ASTM C1401-98

(Guide)Standard Guide for Structural Sealant Glazing

Standard Guide for Structural Sealant Glazing

SCOPE

1.1 Structural sealant glazing, herinafter referred to as SSG, is an application where a sealant not only can function as a barrier against the passage of air and water through a building envelope, but also primarily provides structural support and attachment of glazing or other components to a window, curtain wall, or other framing system.

1.2 This guide provides information useful to design professionals, manufacturers, contractors, and others for the design and installation of a SSG system. This information is applicable only to this glazing method when used for a building wall that is not more than 15° from vertical; however, limited information is included concerning a sloped SSG application.

1.3 Only silicone chemically curing sealant specifically formulated, tested, and marketed for structural sealant glazing is acceptable for a SSG system application.

1.4 The calculations and values stated in SI units are to be regarded as the standard. Values in parenthesis and inch-pound units are for information only. SI units in this guide are in conformance with IEEE/ASTM SI 10.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: C 1401 – 98

Standard Guide for

Structural Sealant Glazing

This standard is issued under the fixed designation C 1401; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 719 Test Method for Adhesion and Cohesion of Elasto-

meric Joint Sealants Under Cyclic Movement (Hockman

1.1 Structural sealant glazing, hereinafter referred to as

Cycle)

SSG, is an application where a sealant not only can function as

C 794 Test Method for Adhesion-in-Peel of Elastomeric

abarrieragainstthepassageofairandwaterthroughabuilding

Joint Sealants

envelope, but also primarily provides structural support and

C 864 Specification for Dense Elastomeric Compression

attachment of glazing or other components to a window,

Seal Gaskets, Setting Blocks and Spacers

curtain wall, or other framing system.

C 880 Test Method for Flexural Strength of Dimensional

1.2 This guide provides information useful to design pro-

Stone

fessionals, manufacturers, contractors, and others for the de-

C 920 Specification for Elastomeric Joint Sealants

sign and installation of a SSG system. This information is

C 1036 Specification for Flat Glass

applicableonlytothisglazingmethodwhenusedforabuilding

C 1048 Specification for Heat-Treated Flat Glass—Kind

wall that is not more than 15° from vertical; however, limited

HS, Kind FT Coated and Uncoated Glass

information is included concerning a sloped SSG application.

C 1087 Test Method for Determining Compatibility of

1.3 Only a silicone chemically curing sealant specifically

Liquid-Applied Sealants with Accessories Used in Struc-

formulated, tested, and marketed for structural sealant glazing

tural Glazing Systems

is acceptable for a SSG system application.

C 1115 Specification for Dense Elastomeric Silicone Rub-

1.4 The calculations and values stated in SI units are to be

ber Gaskets and Accessories

regarded as the standard. Values in parenthesis and inch-pound

C 1135 Test Method for Determining Tensile-Adhesion

units are for information only. SI units in this guide are in

Properties of Structural Sealants

conformance with IEEE/ASTM SI 10.

C 1172 Specification for Laminated Architectural Flat

1.5 This standard does not purport to address all of the

Glass

safety concerns, if any, associated with its use. It is the

C 1184 Specification for Structural Silicone Sealants

responsibility of the user of this standard to establish appro-

C 1193 Guide for Use of Joint Sealants

priate safety and health practices and determine the applica-

C 1249 Guide for Secondary Seal for Sealed Insulating

bility of regulatory limitations prior to use.

Glass Units for Structural Sealant Glazing Applications

2. Referenced Documents C 1253 Test Method for Determining the Outgassing Poten-

tial of Sealant Backing

2.1 ASTM Standards:

C 1265 Test Method for Determining the Tensile Properties

C 99 Test Method for Modulus of Rupture of Dimension

of an Insulating Glass Edge Seal for Structural Glazing

Stone

Applications

C 162 Terminology of Glass and Glass Products

C 1294 Test Method for Compatibility of Insulating Glass

C 503 Specification for Marble Dimension Stone (Exte-

Edge Sealants with Liquid-Applied Glazing Materials

rior)

C 1330 Specification for Cylindrical Sealant Backing for

C 509 Specification for Elastomeric Cellular Preformed

Use With Cold Liquid-Applied Sealants

Gasket and Sealing Material

C 1369 Specification for Secondary Edge Sealants for

C 568 Specification for Limestone Dimension Stone

Structurally-Glazed Insulating Glass Units

C 615 Specification for Granite Dimension Stone

D 1566 Terminology Relating to Rubber

C 717 Terminology of Building Seals and Sealants

D 4541 Test Method for Pull-Off Strength of Coatings

Using Portable Adhesion Testers

E 283 TestMethodforDeterminingtheRateofAirLeakage

This guide is under the jurisdiction ofASTM Committee C-24 on Sealants and

is the direct responsibility of Subcommittee C24.35 on Structural Sealants.

Current edition approved July 10, 1998. Published May 1999.

2 4

Annual Book of ASTM Standards, Vol 04.07. Annual Book of ASTM Standards, Vol 09.01.

3 5

Annual Book of ASTM Standards, Vol 15.02. Annual Book of ASTM Standards, Vol 06.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1401–98

Through Exterior Windows, Curtain Walls, and Doors Z97.1 Safety Performance Specifications and Methods of

Under Specified Pressure Differences Across the Speci- Test for Glazing Materials Used in Buildings

men 2.7 CPSC Standard:

E 330 Test Method for Structural Performance of Exterior 16CFR1201 StandardonArchitecturalGlazingMaterials

Windows, Curtain Walls, and Doors by Uniform StaticAir

Pressure Difference 3. Terminology

E 331 Test Method for Water Penetration of Exterior Win-

3.1 Definitions:

dows, Curtain Walls, and Doors by Uniform Static Air

3.1.1 Refer to Terminology C 162 for definitions of the

Pressure Difference

following terms used in this guide: chip, chipped glass, double

E 547 Test Method for Water Penetration of Exterior Win-

glazing unit, flat glass, glass, heat-strengthened glass, heat-

dows, Curtain Walls, and Doors by Cyclic Static Air

treated, laminated glass, lite, pyrolitic coating, safety glass,

Pressure Difference

skylight, spandrel glass, tempered glass, thermal stress, tough-

E 631 Terminology of Building Constructions

ened glass, and wave.

E 783 Test Method for Field Measurement of Air Leakage

3.1.2 Refer to Terminology C 717 for definitions of the

Through Installed Exterior Windows and Doors

following terms used in this guide: adhesive failure, bicellular

E 1105 Test Method for Field Determination of Water

sealant backing, bond breaker, butt glazing, cell, chemically

Penetration of Installed Exterior Windows, Curtain Walls,

curing sealant, closed cell, closed cell material, closed cell

and Doors by Uniform or Cyclic Static Air Pressure

sealant backing, cohesive failure, compatibility, compound,

Difference

cure, elastomeric, elongation, gasket, glazing, hardness, joint,

E 1233 Test Method for Structural Performance of Exterior

lite, modulus, open cell, open cell material, open cell sealant

Windows, Curtain Walls, and Doors by Cyclic Static Air

backing, outgassing, primer, seal, sealant, sealant backing,

Pressure Difference

secant modulus, setting block, silicone sealant, spacer, struc-

E 1300 Practice for Determining Load Resistance of Glass

tural sealant, substrate, and tooling.

in Buildings

3.1.3 Refer to Terminology D 1566 for the definition of the

E 1424 Test Method for Determining the Rate of Air Leak-

following term used in this guide: compression.

age Through Exterior Windows, Curtain Walls, and Doors

3.1.4 Refer to Terminology E 631 for the definitions of the

Under Specified Pressure and Temperature Differences

following terms used in this guide: air-leakage, anchorage,

Across the Specimen

anchorage system, building envelope, cladding system, curtain

E 1425 Practice for Determining the Acoustical Perfor-

wall, glaze, mechanical connection, mockup, operable, panel,

mance of Exterior Windows and Doors

performance standard, sealed insulating glass, shop drawing,

E 1886 Test Method for Performance of Exterior Windows,

specification,staticload,tolerance,water-vaporretarder,weep-

Curtain Walls, Doors and Storm Shutters Impacted by

hole, and working drawing.

Missile(s) and Exposed to Cyclic Pressure Differentials

3.1.5 Refer to Terminology G 15 for the definition of the

G 15 Terminology Relating to Corrosion and Corrosion

following term used in this guide: chemical conversion coat-

Testing

ing.

2.2 IEEE/ASTM Standard:

3.2 Definitions of Terms Specific to This Standard:

IEEE/ASTM SI 10 Standard for Use of the International

3.2.1 aspect ratio (AR), n—the ratio of the long dimension

System of Units (SI): The Modern Metric System

of the glass to the short dimension of the glass. AR is always

2.3 Aluminum Association Manual:

equal to or greater than 1.0.

Aluminum Design Manual

3.2.2 bite, n—The effective structural contact dimension of

2.4 ANSI/ASCE Standard:

the structural sealant (see Figs. 1 and 2).

ANSI/ASCE 7, Minimum Design Loads for Buildings and

3.2.3 construction-site glazing, n—the installation, at a

Other Structures

constructionsite,ofglassorpanelsintoametalframingsystem

2.5 AAMA Standards:

under generally uncontrolled environmental conditions.

501.1 Standard Test Method for Metal Curtain Walls for

3.2.4 durability, n—ability of a SSG system and its parts to

Water Penetration Using Dynamic Pressure

perform its required function over a period of time under the

501.2 Field Check of Metal Curtain Walls for Water Leak-

influence of the environment.

age

3.2.5 durabilitylimit,n—pointatwhichlossofperformance

2.6 ANSI Standard:

leads to the end of service life.

3.2.6 negative pressure, n—an applied load, usually wind

induced, that tends to pull a glass lite or panel away from a

6 building surface.

Annual Book of ASTM Standards, Vol 04.11.

Annual Book of ASTM Standards, Vol 03.02. 3.2.7 opacifier, n—an opaque material applied to the inte-

Annual Book of ASTM Standards, Vol 14.02.

rior facing surface of a glass spandrel panel, which can include

Available from theAluminumAssociation, 900 19th St., N.W.Washington, DC

20006.

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

11 12

Available from the Architectural Aluminum Manufacturers Association Available from the Consumer Product Safety Commission (CPSC), Washing-

(AAMA). ton, D.C. 20207.

C1401–98

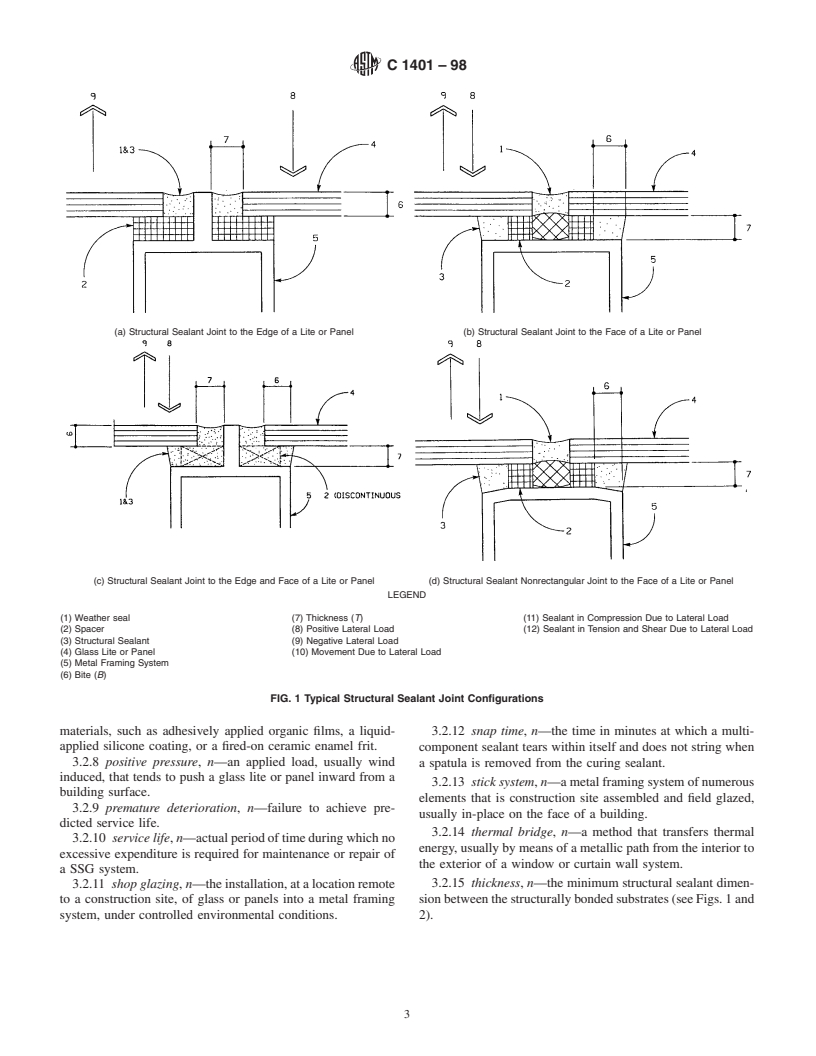

(a) Structural Sealant Joint to the Edge of a Lite or Panel (b) Structural Sealant Joint to the Face of a Lite or Panel

(c) Structural Sealant Joint to the Edge and Face of a Lite or Panel (d) Structural Sealant Nonrectangular Joint to the Face of a Lite or Panel

LEGEND

(1) Weather seal (7) Thickness (T) (11) Sealant in Compression Due to Lateral Load

(2) Spacer (8) Positive Lateral Load (12) Sealant in Tension and Shear Due to Lateral Load

(3) Structural Sealant (9) Negative Lateral Load

(4) Glass Lite or Panel (10) Movement Due to Lateral Load

(5) Metal Framing System

(6) Bite (B)

FIG. 1 Typical Structural Sealant Joint Configurations

materials, such as adhesively applied organic films, a liquid- 3.2.12 snap time, n—the time in minutes at which a multi-

applied silicone coating, or a fired-on ceramic enamel frit.

component sealant tears within itself and does not string when

3.2.8 positive pressure, n—an applied load, usually wind

a spatula is removed from the curing sealant.

induced, that tends to push a glass lite or panel inward from a

3.2.13 sticksystem,n—ametalframingsystemofnumerous

building surface.

elements that is construction site assembled and field glazed,

3.2.9 premature deterioration, n—failure to achieve pre-

usually in-place on the face of a building.

dicted service life.

3.2.14 thermal bridge, n—a method that transfers thermal

3.2.10 servicelife,n—actualperiodoftimeduringwhichno

energy, usually by means of a metallic path from the interior to

excessive expenditure is required for maintenance or repair of

the exterior of a window or curtain wall system.

a SSG system.

3.2.15 thickness, n—the minimum structural sealant dimen-

3.2.11 shopglazing,n—theinstallation,atalocationremote

to a construction site, of glass or panels into a metal framing sionbetweenthestructurallybondedsubstrates(seeFigs.1and

system, under controlled environmental conditions. 2).

C1401–98

(a) Vertical Corner With One Lite or Panel Structurally (b) Positive Applied Lateral Load (c) Negative Applied Lateral Load

Sealed to the Other

FIG. 2 Applied Load Transfer at a Vertical Corner Structural Sealant Joint (see Fig. 1 for Legend)

3.2.16 unitized system, n—a panelized metal framing sys- information. For a more detailed listing of guide topics and

tem that is preassembled and usually shop-glazed, with the section headings, refer to Appendix X1 for a complete listing

panels transported to a construction site for erection on a

of the numbered sections and their descriptors.

building.

4.2 Predesign Considerations (Section 6), in general, the

3.3 Symbols:

responsibilities and relationships of the various participants in

SSG system development and implementation.

A = solar absorptivity coefficient.

4.3 Performance Criteria Considerations (Sections 7-14),

a = coefficient of linear thermal movement mm/mm/°C

SSG system structural loads, movements, construction toler-

(in./in./°F).

ances, weather tightness, sound transmission, fire resistance,

B = structural sealant joint bite mm (in.).

and durability.

C = perpendiculardistancebetweenparallelsidesm(ft).

4.4 System Design Considerations (Sections 15-18), infor-

DL = thermal movement mm (in.).

mation is provided about the basic types of SSG and related

DT = summer temperature differential °C (°F).

s

systems, as well as system weatherproofing concepts.

DT = winter temperature differential °C (°F).

w

F = allowable structural sealant dead load stress kPa

d 4.5 Component Design Considerations (Sections 19-26),

(psi).

framing systems, framing finishes, glass, panels, structural

F = allowable structural sealant tension stress kPa (psi).

t

sealants, weather seal sealants, and accessory material infor-

F = allowable structural sealant shear stress kPa (psi).

v

mation.

f = computed tensile stress kPa (psi).

t

4.6 Structural Sealant Design Considerations (Sections 27-

f = computed shear stress kPa (psi).

v

H = heat capacity constant. 31), structural joint location and configuration, adhesion and

L = side of lite or panel m (ft).

compatibility concerns, theoretical structural design, and other

L = long side of lite or panel m (ft).

1 design and weather seal considerations.

L = short side of the lite or panel m (ft).

4.7 Testing Considerations (Sections 32-37), predesign

% = shear movement percent.

scalemodelwindandsnowloadtesting,designandfabrication

P = lateral load due to wind kPa (psf).

w

component testing for quality, adhesion, and compatibility, and

R = radius of a lite or panel m (ft).

full-size assembly mock-up testing information.

T = structural sealant joint thickness mm (in.).

T = ambient summer temperature °C (°F).

a 4.8 Shop Glazing Considerations (Sections 38-42), materi-

T = summer surface temperature °C (°F).

s

als prequalification, quality control programs, and inspection

T = ambient winter temperature °C (°F).

w

and testing quality assurance issues.

2 2

W = unit weight of lite or panel kg/m (lb/ft ).

4.9 Construction-Site Glazing Considerations (Sections 43-

f = angle in degree

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.