ASTM C1285-21

(Test Method)Standard Test Methods for Determining Chemical Durability of Nuclear, Hazardous, and Mixed Waste Glasses and Multiphase Glass Ceramics: The Product Consistency Test (PCT)

Standard Test Methods for Determining Chemical Durability of Nuclear, Hazardous, and Mixed Waste Glasses and Multiphase Glass Ceramics: The Product Consistency Test (PCT)

SIGNIFICANCE AND USE

5.1 These test methods provide data useful for evaluating the chemical durability (see 3.1.5) of glass waste forms as measured by elemental release. Accordingly, it may be applicable throughout manufacturing, research, and development.

5.1.1 Test Method A can specifically be used to obtain data to evaluate whether the chemical durability of glass waste forms have been consistently controlled during production (see Table 1).

5.1.2 Test Method B can specifically be used to measure the chemical durability of glass waste forms under various test conditions, for example, varying test durations, test temperatures, sample surface area (SA)-to-leachant volume (V) ratios (see Appendix X1), and leachant types (see Table 1). Data from this test may form part of the larger body of data that are necessary in the logical approach to long-term prediction of waste form behavior (see Practice C1174).

SCOPE

1.1 These product consistency Test Methods A and B provide a measure of the chemical durability of homogeneous glasses, phase separated glasses, devitrified glasses, glass ceramics, multiphase glass ceramic waste forms, or combinations thereof, hereafter collectively referred to as “glass waste forms” by measuring the concentrations of the chemical species released to a test solution under carefully controlled conditions.

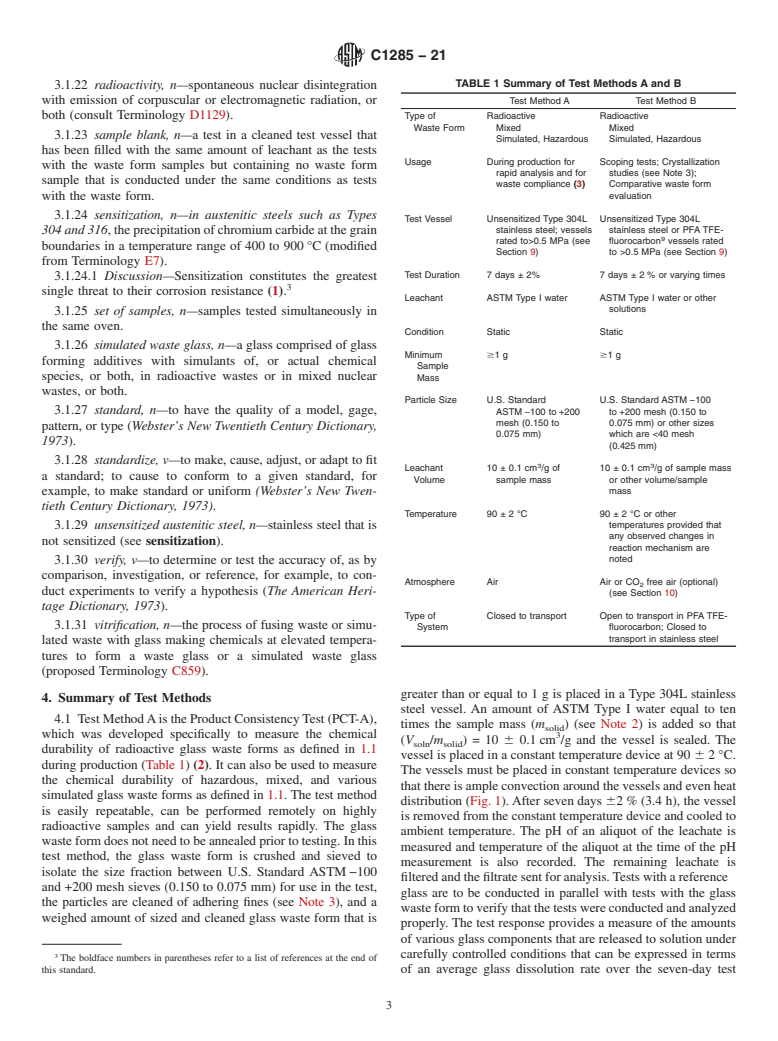

1.1.1 Test Method A is a seven-day chemical durability test performed at 90 ± 2 °C in a leachant of ASTM-Type I water. The test method is static and conducted in stainless steel vessels. The stainless steel vessels require a gasket to remain leak-tight (see Note 1) The stainless steel vessels are considered to be “closed system” tests. Test Method A can specifically be used to evaluate whether the chemical durability and elemental release characteristics of nuclear, hazardous, and mixed glass waste forms have been consistently controlled during production. This test method is applicable to radioactive and simulated glass waste forms as defined above.

Note 1: TFE-fluorocarbon gaskets, available commercially, are acceptable and chemically inert up to radiation doses of 1 × 105 R of beta or gamma radiation which have been shown not to damage TFE-fluorocarbon. If higher radiation doses are anticipated, special gaskets fabricated from metals such as copper, gold, lead, or indium are recommended.

1.1.2 Test Method B is a durability test that allows testing at various test durations, test temperatures, particle size and masses of glass sample, leachant volumes, and leachant compositions. This test method is static and can be conducted in stainless steel or PFA TFE-fluorocarbon vessels. The stainless steel vessels are considered to be “closed system” while the PFA TFE-fluorocarbon vessels are considered to be “open system” tests. Test Method B can specifically be used to evaluate the relative chemical durability characteristics of homogeneous glasses, phase separated glasses, devitrified glasses, glass ceramics, or multiphase glass ceramic waste forms, or combinations thereof. This test method is applicable to radioactive (nuclear) and mixed, hazardous, and simulated glass waste forms as defined above. Test Method B cannot be used as a consistency test for production of high level radioactive glass waste forms.

1.2 These test methods must be performed in accordance with all quality assurance requirements for acceptance of the data.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with ...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1285 − 21

Standard Test Methods for

Determining Chemical Durability of Nuclear, Hazardous, and

Mixed Waste Glasses and Multiphase Glass Ceramics: The

1

Product Consistency Test (PCT)

This standard is issued under the fixed designation C1285; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope homogeneous glasses, phase separated glasses, devitrified

glasses, glass ceramics, or multiphase glass ceramic waste

1.1 These product consistency Test Methods A and B

forms, or combinations thereof. This test method is applicable

provide a measure of the chemical durability of homogeneous

to radioactive (nuclear) and mixed, hazardous, and simulated

glasses, phase separated glasses, devitrified glasses, glass

glass waste forms as defined above. Test Method B cannot be

ceramics, multiphase glass ceramic waste forms, or combina-

used as a consistency test for production of high level

tions thereof, hereafter collectively referred to as “glass waste

radioactive glass waste forms.

forms” by measuring the concentrations of the chemical

species released to a test solution under carefully controlled 1.2 These test methods must be performed in accordance

conditions. with all quality assurance requirements for acceptance of the

1.1.1 Test MethodAis a seven-day chemical durability test data.

performed at 90 6 2 °C in a leachant ofASTM-Type I water.

1.3 The values stated in SI units are to be regarded as

The test method is static and conducted in stainless steel

standard. The values given in parentheses after SI units are

vessels. The stainless steel vessels require a gasket to remain

providedforinformationonlyandarenotconsideredstandard.

leak-tight (see Note 1) The stainless steel vessels are consid-

1.4 This standard does not purport to address all of the

eredtobe“closedsystem”tests.TestMethodAcanspecifically

safety concerns, if any, associated with its use. It is the

be used to evaluate whether the chemical durability and

responsibility of the user of this standard to establish appro-

elemental release characteristics of nuclear, hazardous, and

priate safety, health, and environmental practices and deter-

mixed glass waste forms have been consistently controlled

mine the applicability of regulatory limitations prior to use.

duringproduction.Thistestmethodisapplicabletoradioactive

1.5 This international standard was developed in accor-

and simulated glass waste forms as defined above.

dance with internationally recognized principles on standard-

NOTE 1—TFE-fluorocarbon gaskets, available commercially, are ac-

ization established in the Decision on Principles for the

5

ceptable and chemically inert up to radiation doses of1×10 R of beta

Development of International Standards, Guides and Recom-

or gamma radiation which have been shown not to damage TFE-

mendations issued by the World Trade Organization Technical

fluorocarbon. If higher radiation doses are anticipated, special gaskets

Barriers to Trade (TBT) Committee.

fabricated from metals such as copper, gold, lead, or indium are recom-

mended.

2. Referenced Documents

1.1.2 TestMethodBisadurabilitytestthatallowstestingat

2

2.1 ASTM Standards:

various test durations, test temperatures, particle size and

C92Test Methods for Sieve Analysis and Water Content of

masses of glass sample, leachant volumes, and leachant com-

Refractory Materials

positions. This test method is static and can be conducted in

C162Terminology of Glass and Glass Products

stainless steel or PFATFE-fluorocarbon vessels. The stainless

C169Test Methods for Chemical Analysis of Soda-Lime

steel vessels are considered to be “closed system” while the

and Borosilicate Glass

PFA TFE-fluorocarbon vessels are considered to be “open

C225Test Methods for Resistance of Glass Containers to

system” tests. Test Method B can specifically be used to

Chemical Attack

evaluate the relative chemical durability characteristics of

C371Test Method for Wire-Cloth Sieve Analysis of Non-

plastic Ceramic Powders

1

These test methods are under the jurisdiction of ASTM Committee C26 on

Nuclear Fuel Cycle and are the direct responsibility of Subcommittee C26.13 on

2

Spent Fuel and High Level Waste. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2021. Published April 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1994. Last previous edition approved in 2014 as

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1285 − 14 C1285 − 21

Standard Test Methods for

Determining Chemical Durability of Nuclear, Hazardous, and

Mixed Waste Glasses and Multiphase Glass Ceramics: The

1

Product Consistency Test (PCT)

This standard is issued under the fixed designation C1285; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These product consistency test methodsTest Methods A and B provide a measure of the chemical durability of homogeneous

glasses, phase separated glasses, devitrified glasses, glass ceramics, multiphase glass ceramic waste forms, or combinations

thereof, hereafter collectively referred to as “glass waste forms” by measuring the concentrations of the chemical species released

to a test solution under carefully controlled conditions.

1.1.1 Test Method A is a seven-day chemical durability test performed at 90 6 2°C 2 °C in a leachant of ASTM-Type I water.

The test method is static and conducted in stainless steel vessels. The stainless steel vessels require a gasket to remain

leak-tight.leak-tight (see Note 1) The stainless steel vessels are considered to be “closed system” tests. Test Method A can

specifically be used to evaluate whether the chemical durability and elemental release characteristics of nuclear, hazardous, and

mixed glass waste forms have been consistently controlled during production. This test method is applicable to radioactive and

simulated glass waste forms as defined above.

5

NOTE 1—TFE-fluorocarbon gaskets, available commercially, are acceptable and chemically inert up to radiation doses of 1 × 10 R of beta or gamma

radiation which have been shown not to damage TFE-fluorocarbon. If higher radiation doses are anticipated, special gaskets fabricated from metals such

as copper, gold, lead, or indium are recommended.

1.1.2 Test Method B is a durability test that allows testing at various test durations, test temperatures, particle size and masses of

glass sample, leachant volumes, and leachant compositions. This test method is static and can be conducted in stainless steel or

PFA TFE-fluorocarbon vessels. The stainless steel vessels are considered to be “closed system” while the PFA TFE-fluorocarbon

vessels are considered to be “open system” tests. Test Method B can specifically be used to evaluate the relative chemical durability

characteristics of homogeneous glasses, phase separated glasses, devitrified glasses, glass ceramics, or multiphase glass ceramic

waste forms, or combinations thereof. This test method is applicable to radioactive (nuclear) and mixed, hazardous, and simulated

glass waste forms as defined above. Test Method B cannot be used as a consistency test for production of high level radioactive

glass waste forms.

1.2 These test methods must be performed in accordance with all quality assurance requirements for acceptance of the data.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this The values

given in parentheses after SI units are provided for information only and are not considered standard.

1

These test methods are under the jurisdiction of ASTM Committee C26 on Nuclear Fuel Cycle and are the direct responsibility of Subcommittee C26.13 on Spent Fuel

and High Level Waste.

Current edition approved Jan. 1, 2014Feb. 1, 2021. Published April 2014April 2021. Originally approved in 1994. Last previous edition approved in 20082014 as

C1285 – 02 (2008).C1285 – 14. DOI: 10.1520/C1285-14.10.1520/C1285-21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1285 − 21

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Refer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.