ASTM D5581-06

(Test Method)Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 inch-Diameter Specimen)

Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus (6 inch-Diameter Specimen)

SCOPE

1.1 This test method covers the measurement of the resistance to plastic flow of cylindrical specimens of bituminous paving mixture loaded on the lateral surface by means of the Marshall apparatus. This test method is for use with mixtures containing asphalt cement and aggregate up to 11/2 in. (37.5 mm) nominal maximum size.

1.2 The values stated in inch-pound units are to be regarded as standard except for reference to sieve sizes and size of aggregate as measured by testing sieves in which SI units are standard according to Specification E 11. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5581–06

Standard Test Method for

Resistance to Plastic Flow of Bituminous Mixtures Using

1

Marshall Apparatus (6 inch-Diameter Specimen)

This standard is issued under the fixed designation D 5581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This test method covers the measurement of the resis- 3.1 This test method is used in the laboratory mix design of

tance to plastic flow of cylindrical specimens of bituminous bituminous mixtures. Specimens are prepared in accordance

paving mixture loaded on the lateral surface by means of the with the method and tested for maximum load and flow.

Marshall apparatus. This test method is for use with mixtures Density and voids properties may also be determined on

1

containing asphalt cement and aggregate up to 1 ⁄2 in. (37.5 specimenspreparedinaccordancewiththemethod.Thetesting

mm) nominal maximum size. section of this method can also be used to obtain maximum

1.2 The values stated in inch-pound units are to be regarded load and flow for bituminous paving specimens cored from

as standard except for reference to sieve sizes and size of pavements or prepared by other methods. These results may

aggregate as measured by testing sieves in which SI units are differ from values obtained on specimens prepared by this test

standard according to SpecificationE11. The values given in method.

parentheses are mathematical conversions to SI units that are 3.2 It has been determined that 75 and 112 compaction

provided for information only and are not considered standard. blows applied to a 6-in. (152.4 mm) diameter specimen using

1.3 This standard does not purport to address all of the the apparatus and procedure in this standard give densities

safety concerns, if any, associated with its use. It is the equivalent to 50 and 75 compaction blows, respectively,

responsibility of the user of this standard to establish appro- applied to a 4-in. (101.6-mm) diameter specimen using Test

priate safety and health practices and determine the applica- Method D 6926.

bility of regulatory limitations prior to use.

4. Apparatus

2. Referenced Documents

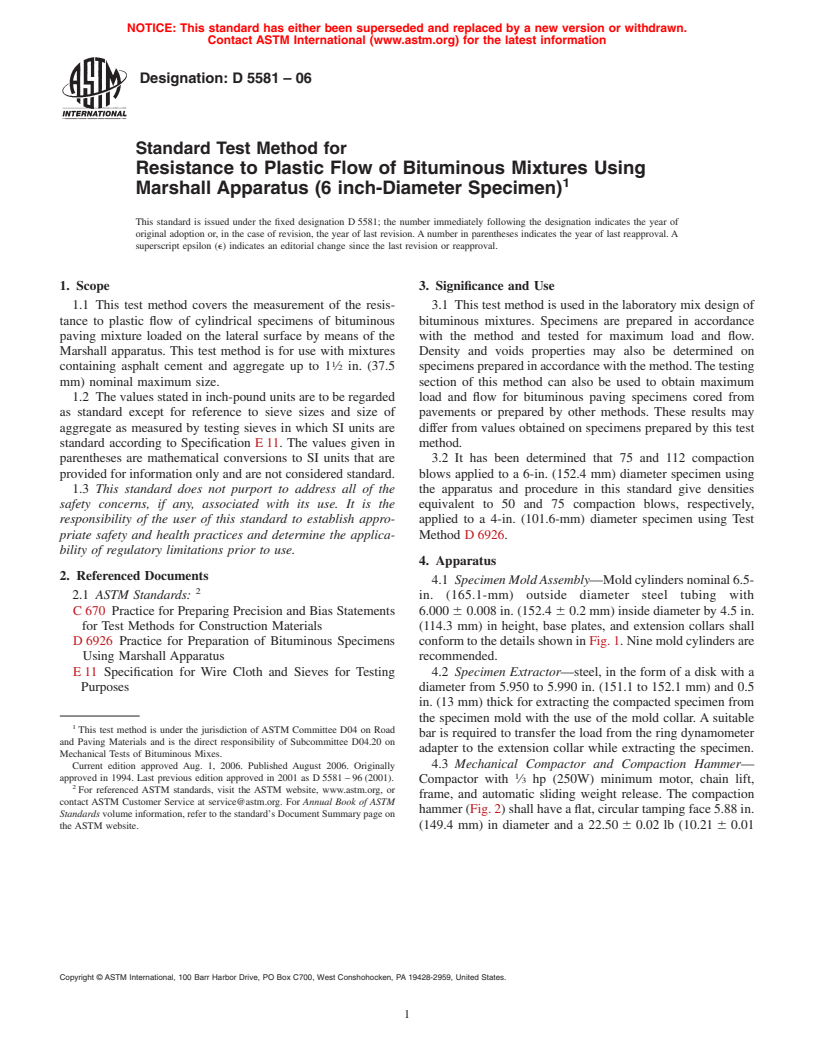

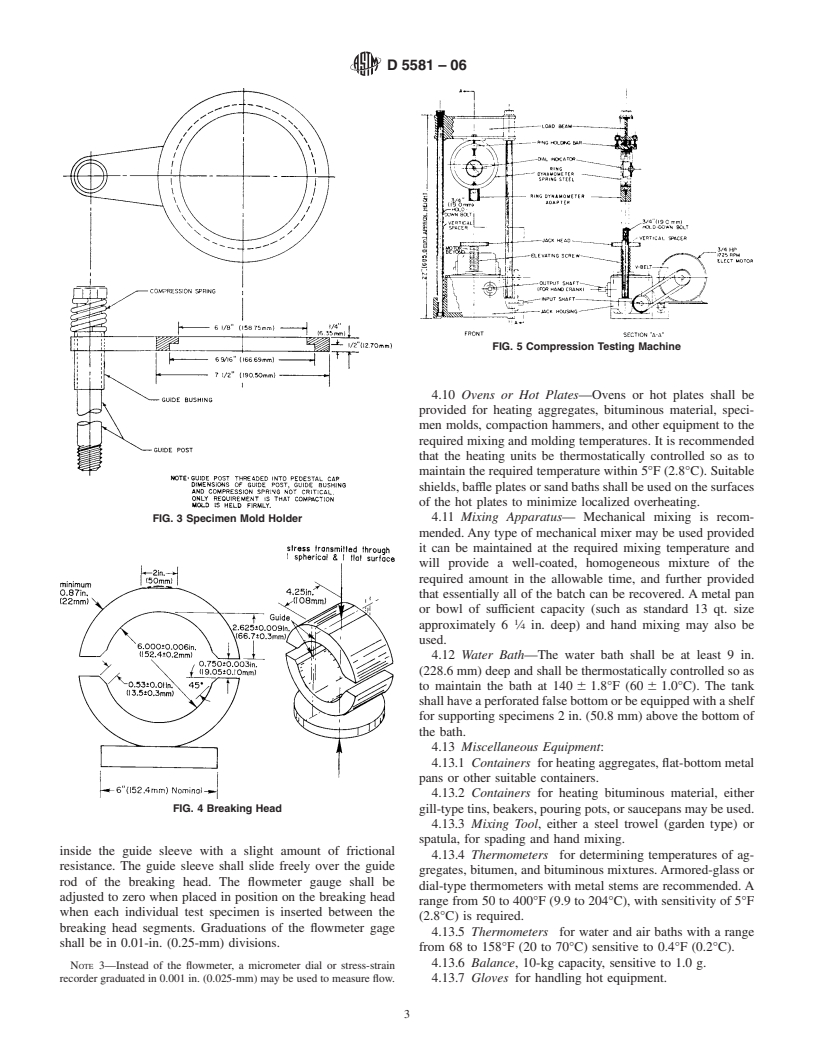

4.1 SpecimenMoldAssembly—Moldcylindersnominal6.5-

2

2.1 ASTM Standards: in. (165.1-mm) outside diameter steel tubing with

C 670 Practice for Preparing Precision and Bias Statements 6.000 6 0.008 in. (152.4 6 0.2 mm) inside diameter by 4.5 in.

for Test Methods for Construction Materials (114.3 mm) in height, base plates, and extension collars shall

D 6926 Practice for Preparation of Bituminous Specimens conform to the details shown in Fig. 1. Nine mold cylinders are

Using Marshall Apparatus recommended.

E11 Specification for Wire Cloth and Sieves for Testing 4.2 Specimen Extractor—steel, in the form of a disk with a

Purposes diameter from 5.950 to 5.990 in. (151.1 to 152.1 mm) and 0.5

in. (13 mm) thick for extracting the compacted specimen from

the specimen mold with the use of the mold collar. A suitable

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

bar is required to transfer the load from the ring dynamometer

and Paving Materials and is the direct responsibility of Subcommittee D04.20 on

adapter to the extension collar while extracting the specimen.

Mechanical Tests of Bituminous Mixes.

4.3 Mechanical Compactor and Compaction Hammer—

Current edition approved Aug. 1, 2006. Published August 2006. Originally

1

approved in 1994. Last previous edition approved in 2001 as D 5581 – 96 (2001).

Compactor with ⁄3 hp (250W) minimum motor, chain lift,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

frame, and automatic sliding weight release. The compaction

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

hammer (Fig. 2) shall have a flat, circular tamping face 5.88 in.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (149.4 mm) in diameter and a 22.50 6 0.02 lb (10.21 6 0.01

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5581–06

FIG. 2 Compaction Hammer (Generic)

FIG. 1 Compaction Mold

appreciable binding or loose motion on the guide rods. When

a 6.000 in. (152.4 mm) diameter by 4 in. (100 mm) thick metal

block is placed between the two segments, the inside diameters

kg) sliding weight with a free fall of 18.0 6 0.1 in.

and the gaps between the segments shall conform to Fig. 4.All

(457.2 6 2.5 mm). Two compaction hammers are recom-

steel components shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.