ASTM C426-99

(Test Method)Standard Test Method for Linear Drying Shrinkage of Concrete Masonry Units

Standard Test Method for Linear Drying Shrinkage of Concrete Masonry Units

SCOPE

1.1 This test method covers a routine standardized procedure for determining the linear drying shrinkage of concrete masonry units or related concrete units under specified accelerated drying conditions.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C426–99

Standard Test Method for

Linear Drying Shrinkage of Concrete Masonry Units

This standard is issued under the fixed designation C426; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* laboratory method are considered in determining concrete

masonry crack control provisions.

1.1 This test method covers a routine standardized proce-

dure for determining the linear drying shrinkage of concrete

NOTE 1—The testing laboratory performing this test method should be

masonry units or related concrete units under specified accel-

evaluated in accordance with Practice C1093.

erated drying conditions.

5. Apparatus

1.2 The values stated in inch-pound units are to be regarded

5.1 Strain Gage—The instruments for measuring linear

as the standard. The values given in parentheses are for

information only. drying shrinkage shall be so designed as to permit or provide

the conditions described in 5.1.1 through 5.1.5.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

NOTE 2—Strain gages may be obtained with various gage lengths. The

responsibility of the user of this standard to establish appro-

10-in. (254-mm) gage length is recommended for use with regular

priate safety and health practices and determine the applica-

concrete masonry units, however, particular sizes of products may require

bility of regulatory limitations prior to use. other lengths. The length of the shrinkage specimen shall not be less than

requiredforaminimumgagelength(distancebetweengageplugs)of6in.

2. Referenced Documents

(152.4 mm).

2.1 ASTM Standards:

5.1.1 A means of positive contact with the specimen that

C490 Practice for Use of Apparatus for the Determination

will ensure reproducible measurements of length.

of Length Change of Hardened Cement Paste, Mortar, and

5.1.2 Means for precise measurement, consisting of a dial

Concrete

micrometer or other measuring device graduated to read in

C1093 Practice for Accreditation of Testing Agencies for

0.0001-in. (0.0025-mm) units, and accurate within 0.0001 in.

Unit Masonry

(0.0025 mm) in any 0.0010-in. (0.025-mm) range, and within

2.2 ANSI Standard:

0.0002 in. (0.0050-mm) in any 0.0100-in. (0.254-mm) range.

B94.11M—1993 Twist Drills

5.1.3 Sufficient range to allow for small variations in the

gage lengths.

3. Terminology

NOTE 3—If the shrinkage reference points are set carefully to position,

3.1 Definition:

a dial micrometer with a travel of 0.2 or 0.3 in. (5.1 or 7.6 mm) provides

3.1.1 linear drying shrinkage—in this test method, the

ample range in the instrument.

change in linear dimension of the test specimen due to drying

5.1.4 Meansforcheckingthestraingageatregularintervals

from a saturated condition to an equilibrium weight and length

against a standard reference bar. The standard reference bar

under specified accelerated drying conditions.

shall be protected from air currents by placing it inside a

wooden box which should be closed except when the strain

4. Significance and Use

gage is being checked against it.

4.1 This test method is intended to evaluate the drying

shrinkage characteristics of a given unit. The results of this

NOTE 4—A standard reference bar shall be furnished by the manufac-

turer of the instrument.Astandard bar of ordinary steel is satisfactory, but

corrections must be made for variations in its length due to temperature

This test method is under the jurisdiction of ASTM Committee C-15 on changes. When a more nearly constant datum is desired, Invar is

Manufactured Masonry Units and is the direct responsibility of Subcommittee

preferable because of its low coefficient of thermal expansion.

C15.03 on Concrete Masonry Units and Related Units.

5.1.5 Convenient and rapid measurement of specimens.

Current edition approved Nov. 10, 1999. Published January 2000. Originally

published as C426–58. Last previous edition C426–96a. 5.2 Comparator—When desirable to measure specimens

Annual Book of ASTM Standards, Vol 04.01.

end to end, a comparator conforming to the requirements of

Annual Book of ASTM Standards, Vol 04.05.

4 Practice C490 may be used as an alternative to the strain gage

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036. for measuring linear drying shrinkage.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C426–99

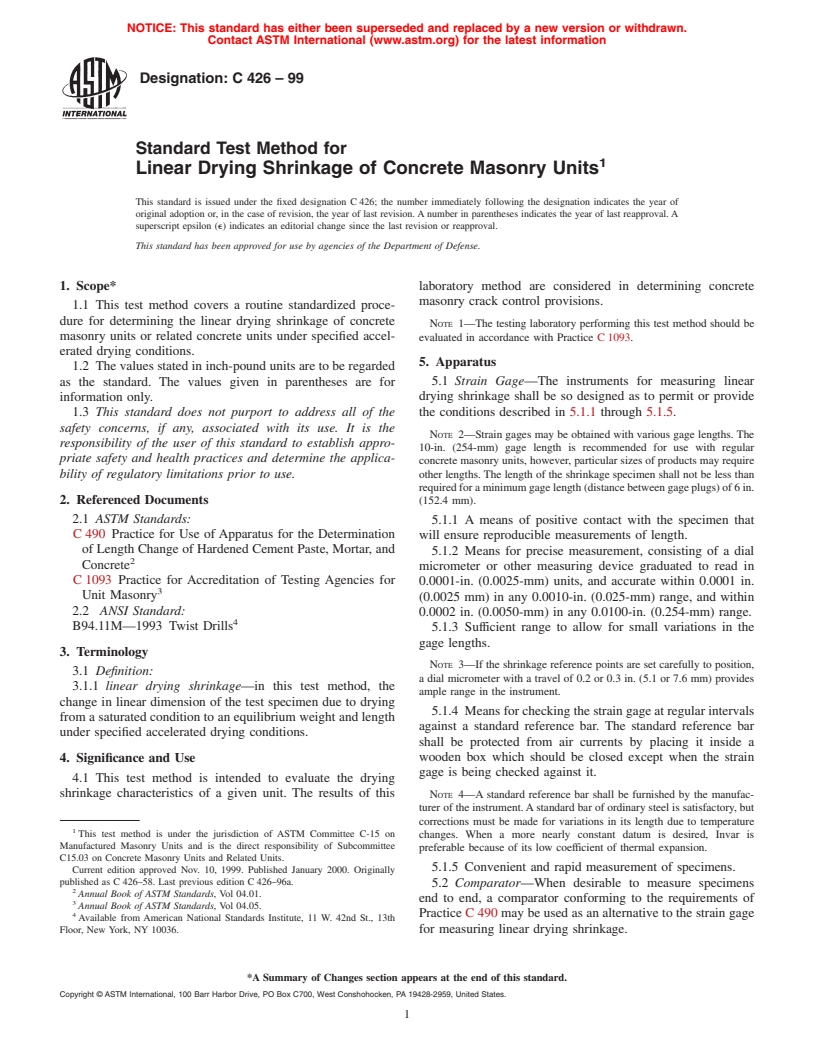

NOTE 1—Provide access to heaters.

NOTE 2—Insulating fill is recommended in cabinets having outer covers of sheet metal

NOTE 3—The following materials are required:

Quantity Description

1 5-in. (127-mm) fan assembly, as shown

1 ⁄30-hp (25-W) shaded-pole, fan-cooled, stud-mounted electric motor

75 ft (22.9 m) 1-in. (25.4-mm) angle, steel or aluminum

2 2

60 ft (5.6 m ) Outer cover, ⁄2-in. (12.7-mm) plywood or equivalent, faced with sheet metal or other material to provide a positive vapor barrier

2 2

60 ft (5.6 m ) Inner cover, ⁄8-in. (9.5-mm) asbestos board or equivalent

1 Heat baffle, 25 by 34-in. (635 by 864-mm), sheet metal

16 ft (4.8 m) ⁄2-in. iron pipe

4 100-W porcelain light fixtures

1 500-W thermostat

124 3 30 3 1 ⁄2-in. (610 3 762 3 38-mm) tray, borosilicate glass or equivalent

1 pr 8-in. (203-mm) hinges and hasp

FIG. 1 Drying Oven Suitable for Determining Drying Shrinkage of Concrete Block

presence of carbon dioxide and water and their possible effect on the

5.3 Gage Plugs—The gage plugs shall be made from metal

drying characteristics of portland cement products.

that is resistant to corrosion. Plugs for use with strain gages

3 1 1 1

shall be ⁄8 to ⁄2 in. (9.5 to 12.7 mm) in diameter and ⁄2 6 ⁄8

5.4.3 A means of drying specimens to a condition of

(12.7 6 3.2 mm) in thickness. Plugs for use with the compara-

equilibrium with a relative humidity of 17 62%(Note 7).

tor shall consist of ⁄4-in. (6.4-mm) diameter stainless steel

5.4.3.1 Calcium chloride (CaCl ), if used for this purpose,

gage studs shown in Practice C490.

shallbeinflakeform.Suitabledishesortraysshallbeprovided

5.4 Drying Oven—Theovenshallbereasonablyairtightand

togiveanexposedsolutionareaofnotlessthan25in. foreach

2 3

provide the features described in 5.4.1 through 5.4.4.

cubic foot (5800 cm for each m ) of oven volume. Dishes or

trays shall contain sufficient solid calcium chloride so that the

NOTE 5—One suggested oven construction is shown in Fig. 1.

crystals will be exposed above the surface of the solution

5.4.1 A minimum storage capacity of three whole test

throughout the test. The calcium chloride solution shall be

specimens and a clearance of 1 in. (25.4 mm) on all sides of

thoroughly stirred every 24 h, and more often if necessary, to

each test specimen.

prevent the formation of lumps and crusting over.

5.4.2 Aconstant, uniform temperature of 122 6 2°F (50 6

0.9°C) throughout the insulated cabinet attained by means of NOTE 7—The air immediately above a saturated solution of calcium

chloride (CaCl ) at 122°F (50°C) is approximately 17%.

an electrical heat source (Note 6). 2

5.4.4 Moderate circulation of air within the oven, over and

NOTE 6—Direct heating of test specimens with the combustion prod-

ucts of gas or other carbonaceous fuels is not satisfactory due to the around all test specimens and the drying agent.

C426–99

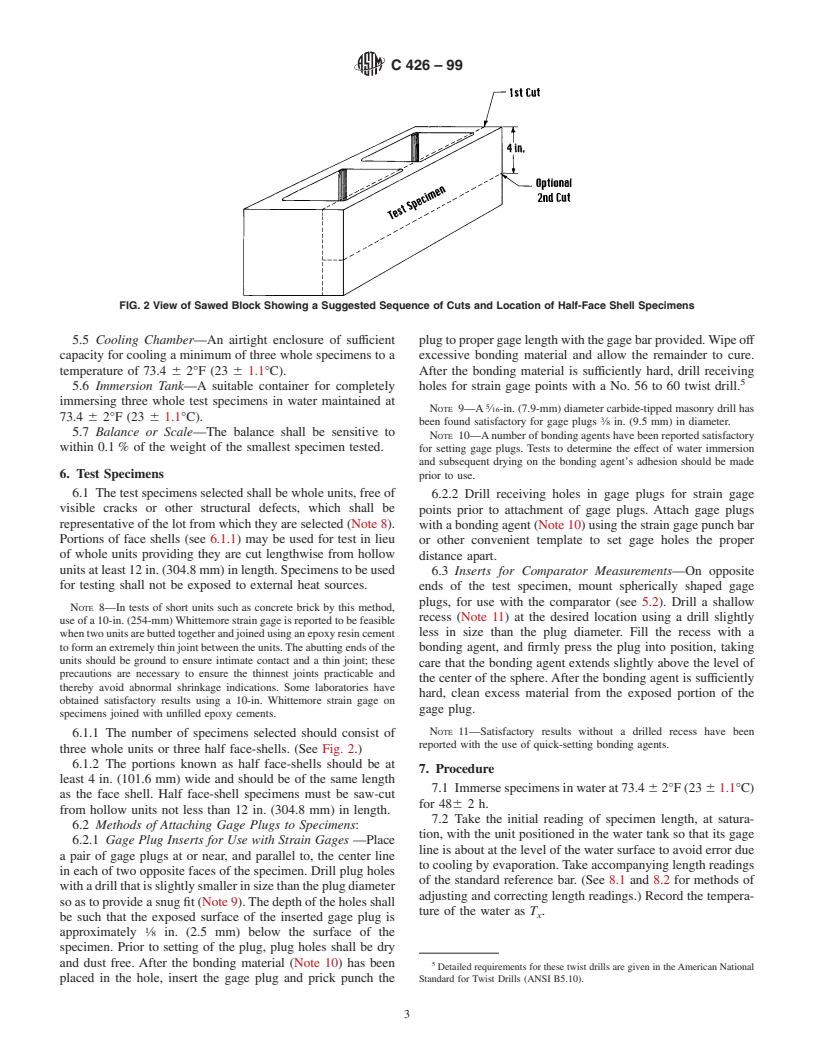

FIG. 2 View of Sawed Block Showing a Suggested Sequence of Cuts and Location of Half-Face Shell Specimens

5.5 Cooling Chamber—An airtight enclosure of sufficient plugtopropergagelengthwiththegagebarprovided.Wipeoff

capacity for cooling a minimum of three whole specimens to a excessive bonding material and allow the remainder to cure.

temperature of 73.4 6 2°F (23 6 1.1°C). After the bonding material is sufficiently hard, drill receiving

5.6 Immersion Tank—A suitable container for completely holes for strain gage points with a No. 56 to 60 twist drill.

immersing three whole test specimens in water maintained at

NOTE 9—A ⁄16-in. (7.9-mm) diameter carbide-tipped masonry drill has

73.4 6 2°F (23 6 1.1°C).

been found satisfactory for gage plugs ⁄8 in. (9.5 mm) in diameter.

5.7 Balance or Scale—The balance shall be sensitive to

NOTE 10—Anumber of bonding agents have been reported satisfactory

within 0.1% of the weight of the smallest specimen tested. for setting gage plugs. Tests to determine the effect of water immersion

and subsequent drying on the bonding agent’s adhesion should be made

6. Test Specimens prior to use.

6.1 The test specimens selected shall be whole units, free of

6.2.2 Drill receiving holes in gage plugs for strain gage

visible cracks or other structural defects, which shall be

points prior to attachment of gage plugs. Attach gage plugs

representative of the lot from which they are selected (Note 8).

withabondingagent(Note10)usingthestraingagepunchbar

Portions of face shells (see 6.1.1) may be used for test in lieu

or other convenient template to set gage holes the proper

of whole units providing they are cut lengthwise from hollow

distance apart.

unitsatleast12in.(304.8mm)inlength.Specimenstobeused

6.3 Inserts for Comparator Measurements—On opposite

for testing shall not be exposed to external heat sources.

ends of the test specimen, mount spherically shaped gage

plugs, for use with the comparator (see 5.2). Drill a shallow

NOTE 8—In tests of short units such as concrete brick by this method,

recess (Note 11) at the desired location using a drill slightly

useofa10-in.(254-mm)Whittemorestraingageisreportedtobefeasible

less in size than the plug diameter. Fill the recess with a

whentwounitsarebuttedtogetherandjoinedusinganepoxyresincement

toformanextremelythinjointbetweentheunits.Theabuttingendsofthe bonding agent, and firmly press the plug into position, taking

units should be ground to ensure intimate contact and a thin joint; these

care that the bonding agent extends slightly above the level of

precautions are necessary to ensure the thinnest joints practicable and

the center of the sphere.After the bonding agent is sufficiently

thereby avoid abnormal shrinkage indications. Some laboratories have

hard, clean excess material from the exposed portion of the

ob

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.