ASTM A341/A341M-16

(Test Method)Standard Test Method for Direct Current Magnetic Properties of Soft Magnetic Materials Using D-C Permeameters and the Point by Point (Ballistic) Test Methods

Standard Test Method for Direct Current Magnetic Properties of Soft Magnetic Materials Using D-C Permeameters and the Point by Point (Ballistic) Test Methods

SIGNIFICANCE AND USE

3.1 Permeameters require the use of yokes to complete the magnetic circuit and are therefore inherently less accurate than ring test methods. Refer to Test Method A596/A596M for further details on ring test methods. However, when testing certain shapes as bars or when magnetic field strength in excess of 200 Oe [16 kA/m] is required, permeameters are the only practical means of measuring magnetic properties.

3.2 This test method is suitable for specification acceptance, service evaluation, research and development and design.

3.3 When the test specimen is fabricated from a larger sample and is in the same condition as the larger sample, it may not exhibit magnetic properties representative of the original sample. In such instances the test results, when viewed in context of past performance history, will be useful for judging the suitability of the material for the intended application.

SCOPE

1.1 This test method provides dc permeameter tests for the basic magnetic properties of soft magnetic materials in the form of bars, rods, wire, or strip specimens which may be cut, machined, or ground from cast, compacted, sintered, forged, extruded, rolled, or other fabricated materials. It includes tests for determination of the normal induction under symmetrically cyclically magnetized (SCM) conditions and the hysteresis loop (B-H loop) taken under conditions of rapidly changing or steep wavefront reversals of the direct current magnetic field strength. This method has been historically referred to as the ballistic test method. For testing hard or permanent magnet materials, Test Method A977/A977M shall be used.

1.2 This test method shall be used in conjunction with Practice A34/A34M.

1.3 This test method covers a range of magnetic field strength in the specimen from about 0.05 Oe [4 A/m] up to above 5000 Oe [400 kA/m] through the use of several permeameters. The separate permeameters cover this test region in several overlapping ranges.

1.4 Normal induction and hysteresis properties may be determined over the magnetic flux density range from essentially zero to the saturation induction for most materials.

1.5 Recommendations of the useful magnetic field strength range for each of the permeameters are shown in Table 1.2 Permeameters particularly well suited for general testing of soft magnetic materials are shown in boldface. Also, see Sections 3 and 4 for general limitations relative to the use of permeameters. (A) Although the permeameters are capable of being used at the lower end of the measurement range, the measurement accuracy is reduced.(B) I—magnetizing current; HC—fixed H coil; FC—flip coil; HP—Hall probe; RCC —Rogowski-Chattock coil.(C) Fahy permeameters require a standard of known magnetic properties for calibration of the H coil.(D) The boldface numbers in parentheses refer to a list of references at the end of this standard.

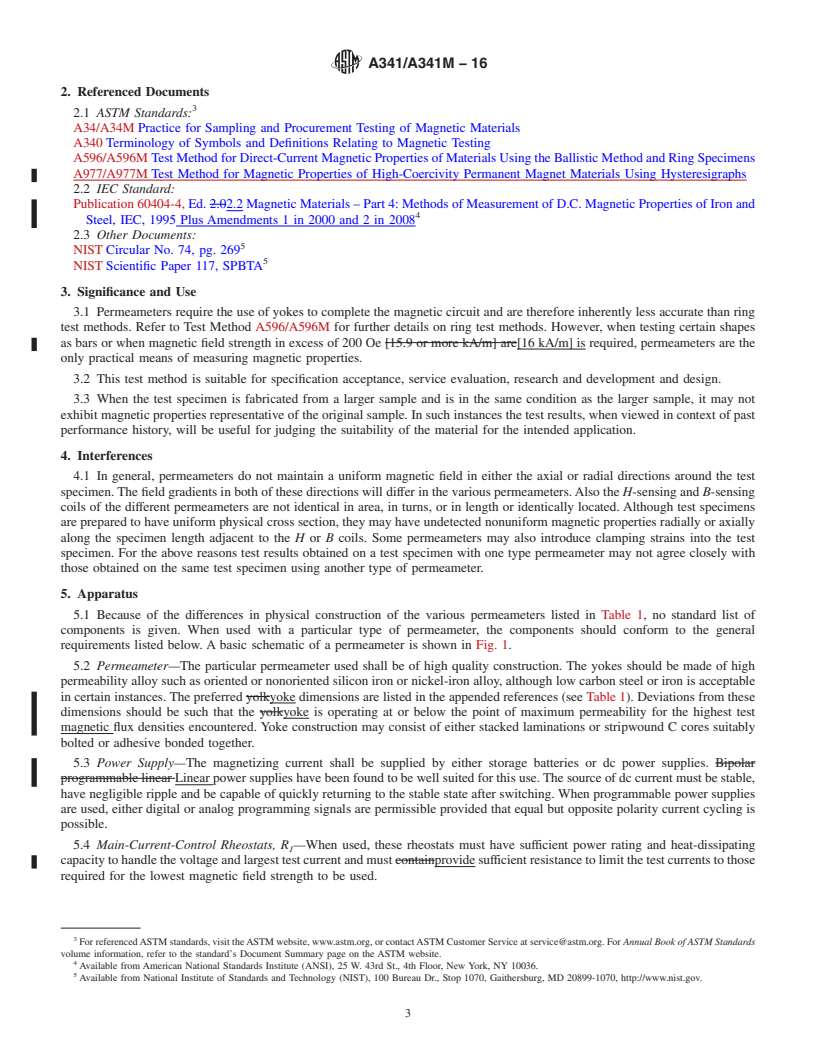

1.6 The symbols and abbreviated definitions used in this test method appear with Fig. 1 and in appropriate sections of this document. For the official definitions, see Terminology A340. Note that the term magnetic flux density used in this document is synonymous with the term magnetic induction.SP—Specimen

1.7 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm ) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.8 The values and equations stated in customary (cgs-emu and inch-pound) or SI units are to be regarded separately as standard. Within this...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A341/A341M − 16

Standard Test Method for

Direct Current Magnetic Properties of Soft Magnetic

Materials Using D-C Permeameters and the Point by Point

1

(Ballistic) Test Methods

This standard is issued under the fixed designationA341/A341M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.6 Thesymbolsandabbreviateddefinitionsusedinthistest

method appear with Fig. 1 and in appropriate sections of this

1.1 This test method provides dc permeameter tests for the

document. For the official definitions, see Terminology A340.

basic magnetic properties of soft magnetic materials in the

Notethatthetermmagneticfluxdensityusedinthisdocument

form of bars, rods, wire, or strip specimens which may be cut,

is synonymous with the term magnetic induction.

machined, or ground from cast, compacted, sintered, forged,

1.7 Warning—Mercury has been designated by EPA and

extruded, rolled, or other fabricated materials. It includes tests

many state agencies as a hazardous material that can cause

fordeterminationofthenormalinductionundersymmetrically

central nervous system, kidney, and liver damage. Mercury, or

cyclically magnetized (SCM) conditions and the hysteresis

its vapor, may be hazardous to health and corrosive to

loop (B-H loop) taken under conditions of rapidly changing or

materials.Cautionshouldbetakenwhenhandlingmercuryand

steep wavefront reversals of the direct current magnetic field

mercury-containing products. See the applicable product Ma-

strength. This method has been historically referred to as the

terial Safety Data Sheet (MSDS) for details and EPA’s website

ballistic test method. For testing hard or permanent magnet

(http://www.epa.gov/mercury/faq.htm)foradditionalinforma-

materials, Test Method A977/A977M shall be used.

tion. Users should be aware that selling mercury or mercury-

1.2 This test method shall be used in conjunction with

containingproducts,orboth,inyourstatemaybeprohibitedby

Practice A34/A34M.

state law.

1.3 This test method covers a range of magnetic field

1.8 The values and equations stated in customary (cgs-emu

strength in the specimen from about 0.05 Oe [4 A/m] up to

and inch-pound) or SI units are to be regarded separately as

above 5000 Oe [400 kA/m] through the use of several

standard. Within this standard, SI units are shown in brackets

permeameters. The separate permeameters cover this test

except for the sections concerning calculations where there are

region in several overlapping ranges.

separate sections for the respective unit systems. The values

stated in each system may not be exact equivalents; therefore,

1.4 Normal induction and hysteresis properties may be

each system shall be used independently of the other. Combin-

determined over the magnetic flux density range from essen-

ingvaluesfromthetwosystemsmayresultinnonconformance

tially zero to the saturation induction for most materials.

with this standard.

1.5 Recommendations of the useful magnetic field strength

2 1.9 This standard does not purport to address all of the

range for each of the permeameters are shown in Table 1.

safety concerns, if any, associated with its use. It is the

Permeameters particularly well suited for general testing of

responsibility of the user of this standard to establish appro-

soft magnetic materials are shown in boldface. Also, see

priate safety and health practices and determine the applica-

Sections 3 and 4 for general limitations relative to the use of

bility of regulatory limitations prior to use.

permeameters.

2. Referenced Documents

3

2.1 ASTM Standards:

1

This test method is under the jurisdiction of ASTM Committee A06 on

A34/A34MPractice for Sampling and Procurement Testing

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

Methods.

Current edition approved May 1, 2016. Published May 2016. Originally

3

approved in 1969. Last previous edition approved in 2011 as A341/ For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ε1

A341M–00(2011) . DOI: 10.1520/A0341_A0341M-16. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A341/A341M − 16

TABLE 1 Permeameters

A

Ma

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A341/A341M − 00 (Reapproved 2011) A341/A341M − 16

Standard Test Method for

Direct Current Magnetic Properties of Soft Magnetic

Materials Using D-C Permeameters and the Ballistic Point

1

by Point (Ballistic) Test Methods

This standard is issued under the fixed designation A341/A341M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Corrected text and Fig. 1 editorially in December 2011.

1. Scope

1.1 This test method provides dc permeameter tests for the basic magnetic properties of soft magnetic materials in the form of

bars, rods, wire, or strip specimens which may be cut, machined, or ground from cast, compacted, sintered, forged, extruded, rolled,

or other fabricated materials. It includes tests for determination of the normal induction under symmetrically cyclically magnetized

(SCM) conditions and the hysteresis loop (B-H loop) taken under conditions of rapidly changing or steep wavefront reversals of

the direct current magnetic field strength. This method has been historically referred to as the ballistic test method. For testing hard

or permanent magnet materials, Test Method A977/A977M shall be used.

1.2 This test method shall be used in conjunction with Practice A34/A34M.

1.3 This test method covers a range of magnetic field strength in the specimen from about 0.05 Oe [4 A/m] up to above 5000

Oe [400 kA/M]kA/m] through the use of several permeameters. The separate permeameters cover this test region in several

overlapping ranges.

1.4 Normal induction and hysteresis properties may be determined over the magnetic flux density range from essentially zero

to intrinsicthe saturation induction for most materials.

1

This test method is under the jurisdiction of ASTM Committee A06 on Magnetic Properties and is the direct responsibility of Subcommittee A06.01 on Test Methods.

Current edition approved Oct. 1, 2011May 1, 2016. Published October 2011May 2016. Originally approved in 1969. Last previous edition approved in 20052011 as

ε1

A341/A341M – 00(2005)(2011) . DOI: 10.1520/A0341_A0341M-00R11E01.10.1520/A0341_A0341M-16.

TABLE 1 Permeameters

A

Magnetizing Coil

Useful Magnetic Field Strength Range

H Measuring Reluctance

D

Permeameter Surrounds References

B

Device Compensation

Oe kA/m Specimen

Babbit 40/1000 3.2/80 I, HC yes yes (1,2)

Burroughs 0.1/300 0.008/24 I yes yes (1,3,4,5)

C

Fahy Simplex 0.1/300 0.008/24 HC no no (1,4,5,6,7)

Fahy Simplex

100/2500 8/200 HC no no (1,3)

C

Super H adapter

Full range 0.05/1400 0.004/112 HC yes yes (1,8)

High H 100/5000 8/400 FC yes no (1,5,7,9)

Iliovici 0.5/500 0.04/400 I, HC yes yes (4,10,11)

IEC Type A 0.1/2500 0.008/200 HC, HP no yes IEC 60404-4

IEC Type B 0.1/630 0.008/50 RCC no no IEC 60404-4

Isthmus 100/20 000+ 8/1600+ HC, HP no no (1,4,12,13)

MH 0.1/300 0.008/24 FC yes yes (1,6,14)

NPL 0.5/2500 0.04/200 I, HC yes yes (15)

Saturation 100/4000 8/320 HC no yes (5,16,17)

A

Although the permeameters are capable of being used at the lower end of the measurement range, the measurement accuracy is reduced.

B

I—magnetizing current; HC—fixed H coil; FC—flip coil; HP—Hall probe; RCC —Rogowski-Chattock coil.

C

Fahy permeameters require a standard of known magnetic properties for calibration of the H coil.

D

The boldface numbers in parentheses refer to a list of references at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A341/A341M − 16

NOTE 1—

A —Multirange ammeter (main current)

1

A —Multirange ammeter (hysteresis current)

2

B—Flux —Magnetic flux density test position for Switch S

3

F—Electronic IntegratorFluxmeter

H—Magnetic field strength test position for Switch S

3

N —Magnetizing coil

1

N —Flux —Magnetic flux sensing (B) coil

2

N —Magnetic field strength (H) sensing coil

3

R —Main current control rheostat

1

R —Hysteresis current control rheostat

2

S —Reversing switch for magnetizing current

1

S —Shunting switch for hysteresis current control rheostat

2

S —Integrator—Fluxmeter selector switch

3

SP—Specimen

FIG. 1 Basic Circuit Using Permeameter

2

1.5 Recommendations of the useful magnetic field strength range for each of the permeameters are

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.