ASTM C1273-95a(2000)

(Test Method)Standard Test Method for Tensile Strength of Monolithic Advanced Ceramics at Ambient Temperatures

Standard Test Method for Tensile Strength of Monolithic Advanced Ceramics at Ambient Temperatures

SCOPE

1.1 This test method covers the determination of tensile strength under uniaxial loading of monolithic advanced ceramics at ambient temperatures. This test method addresses, but is not restricted to, various suggested test specimen geometries as listed in the appendix. In addition, specimen fabrication methods, testing modes (load, displacement, or strain control), testing rates (load rate, stress rate, displacement rate, or strain rate), allowable bending, and data collection and reporting procedures are addressed. Note that tensile strength as used in this test method refers to the tensile strength obtained under uniaxial loading.

1.2 This test method applies primarily to advanced ceramics that macroscopically exhibit isotropic, homogeneous, continuous behavior. While this test method applies primarily to monolithic advanced ceramics, certain whisker- or particle-reinforced composite ceramics as well as certain discontinuous fiber-reinforced composite ceramics may also meet these macroscopic behavior assumptions. Generally, continuous fiber ceramic composites (CFCCs) do not macroscopically exhibit isotropic, homogeneous, continuous behavior and application of this practice to these materials is not recommended.

1.3 Values expressed in this test method are in accordance with the International System of Units (SI) and Practice E380.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1273 – 95a (Reapproved 2000)

Standard Test Method for

Tensile Strength of Monolithic Advanced Ceramics at

Ambient Temperatures

This standard is issued under the fixed designation C 1273; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C1161 Test Method for Flexural Strength of Advanced

Ceramics at Ambient Temperature

1.1 This test method covers the determination of tensile

C1239 Practice for Reporting Uniaxial Strength Data and

strengthunderuniaxialloadingofmonolithicadvancedceram-

Estimating Weibull Distribution Parameters for Advanced

ics at ambient temperatures. This test method addresses, but is

Ceramics

notrestrictedto,varioussuggestedtestspecimengeometriesas

D3379 Test Method for Tensile Strength and Young’s

listed in the appendix. In addition, specimen fabrication

Modulus for High-Modulus Single-Filament Materials

methods, testing modes (load, displacement, or strain control),

E4 Practices for Force Verification of Testing Machines

testing rates (load rate, stress rate, displacement rate, or strain

E6 Terminology Relating to Methods of Mechanical Test-

rate), allowable bending, and data collection and reporting

ing

procedures are addressed. Note that tensile strength as used in

E83 Practice for Verification and Classification of Exten-

this test method refers to the tensile strength obtained under

someters

uniaxial loading.

E337 Test Method for Measured Humidity with a Psy-

1.2 Thistestmethodappliesprimarilytoadvancedceramics

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

that macroscopically exhibit isotropic, homogeneous, continu-

peratures)

ous behavior. While this test method applies primarily to

E380 Practice for Use of the International System of Units

monolithic advanced ceramics, certain whisker- or particle-

(SI) (The Modernized Metric System)

reinforcedcompositeceramicsaswellascertaindiscontinuous

E1012 Practice for Verification of Specimen Alignment

fiber-reinforced composite ceramics may also meet these

Under Tensile Loading

macroscopicbehaviorassumptions.Generally,continuousfiber

2.2 Military Handbook:

ceramic composites (CFCCs) do not macroscopically exhibit

MIL-HDBK-790 Fractography and Characterization of

isotropic, homogeneous, continuous behavior and application

Fracture Origins in Advanced Structural Ceramics

of this practice to these materials is not recommended.

1.3 Values expressed in this test method are in accordance

3. Terminology

with the International System of Units (SI) and Practice E380.

3.1 Definitions—The definitions of terms relating to tensile

1.4 This standard does not purport to address all of the

testingappearinginTerminologyE6applytothetermsusedin

safety concerns, if any, associated with its use. It is the

this test method on tensile testing. The definitions of terms

responsibility of the user of this standard to establish appro-

relating to advanced ceramics testing appearing in Terminol-

priate safety and health practices and determine the applica-

ogy C1145 apply to the terms used in this test method.

bility of regulatory limitations prior to use. Specific precau-

Pertinent definitions as listed in Practice C1239, Practice

tionary statements are given in Section 7.

E1012, Terminology C1145, and Terminology E6 are shown

2. Referenced Documents in the following with the appropriate source given in paren-

theses. Additional terms used in conjunction with this test

2.1 ASTM Standards:

method are defined in the following:

C1145 Terminology of Advanced Ceramics

1 3

This test method is under the jurisdiction of ASTM Committee C-28 on Annual Book of ASTM Standards, Vol 15.03.

Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 on Annual Book of ASTM Standards, Vol 03.01.

Properties and Performance. Annual Book of ASTM Standards, Vol 11.03.

Current edition approved Sept. 10, 1995. Published November 1995. Originally Annual Book of ASTM Standards, Vol 14.02.

published as C1273-94. Last previous edition C1273-95. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 15.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1273 – 95a (2000)

3.1.1 advanced ceramic—a highly engineered, high perfor- testingconditionisrequiredforstatisticalanalysisandeventual

mance predominately nonmetallic, inorganic, ceramic material design, with guidelines for sufficient numbers provided in this

having specific functional attributes. (See Terminology test method. Note that size-scaling effects as discussed in

C1145.) Practice C1239 will affect the strength values. Therefore,

3.1.2 axial strain—the average of longitudinal strains mea- strengths obtained using different recommended tensile speci-

sured at the surface on opposite sides of the longitudinal axis mens with different volumes or surface areas of material in the

of symmetry of the specimen by two strain-sensing devices gage sections will be different due to these size differences.

located at the mid length of the reduced section. (See Practice Resulting strength values can be scaled to an effective volume

E1012.) or surface area of unity as discussed in Practice C1239.

3.1.3 bending strain—the difference between the strain at 4.4 Tensile tests provide information on the strength and

the surface and the axial strain. In general, the bending strain deformation of materials under uniaxial tensile stresses. Uni-

variesfrompointtopointaroundandalongthereducedsection form stress states are required to effectively evaluate any

of the specimen. (See Practice E1012.) non-linear stress-strain behavior which may develop as the

3.1.4 breaking load—theloadatwhichfractureoccurs.(See result of testing mode, testing rate, processing or alloying

Terminology E6.) effects, or environmental influences. These effects may be

3.1.5 fractography—the analysis and characterization of consequences of stress corrosion or subcritical (slow) crack

patterns generated on the fracture surface of a test specimen. growth which can be minimized by testing at appropriately

Fractography can be used to determine the nature and the rapid rates as outlined in this test method.

location of the critical fracture origin causing catastrophic 4.5 The results of tensile tests of specimens fabricated to

fracture in an advanced ceramic test specimen or component. standardized dimensions from a particular material and/or

(See Practice C1239.) selectedportionsofapartmaynottotallyrepresentthestrength

3.1.6 fracture origin—that flaw (discontinuity) from which and deformation properties of the entire, full-size end product

the strength-limiting crack emanates. (See Terminology or its in-service behavior in different environments.

C1145.) 4.6 For quality control purposes, results derived from stan-

3.1.7 percent bending—the bending strain times 100 di- dardized tensile test specimens can be considered to be

vided by the axial strain. (See Practice E1012.) indicativeoftheresponseofthematerialfromwhichtheywere

3.1.8 slow crack growth—subcritical crack growth (exten- taken for given primary processing conditions and post-

sion) that may result from, but is not restricted to, such processing heat treatments.

mechanisms as environmentally-assisted stress corrosion or 4.7 The tensile strength of a ceramic material is dependent

diffusive crack growth. on both its inherent resistance to fracture and the presence of

3.1.9 tensile strength,—S —the maximum tensile stress flaws. Analysis of fracture surfaces and fractography, though

u

which a material is capable of sustaining. Tensile strength is beyond the scope of this test method, is highly recommended

calculatedfromthemaximumloadduringatensiontestcarried for all purposes, especially for design data.

toruptureandtheoriginalcross-sectionalareaofthespecimen.

5. Interferences

(See Terminology E6.)

5.1 Test environment (vacuum, inert gas, ambient air, etc.)

4. Significance and Use

including moisture content (for example, relative humidity)

4.1 Thistestmethodmaybeusedformaterialdevelopment, may have an influence on the measured tensile strength. In

material comparison, quality assurance, characterization, and particular, the behavior of materials susceptible to slow crack

design data generation. growthfracturewillbestronglyinfluencedbytestenvironment

4.2 High strength, monolithic advanced ceramic materials and testing rate. Testing to evaluate the maximum strength

generallycharacterizedbysmallgrainsizes(<50µm)andbulk potential of a material should be conducted in inert environ-

densities near the theoretical density are candidates for load- ments or at sufficiently rapid testing rates, or both, so as to

bearing structural applications requiring high degrees of wear minimizeslowcrackgrowtheffects.Conversely,testingcanbe

and corrosion resistance, and high temperature strength. Al- conducted in environments and testing modes and rates repre-

though flexural test methods are commonly used to evaluate sentative of service conditions to evaluate material perfor-

strength of advanced ceramics, the non-uniform stress distri- mance under use conditions. When testing is conducted in

bution of the flexure specimen limits the volume of material uncontrolled ambient air with the intent of evaluating maxi-

subjected to the maximum applied stress at fracture. mum strength potential, relative humidity and temperature

Uniaxially-loaded tensile strength tests provide information on must be monitored and reported. Testing at humidity levels

strength-limiting flaws from a greater volume of uniformly >65% relative humidity (RH) is not recommended and any

stressed material. deviations from this recommendation must be reported.

4.3 Although the volume or surface area of material sub- 5.2 Surface preparation of test specimens can introduce

jected to a uniform tensile stress for a single uniaxially-loaded fabrication flaws that may have pronounced effects on tensile

tensile test may be several times that of a single flexure strength. Machining damage introduced during specimen

specimen, the need to test a statistically significant number of preparation can be either a random interfering factor in the

tensile specimens is not obviated. Therefore, because of the determination of ultimate strength of pristine material (that is,

probabilistic strength distributions of brittle materials such as increase frequency of surface initiated fractures compared to

advanced ceramics, a sufficient number of specimens at each volume initiated fractures), or an inherent part of the strength

C 1273 – 95a (2000)

characteristics to be measured. Surface preparation can also ponents and the gripped section of the specimen. Line or point

lead to the introduction of residual stresses. Universal or contacts and non-uniform pressure can produce Hertizan-type

standardizedtestmethodsofsurfacepreparationdonotexist.It stressesleadingtocrackinitiationandfractureofthespecimen

should be understood that final machining steps may or may in the gripped section. Gripping devices can be classed

not negate machining damage introduced during the early generally as those employing active and those employing

coarse or intermediate machining. Thus, specimen fabrication passive grip interfaces as discussed in the following sections.

history may play an important role in the measured strength 6.2.2 Active Grip Interfaces—Active grip interfaces require

distributions and should be reported. a continuous application of a mechanical, hydraulic, or pneu-

5.3 Bending in uniaxial tensile tests can cause or promote matic force to transmit the load applied by the test machine to

non-uniformstressdistributionswithmaximumstressesoccur- the test specimen. Generally, these types of grip interfaces

ring at the specimen surface leading to non-representative cause a load to be applied normal to the surface of the gripped

fracturesoriginatingatsurfacesorneargeometricaltransitions. section of the specimen. Transmission of the uniaxial load

In addition, if strains or deformations are measured at surfaces applied by the test machine is then accomplished by friction

where maximum or minimum stresses occur, bending may between the specimen and the grip faces. Thus, important

introduce over or under measurement of strains. Similarly, aspects of active grip interfaces are uniform contact between

fracturefromsurfaceflawsmaybeaccentuatedormutedbythe the gripped section of the specimen and the grip faces and

presence of the non-uniform stresses caused by bending. constant coefficient of friction over the grip/specimen inter-

face.

6. Apparatus

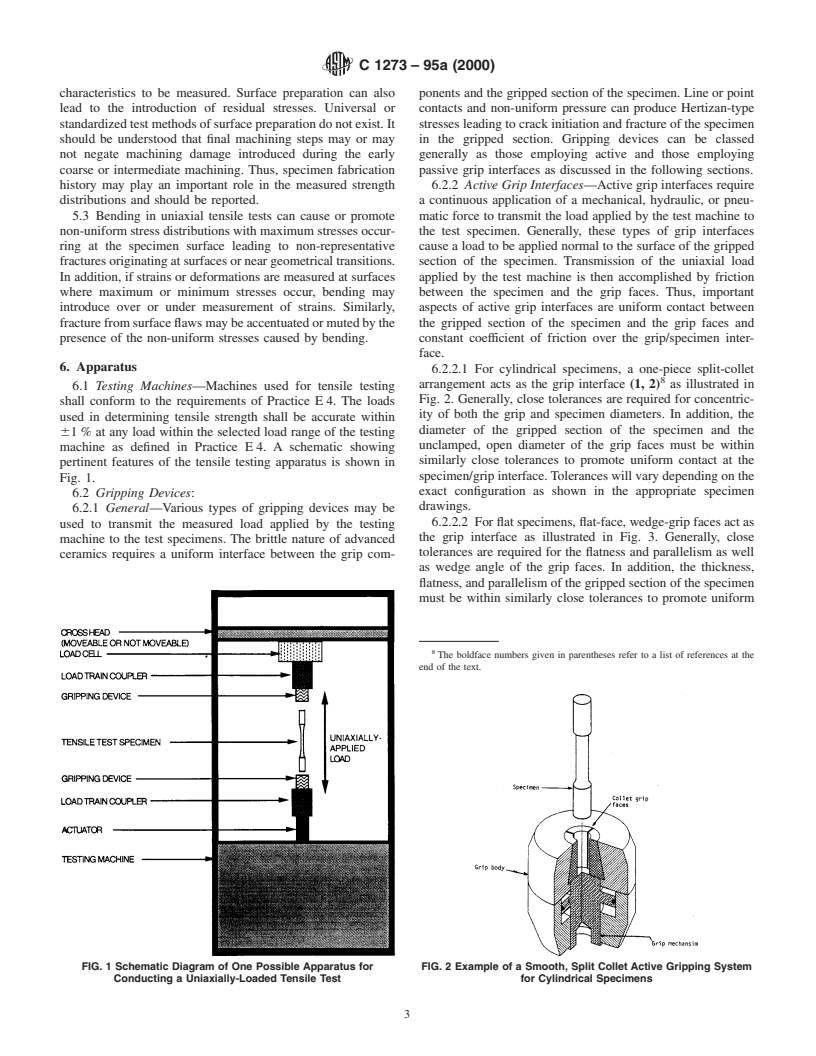

6.2.2.1 For cylindrical specimens, a one-piece split-collet

arrangement acts as the grip interface (1, 2) as illustrated in

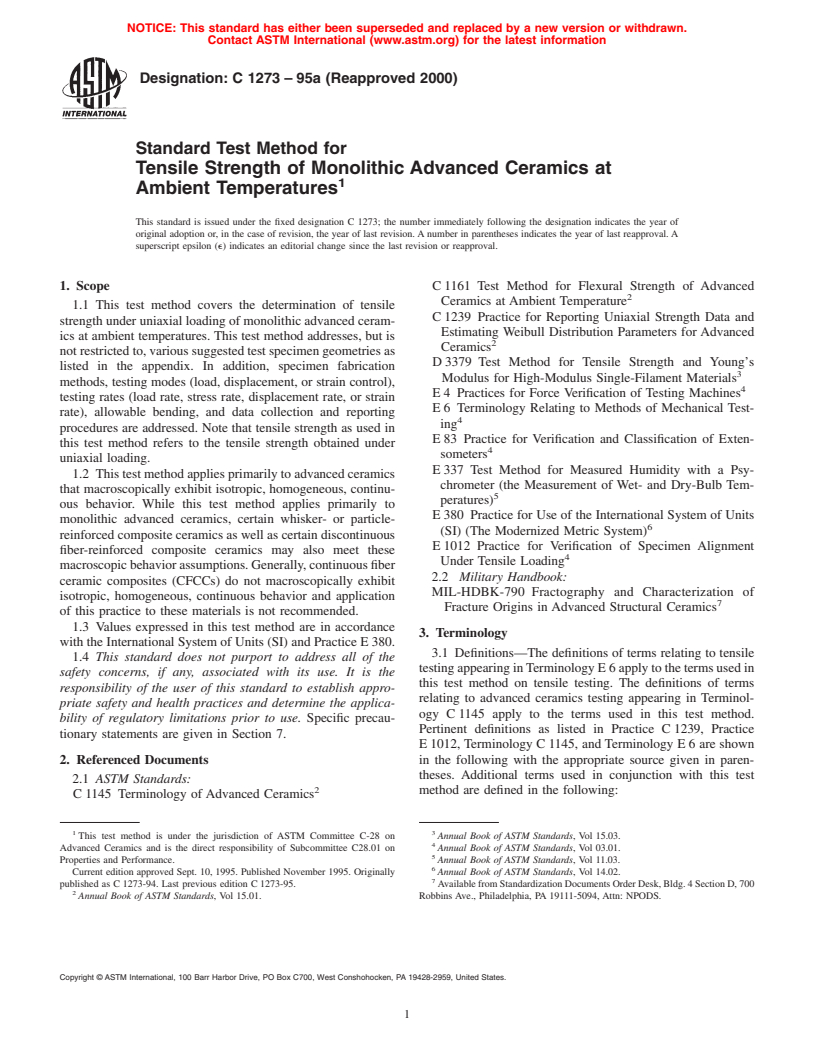

6.1 Testing Machines—Machines used for tensile testing

Fig. 2. Generally, close tolerances are required for concentric-

shall conform to the requirements of Practice E4. The loads

ity of both the grip and specimen diameters. In addition, the

used in determining tensile strength shall be accurate within

diameter of the gripped section of the specimen and the

61% at any load within the selected load range of the testing

unclamped, open diameter of the grip faces must be within

machine as defined in Practice E4. A schematic showing

similarly close tolerances to promote uniform contact at the

pertinent features of the tensile testing apparatus is shown in

specimen/gripinterface.Toleranceswillvarydependingonthe

Fig. 1.

exact configuration as shown in the appropriate specimen

6.2 Gripping Devices:

drawings.

6.2.1 General—Various types of gripping devices may be

6.2.2.2 For flat specimens, flat-face, wedge-grip faces act as

used to transmit the measured load applied by the testing

the grip interface as illustrated in Fig. 3. Generally, close

machine to the test specimens. The brittle nature of advanced

tolerances are required for the flatness and parallelism as well

ceramics requires a uniform interface between the grip com-

as wedge angle of the grip faces. In addition, the thickness,

flatness,andparallelismofthegrippedsectionofthe specimen

must be within similarly close tolerances to promote uniform

The boldface numbers given in parentheses refer to a list of references at the

end of the text.

FIG. 1 Schematic Diagram of One Possible Apparatus for FIG. 2 Example of a Smooth, Split Collet Active Gripping System

Conducting a Uniaxially-Loaded Tens

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.