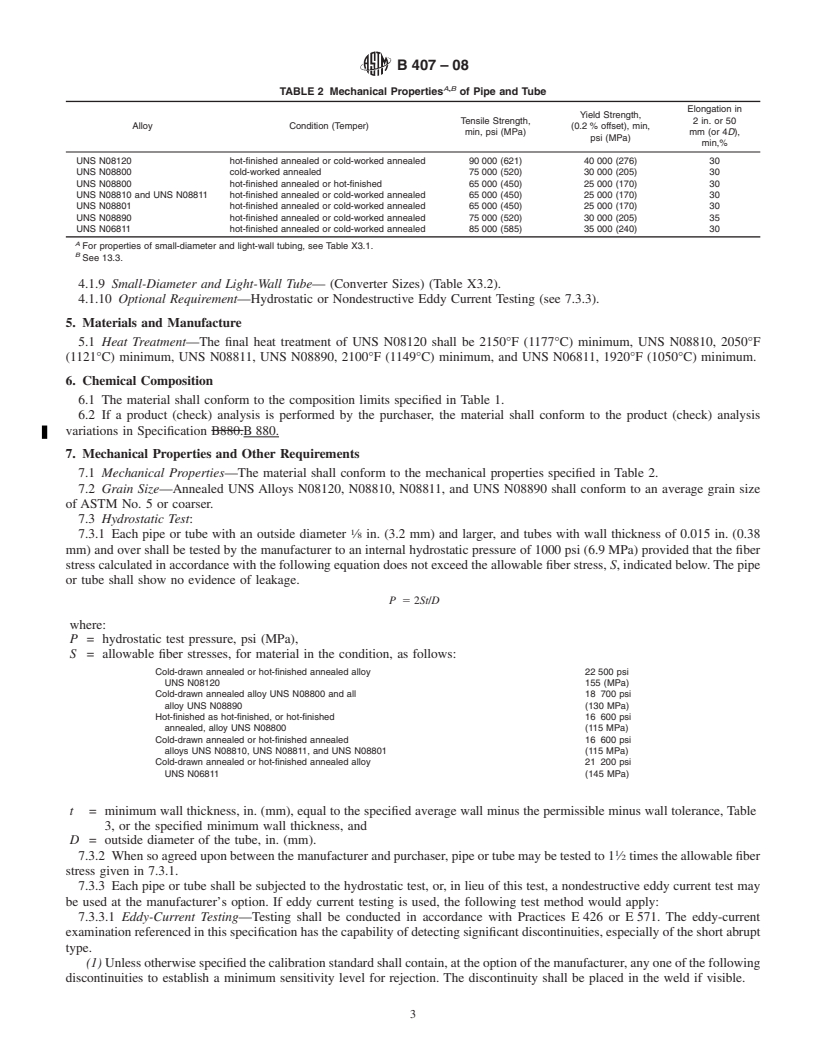

4.1.1 Alloy (Table 1).

E8 Test Methods for Tension Testing of Metallic Materials

4.1.2 Condition Temper (Table 2 and Table X3.1, and

E18 Test Methods for Rockwell Hardness of Metallic

Appendix X2 and Appendix X3).

Materials

4.1.3 Finish (Table X1.1 and Table X3.2).

4.1.4 Dimensions:

1

This specification is under the jurisdiction of ASTM Committee B02 on

4.1.4.1 Tube—May be specified in two dimensions only

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

(length excepted) as follows: Outside diameter and average or

B02.07 on Refined Nickel and Cobalt and Their Alloys.

minimum wall, inside diameter and average wall, or outside

Current edition approved March 1, 2008. Published April 2008. Originally

approved in 1957. Last previous edition approved in 2004 as B 407 – 04.

diameter and inside diameter.

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SB-407 in Section II of that Code. NOTE 1—Tubeproducedtooutsidediameterandminimumwallmaybe

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or furnished upon agreement between the manufacturer and the purchaser.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.4.2 Pipe—Standard pipe size and schedule (Table

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. X3.1).

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B407–08

TABLE 1 Chemical Requirements

Composition Lim

...

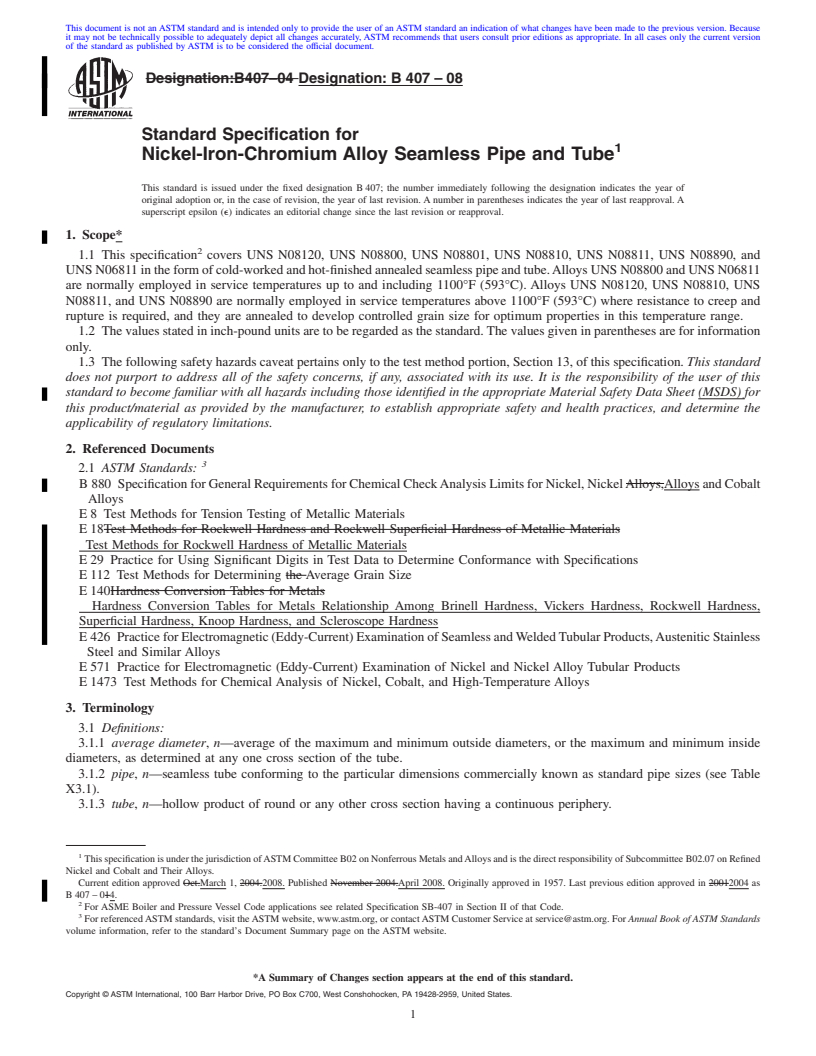

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B407–04 Designation: B 407 – 08

Standard Specification for

1

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

This standard is issued under the fixed designation B 407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and

UNSN06811intheformofcold-workedandhot-finishedannealedseamlesspipeandtube.AlloysUNSN08800andUNSN06811

are normally employed in service temperatures up to and including 1100°F (593°C). Alloys UNS N08120, UNS N08810, UNS

N08811, and UNS N08890 are normally employed in service temperatures above 1100°F (593°C) where resistance to creep and

rupture is required, and they are annealed to develop controlled grain size for optimum properties in this temperature range.

1.2 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 13, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for

this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the

applicability of regulatory limitations.

2. Referenced Documents

3

2.1 ASTM Standards:

B 880 SpecificationforGeneralRequirementsforChemicalCheckAnalysisLimitsforNickel,NickelAlloys,AlloysandCobalt

Alloys

E 8 Test Methods for Tension Testing of Metallic Materials

E 18Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

Test Methods for Rockwell Hardness of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 112 Test Methods for Determining the Average Grain Size

E 140Hardness Conversion Tables for Metals

Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, and Scleroscope Hardness

E 426 PracticeforElectromagnetic(Eddy-Current)ExaminationofSeamlessandWeldedTubularProducts,AusteniticStainless

Steel and Similar Alloys

E 571 Practice for Electromagnetic (Eddy-Current) Examination of Nickel and Nickel Alloy Tubular Products

E 1473 Test Methods for Chemical Analysis of Nickel, Cobalt, and High-Temperature Alloys

3. Terminology

3.1 Definitions:

3.1.1 average diameter, n—average of the maximum and minimum outside diameters, or the maximum and minimum inside

diameters, as determined at any one cross section of the tube.

3.1.2 pipe, n—seamless tube conforming to the particular dimensions commercially known as standard pipe sizes (see Table

X3.1).

3.1.3 tube, n—hollow product of round or any other cross section having a continuous periphery.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB02onNonferrousMetalsandAlloysandisthedirectresponsibilityofSubcommitteeB02.07onRefined

Nickel and Cobalt and Their Alloys.

Current edition approved Oct.March 1, 2004.2008. Published November 2004.April 2008. Originally approved in 1957. Last previous edition approved in 20012004 as

B 407 – 014.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-407 in Section II of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B407–08

4. Ordering Information

4.1 Orders for material to this specification should include information with respect to the following:

4.1.1 Alloy (Table 1).

4.1.2 Condition Temper (Table 2 and Table X3.1, and Appendix X2 and Appendix X3).

4.1.3 Finish (Table X1.1 and Table X3.2).

4.1.4 Dimensions:

4.1.4.1 Tube—May be specified in two d

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B407–04 Designation: B 407 – 08

Standard Specification for

1

Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

This standard is issued under the fixed designation B 407; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers UNS N08120, UNS N08800, UNS N08801, UNS N08810, UNS N08811, UNS N08890, and

UNSN06811intheformofcold-workedandhot-finishedannealedseamlesspipeandtube.AlloysUNSN08800andUNSN06811

are normally employed in service temperatures up to and including 1100°F (593°C). Alloys UNS N08120, UNS N08810, UNS

N08811, and UNS N08890 are normally employed in service temperatures above 1100°F (593°C) where resistance to creep and

rupture is required, and they are annealed to develop controlled grain size for optimum properties in this temperature range.

1.2 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 13, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for

this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the

applicability of regulatory limitations.

2. Referenced Documents

3

2.1 ASTM Standards:

B 880 SpecificationforGeneralRequirementsforChemicalCheckAnalysisLimitsforNickel,NickelAlloys,AlloysandCobalt

Alloys

E8 Test Methods for Tension Testing of Metallic Materials

E18 Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials

Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E112 Test Methods for Determining the Average Grain Size

E 140 Hardness Conversion Tables for Metals

Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, and Scleroscope Hardness

E 426 PracticeforElectromagnetic(Eddy-Current)ExaminationofSeamlessandWeldedTubularProducts,AusteniticStainless

Steel and Similar Alloys

E 571 Practice for Electromagnetic (Eddy-Current) Examination of Nickel and Nickel Alloy Tubular Products

E 1473 Test Methods for Chemical Analysis of Nickel, Cobalt, and High-Temperature Alloys

3. Terminology

3.1 Definitions:

3.1.1 average diameter, n—average of the maximum and minimum outside diameters, or the maximum and minimum inside

diameters, as determined at any one cross section of the tube.

3.1.2 pipe, n—seamless tube conforming to the particular dimensions commercially known as standard pipe sizes (see Table

X3.1).

3.1.3 tube, n—hollow product of round or any other cross section having a continuous periphery.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB02onNonferrousMetalsandAlloysandisthedirectresponsibilityofSubcommitteeB02.07onRefined

Nickel and Cobalt and Their Alloys.

Current edition approved Oct.March 1, 2004.2008. Published November 2004.April 2008. Originally approved in 1957. Last previous edition approved in 20012004 as

B 407 – 014.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-407 in Section II of that Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B407–08

4. Ordering Information

4.1 Orders for material to this specification should include information with respect to the following:

4.1.1 Alloy (Table 1).

4.1.2 Condition Temper (Table 2 and Table X3.1, and Appendix X2 and Appendix X3).

4.1.3 Finish (Table X1.1 and Table X3.2).

4.1.4 Dimensions:

4.1.4.1 Tube—May be specified in two dim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.