ASTM F1498-08

(Specification)Standard Specification for Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

Standard Specification for Taper Pipe Threads 60<span class='unicode'>°</span> for Thermoplastic Pipe and Fittings

ABSTRACT

This specification establishes requirements for dimensions and gaging of taper pipe threads used on threaded plastic pipe and fittings. The type of pipe threads are designated by specifying in sequence the nominal pipe size, number of threads per inch, and the thread series symbols as follows. For left-hand threads add LH to the designation, otherwise right-hand threads will be understood. Different physical properties of pipe threads such as form, dimensions, angle, truncation, height, sealing capacity, and tightness shall be in accordance with the requirements specified. The gages have two types which may be used to completely cover gage requirements: (1) master gages used to check working gages; and (2) working gages used to check threads during manufacture and for conformance inspection. Both external and internal taper threads shall be gaged.

SCOPE

1.1 This specification establishes requirements for dimensions and gaging of taper pipe threads used on threaded plastic pipe and fittings.

1.2 Threads meeting this specification shall only be used on those plastic materials deemed suitable by the manufacturer.

1.3 Specialty threads or threads not requiring a leak-tight joint are not covered in this specification.

Note 1—The terms “wrench makeup” and “wrench tight” are standard terminology for tightness and do not imply using a pipe wrench or other tools which would damage plastic pipe and fittings. The terms “hand-tight” and “hand-tight engagement” refer only to thread gaging (not pipe and fitting connections) and is the definition of the L1 gage length.

1.4 Thread Designations—The type of pipe threads included in this specification are designated by specifying in sequence the nominal pipe size, number of threads per inch, and the thread series symbols as follows in accordance with ANSI/ASME B 1.20.1: 3/8-18 NPT. For left-hand threads add LH to the end of the designation, otherwise right-hand threads will be understood. For example: 3/8-18 NPT-LH.

1.4.1 Each of these letters in the symbol has a definite significance as follows:

N = National (American Standard) P = Pipe T = Taper

1.5 The values stated in inch-pound units are to be regarded as the standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see 7.2.1 and 8.3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1498 −08 AnAmerican National Standard

Standard Specification for

1

Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

This standard is issued under the fixed designation F1498; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification establishes requirements for dimen-

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

sions and gaging of taper pipe threads used on threaded plastic

tics

pipe and fittings.

E177Practice for Use of the Terms Precision and Bias in

1.2 Threads meeting this specification shall only be used on

ASTM Test Methods

those plastic materials deemed suitable by the manufacturer.

F412Terminology Relating to Plastic Piping Systems

3

2.2 ASME Standards:

1.3 Specialty threads or threads not requiring a leak-tight

B1.20.1Pipe Threads, General Purpose (inch)

joint are not covered in this specification.

B1.7 Nomenclature, Definitions and Letter Symbols for

3

Screw Threads

NOTE 1—The terms “wrench makeup” and “wrench tight” are standard

terminology for tightness and do not imply using a pipe wrench or other B47.1Gage Blanks

tools which would damage plastic pipe and fittings. The terms “hand-

tight” and “hand-tight engagement” refer only to thread gaging (not pipe

3. Terminology

and fitting connections) and is the definition of the L gage length.

1

3.1 Terminology is in accordance with Terminology F412

1.4 ThreadDesignations—Thetypeofpipethreadsincluded and abbreviations are in accordance with Terminology D1600,

in this specification are designated by specifying in sequence unless otherwise indicated.

the nominal pipe size, number of threads per inch, and the

3.2 Nomenclature, definitions, and letter symbols for screw

thread series symbols as follows in accordance with ANSI/

threads are in accordance with ASME/ANSI B1.7.

3

ASME B 1.20.1: ⁄8-18 NPT. For left-hand threads add LH to

4. American National Standard Taper Pipe Thread Form

theendofthedesignation,otherwiseright-handthreadswillbe

3

understood. For example: ⁄8-18 NPT-LH.

4.1 Thread Form—The form of thread profile specified in

1.4.1 Each of these letters in the symbol has a definite this specification shall be known as the American National

significance as follows: Standard Taper Pipe Thread Form. The relations as specified

herein, for form of thread and general notations are shown in

N = National (American Standard)

P = Pipe

Fig. 1.

T = Taper

4.2 Angle of Thread—The angle between the sides of the

1.5 The values stated in inch-pound units are to be regarded

thread is 60° when measured in an axial plane. The line

as the standard. No other units of measurement are included in

bisecting this angle is perpendicular to the axis.

this standard.

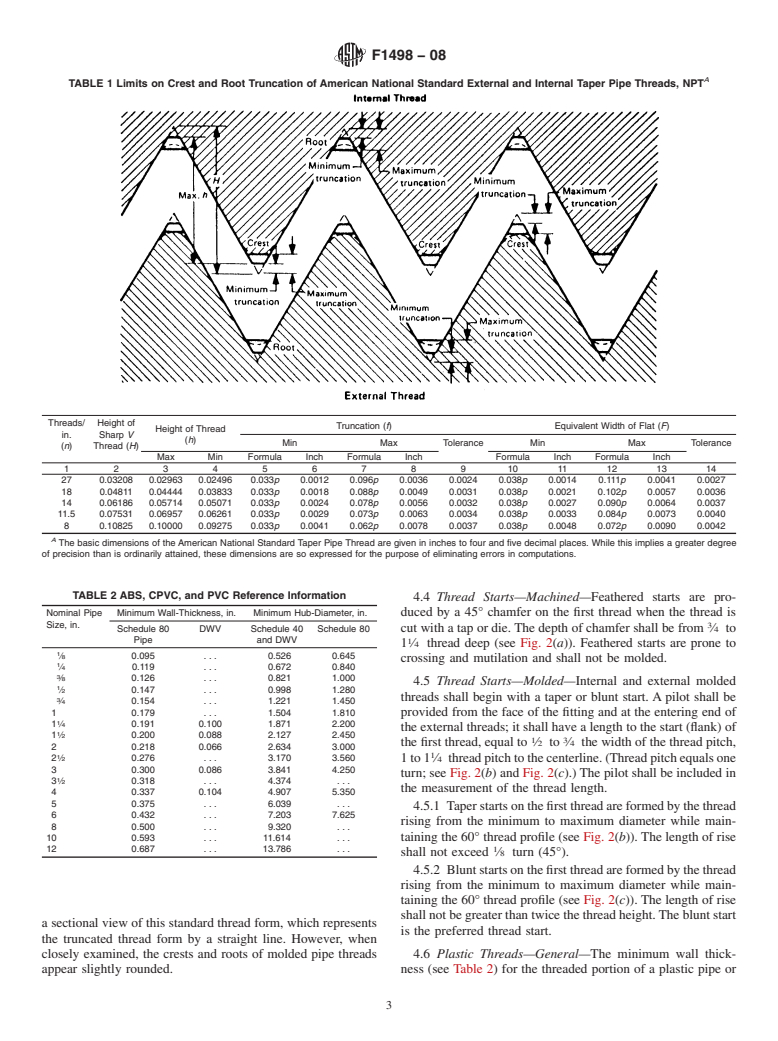

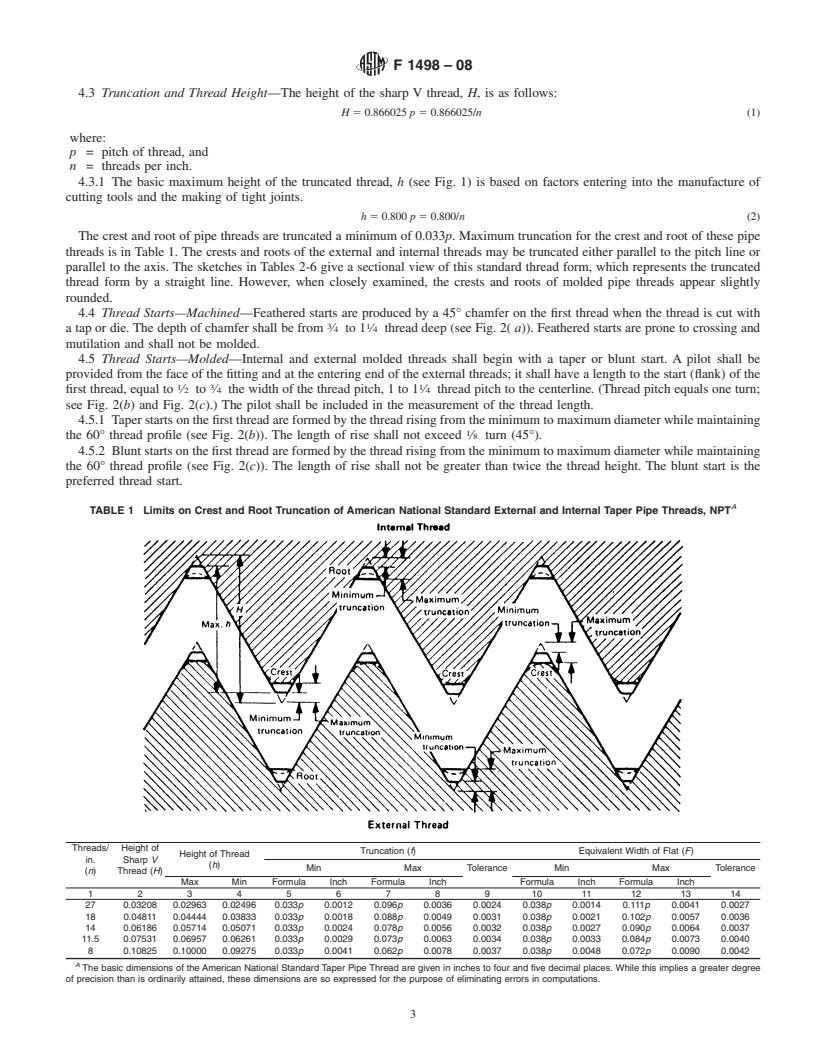

4.3 Truncation and Thread Height—The height of the sharp

1.6 This standard does not purport to address all of the

V thread, H, is as follows:

safety concerns, if any, associated with its use. It is the

H 50.866025p 50.866025/n (1)

responsibility of the user of this standard to establish appro-

where:

priate safety and health practices and determine the applica-

p = pitch of thread, and

bility of regulatory limitations prior to use. For specific

precautionary statements, see 7.2.1 and 8.3.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings. the ASTM website.

3

Current edition approved April 15, 2008. Published May 2008. Originally Available from American Society of Mechanical Engineers (ASME), ASME

ϵ1

approved in 1994. Last previous edition approved in 2000 as F1498–00 . DOI: International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

10.1520/F1498-08. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1498−08

1

H = 0.866025p = height of 60° sharp V thread b = 1° 47 min. = thread taper angle for ⁄16 taper

h = 0.800000p = height of thread on product f = depth of truncation at crest

c

p =1/n = pitch (measured parallel to axis) f = depth of truncation at root

r

n = number of threads per inch F = width of flat at crest

c

a = 30° = thread flank angle F = width of flat at root

r

2

NOTE 1—F

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

e1

Designation:F 1498–00 Designation: F 1498 – 08

Standard Specification for

1

Taper Pipe Threads 60° for Thermoplastic Pipe and Fittings

This standard is issued under the fixed designation F 1498; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Fig. 1 was editorially updated in November 2004.

1. Scope*

1.1 This specification establishes requirements for dimensions and gaging of taper pipe threads used on threaded plastic pipe

and fittings.

1.2 Threads meeting this specification shall only be used on those plastic materials deemed suitable by the manufacturer.

1.3 Specialty threads or threads not requiring a leak-tight joint are not covered in this specification.

NOTE 1—The terms “wrench makeup” and “wrench tight” are standard terminology for tightness and do not imply using a pipe wrench or other tools

which would damage plastic pipe and fittings. The terms “hand-tight” and “hand-tight engagement” refer only to thread gaging (not pipe and fitting

connections) and is the definition of the L gage length.

1

1.4 Thread Designations—The type of pipe threads included in this specification are designated by specifying in sequence the

nominalpipesize,numberofthreadsperinch,andthethreadseriessymbolsasfollowsinaccordancewithANSI/ASMEB1.20.1:

3

⁄8-18 NPT. For left-hand threads add LH to the end of the designation, otherwise right-hand threads will be understood. For

3

example: ⁄8-18 NPT-LH.

1.4.1 Each of these letters in the symbol has a definite significance as follows:

N = National (American Standard)

P = Pipe

T = Taper

1.5The values stated in inch-pound units are to be regarded as the standard.

1.5 Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.Nootherunitsofmeasurementareincludedinthis

standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautionary statements, see 7.2.1 and 8.3.

2. Referenced Documents

2

2.1 ASTM Standards:

D1600 Terminology for Abbreviated Terms Relating to Plastics

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

F412 Terminology Relating to Plastic Piping Systems

3

2.2 ANSI/ASME Standards: ASME Standards:

B1.20.1 Pipe Threads, General Purpose (inch)

3

B1.7MB1.7 Nomenclature, Definitions and Letter Symbols for Screw Threads

3

B47.1 Gage Blanks B47.1 Gage Blanks

3. Terminology

3.1 Terminology is in accordance with Terminology F412 and abbreviations are in accordance with Terminology D1600,

unless otherwise indicated.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved . Published July 2000. Originally published as F1498–94. Last previous edition F1498–94.

e1

Current edition approved April 15, 2008. Published May 2008. Originally approved in 1994. Last previous edition approved in 2000 as F1498–00 .

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

3

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

www.asme.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1498 – 08

3.2 Nomenclature, definitions, and letter symbols for screw threads are in accordance withANSI/ASME B 1.7MASME/ANSI

B1.7.

4. American National Standard Taper Pipe Thread Form

4.1 Thread Form—The form of thread profile specified in this specification shall be known as theAmerican National Standard

Taper Pipe Thread Form. The relations as specified herein, for form of thread and general notations are shown in Fig. 1.

4.2 Angle of Thread—Th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.