ASTM E1123-86(1998)

(Practice)Standard Practices for Mounting Test Specimens for Sound Transmission Loss Testing of Naval and Marine Ship Bulkhead Treatment Materials

Standard Practices for Mounting Test Specimens for Sound Transmission Loss Testing of Naval and Marine Ship Bulkhead Treatment Materials

SCOPE

1.1 These practices describe test specimen mountings to be used for naval and marine ship applications during sound transmission loss tests performed in accordance with Test Method E90.

1.2 The structure specified in these practices is intended for mounting of single-layer treatments or composite treatments consisting of various materials and configurations. Acoustical treatment materials may be combinations of acoustical absorbent materials, limp mass septums, and insulation materials.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1123 – 86 (Reapproved 1998)

Standard Practices for

Mounting Test Specimens for Sound Transmission Loss

Testing of Naval and Marine Ship Bulkhead Treatment

Materials

This standard is issued under the fixed designation E 1123; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.3 Test reports may refer to this mounting by Practices

E 1123 instead of providing a detailed description of the

1.1 These practices describe test specimen mountings to be

mounting used.

used for naval and marine ship applications during sound

transmission loss tests performed in accordance with Test

4. Mounting Structure and Methods

Method E 90.

4.1 The mounting structure consists of a fabricated alumi-

1.2 The structure specified in these practices is intended for

num bulkhead. This bulkhead is designed to fit within a 2.44-m

mounting of single-layer treatments or composite treatments

(8-ft) opening in the filler walls between the reverberation

consisting of various materials and configurations. Acoustical

rooms of a test facility. Test result measurements due to the

treatment materials may be combinations of acoustical absor-

effects of the filler walls may be accounted for as specified in

bent materials, limp mass septums, and insulation materials.

Test Method E 90. A larger mounting structure may be used if

1.3 The values stated in SI units are to be regarded as the

it can be demonstrated that this structure yields results com-

standard. The values in parentheses are for information only.

parable to the 2.44 by 2.44-m (8 by 8-ft) mounting structure.

1.4 This standard does not purport to address all of the

4.1.1 The bulkhead is fabricated in two sections, 1.22 by

safety concerns, if any, associated with its use. It is the

2.44 m (4 by 8 ft) and is fastened together by a 10.2 by 10.2 by

responsibility of the user of this standard to establish appro-

10.2-cm (4 by 4 by 4-in.) aluminum I-beam.

priate safety and health practices and determine the applica-

4.1.2 The coupling is accomplished by using 8-mm ( ⁄16-in.)

bility of regulatory limitations prior to use.

SAE grade B steel stove bolts, torqued to 3.33 m/kg (25 ft/lb).

2. Referenced Documents 4.1.3 The 6.4-mm ( ⁄4-in.) sheet aluminum panels, 1.22 by

2.44 m (4 by 8 ft), are supported with 10.2 by 10.2 cm (4 by

2.1 ASTM Standards:

4 in.), 2.976-kg per linear metre (2-lb per linear ft) tee beams.

C 634 Terminology Relating to Environmental Acoustics

4.1.3.1 The tee beams are welded to the 6.4-mm ( ⁄4-in.)

E 90 Test Method for Laboratory Measurement of Airborne

aluminum sheets with welds on either side of the center

Sound Transmission Loss of Building Partitions

member of the tee at 53.3-cm (21-in.) intervals.

3. Significance and Use 4.1.3.2 Weld areas should be approximately 7.6 cm (3 in.)

long. Welding in excess of these intervals may cause severe

3.1 The sound transmission loss provided by a material that

warpage of the bulkhead. The tee beams are positioned on the

covers a flat surface depends not only on the physical proper-

aluminum sheets to obtain a distance of 61 cm (2 ft) between

ties of the material but also on the type of structure to which it

tee beam centers with the I-beam serving as the bulkhead

is mounted and the mounting method used.

center support.

3.2 Naval and marine architects and design engineers re-

4.1.4 Fig. 1 illustrates the construction details. The bulkhead

quire specific transmission loss characteristics of acoustical

shall be installed with the smooth side facing the acoustical

treatment materials as they would exhibit installed on a ship’s

source room and fastened in the filler wall opening by any

structure. The mounting structure and procedures specified in

means which will provide a secure, rigid structure. Tapered

these practices are intended to simulate such a shipboard

wooden wedges driven between the filler wall at each tee beam

environment.

support will provide the necessary rigidity. Acoustical sealant

shall be applied around the bulkhead edges, between the filler

These practices are under the jurisdiction of ASTM Committee E-33 on

wall and the bulkhead and the I-beam panel connector to

Environmental Acoustics and are the direct responsibility of Subcommittee E33.03

ensure an airtight seal. This seal should be confirmed by

on Sound Transmission.

energizing the acoustical source and listening for spurious

Current edition approved Aug. 29, 1986. Published January 1987. Originally

published as E1123–86. Last previous edition E1123–86 (1994){1.

Annual Book of ASTM Standards, Vol 04.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1123 – 86 (1998)

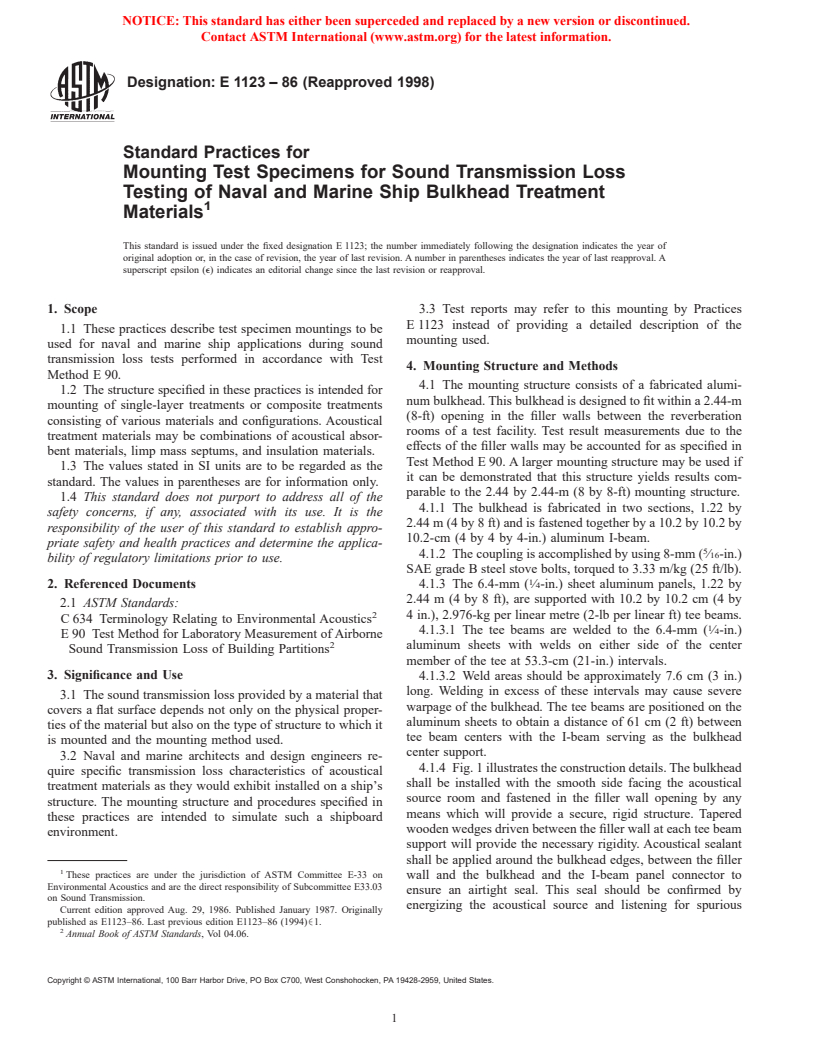

NOTE 1—6.4-mm sheet plate.

NOTE 2—10.2 by 10.2-cm tees, 2.976 kg per linear metre.

NOTE 3—Two 1.22 by 2.44-m bulkhead sections joined with I-beam using 8-mm bolts.

NOTE 4—Bulkhead sections delivered unassembled.

FIG. 1 Aluminum Bulkhead Details

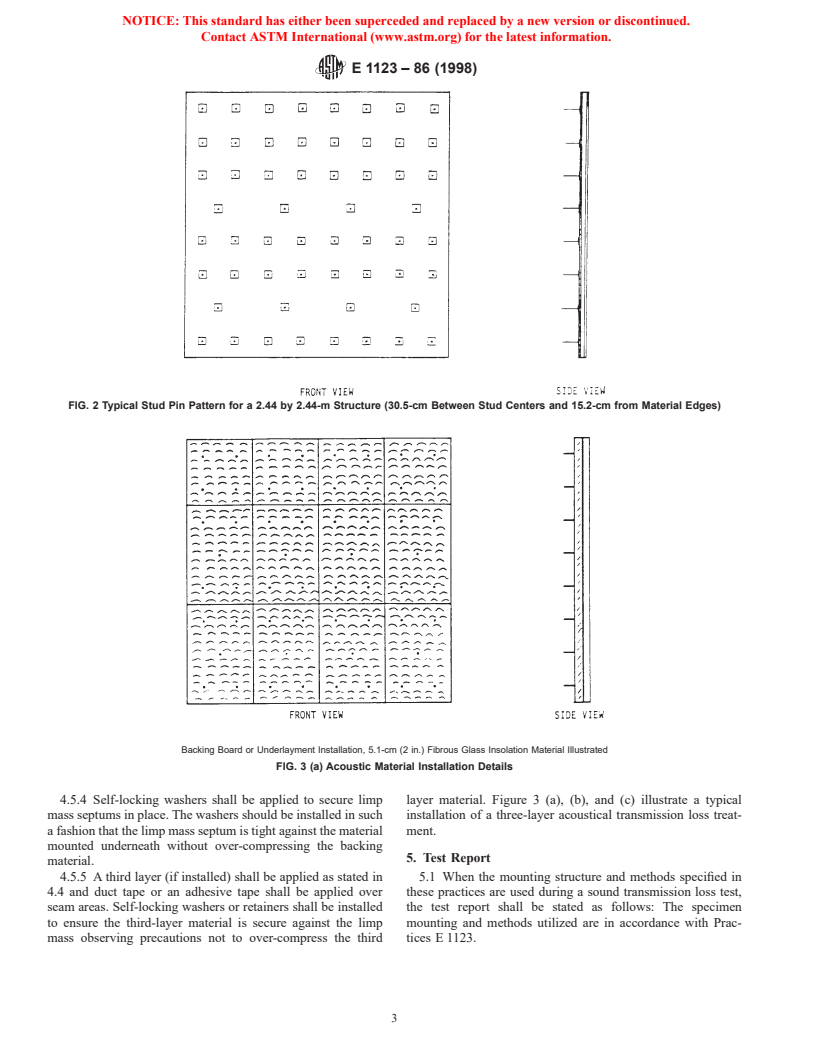

noise transmission around the sealed perimeter crevices with a where required to hold treatment materials securely against the

stethoscope on the receiver room side. bulkhead. Lightweight backing materials use

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.