ASTM D7563-10

(Test Method)Standard Test Method for Evaluation of the Ability of Engine Oil to Emulsify Water and Simulated Ed85 Fuel

Standard Test Method for Evaluation of the Ability of Engine Oil to Emulsify Water and Simulated Ed85 Fuel

SIGNIFICANCE AND USE

During engine operation, engine oil can become contaminated by water and fuel. In the case of Ed85 fuels, this contamination can result in a non-emulsified aqueous bottom layer in the oil that can affect the lubrication and detergency of the engine oil. To avoid field problems, engine oil should be capable of emulsifying water contamination to the extent that no aqueous layer appears.

The test described in this method is designed to evaluate the ability of an engine oil, contaminated with a specified amount of water (volume fraction of 10 % of the original oil sample) and simulated Ed85 fuel (also a volume fraction of 10 % of the original oil sample), to emulsify the water after agitation in a blender and to maintain this emulsion at temperatures of 20 °C to 25 °C and -5 °C to 0 °C for at least 24 h.

This test method has potential use in specifications of engine lubricating oils, such as Specification D4485.

SCOPE

1.1 This test method describes a qualitative procedure to measure the ability of a specific volume of engine oil to emulsify a specific added volume of combined water and simulated Ed85 fuel upon agitation in a high-speed blender and to retain this emulsified state for at least 24 h at temperatures of both 20 °C to 25 °C and -5 °C to 0 °C.

1.2 Information Letters are published periodically by the ASTM Test Monitoring Center (TMC) to update this and other test methods under the jurisdiction of Subcommittee D02.B0. Copies of these letters can be obtained by writing the Center.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7563 − 10

StandardTest Method for

Evaluation of the Ability of Engine Oil to Emulsify Water and

Simulated Ed85 Fuel

This standard is issued under the fixed designation D7563; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5854 Practice for Mixing and Handling of Liquid Samples

of Petroleum and Petroleum Products

1.1 This test method describes a qualitative procedure to

E1272 Specification for Laboratory Glass Graduated Cylin-

measure the ability of a specific volume of engine oil to

ders

emulsify a specific added volume of combined water and

simulatedEd85fueluponagitationinahigh-speedblenderand

3. Terminology

to retain this emulsified state for at least 24 h at temperatures

3.1 Definitions:

of both 20 °C to 25 °C and -5 °C to 0 °C.

3.1.1 denatured fuel ethanol, n—fuel ethanol made unfit for

1.2 Information Letters are published periodically by the

beverage use by the addition of denaturants. D4806

ASTM Test Monitoring Center (TMC) to update this and other

3.1.2 fuel ethanol (Ed75-Ed85), n—blend of ethanol and

test methods under the jurisdiction of Subcommittee D02.B0.

hydrocarbonofwhichtheethanolportionisnominally75to85

Copies of these letters can be obtained by writing the Center.

volume % denatured fuel ethanol. D5798

1.3 The values stated in SI units are to be regarded as

3.1.3 engine oil, n—liquid that reduces friction or wear, or

standard. No other units of measurement are included in this

both, between the moving parts within an engine; removes

standard.

heat, particularly from the underside of pistons; and serves as

1.4 This standard does not purport to address all of the

a combustion gas sealant for piston rings.

safety concerns, if any, associated with its use. It is the

3.1.3.1 Discussion—It may contain additives to enhance

responsibility of the user of this standard to establish appro-

certain properties. Inhibition of engine rusting, deposit

priate safety and health practices and determine the applica-

formation, valve train wear, oil oxidation, and foaming are

bility of regulatory limitations prior to use.

examples. D4175

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

3.2.1 simulated Ed85 fuel, n—laboratory blend made to

2.1 ASTM Standards:

simulate Ed85 fuel by mixing 85 % denatured fuel ethanol and

D1193 Specification for Reagent Water

15 % unleaded gasoline by volume.

D4175 Terminology Relating to Petroleum, Petroleum

Products, and Lubricants 3.2.2 test oil, n—any engine oil subjected to evaluation in

D4485 Specification for Performance of Active API Service this test method.

Category Engine Oils

4. Summary of Test Method

D4806 Specification for Denatured Fuel Ethanol for Blend-

ing with Gasolines for Use as Automotive Spark-Ignition

4.1 Distilled water, simulated Ed85 fuel, and the test oil are

Engine Fuel

emulsified in a high-speed blender. Portions of the resulting

D5798 Specification for Ethanol Fuel Blends for Flexible-

emulsion are stored in two graduated cylinders (or suitably

Fuel Automotive Spark-Ignition Engines

dimensionedalternativecontainers)attemperaturesof20°Cto

25 °C and -5 °C to 0 °C for 24 h. Presence or absence of an

1 aqueouslayeratthebottomofeitherofthecontainersafterthis

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee time interval is observed and reported.

D02.B0.07 on Development and Surveillance of Bench Tests Methods.

Current edition approved Jan. 1, 2010. Published March 2010.

5. Significance and Use

Information letters may be obtained from the ASTM Test Monitoring Center,

6555 Penn Avenue, Pittsburgh, PA 15206-4489. www.standards.astmtmc.cmu.edu.

5.1 During engine operation, engine oil can become con-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

taminated by water and fuel. In the case of Ed85 fuels, this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

contamination can result in a non-emulsified aqueous bottom

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. layer in the oil that can affect the lubrication and detergency of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7563 − 10

the engine oil. To avoid field problems, engine oil should be 6.5 Time-Measuring Equipment:

capable of emulsifying water contamination to the extent that 6.5.1 Stopwatch or other timer capable of measuring 1 min

no aqueous layer appears. with a minimum precision of 61s.

6.5.2 Clock or other timer capable of measuring 24 h with a

5.2 The test described in this method is designed to evaluate

minimum precision of 6 5 min.

the ability of an engine oil, contaminated with a specified

amount of water (volume fraction of 10 % of the original oil 6.6 Laboratory Hood Vented Exteriorly or Other Well-

sample) and simulated Ed85 fuel (also a volume fraction of Ventilated Work Space—Suitable for pouring volatile, flam-

10 % of the original oil sample), to emulsify the water after mable fluids such as denatured fuel ethanol and gasoline into

agitation in a blender and to maintain this emulsion at graduated cylinders and containers. Ensure there is no ignition

temperatures of 20 °C to 25 °C and -5 °C to 0 °C for at least source within the hood or nearby when using an open work

24 h. space, particularly at lower levels where hydrocarbon volatiles

tend to congregate.

5.3 This test method has potential use in specifications of

engine lubricating oils, such as Specification D4485.

7. Reagents and Materials

7.1 Purity of Water—Unless otherwise indicated, references

6. Apparatus and Supporting Equipment

to water shall be understood to mean reagent water that meets

6.1 Blender—Commercial laboratory blender with its asso-

or exceeds that defined as Type IV of Specification D1193.

ciated glass or stainless steel liquid container having suitable

7.2 Denatured Fuel Ethanol—Use product conforming to

blending capacity for this use and a blade rotating at approxi-

Specification D4806. Refer to Specification D4806 and Prac-

mately 10 000 r/min 6 2000 r/min as measured by a strobo-

tice D5854 for information on container selection, storage and

scopic tachometer.

handling. Product stored for more than three months should be

NOTE 1—This speed is generally equivalent to the low-speed setting on

checked to ensure it has not deteriorated or been contaminated

two-speed commercial mixers or the “2” or “3” setting on seven-speed

before use. (Warning—Danger! Extremely flammable. Vapors

commercial mixers.

may cause flash fire.)

6.2 Glass, Graduated Cylinders—Unless otherwise stated,

7.3 Unleaded Gasoline—Use only Haltermann EEE un-

all graduated cylinders shall conform to Specification E1272,

leaded fuel coded HF003. Fuel stored for more than three

Class B, Style I.

months should be checked to ensure it has not deteriorated or

6.2.1 For Measuring Volume of Test Oil and Unleaded

been contaminated before use. (Warning—Danger! Extremely

Fuel—Having a capacity of 250 mL with graduation marks of

flammable. Health Hazard.)

2 mL.

6.2.2 For Measuring Volumes of Simulated Ed85 Fuel and

7.4 Cleaning Solvents—Reagent grade acetone and isooc-

Water—Having a capacity of 25 mL with graduation marks of

tane. (Warning—Danger! Extremely flammable. Vapors may

0.2 mL.

cause flash fire.)

6.2.3 For Preparing the Simulated Ed85 Fuel—Glass-

stoppered and conforming to Specification E1272, Class B,

8. Hazards

Style II and having a capacity of 1 Lwith graduation marks of

8.1 SpecificHazards—Becauseoffiredanger,carefullypour

10 mL.

denatured fuel ethanol and gasoline into graduated cylinders

6.3 Containers for Observation of Emulsified Samples—Use andcontainersinalaboratoryhood,preferablyfromcontainers

either of the following types: of capacity no greater than about 2 L. See also 7.2 and 7.3.

6.3.1 Glass-stoppered, graduated cylinders conforming to

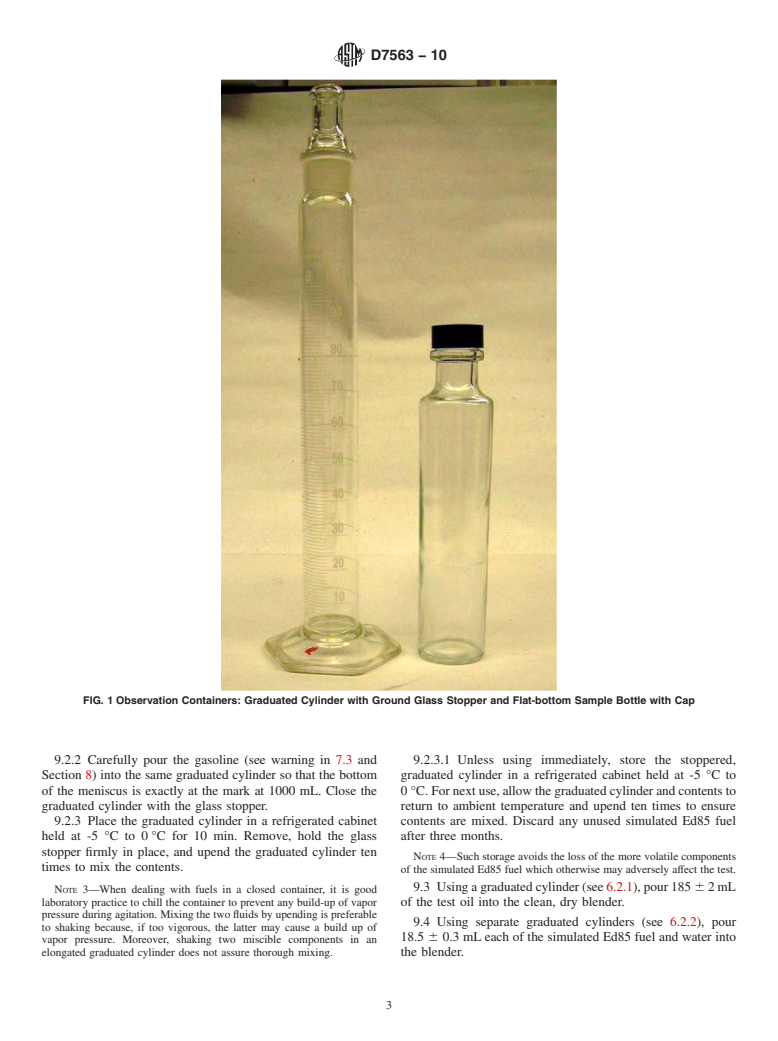

9. Procedure

Specification E1272, Class B, Style II and having a capacity of

100 mL with graduation marks of 1 mL (see Fig. 1).

9.1 Clean blender and other glassware with isooctane fol-

6.3.2 Glass, flat-bottomed, sample bottles with an outer

lowed by acetone (see warning in 7.4).

diameter of approximately 30 mm, a minimum height of

9.1.1 First, rinse total inner surface of all vessels three

150 mm and capable of being closed by a solvent resistant

times with isooctane followed by similarly rinsing three times

screw cap (see Fig. 1).The height of the bottles should be such

with acetone and dry thoroughly.

that 100 mL of fluid comes below the shoulder to allow

9.2 Blending the Simulated Ed85 Fuel:

accurate measurement of the height of 100 mL of emulsion

9.2.1 In a laboratory hood, carefully pour denatured fuel

(see 9.6 and X1.2.1).

ethanol (see warning in 7.2 and Section 8) into a clean, dry,

NOTE2—Asimplewayofmarkingthesamplebottlesistopour100 mL

graduated cylinder with capacity of 1 L (see 6.2.3) so that the

ofwaterfromagraduatedcylinderintoeachcleananddrybottle,markthe

bottom of the meniscus is exactly at the mark at 850 mL.

level of the water meniscus on the bottle (suggest using a glass scribing

tool or triangular metal file), and dry the bottle before proceeding.

6.4 Temperature Chambers:

The sole source of supply of this fuel known to the committee at this time i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.